ASTM D2103-15

(Specification)Standard Specification for Polyethylene Film and Sheeting

Standard Specification for Polyethylene Film and Sheeting

ABSTRACT

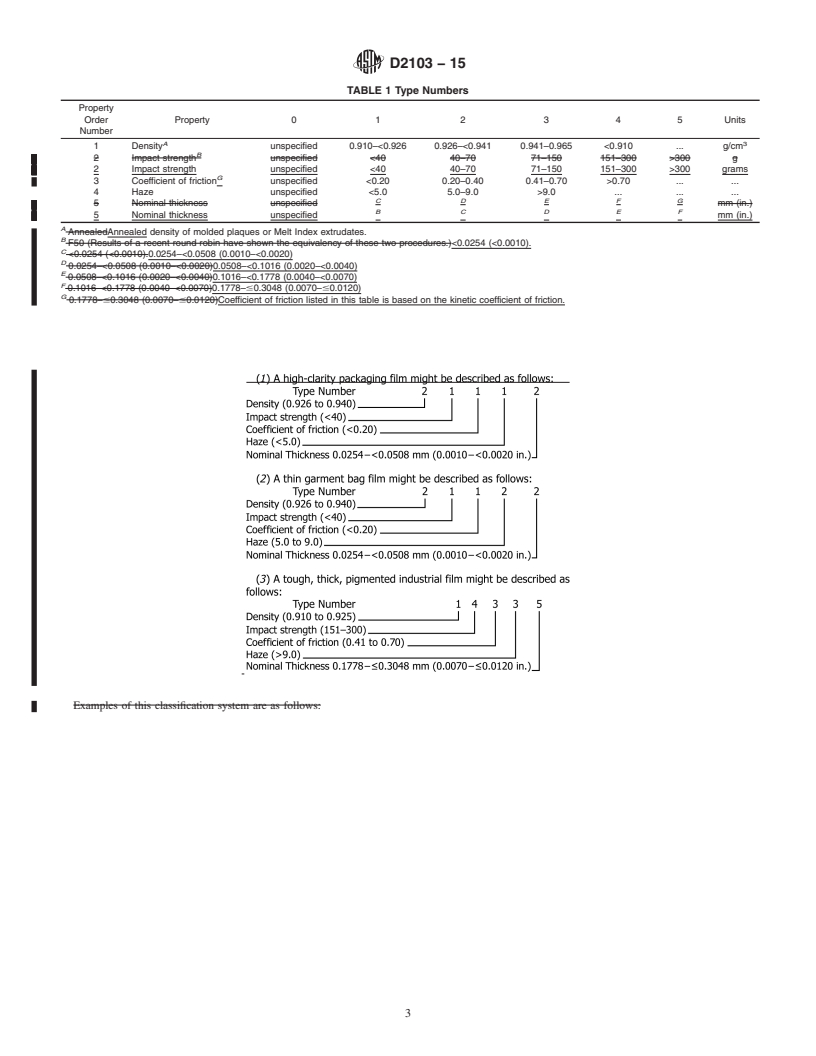

This specification covers the classification of polyethylene film and sheeting. Recycled polyethylene film or resin may be used as feedstock, and the film or sheeting may contain additives for surface property improvement, pigments, or stabilizers, or a combination of these, but they must conform to the requirements specified. Material covered in this specification shall be designated by a five-digit type number, with each numeral (from 0 to 5) indicating the cell limit within which the values of the density, impact strength, kinetic coefficient of friction, haze, and nominal thickness of the material falls under. The sheet or film shall be manufactured free, as commercially possible, of gels, streaks, pinholes, particles of foreign matter, and undispersed raw material, and without any other visible defects such as holes, tears, or blisters. The edges of the sheet or film shall be free of nicks and cuts. The surface of the sheet or film may also be treated by flame, corona discharge, or other means to improve the surface properties. Tests to determine the density, impact strength, kinetic coefficient of friction, haze, and nominal thickness of the material shall be performed and shall conform to the requirements specified.

SCOPE

1.1 This specification covers the classification of polyethylene film and sheeting up to 0.3 mm (0.012 in.) in thickness, inclusive. The film or sheeting may contain additives for the improvement of the surface properties, pigments, or stabilizers, or combinations thereof.

