ASTM E572-94(2000)

(Test Method)Standard Test Method for X-Ray Emission Spectrometric Analysis of Stainless Steel

Standard Test Method for X-Ray Emission Spectrometric Analysis of Stainless Steel

SCOPE

1.1 This test method provides for the X-ray spectrochemical analysis of stainless steels for the determination of the following elements in the ranges indicated:ElementConcentration Range, %Chromium11.0 to 19.0Nickel0.20 to 13.0Copper0.05 to 3.50Molybdenum0.05 to 3.00Manganese0.40 to 2.00Columbium (Niobium)0.30 to 0.70Cobalt0.05 to 0.50

Note 1--These concentration ranges can be extended by the use of suitable reference materials. The detection limit for the elements is lower than the listed value. The ranges represent the nominal levels at which this method was tested.

1.2 This test method is applicable to the control analysis of either chill-cast or wrought samples having a diameter of approximately 25 mm.

Note 2--Samples of greater or lesser size than those designated may be used with specially designed sample holders.

1.3 Matrix effects exist between the elements listed. To compensate for these effects, a series of calibration curves are required to cover the designated concentration ranges. The composition of the sample must approximate closely one or more of the reference materials used in the calibration curve which is applied. Mathematical corrections may also be used to solve for matrix effects. (Refer to Practice E1361.) A variety of such systems is commonly used. Any of these are acceptable that will achieve analytical accuracy equivalent to that reported for the method.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. Specific hazard statements are given in Section 7.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: E 572 – 94 (Reapproved 2000)

Standard Test Method for

X-Ray Emission Spectrometric Analysis of Stainless Steel

This standard is issued under the fixed designation E 572; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope 2. Referenced Documents

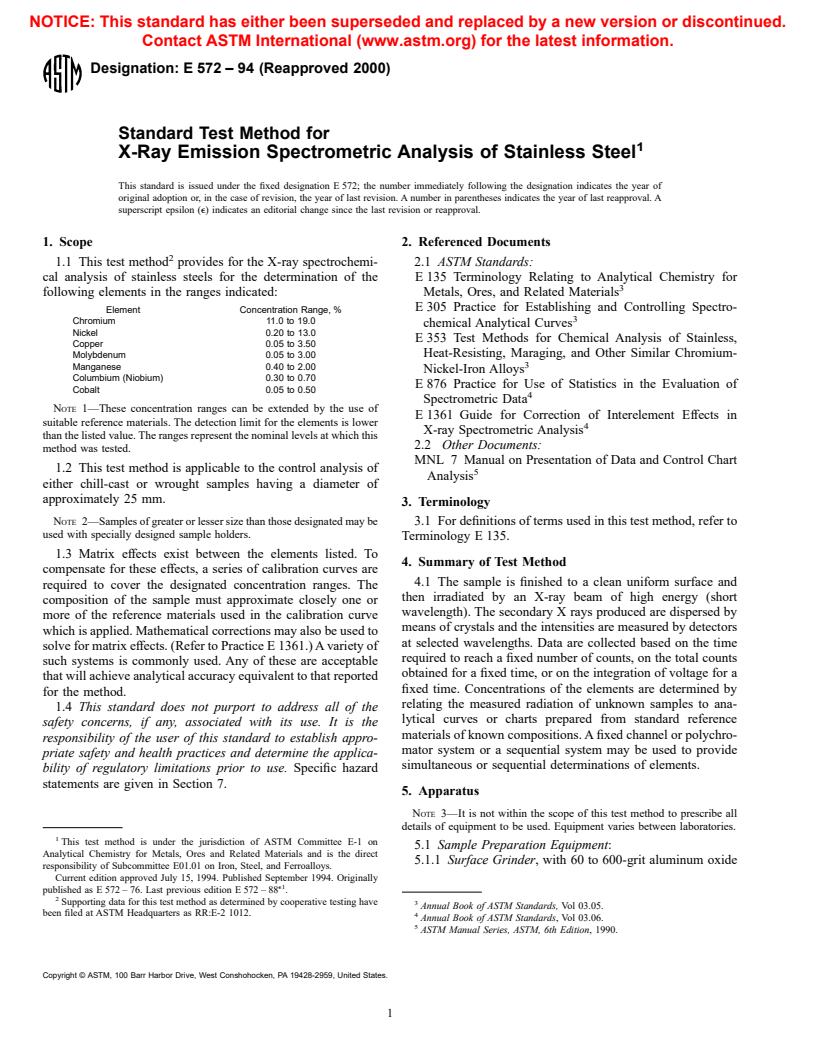

1.1 This test method provides for the X-ray spectrochemi- 2.1 ASTM Standards:

cal analysis of stainless steels for the determination of the E 135 Terminology Relating to Analytical Chemistry for

