ASTM D4397-00

(Specification)Standard Specification for Polyethylene Sheeting for Construction, Industrial, and Agricultural Applications

Standard Specification for Polyethylene Sheeting for Construction, Industrial, and Agricultural Applications

SCOPE

1.1 This specification covers polyethylene sheeting, 250 µm (0.010 in. or 10 mils) or less in thickness, intended for construction, industrial, and agricultural applications.

1.2 The values stated in SI units are to be regarded as the standard.

1.3 The following precautionary statement pertains only to the test methods portion, Section 8 of this specification: This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

Note 1-- There is no known ISO equivalent to this specification.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: D 4397 – 00

Standard Specification for

Polyethylene Sheeting for Construction, Industrial, and

Agricultural Applications

This standard is issued under the fixed designation D 4397; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope * deg 0-deg, of Opaque Specimens by Broad-Band Filter

Reflectometry

1.1 This specification covers polyethylene sheeting, 250 μm

F 88 Test Methods for Seal Strength of Flexible Barrier

(0.010 in. or 10 mils) or less in thickness, intended for

Materials

construction, industrial, and agricultural applications.

2.2 Military Standard:

1.2 The values stated in SI units are to be regarded as the

MIL-STD-105 Sampling Procedures and Tables for Inspec-

standard.

tion by Attributes

1.3 The following precautionary statement pertains only to

the test methods portion, Section 8 of this specification: This

3. Terminology

standard does not purport to address all of the safety concerns,

3.1 Definitions—The plastics terminology used in this

if any, associated with its use. It is the responsibility of the user

specification is in accordance with the definitions given in

of this standard to establish appropriate safety and health

Terminology D 883.

practices and determine the applicability of regulatory limita-

3.2 Definitions of Terms Specific to This Standard:

tions prior to use.

3.2.1 nominal length—the length of sheeting in any roll, as

NOTE 1—There is no known ISO equivalent to this specification.

specified on product labels, invoices, sales literature, and the

like.

2. Referenced Documents

3.2.2 nominal net weight—the weight of sheeting in any

2.1 ASTM Standards:

roll, as specified on product labels, invoices, sales literature,

D 374 Test Methods for Thickness of Solid Electrical Insu-

and the like.

lation

3.2.3 nominal thickness—the thickness of sheeting in any

D 618 Practice for Conditioning Plastics and Electrical

roll, as specified on product labels, invoices, sales literature,

Insulating Materials for Testing

and the like.

D 882 Test Methods for Tensile Properties of Thin Plastic

3.2.4 nominal width—the width of sheeting in any rolls, as

Sheeting

specified on product labels, invoices, sales literature, and the

D 883 Terminology Relating to Plastics

like.

D 1505 Test Method for Density of Plastics by the Density-

Gradient Technique 4. Materials

D 1709 Test Method for Impact Resistance of Polyethylene

4.1 The sheeting shall be made from polyethylene or modi-

Film by the Free Falling Dart Method

fied polyethylene, such as an ethylene copolymer consisting of

D 1898 Practice for Sampling of Plastics

a major portion of ethylene in combination with a minor

D 2103 Specification for Polyethylene Film and Sheeting

portion of some other monomer, or a mixture of polyethylene

D 3892 Practice for Packaging/Packing of Plastics

with a lesser amount of other polymers.

E 96 Test Methods for Water Vapor Transmission of Mate-

NOTE 2—Polyethylene sheeting is made in a variety of colors, opaci-

rials

ties, translucencies, and dimensions. It is recommended that manufactur-

E 97 Test Method for Directional Reflectance Factor, 45-

ers be consulted on the varieties available.

5. General Requirements

This specification is under the jurisdiction of ASTM Committee D20 on

5.1 Appearance—The sheeting shall have appearance quali-

Plastics and is the direct responsibility of Subcommittee D20.19 on Film and

Sheeting.

ties conforming with those produced by good commercial

Current edition approved Nov. 10, 2000. Published January 2001. Originally

published as D 4397 – 84. Last previous edition D 4397 – 96.

