ASTM D2902-00

(Specification)Standard Specification for Fluoropolymer Resin Heat-Shrinkable Tubing for Electrical Insulation

Standard Specification for Fluoropolymer Resin Heat-Shrinkable Tubing for Electrical Insulation

SCOPE

1.1 This specification applies to flexible heat-shrinkable extruded tubing made from tetrafluoroethylene resin, copolymer of tetrafluoroethylene and hexafluoropropylene, and from perfluoroalkoxy resin for use as electrical insulation.

1.2 The values stated in inch-pound units are to be regarded as the standard except temperature which shall be stated in degrees Celsius. Values in parentheses are for information only.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

An American National Standard

Designation: D 2902 – 00

Standard Specification for

Fluoropolymer Resin Heat-Shrinkable Tubing for Electrical

Insulation

This standard is issued under the fixed designation D 2902; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope Sheets 240 to 243: Heat-shrinkable PTFE sleeving

1.1 This specification applies to flexible heat-shrinkable

3. Terminology

extruded tubing made from tetrafluoroethylene resin, copoly-

3.1 Definitions:

mer of tetrafluoroethylene and hexafluoropropylene, and from

3.1.1 For definitions pertaining to electrical insulation, refer

perfluoroalkoxy resin for use as electrical insulation.

to Terminology D 1711.

NOTE 1—This standard is similar but not identical to IEC 60684–3–240

3.1.2 For definitions pertaining to fire standards, refer to

to –243.

Terminology E 176.

1.2 The values stated in inch-pound units are to be regarded

4. Classification

as the standard except temperature which shall be stated in

degreesCelsius.Valuesinparenthesesareforinformationonly.

4.1 Type I—Tubing made from tetrafluoroethylene polymer

(TFE) and capable of being heat shrunk at a temperature of

2. Referenced Documents

327°C (621°F).

2.1 ASTM Standards:

4.2 Type II—Tubing made from a copolymer of tetrafluo-

C 618 Specification for Coal Fly Ash and Raw or Calcined

roethylene and hexafluoropropylene (FEP) and capable of

Natural Pozzolan for Use as a Mineral Admixture in

being heat shrunk at a temperature of 150°C (302°F).

Portland Cement Concrete

4.3 Type III—Tubing made from perfluoroalkoxy resin

D 638 Test Method for Tensile Properties of Plastics

(PFA) and capable of being heat shrunk at a temperature of

D 1711 Terminology Relating to Electrical Insulation

175°C (347°F).

D 2116 Specification for FEP-Fluorocarbon Molding and

5. Ordering Information

Extrusion Materials

D 2671 Test Methods for Heat-Shrinkable Tubing for Elec-

5.1 When ordering to this specification, the purchaser must

trical Use

state the size, and type of the required tubing.

D 3307 Specification for PFA-Fluorocarbon Molding and

6 6. Materials and Manufacture

Extrusion Materials

D 3636 Practice for Sampling and Judging Quality of Solid 6.1 The compound used in the manufacture of this tubing

Electrical Insulating Materials shall be modified fluoropolymer resin, and the finished com-

D 4895 Specification for Polytetrafluoroethylene (PTFE) pound shall be free of all foreign matter other than intended

Resins Produced from Dispersion formulation additives as appropriate.

E 176 Terminology of Fire Standards 6.2 Type I tubing is normally made by paste extrusion.Type

2.2 IEC Standards: II and Type III tubings are normally made by melt extrusion.

60684–3–240 to –243 Flexible insulating sleeving, Part 3, All types are expanded by mechanical means.

7. Chemical and Physical Property Requirements

7.1 The material shall conform to the chemical and physical

This specification is under the jurisdiction of ASTM Committee D09 on

Electrical and Electronic Insulating Materials and is the direct responsibility of property requirements specified in Table 1.

Subcommittee D09.07 on Flexible and Rigid Insulating Materials.

7.2 Every lot of material manufactured should be tested for

Current edition approved Apr. 10, 2000. Published July 2000. Originally

dimensional requirements and restricted shrinkage. Other re-

published as D 2902 – 70 T. Last previous edition D 2902 – 95a.

quirements may be tested less frequently or with a frequency

Annual Book of ASTM Standards, Vol 04.02.

