ASTM D7679-16

(Test Method)Standard Test Method for Sulfur Content in Carbon Black Feedstock Oils

Standard Test Method for Sulfur Content in Carbon Black Feedstock Oils

SIGNIFICANCE AND USE

3.1 Measuring the total sulfur content of feedstock oil is often a necessary component in calculations for sulfur dioxide emissions.

3.2 The carbon black industry measures sulfur content of feedstock oils along with sulfur content of carbon black products per Test Method D1619 in calculations to determine sulfur dioxide emissions for compliance with governmental reporting requirements.

SCOPE

1.1 This test method covers the instrumental determination of sulfur content in samples of carbon black feedstock oils. Values obtained represent the total sulfur content. Two analysis methods are available for use:

Test Method A: High-Temperature Combustion With

Infrared Absorption Detection Procedures

Sections 4 – 10

Test Method B: X-Ray Fluorescence

Sections 13 – 17

1.2 This test method is applicable to carbon black feedstock oils derived from petroleum, coal, and other sources which include fuel oils, residues, tars, pitches, reclaimed oils, and similar materials that are normally handled as liquids. This test method is applicable to products typically containing 0 to 5 mass % sulfur.

1.3 The results of these tests can be expressed as mass % sulfur.

1.4 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D7679 − 16

Standard Test Method for

1

Sulfur Content in Carbon Black Feedstock Oils

This standard is issued under the fixed designation D7679; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope D4483 Practice for Evaluating Precision for Test Method

Standards in the Rubber and Carbon Black Manufacturing

1.1 This test method covers the instrumental determination

Industries

of sulfur content in samples of carbon black feedstock oils.

Values obtained represent the total sulfur content.Two analysis

3. Significance and Use

methods are available for use:

Test Method A: High-Temperature Combustion Sections4–10 3.1 Measuring the total sulfur content of feedstock oil is

With

often a necessary component in calculations for sulfur dioxide

Infrared Absorption Detection Procedures

emissions.

Test Method B: X-Ray Fluorescence Sections13–17

3.2 The carbon black industry measures sulfur content of

1.2 This test method is applicable to carbon black feedstock

feedstock oils along with sulfur content of carbon black

oils derived from petroleum, coal, and other sources which

products per Test Method D1619 in calculations to determine

include fuel oils, residues, tars, pitches, reclaimed oils, and

sulfur dioxide emissions for compliance with governmental

similar materials that are normally handled as liquids. This test

reporting requirements.

method is applicable to products typically containing 0 to 5

mass % sulfur.

TEST METHOD A: HIGH-TEMPERATURE

1.3 The results of these tests can be expressed as mass %

COMBUSTION WITH INFRARED ABSORPTION

sulfur.

DETECTION PROCEDURES

1.4 The values stated in SI units are to be regarded as

standard. No other units of measurement are included in this 4. Summary of Test Method

standard.

4.1 In this test method, a sample of feedstock oil is weighed

1.5 This standard does not purport to address all of the

in a combustion boat containing either a tungsten oxide based

safety concerns, if any, associated with its use. It is the

accelerator, sand or aluminum oxide absorbent, and the sulfur

responsibility of the user of this standard to establish appro-

content is determined by placing the boat in a tube furnace at

priate safety and health practices and determine the applica-

1350°C in an air or oxygen-enriched atmosphere resulting in

bility of regulatory limitations prior to use. complete combustion. Sulfur in the sample is completely

oxidized to sulfur dioxide. Moisture and particulates are

2. Referenced Documents

removed from the gas stream by traps filled with anhydrous

2

magnesium perchlorate. The gas stream is then passed through

2.1 ASTM Standards:

a cell in which sulfur dioxide concentration is measured by an

D1619 Test Methods for Carbon Black—Sulfur Content

infrared (IR) absorption detector at a precise wavelength in the

D4057 Practice for Manual Sampling of Petroleum and

IR spectrum.The IR absorption detects sulfur dioxide through-

Petroleum Products

out the entire combustion process. The integral of the detector

D4177 Practice for Automatic Sampling of Petroleum and

signal is the basis for the total sulfur content of a sample.

Petroleum Products

4.2 This test method is for use with commercially available

sulfur analyzers equipped to carry out the combustion and

1

This test method is under the jurisdiction ofASTM Committee D24 on Carbon

measurement operations automatically.

Black and is the direct responsibility of Subcommittee D24.66 on Environment,

Health, and Safety.

4.3 The sulfur analyzer shall be calibrated using appropriate

Current edition approved Jan. 1, 2016. Published February 2016. Originally

calibration standards (see 6.7).

approved in 2010. Last previous edition approved in 2013 as D7679 – 13. DOI:

10.1520/D7679-16.