Note 1: Film is defined in Terminology D883 as an optional term for sheeting having a nominal thickness no greater than 0.254 mm (0.010 in.).

1.2 The values stated in SI units are to be regarded as standard. The values given in parentheses are for information only.

1.3 The following precautionary caveat pertains only to the test method portion, Section 8, of this specification: This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

1.4 This specification allows for the use of recycled polyethylene film or resin as feedstock, in whole or in part, as long as all the requirements as governed by the producer and end user are also met (see Note 2).

Note 2: Guide D7209 describes terminology and definitions related to recycled plastics.

Note 3: There is no known ISO equivalent to this standard.

General Information

Relations

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation:D2103 −15

Standard Specification for

1

Polyethylene Film and Sheeting

This standard is issued under the fixed designation D2103; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope* D792 Test Methods for Density and Specific Gravity (Rela-

tive Density) of Plastics by Displacement

1.1 This specification covers the classification of polyethyl-

D882 Test Method for Tensile Properties of Thin Plastic

ene film and sheeting up to 0.3 mm (0.012 in.) in thickness,

Sheeting

inclusive. The film or sheeting may contain additives for the

D883 Terminology Relating to Plastics

improvementofthesurfaceproperties,pigments,orstabilizers,

D1003 Test Method for Haze and Luminous Transmittance

or combinations thereof.

of Transparent Plastics

NOTE 1—Film is defined in Terminology D883 as an optional term for

D1004 Test Method for Tear Resistance (Graves Tear) of

sheetinghavinganominalthicknessnogreaterthan0.254mm(0.010in.).

Plastic Film and Sheeting

1.2 The values stated in SI units are to be regarded as

D1434 TestMethodforDeterminingGasPermeabilityChar-

standard. The values given in parentheses are for information

acteristics of Plastic Film and Sheeting

only.

D1505 Test Method for Density of Plastics by the Density-

1.3 The following precautionary caveat pertains only to the Gradient Technique

D1709 Test Methods for Impact Resistance of Plastic Film

test method portion, Section 8, of this specification: This

standard does not purport to address all of the safety concerns, by the Free-Falling Dart Method

if any, associated with its use. It is the responsibility of the user D1746 Test Method for Transparency of Plastic Sheeting

of this standard to establish appropriate safety and health D1894 Test Method for Static and Kinetic Coefficients of

practices and determine the applicability of regulatory limita- Friction of Plastic Film and Sheeting

tions prior to use. D1922 Test Method for Propagation Tear Resistance of

1.4 This specification allows for the use of recycled poly-

Plastic Film and Thin Sheeting by Pendulum Method

ethylene film or resin as feedstock, in whole or in part, as long D1938 Test Method for Tear-Propagation Resistance (Trou-

as all the requirements as governed by the producer and end

ser Tear) of Plastic Film and Thin Sheeting by a Single-

user are also met (see Note 2).

Tear Method

D2457 Test Method for Specular Gloss of Plastic Films and

NOTE 2—Guide D7209 describes terminology and definitions related to

Solid Plastics

recycled plastics.

NOTE 3—There is no known ISO equivalent to this standard. D2578 TestMethodforWettingTensionofPolyethyleneand

Polypropylene Films

2. Referenced Documents

D2839 Practice for Use of a Melt Index Strand for Deter-

2

2.1 ASTM Standards:

mining Density of Polyethylene

D618 Practice for Conditioning Plastics for Testing

D3892 Practice for Packaging/Packing of Plastics

D4321 Test Method for Package Yield of Plastic Film

1

This specification is under the jurisdiction of ASTM Committee D20 on

D4703 Practice for Compression Molding Thermoplastic

Plastics and is the direct responsibility of Subcommittee D20.19 on Film, Sheeting,

Materials into Test Specimens, Plaques, or Sheets

and Molded Products.

D4976 Specification for Polyethylene Plastics Molding and

Current edition approved April 1, 2015. Published April 2015. Originally

Extrusion Materials

approved in 1962. Last previous edition approved in 2010 as D2103 – 10. DOI:

10.1520/D2103-15.