Annual Book of ASTM Standards, Vol 08.01.

agreed upon between seller and purchaser.

Annual Book of ASTM Standards, Vol 10.01.

Annual Book of ASTM Standards, Vol 10.02.

Annual Book of ASTM Standards, Vol 08.02.

7 9

Annual Book of ASTM Standards, Vol 08.03. Available from American National Standards Institute, 11 W. 42nd St., New

Annual Book of ASTM Standards, Vol 04.07. York, NY 10036.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D 2902

TABLE 1 Chemical and Physical Property Requirements

Requirement

Property

Type I Type II Type III

A

Restricted shrinkage, Procedure B, 2000 V, 10 min no cracking no cracking no cracking

Specific gravity 2.13 to 2.18 2.12 to 2.20 2.13 to 2.20

Longitudinal change, max, % + 20 615 615

Tensile modulus at 200 % elongation, min, psi (MPa) Test Method D 638 2000 (13.8) 1500 (10.3) 2500 (17.3)

2 in./min (50 mm/min)

B 16 16 16

Volume resistivity , ohm-cm, at standard laboratory atmosphere, min 10 10 10

Dielectric breakdown voltage, min kV:

Wall thickness 0.004 to 0.006 in. 8 8 8

0.007 to 0.008 in. 10 10 10

0.009 in. 11.5 11.5 11.5

0.010 to 0.011 in. 12.5 12.5 12.5

0.012 to 0.014 in. 14.6 14.6 14.6

0.015 in. 15 15 15

0.016 to 0.019 in. 16.3 16.3 16.3

0.020 in. and larger 17 17 17

Heat resistance: for 96 h followed by tests for tensile modulus at

200 % elongation, min, psi (MPa)

Type I—350 6 4°C (662 6 7°F) 2000 (13.8)

Type II—250 6 3°C (482 6 6°F) 1500 (10.3)

Type III—275 6 4°C (527 6 7°F) 2500 (17.3)

Low-temperature flexibility, − 556 2°C (−67 6 4°F) no cracking no cracking no cracking

Melting point:

Specification D 4895 327 6 10°C

(6216 20°F)

Specification D 2116 270 6 20°C

(518 6 40°F)

Specification D 3307 endotherm peak, min 300 6 2°C

(572 6 7°F)

Specification D 3307 305 6 3°C

(5816 5°F)

A

For over-expanded sleeving, use a mandrel equal to the enclosable diameters (D + d)/2.

B

See Specification C 618.

8. Dimensional Requirements

8.1 Type I material shall conform to the requirements

specified in Table 3.