2 6

Annual Book of ASTM Standards, Vol 10.01. Annual Book of ASTM Standards, Vol 06.01.

3 7

Annual Book of ASTM Standards, Vol 08.01. Annual Book of ASTM Standards, Vol 15.09.

4 8

Annual Book of ASTM Standards, Vol 08.02. Available from Standardization Documents Order Desk, Bldg. 4 Section D, 700

Annual Book of ASTM Standards, Vol 04.06. Robbins Ave., Philadelphia, PA 19111-5094, Attn: NPODS.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

D 4397

TABLE 2 Mechanical Properties

practices. It shall be as free as is commercially possible of gels,

streaks, pinholes, particles of foreign matter, and undispersed Lengthwise Crosswise

Direction Direction

raw material. There shall be no other visible defects such as

Tensile strength, min, MPa (psi) 11.7 (1700) 8.3 (1200)

blocking, holes, tears, or blisters. The edges shall be free of A

Elongation, min, % 225 350

nicks and cuts visible to the unaided eye.

A

For films of nominal thickness of <2 mils (<50 μm), minimum % to be 200 and

5.2 Dimensions:

325, respectively (LD/CD).

5.2.1 Size—The nominal thickness, width, and length of the

sheeting in each roll shall be agreed upon between the buyer

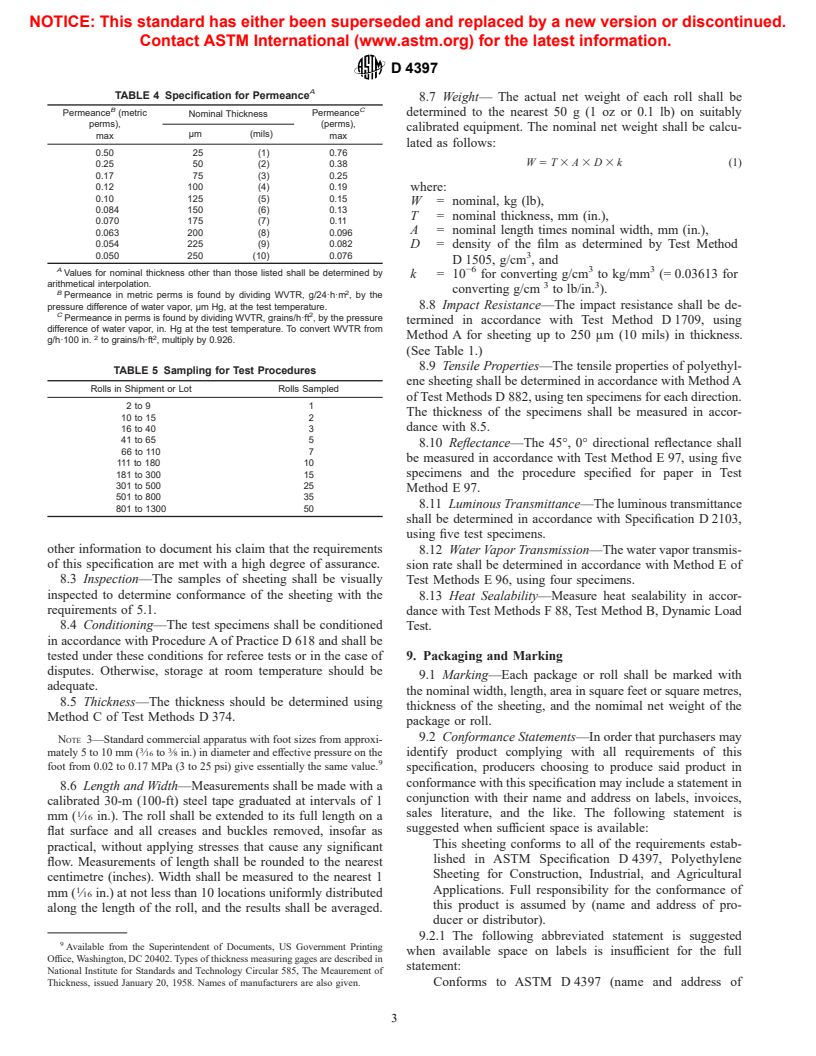

6.6 Water Vapor Transmission Rate (WVTR)—The average

and the seller.