following elements in the ranges indicated: Metals, Ores, and Related Materials

E 305 Practice for Establishing and Controlling Spectro-

Element Concentration Range, %

Chromium 11.0 to 19.0

chemical Analytical Curves

Nickel 0.20 to 13.0

E 353 Test Methods for Chemical Analysis of Stainless,

Copper 0.05 to 3.50

Molybdenum 0.05 to 3.00 Heat-Resisting, Maraging, and Other Similar Chromium-

Manganese 0.40 to 2.00

Nickel-Iron Alloys

Columbium (Niobium) 0.30 to 0.70

E 876 Practice for Use of Statistics in the Evaluation of

Cobalt 0.05 to 0.50

Spectrometric Data

NOTE 1—These concentration ranges can be extended by the use of

E 1361 Guide for Correction of Interelement Effects in

suitable reference materials. The detection limit for the elements is lower

X-ray Spectrometric Analysis

than the listed value. The ranges represent the nominal levels at which this

2.2 Other Documents:

method was tested.

MNL 7 Manual on Presentation of Data and Control Chart

1.2 This test method is applicable to the control analysis of

Analysis

either chill-cast or wrought samples having a diameter of

approximately 25 mm.

3. Terminology

NOTE 2—Samples of greater or lesser size than those designated may be 3.1 For definitions of terms used in this test method, refer to

used with specially designed sample holders.

Terminology E 135.

1.3 Matrix effects exist between the elements listed. To

4. Summary of Test Method

compensate for these effects, a series of calibration curves are

4.1 The sample is finished to a clean uniform surface and

required to cover the designated concentration ranges. The

then irradiated by an X-ray beam of high energy (short

composition of the sample must approximate closely one or

wavelength). The secondary X rays produced are dispersed by

more of the reference materials used in the calibration curve

means of crystals and the intensities are measured by detectors

which is applied. Mathematical corrections may also be used to

at selected wavelengths. Data are collected based on the time

solve for matrix effects. (Refer to Practice E 1361.) A variety of

required to reach a fixed number of counts, on the total counts

such systems is commonly used. Any of these are acceptable

obtained for a fixed time, or on the integration of voltage for a

that will achieve analytical accuracy equivalent to that reported

fixed time. Concentrations of the elements are determined by

for the method.

relating the measured radiation of unknown samples to ana-

1.4 This standard does not purport to address all of the

lytical curves or charts prepared from standard reference

safety concerns, if any, associated with its use. It is the

materials of known compositions. A fixed channel or polychro-

responsibility of the user of this standard to establish appro-

mator system or a sequential system may be used to provide

priate safety and health practices and determine the applica-

simultaneous or sequential determinations of elements.

bility of regulatory limitations prior to use. Specific hazard

statements are given in Section 7.

5. Apparatus

NOTE 3—It is not within the scope of this test method to prescribe all

details of equipment to be used. Equipment varies between laboratories.

This test method is under the jurisdiction of ASTM Committee E-1 on

5.1 Sample Preparation Equipment:

Analytical Chemistry for Metals, Ores and Related Materials and is the direct

5.1.1 Surface Grinder, with 60 to 600-grit aluminum oxide

responsibility of Subcommittee E01.01 on Iron, Steel, and Ferroalloys.

Current edition approved July 15, 1994. Published September 1994. Originally

e1

published as E 572 – 76. Last previous edition E 572 – 88 .

Supporting data for this test method as determined by cooperative testing have 3

Annual Book of ASTM Standards, Vol 03.05.

been filed at ASTM Headquarters as RR:E-2 1012. 4

Annual Book of ASTM Standards, Vol 03.06.