D 2902

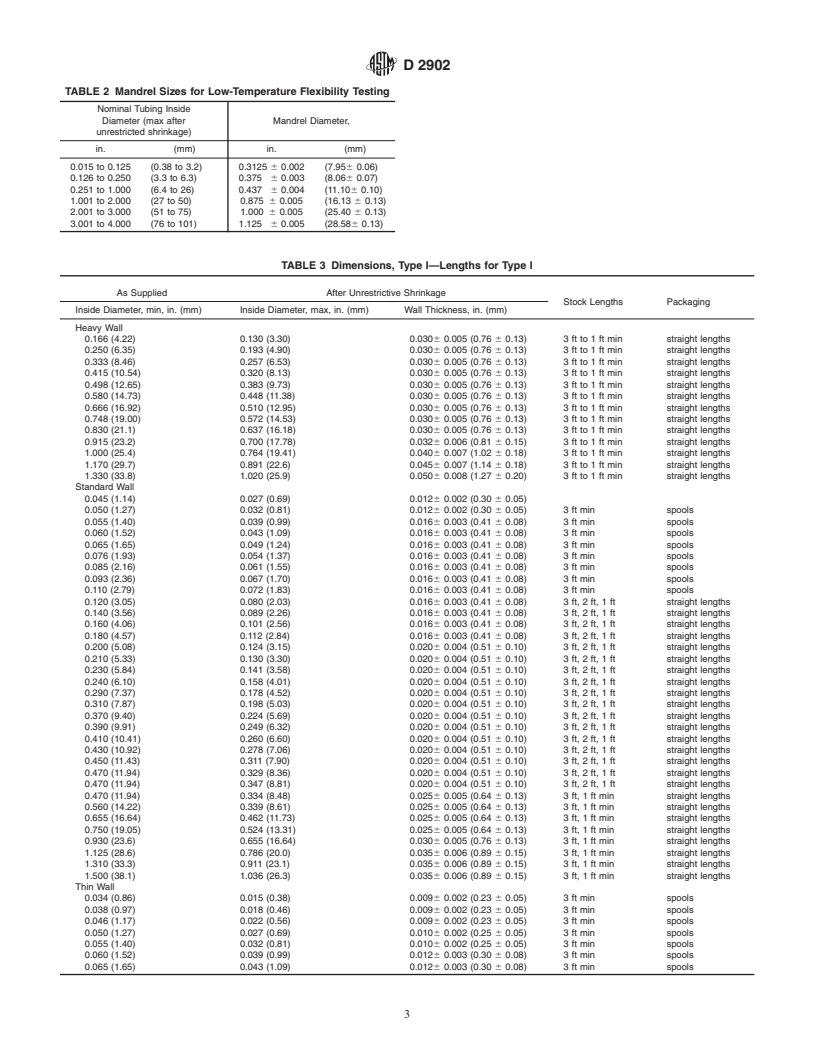

TABLE 2 Mandrel Sizes for Low-Temperature Flexibility Testing

Nominal Tubing Inside

Diameter (max after Mandrel Diameter,

unrestricted shrinkage)

in. (mm) in. (mm)

0.015 to 0.125 (0.38 to 3.2) 0.3125 6 0.002 (7.956 0.06)

0.126 to 0.250 (3.3 to 6.3) 0.375 6 0.003 (8.066 0.07)

0.251 to 1.000 (6.4 to 26) 0.437 6 0.004 (11.106 0.10)

1.001 to 2.000 (27 to 50) 0.875 6 0.005 (16.13 6 0.13)

2.001 to 3.000 (51 to 75) 1.000 6 0.005 (25.40 6 0.13)

3.001 to 4.000 (76 to 101) 1.125 6 0.005 (28.586 0.13)

TABLE 3 Dimensions, Type I—Lengths for Type I

As Supplied After Unrestrictive Shrinkage

Stock Lengths Packaging

Inside Diameter, min, in. (mm) Inside Diameter, max, in. (mm) Wall Thickness, in. (mm)

Heavy Wall

0.166 (4.22) 0.130 (3.30) 0.0306 0.005 (0.76 6 0.13) 3 ft to 1 ft min straight lengths

0.250 (6.35) 0.193 (4.90) 0.0306 0.005 (0.76 6 0.13) 3 ft to 1 ft min straight lengths

0.333 (8.46) 0.257 (6.53) 0.0306 0.005 (0.76 6 0.13) 3 ft to 1 ft min straight lengths

0.415 (10.54) 0.320 (8.13) 0.0306 0.005 (0.76 6 0.13) 3 ft to 1 ft min straight lengths

0.498 (12.65) 0.383 (9.73) 0.0306 0.005 (0.76 6 0.13) 3 ft to 1 ft min straight lengths

0.580 (14.73) 0.448 (11.38) 0.0306 0.005 (0.76 6 0.13) 3 ft to 1 ft min straight lengths

0.666 (16.92) 0.510 (12.95) 0.0306 0.005 (0.76 6 0.13) 3 ft to 1 ft min straight lengths

0.748 (19.00) 0.572 (14.53) 0.0306 0.005 (0.76 6 0.13) 3 ft to 1 ft min straight lengths

0.830 (21.1) 0.637 (16.18) 0.0306 0.005 (0.76 6 0.13) 3 ft to 1 ft min straight lengths

0.915 (23.2) 0.700 (17.78) 0.0326 0.006 (0.81 6 0.15) 3 ft to 1 ft min straight lengths

1.000 (25.4) 0.764 (19.41) 0.0406 0.007 (1.02 6 0.18) 3 ft to 1 ft min straight lengths

1.170 (29.7) 0.891 (22.6) 0.0456 0.007 (1.14 6 0.18) 3 ft to 1 ft min straight lengths