water vapor transmission shall not be greater than 22.0 g/m

5.2.2 Tolerances:

(1.40 g/100 in. ) per 24 h for sheeting 25 μm (1 mil) in

5.2.2.1 Thickness—The thickness at any point, when mea-

thickness, when determined in accordance with 8.12. The

sured in accordance with 8.5, shall not be less than 80 % of the

water vapor transmission rate is inversely proportional to the

nominal thickness.

thickness. Maximum limits for rate of water transmission as a

5.2.2.2 Width—The tolerance for widths of 0.3 m (1 ft) or

function of thickness are given in Table 3. Equivalent maxi-

more, shall be 3.2 mm ( ⁄8 in.) per foot of nominal width. For mum limits in terms of permeance are given in Table 4. It

all widths less than 0.3 m (1 ft), the tolerance shall be 3.2 mm

should be noted that the WVTR requirement is not necessary

( ⁄8 in.). Width to be measured in accordance with 8.6. for all applications (such as pallet wrap). However, Table 3 and

5.2.2.3 Length—The length of sheeting per roll, when

Table 4 may be used for those cases where the WVTR is an

measured in accordance with 8.6, shall be within+3% important consideration.

to−1% of the length specified.

7. Sampling

5.2.3 Minimum Net Weight—The actual net weight of each

roll shall be not less than the nominal net weight, when 7.1 Samples for test purposes shall be taken from rolls,

determined in accordance with the formula established in 8.7. selected at random from the total number of rolls in each

shipment or lot, in accordance with Table 5.

The nominal net weight shall, in turn, be the labeled net

weight. 7.2 The samples for testing shall be full width and shall be

cut at least three full turns, but not less than 1.5 m (5 ft), from

6. Detail Requirements

either end of the sheeting on each roll. Normally about 2 m (20

6.1 Color and Finish—The sheeting may be natural, (essen-

ft ) of sheeting is needed to carry out all the tests. All the tests

tially colorless), color tinted, translucent, or opaque. The

shall be made on each sample roll. Rolls damaged in shipment

surface finish may be plain, printed, or otherwise treated as

shall not be selected for testing.

agreed upon between the buyer and the seller.

7.3 The specimens to be used for a particular test shall be

6.2 Impact Resistance—The average impact resistance shall

cut from different parts of the sheeting sample (that is, they

be not less than the resistance specified in Table 1, when tested

shall not be cut adjacent to one another), unless otherwise

in accordance with 8.8.

specified in the test.

6.3 Mechanical Properties—The average tensile strength

8. Test Methods

and elongation at break for all thicknesses of sheeting shall be

as specified in Table 2, when tested in accordance with 8.9.

8.1 General—The tests given herein are intended primarily

6.4 Reflectance—The average 45°, 0° directional reflec-

for use as production tests in conjunction with manufacturing

tance of white opaque sheeting, intended for use in curing

processes and inspection methods to insure confor-mity of

concrete, shall be not less than 70 %, when determined in

sheeting with the requirements of this specification.

accordance with 8.10.

8.2 Production Inspection and Testing— During the process

6.5 Luminous Transmittance—Black sheeting intended for

of manufacture, the manufacturer shall make inspections and

exclusion of light and for maximum resistance to weathering

tests in accordance with methods described by this specifica-

shall have an average luminous transmittance not greater than

tion. The manufacturer shall keep such essential records and

1 %, when determined in accordance with 8.11. This low level

of luminous transmittance indicates a high degree of opacity. TABLE 3 Specification for Water Vapor Transmission Rate

A

(WVTR)

A

TABLE 1 Dar

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.