4.4 The instrument may be configured to analyze more than

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

one element such as a carbon-sulfur analyzer. In this case, the

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

analyzer has individual detectors for each element that are

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. arranged in series.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

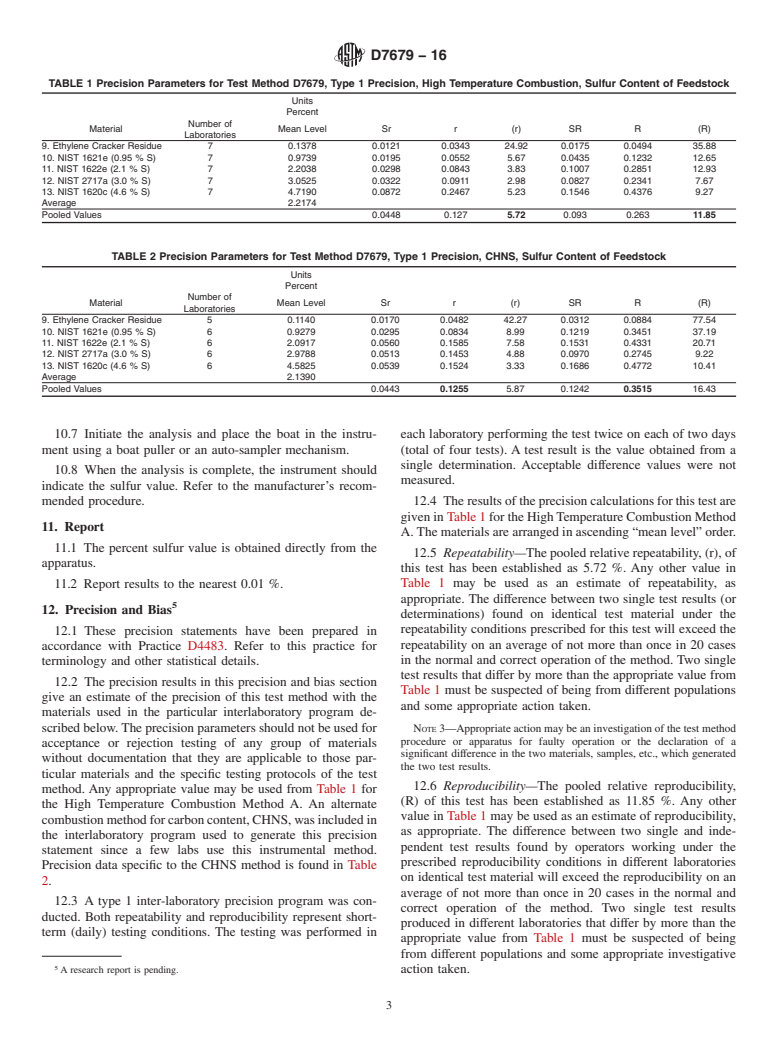

D7679 − 16

5. Apparatus 7.3 Preparation—Warm viscous samples until they are fluid

and shake for 5 s.

5.1 There are a number of commercially available instru-

ments designed to measure sulfur content in organic materials 7.4 Transf

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: D7679 − 13 D7679 − 16

Standard Test Method for

1

Sulfur Content in Carbon Black Feedstock Oils

This standard is issued under the fixed designation D7679; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This test method covers the instrumental determination of sulfur content in samples of carbon black feedstock oils. Values

obtained represent the total sulfur content. Two analysis methods are available for use:

Test Method A: High-Temperature Combustion Sections 4 – 10

With

Infrared Absorption Detection Procedures

Test Method B: X-Ray Fluorescence Sections 13 – 17

1.2 This test method is applicable to carbon black feedstock oils derived from petroleum, coal, and other sources which include

fuel oils, residues, tars, pitches, reclaimed oils, and similar materials that are normally handled as liquids. This test method is

applicable to products typically containing 0 to 5 mass % sulfur.

1.3 The results of these tests can be expressed as mass % sulfur.

1.4 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2

2.1 ASTM Standards:

D1619 Test Methods for Carbon Black—Sulfur Content

D4057 Practice for Manual Sampling of Petroleum and Petroleum Products

D4177 Practice for Automatic Sampling of Petroleum and Petroleum Products

D4483 Practice for Evaluating Precision for Test Method Standards in the Rubber and Carbon Black Manufacturing Industries

3. Significance and Use

3.1 Measuring the total sulfur content of feedstock oil is often a necessary component in calculations for sulfur dioxide

emissions.