D5947 Test Methods for Physical Dimensions of Solid

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Plastics Specimens

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

D6988 GuideforDeterminationofThicknessofPlasticFilm

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. Test Specimens

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D2103−15

D7209 Guide for Waste Reduction, Resource Recovery, and

Use of Recycled Polymeric Materials and Products (With-

3

drawn 2015)

E96/E96M Test Methods for Water Vapor Transmission of

Materials

F1249 Test Method for Water Vapor Transmission Rate

Through Plastic Film and Sheeting U

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: D2103 − 10 D2103 − 15

Standard Specification for

1

Polyethylene Film and Sheeting

This standard is issued under the fixed designation D2103; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope*

1.1 This specification covers the classification of polyethylene film and sheeting up to 0.3 mm (0.012 in.) in thickness, inclusive.

The film or sheeting may contain additives for the improvement of the surface properties, pigments, or stabilizers, or combinations

thereof.

NOTE 1—Film is defined in Terminology D883 as an optional term for sheeting having a nominal thickness no greater than 0.254 mm (0.010 in.).

1.2 The values stated in SI units are to be regarded as standard. The values given in bracketsparentheses are for information

only.

1.3 The following precautionary caveat pertains only to the test method portion, Section 8, of this specification:This standard

does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this

standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

1.4 This specification allows for the use of recycled polyethylene film or resin as feedstock, in whole or in part, as long as all

the requirements as governed by the producer and end user are also met (see Note 12).

NOTE 2—Guide D7209 describes terminology and definitions related to recycled plastics.

NOTE 3—There is no known ISO equivalent to this specification.standard.

1

This specification is under the jurisdiction of ASTM Committee D20 on Plastics and is the direct responsibility of Subcommittee D20.19 on Film, Sheeting, and Molded

Products.

Current edition approved April 1, 2010April 1, 2015. Published May 2010April 2015. Originally approved in 1962. Last previous edition approved in 20082010 as

D2103 – 08.D2103 – 10. DOI: 10.1520/D2103-10.10.1520/D2103-15.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D2103 − 15

2. Referenced Documents

2

2.1 ASTM Standards:

3

D374 Test Methods for Thickness of Solid Electrical Insulation (Withdrawn 2013)

D618 Practice for Conditioning Plastics for Testing

D792 Test Methods for Density and Specific Gravity (Relative Density) of Plastics by Displacement

D882 Test Method for Tensile Properties of Thin Plastic Sheeting

D883 Terminology Relating to Plastics

D1003 Test Method for Haze and Luminous Transmittance of Transparent Plastics

D1004 Test Method for Tear Resistance (Graves Tear) of Plastic Film and Sheeting

D1434 Test Method for Determining Gas Permeability Characteristics of Plastic Film and Sheeting

D1505 Test Method for Density of Plastics by the Density-Gradient Technique

D1709 Test Methods for Impact Resistance of Plastic Film by the Free-Falling Dart Method

D1746 Test Method for Transparency of Plastic Sheeting

D1894 Test Method for Static and Kinetic Coefficients of Friction of Plastic Film and Sheeting

D1922 Test Method for Propagation Tear Resistance of Plastic Film and Thin Sheeting by Pendulum Method

D1938 Test Method for Tear-Propagation Resistance (Trouser Tear) of Plastic Film and Thin Sheeting by a Single-Tear Method

D2457 Test Method for Specular Gloss of Plastic Films and Solid Plastics

D2578 Test Method for Wetting Tension of Polyethylene and Polypropylene Films

D2839 Practice for Use of a Melt Index Strand for Determining Density of Polyethylene

D3892 Practice for Packaging/Packing of Plastics

D4321 Test Method for Package Yield of Plastic Film

D4703 Practice for Compression Molding Thermoplastic Materials into Test Specimens, Plaques, or Sheets

D4976 Specification for Polyethylene Plastics Molding and Extrusion Materials

D5947 Test Methods for Physical Dimensions of Solid Plastics Specimens

D6988 Guide for Determination of Thickness of Plastic Film Test Specimens

D7209 Guide for Waste Reduction, Resource Recovery, and Use of Recycled Polymeric Materials and Products (Withdrawn

3

2015)

E96/E96M Test Methods for Water Vapor Transmission of Materials

F1249 Test Method fo

...