ASTM Manual Series, ASTM, 6th Edition, 1990.

Copyright © ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959, United States.

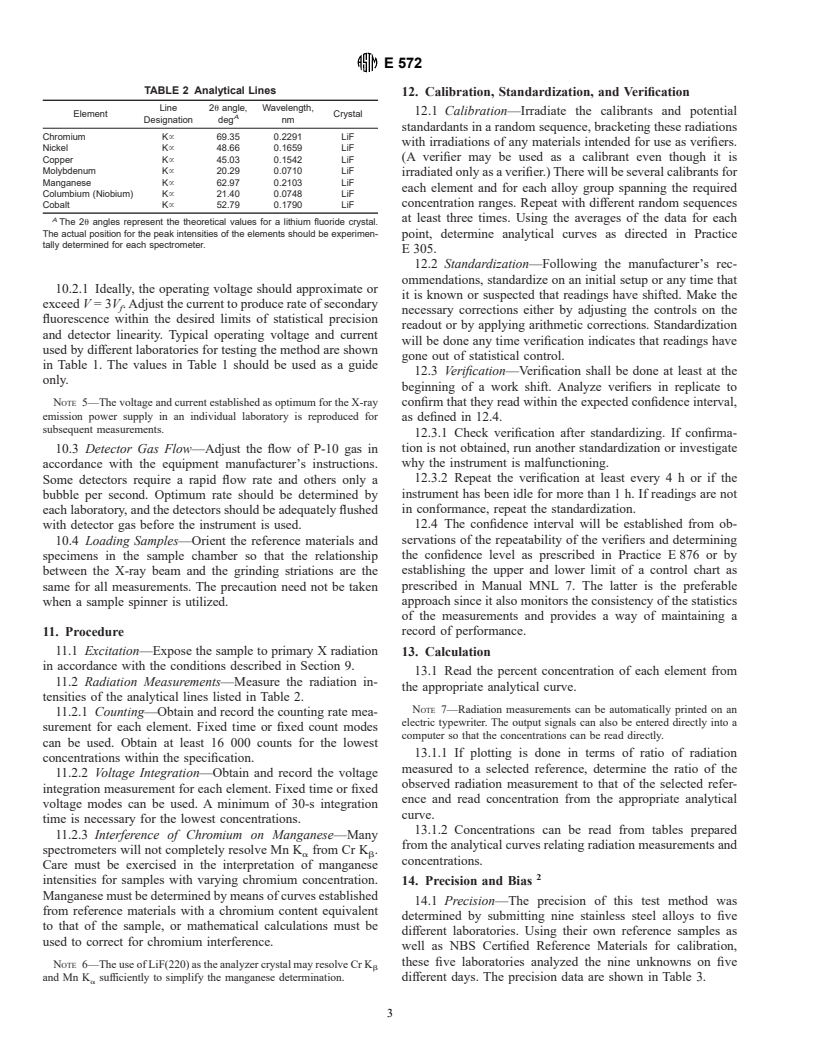

E 572

TABLE 1 Typical Operating Voltages and Currents

that personnel follow the guidelines of safe operating proce-

Element Voltage, kV (Current, mA) dures given in the NIST Handbook X-Ray Protection, HB76,

the booklet Radiation Safety Recommendations for X-Ray

Chromium 60 (45) 60 (24) 50 (40) 20 (8) 40 (8)

Nickel 60 (45) 60 (32) 50 (40) 60 (32) 40 (16)

Diffraction and Spectrographic Equipment, #MORP 68-14, by

Copper 60 (45) 60 (32) 50 (40) 60 (32) 40 (24)

T. M. Moore and D. J. McDonald, 1968, and the U.S.

Molybdenum 60 (45) 60 (32) 50 (40) 60 (32) 40 (24)

Government Handbook 93, Safety Standard for Non-Medical

Manganese 60 (45) 60 (32) 50 (40) 60 (32) 40 (24)

Columbium (Niobium) 60 (45) 60 (32) 50 (40) 60 (32) 40 (24)

X-Ray and Sealed Gamma-Ray Sources, Part 1, general, or

Cobalt 60 (45) 60 (32) 50 (40) 60 (32) 40 (24)

similar handbooks of latest issue.