1.330 (33.8) 1.020 (25.9) 0.0506 0.008 (1.27 6 0.20) 3 ft to 1 ft min straight lengths

Standard Wall

0.045 (1.14) 0.027 (0.69) 0.0126 0.002 (0.30 6 0.05)

0.050 (1.27) 0.032 (0.81) 0.0126 0.002 (0.30 6 0.05) 3 ft min spools

0.055 (1.40) 0.039 (0.99) 0.0166 0.003 (0.41 6 0.08) 3 ft min spools

0.060 (1.52) 0.043 (1.09) 0.0166 0.003 (0.41 6 0.08) 3 ft min spools

0.065 (1.65) 0.049 (1.24) 0.0166 0.003 (0.41 6 0.08) 3 ft min spools

0.076 (1.93) 0.054 (1.37) 0.0166 0.003 (0.41 6 0.08) 3 ft min spools

0.085 (2.16) 0.061 (1.55) 0.0166 0.003 (0.41 6 0.08) 3 ft min spools

0.093 (2.36) 0.067 (1.70) 0.0166 0.003 (0.41 6 0.08) 3 ft min spools

0.110 (2.79) 0.072 (1.83) 0.0166 0.003 (0.41 6 0.08) 3 ft min spools

0.120 (3.05) 0.080 (2.03) 0.0166 0.003 (0.41 6 0.08) 3 ft, 2 ft, 1 ft straight lengths

0.140 (3.56) 0.089 (2.26) 0.0166 0.003 (0.41 6 0.08) 3 ft, 2 ft, 1 ft straight lengths

0.160 (4.06) 0.101 (2.56) 0.0166 0.003 (0.41 6 0.08) 3 ft, 2 ft, 1 ft straight lengths

0.180 (4.57) 0.112 (2.84) 0.0166 0.003 (0.41 6 0.08) 3 ft, 2 ft, 1 ft straight lengths

0.200 (5.08) 0.124 (3.15) 0.0206 0.004 (0.51 6 0.10) 3 ft, 2 ft, 1 ft straight lengths

0.210 (5.33) 0.130 (3.30) 0.0206 0.004 (0.51 6 0.10) 3 ft, 2 ft, 1 ft straight lengths

0.230 (5.84) 0.141 (3.58) 0.0206 0.004 (0.51 6 0.10) 3 ft, 2 ft, 1 ft straight lengths

0.240 (6.10) 0.158 (4.01) 0.0206 0.004 (0.51 6 0.10) 3 ft, 2 ft, 1 ft straight lengths

0.290 (7.37) 0.178 (4.52) 0.0206 0.004 (0.51 6 0.10) 3 ft, 2 ft, 1 ft straight lengths

0.310 (7.87) 0.198 (5.03) 0.0206 0.004 (0.51 6 0.10) 3 ft, 2 ft, 1 ft straight lengths

0.370 (9.40) 0.224 (5.69) 0.0206 0.004 (0.51 6 0.10) 3 ft, 2 ft, 1 ft straight lengths

0.390 (9.91) 0.249 (6.32) 0.0206 0.004 (0.51 6 0.10) 3 ft, 2 ft, 1 ft straight lengths

0.410 (10.41) 0.260 (6.60) 0.0206 0.004 (0.51 6 0.10) 3 ft, 2 ft, 1 ft straight lengths

0.430 (10.92) 0.278 (7.06) 0.0206 0.004 (0.51 6 0.10) 3 ft, 2 ft, 1 ft straight lengths

0.450 (11.43) 0.311 (7.90) 0.0206 0.004 (0.51 6 0.10) 3 ft, 2 ft, 1 ft straight lengths

0.470 (11.94) 0.329 (8.36) 0.0206 0.004 (0.51 6 0.10) 3 ft, 2 ft, 1 ft straight lengths

0.470 (11.94) 0.347 (8.81) 0.0206 0.004 (0.51 6 0.10) 3 ft, 2 ft, 1 ft straight lengths

0.470 (11.94) 0.334 (8.48) 0.0256 0.005 (0.64 6 0.13) 3 ft, 1 ft min straight lengths

0.560 (14.22) 0.339 (8.61) 0.0256 0.005 (0.64 6 0.13) 3 ft, 1 ft min straight lengths