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D2103 − 15

Standard Specification for

1

Polyethylene Film and Sheeting

This standard is issued under the fixed designation D2103; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope* D792 Test Methods for Density and Specific Gravity (Rela-

tive Density) of Plastics by Displacement

1.1 This specification covers the classification of polyethyl-

D882 Test Method for Tensile Properties of Thin Plastic

ene film and sheeting up to 0.3 mm (0.012 in.) in thickness,

Sheeting

inclusive. The film or sheeting may contain additives for the

D883 Terminology Relating to Plastics

improvement of the surface properties, pigments, or stabilizers,

D1003 Test Method for Haze and Luminous Transmittance

or combinations thereof.

of Transparent Plastics

NOTE 1—Film is defined in Terminology D883 as an optional term for

D1004 Test Method for Tear Resistance (Graves Tear) of

sheeting having a nominal thickness no greater than 0.254 mm (0.010 in.).

Plastic Film and Sheeting

1.2 The values stated in SI units are to be regarded as

D1434 Test Method for Determining Gas Permeability Char-

standard. The values given in parentheses are for information

acteristics of Plastic Film and Sheeting

only.

D1505 Test Method for Density of Plastics by the Density-

Gradient Technique

1.3 The following precautionary caveat pertains only to the

test method portion, Section 8, of this specification: This D1709 Test Methods for Impact Resistance of Plastic Film

by the Free-Falling Dart Method

standard does not purport to address all of the safety concerns,

if any, associated with its use. It is the responsibility of the user D1746 Test Method for Transparency of Plastic Sheeting

of this standard to establish appropriate safety and health D1894 Test Method for Static and Kinetic Coefficients of

practices and determine the applicability of regulatory limita- Friction of Plastic Film and Sheeting

tions prior to use.

D1922 Test Method for Propagation Tear Resistance of

1.4 This specification allows for the use of recycled poly- Plastic Film and Thin Sheeting by Pendulum Method

ethylene film or resin as feedstock, in whole or in part, as long

D1938 Test Method for Tear-Propagation Resistance (Trou-

as all the requirements as governed by the producer and end

ser Tear) of Plastic Film and Thin Sheeting by a Single-

user are also met (see Note 2).

Tear Method

D2457 Test Method for Specular Gloss of Plastic Films and

NOTE 2—Guide D7209 describes terminology and definitions related to

Solid Plastics

recycled plastics.

NOTE 3—There is no known ISO equivalent to this standard. D2578 Test Method for Wetting Tension of Polyethylene and

Polypropylene Films

2. Referenced Documents

D2839 Practice for Use of a Melt Index Strand for Deter-

2

2.1 ASTM Standards:

mining Density of Polyethylene

D618 Practice for Conditioning Plastics for Testing

D3892 Practice for Packaging/Packing of Plastics

D4321 Test Method for Package Yield of Plastic Film

1

This specification is under the jurisdiction of ASTM Committee D20 on D4703 Practice for Compression Molding Thermoplastic

Plastics and is the direct responsibility of Subcommittee D20.19 on Film, Sheeting,

Materials into Test Specimens, Plaques, or Sheets

and Molded Products.

D4976 Specification for Polyethylene Plastics Molding and

Current edition approved April 1, 2015. Published April 2015. Originally

Extrusion Materials

approved in 1962. Last previous edition approved in 2010 as D2103 – 10. DOI:

10.1520/D2103-15.

D5947 Test Methods for Physical Dimensions of Solid

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Plastics Specimens

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

D6988 Guide for Determination of Thickness of Plastic Film

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. Test Specimens

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D2103 − 15

D7209 Guide for Waste Reduction, Resource Recovery, and

Use of Recycled Polymeric Materials and Products (With-

3

drawn 2015)

E96/E96M Test Methods for Water Vapor Transmission of

Materials

F1249 Test Method for Water Vapor Transmission Rate

Through Plastic Film and Sheeting Using a Modulated

Infrared Sensor

3. Terminology

3.1 Definitions:

3.1.1 Unless otherwise specified, th

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.