7.2 X-ray equipment should be used only under the guid-

ance and supervision of a responsible, qualified person.

belts or disks capable of providing test specimens with a

7.3 Suitable monitoring devices, either film badges or do-

uniform flat finish. 10

simeters, shall be worn by all personnel using the equipment.

5.2 Excitation Source:

To meet local, state, and federal radiation standards, periodic

5.2.1 X-Ray Generator, providing constant potential or

radiation surveys of the equipment for leaks and excessive

rectified power of sufficient energy to produce secondary

scattered radiation shall be made by a qualified person using an

radiation of the sample for the elements specified. The genera- 11

ionization-chamber detector. The personal film badge survey

tor may be equipped with a line voltage regulator and a current

record, the radiation survey records, and a maintenance record

stabilizer.

shall be available upon request.

5.2.2 X-Ray Tubes, with targets of various high-purity

7.4 Special precautions for the operator shall be posted.

elements, that are capable of continuous operation up to the

7.5 X-ray caution signs shall be posted near the X-ray

potentials and currents shown in Table 1.

equipment and at all entrances to the radiation area.

7.6 Fail-safe “X-ray On” warning lights shall be used at the

NOTE 4—X-ray tubes with tungsten, gold, and rhodium targets were

used in the testing of this method. X-ray tube.

5.3 Spectrometer, designed for X-ray emission analysis,

8. Preparation of Reference Materials and Samples

using air or vacuum, and equipped with specimen holders and

8.1 Grind the samples to provide a flat, clean area over the

specimen chamber. The chamber should contain a sample

entire surface to be exposed to the X-ray beam. Adhere

spinner.

rigorously to the preparation technique established.

5.3.1 Analyzing Crystal, flat or curved lithium fluoride

LiF(200) or LiF(220).

9. Reference Materials

5.3.2 Collimator, for limiting the characteristic X-rays to a

9.1 Certified Reference Materials are available from the

parallel bundle when flat crystals are used in the instrument.

National Institute of Standards and Technology and other

For curved crystal optics, no collimator is necessary.

sources.

5.3.3 Detectors—Sealed or gas-flow proportional counters

9.2 Reference Materials can be used, provided they are

or equivalent.

analyzed in accordance with Test Methods E 353.

5.3.4 Vacuum System, if used, should consist of a vacuum

pump, gage, and electrical controls to provide automatic

10. Preparation of Apparatus

pumpdown of the optical path and to start the analysis at a

10.1 Start-up—Energize the power supply and electronic

pressure of 100 μm or less, controllable to 6 20 μm.

circuits for at least ⁄2 h prior to taking measurements.

5.4 Measuring System—An electronic circuit capable of

10.2 Power Supply—Adjust the voltage of the power supply

amplifying and integrating pulses received from the detector

to produce secondary fluorescence according to the expression:

tube. The system should be equipped with visual and automatic

recording devices.

V 5 12 350/ K (1)

f l abs

6. Reagents where:

= the minimum voltage required for exciting the

V

f

6.1 Detector Gas (P-10), consisting of 90 % argon and

element, and

10 % methane.

K = wavelength of the K adsorption edge of the

l abs

fluorescent element.

7. Hazards

7.1 Guidelines on ionizing radiation given in Occupational

Health and Safety Standards shall be observed at all X-ray

emission spectrometer installations. It is also recommended

Available from Superintendent of Documents, U.S. Government Printing

Office, Washington, DC 20025.

Available from U.S. Department of Health, Education, and Welfare, Rockville,

A two-stage mechanical pump meeting the requirements can be purchased from MD 20850.

Precision Scientific Co., Chicago, IL 60647, or Sargent-Welch Scientific Co., Available from Siemens Gammasonics, Inc., 2000 Nuclear Drive, Des Plaines,

Skokie, IL 60076. IL 60018.

7 11

Federal Register, Vol. 36, No. 105, May 29, 1971, Section 1910.96 or of latest A survey meter called Cutie-Pie has been found satisfactory for this purpose

issue of Subpart G, available from Superintendent of Documents, U.S. Government and is available from Nuclear Associates, Westbury, Long Island, NY 11590.

Printing Office, Washington, DC 20025;

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.