3.2 The carbon black industry measures sulfur content of feedstock oils along with sulfur content of carbon black products per

Test Method D1619 in calculations to determine sulfur dioxide emissions for compliance with governmental reporting

requirements.

TEST METHOD A: HIGH-TEMPERATURE COMBUSTION WITH INFRARED ABSORPTION DETECTION

PROCEDURES

4. Summary of Test Method

4.1 In this test method, a sample of feedstock oil is weighed in a combustion boat containing either a tungsten oxide based

accelerator, sand or aluminum oxide absorbent, and the sulfur content is determined by placing the boat in a tube furnace at 1350°C

in an air or oxygen-enriched atmosphere resulting in complete combustion. Sulfur in the sample is completely oxidized to sulfur

1

This test method is under the jurisdiction of ASTM Committee D24 on Carbon Black and is the direct responsibility of Subcommittee D24.66 on Environment, Health,

and Safety.

Current edition approved Nov. 1, 2013Jan. 1, 2016. Published December 2013February 2016. Originally approved in 2010. Last previous edition approved in 20112013

as D7679 – 11.D7679 – 13. DOI: 10.1520/D7679-13.10.1520/D7679-16.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

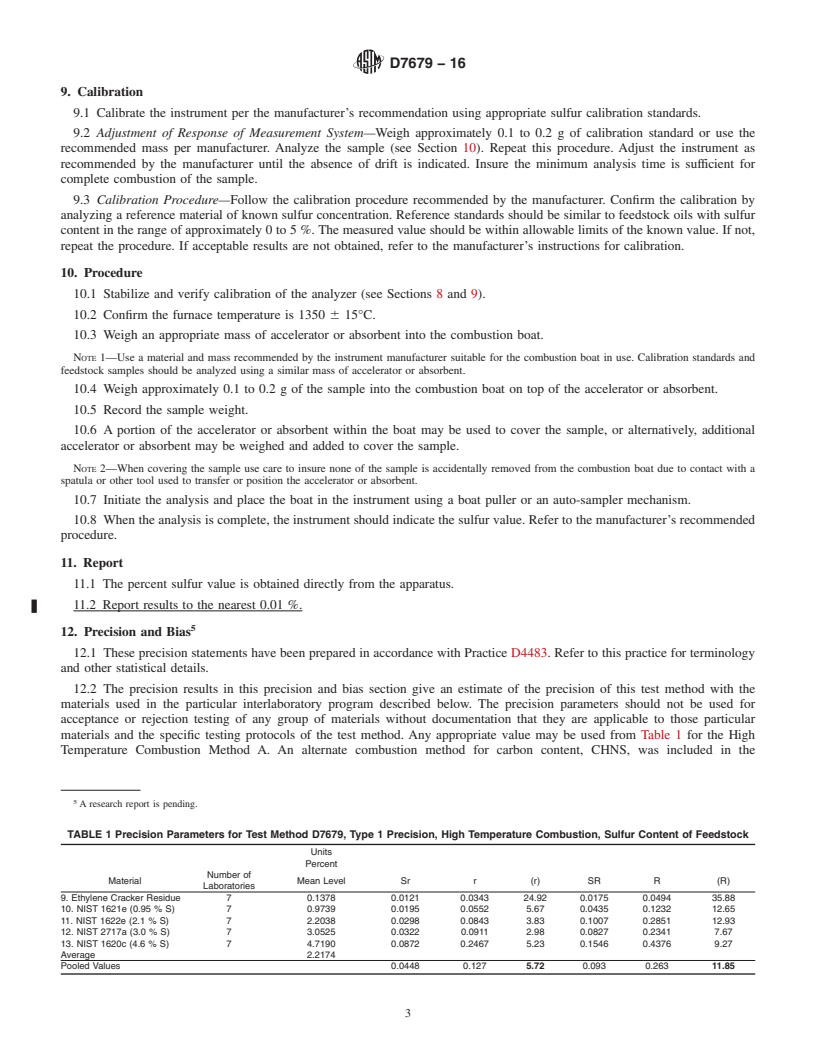

D7679 − 16

dioxide. Moisture and particulates are removed from the gas stream by traps filled with anhydrous magnesium perchlorate. The

gas stream is then passed through a cell in which sulfur dioxide concentration is measured by an infrared (IR) absorption detector

at a precise wavelength in the IR spectrum. The IR absorption detects sulfur dioxide throughout the entire combustion process. The

integral of the detector signal is the basis for the total sulfur content of a sample.

4.2 This test method is for use with commercially available sulfur analyzers equipped to carry out the combustion and

measurement operations automatically.

4.3 The sulfur analyzer shall be calibrated using appropriate calibration standards (see 6.7).

4.4 The instrument may be configured to analyze more than one element

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.