0.655 (16.64) 0.462 (11.73) 0.0256 0.005 (0.64 6 0.13) 3 ft, 1 ft min straight lengths

0.750 (19.05) 0.524 (13.31) 0.0256 0.005 (0.64 6 0.13) 3 ft, 1 ft min straight lengths

0.930 (23.6) 0.655 (16.64) 0.0306 0.005 (0.76 6 0.13) 3 ft, 1 ft min straight lengths

1.125 (28.6) 0.786 (20.0) 0.0356 0.006 (0.89 6 0.15) 3 ft, 1 ft min straight lengths

1.310 (33.3) 0.911 (23.1) 0.0356 0.006 (0.89 6 0.15) 3 ft, 1 ft min straight lengths

1.500 (38.1) 1.036 (26.3) 0.0356 0.006 (0.89 6 0.15) 3 ft, 1 ft min straight lengths

Thin Wall

0.034 (0.86) 0.015 (0.38) 0.0096 0.002 (0.23 6 0.05) 3 ft min spools

0.038 (0.97) 0.018 (0.46) 0.0096 0.002 (0.23 6 0.05) 3 ft min spools

0.046 (1.17) 0.022 (0.56) 0.0096 0.002 (0.23 6 0.05) 3 ft min spools

0.050 (1.27) 0.027 (0.69) 0.0106 0.002 (0.25 6 0.05) 3 ft min spools

0.055 (1.40) 0.032 (0.81) 0.0106 0.002 (0.25 6 0.05) 3 ft min spools

0.060 (1.52) 0.039 (0.99) 0.0126 0.003 (0.30 6 0.08) 3 ft min spools

0.065 (1.65) 0.043 (1.09) 0.0126 0.003 (0.30 6 0.08) 3 ft min spools

D 2902

TABLE 3 Continued

As Supplied After Unrestrictive Shrinkage

Stock Lengths Packaging

Inside Diameter, min, in. (mm) Inside Diameter, max, in. (mm) Wall Thickness, in. (mm)

0.076 (1.93) 0.049 (1.24) 0.0126 0.003 (0.30 6 0.08) 3 ft min spools

0.085 (2.16) 0.054 (1.37) 0.0126 0.003 (0.30 6 0.08) 3 ft min spools

0.093 (2.36) 0.061 (1.55) 0.0126 0.003 (0.30 6 0.08) 3 ft min spools

0.110 (2.79) 0.067 (1.70) 0.0126 0.003 (0.30 6 0.08) 3 ft min spools

0.120 (3.05) 0.072 (1.83) 0.0126 0.003 (0.30 6 0.08) 3 ft, 2 ft, 1 ft straight lengths

0.140 (3.56) 0.080 (2.03) 0.0126 0.003 (0.30 6 0.08) 3 ft, 2 ft, 1 ft straight lengths

0.150 (3.81) 0.089 (2.26) 0.0126 0.003 (0.30 6 0.08) 3 ft, 2 ft, 1 ft straight lengths

0.170 (4.32) 0.101 (2.56) 0.0126 0.003 (0.30 6 0.08) 3 ft, 2 ft, 1 ft straight lengths

0.191 (4.85) 0.112 (2.84) 0.0126 0.003 (0.30 6 0.08) 3 ft, 2 ft, 1 ft straight lengths

0.205 (5.21) 0.124 (3.15) 0.0156 0.004 (0.38 6 0.10) 3 ft, 2 ft, 1 ft straight lengths

0.215 (5.46) 0.130 (3.30) 0.0156 0.004 (0.38 6 0.10) 3 ft, 2 ft, 1 ft straight lengths

0.240 (6.10) 0.141 (3.58) 0.0156 0.004 (0.38 6 0.10) 3 ft, 2 ft, 1 ft straight lengths

0.270 (6.86) 0.158 (4.01) 0.0156 0.004 (0.38 6 0.10) 3 ft, 2 ft, 1 ft straight lengths

0.302 (7.67) 0.178 (4.53) 0.0156 0.004 (0.38 6 0.10) 3 ft, 2 ft, 1 ft straight lengths

0.320 (8.13) 0.198 (5.03) 0.0156 0.004 (0.38 6 0.10) 3 ft, 2 ft, 1 ft straight lengths

0.370 (9.40) 0.224 (5.69) 0.0156 0.004 (0.38 6 0.10) 3 ft, 2 ft, 1 ft straight lengths

0.390 (9.91) 0.249 (6.32) 0.0156 0.004 (0.38 6 0.10) 3 ft, 2 ft, 1 ft straight lengths

0.410 (10.41) 0.260 (6.60) 0.0156 0.004 (0.38 6 0.10) 3 ft, 2 ft, 1 ft straight lengths

0.430 (10.92) 0.278 (7.06) 0.0156 0.004 (0.38 6 0.10) 3 ft, 2 ft, 1 ft straight lengths

0.450 (11.43) 0.311 (7.90) 0.0156 0.004 (0.38 6 0.10) 3 ft, 2 ft, 1 ft straight lengths

0.470 (11.94) 0.329 (8.36) 0.0156 0.004 (0.38 6 0.10) 3 ft, 2 ft, 1 ft straight lengths

0.470 (11.94) 0.347 (8.81) 0.0156 0.004 (0.38 6 0.10) 3 ft, 2 ft, 1 ft straight lengths

0.560 (14.22) 0.399 (10.13) 0.0156 0.004 (0.38 6 0.10) 3 ft, 2 ft, 1 ft straight lengths

0.560 (14.22) 0.399 (10.13) 0.0206 0.005 (0.51 6 0.13) 3 ft, 2 ft, 1 ft straight lengths

0.655 (16.64) 0.462 (11.73) 0.0186 0.005 (0.46 6 0.13) 3 ft, 2 ft, 1 ft straight lengths

0.655 (16.64) 0.462 (11.73) 0.0206 0.005 (0.51 6 0.13) 3 ft, 2 ft, 1 ft straight lengths

0.750 (19.05) 0.524 (13.31) 0.0186 0.005 (0.46 6 0.13) 3 ft, 2 ft, 1 ft straight lengths

0.750 (19.05) 0.524 (13.31) 0.0206 0.005 (0.51 6 0.13) 3 ft, 2 ft, 1 ft straight lengths

0.930 (23.6) 0.655 (16.64) 0.0206 0.005 (0.51 6 0.13) 3 ft, 2 ft, 1 ft straight lengths

0.930 (23.6) 0.655 (16.64) 0.0256 0.005 (0.64 6 0.13) 3 ft, 2 ft, 1 ft straight lengths

1.125 (28.6) 0.786 (20.0) 0.0256 0.005 (0.64 6 0.13) 3 ft, 2 ft, 1 ft straight lengths

1.125 (28.6) 0.786 (20.0) 0.0306 0.006 (0.76 6 0.15) 3 ft, 2 ft, 1 ft straight lengths

2.0:1 Shrink Factor

0.039 (1) 0.020 (0.50) 0.0106 0.002 (0.25 6 0.05) 4 ft straight lengths

0.059(1.5) 0.030 (0.75) 0.0106 0.002 (0.25 6 0.05) 4 ft straight lengths

0.098 (2.5) 0.049 (1.25) 0.0106 0.002 (0.25 6 0.05) 4 ft straight lengths

0.138 (3.5) 0.069 (1.75) 0.0106 0.002 (0.25 6 0.05) 4 ft straight lengths

0.197 (5) 0.098 (2.5) 0.010 6 0.002 (0.25 6 0.05) 4 ft straight lengths

0.276 (7) 0.138 (3.5) 0.020 6 0.004 (0.50 6 0.10) 4 ft straight lengths

0.394 (10) 0.197 (5.0) 0.020 6 0.004 (0.50 6 0.10) 4 ft straight lengths

0.512 (13) 0.256 (6.5) 0.020 6 0.004 (0.50 6 0.10) 4 ft straight lengths

0.827 (20) 0.394 (10.0) 0.0206 0.004 (0.50 6 0.10) 4 ft straight lengths

1.024 (26) 0.512 (13.0) 0.0306 0.004 (0.75 6 0.10) 4 ft straight lengths

Very Thin Wall

0.050 (1.27) 0.027 (0.69) 0.0066 0.002 (0.15 6 0

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.