ASTM E520-98

(Practice)Standard Practice for Describing Photomultiplier Detectors in Emission and Absorption Spectrometry

Standard Practice for Describing Photomultiplier Detectors in Emission and Absorption Spectrometry

SCOPE

1.1 Radiation in the frequency range common to analytical emission and absorption spectrometry is detected by photomultipliers presently to the exclusion of most other transducers. Detection limits, analytical sensitivity, and accuracy depend on the characteristics of these current-amplifying detectors as well as other factors in the system.

1.2 This practice surveys photomultiplier properties that are essential to their judicious selection and use of photo- multipliers in emission and absorption spectrometry. Descriptions of these properties can be found in the following sections: Section Structural Features 2 General 2.1 External Structure 2.2 Internal Structure 2.3 Electrical Properties 3 General 3.1 Optical-Electronic Characteristics of the Photocathode 3.2 Current Amplification 3.3 Signal Nature 3.4 Dark Current 3.5 Noise Nature 3.6 Photomultiplier as a Component in an Electrical Circuit 3.7 Precautions and Problems 4 General 4 Fatigue and Hysteresis Effects 4.2 Illumination of Photocathode 4.3 Gas Leakage 4.4 Recommendations on Important Selection Criteria 5

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: E 520 – 98

Standard Practice for

Describing Photomultiplier Detectors in Emission and

Absorption Spectrometry

This standard is issued under the fixed designation E 520; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope to Terminology E 135.

3.2 Definitions of Terms Specific to This Standard:

1.1 Radiation in the frequency range common to analytical

3.2.1 solar blind, n—photocathode of photomultiplier tube

emission and absorption spectrometry is detected by photomul-

does not respond to wavelengths on the high side.

tipliers presently to the exclusion of most other transducers.

3.2.1.1 Discussion—In general, solar blind photomultiplier

Detection limits, analytical sensitivity, and accuracy depend on

tubes used in optical emission spectroscopy transmit radiation

the characteristics of these current-amplifying detectors as well

below about 300 nm and do not transmit wavelengths above

as other factors in the system.

300 nm.

1.2 This practice surveys photomultiplier properties that are

essential to their judicious selection and use of photomultipli-

4. Structural Features

ers in emission and absorption spectrometry. Descriptions of

4.1 General—The external structure and dimensions, as

these properties can be found in the following sections:

well as the internal structure and electrical properties, can be

Section

significant in the selection of a photomultiplier.

Structural Features 4

General 4.1

4.2 External Structure—The external structure consists of

External Structure 4.2

envelope configurations, window materials, electrical contacts

Internal Structure 4.3

through the glass-wall envelopes, and exterior housing.

Electrical Properties 5

General 5.1

4.2.1 Envelope Configurations—Glass envelope shapes and

Optical-Electronic Characteristics of the Photocathode 5.2

dimensions are available in an abundant variety. At present,

Current Amplification 5.3

two envelope configurations are common, the end-on (or

Signal Nature 5.4

Dark Current 5.5

head-on), side-on types (see Fig. 1).

Noise Nature 5.6

4.2.2 Window Materials—Various window materials, such

Photomultiplier as a Component in an Electrical Circuit 5.7

as glass, quartz and quartz-like materials, sapphire, magnesium

Precautions and Problems 6

General 6.1

fluoride, and cleaved lithium fluoride, cover the ranges of

Fatigue and Hysteresis Effects 6.2

spectral transmission essential to efficient detection in spectro-

Illumination of Photocathode 6.3

metric applications. Window cross sections for the end-on type

Gas Leakage 6.4

Recommendations on Important Selection Criteria 7

photomultipliers include plano-plano, plano-concave,

convexo-concave forms, and a hemispherical form for collec-

1.3 This standard does not purport to address all of the

tion of 2-p radians of light flux.

safety concerns, if any, associated with its use. It is the

4.2.3 Electrical Connections—Standard pin bases, flying-

responsibility of the user of this standard to establish appro-

leads, or potted pin bases are available to facilitate the location

priate safety and health practices and determine the applica-

of a photomultiplier, or for the use of a photomultiplier at low

bility of regulatory limitations prior to use.

temperatures. TFE-fluorocarbon receptacles for pin-base types

2. Referenced Documents

are recommended to minimize the current leakage between

pins.

2.1 ASTM Standards:

4.2.4 Housing—The housing for a photomultiplier should

E 135 Terminology Relating to Analytical Chemistry for

be “light tight.” Light leaks into a housing or monochromator

Metals, Ores, and Related Materials

from fluorescent lamps are particularly bad noise sources

3. Terminology

which can be readily detected with an oscilloscope adjusted for

twice the power line frequency. A mu-metal housing or shield

3.1 Definitions—For terminology relating to detectors refer

is recommended to diminish stray magnetic field interferences

with the internal focus on electron trajectories between tube

This practice is under the jurisdiction of ASTM Committee E-1 on Analytical

elements.

Chemistry for Metals, Ores, and Related Materials and is the direct responsibility of

Subcommittee E01.20 on Fundamental Practices. 4.3 Internal Structure—The internal structure consists of

Current edition approved Jan. 10, 1998. Published June 1998.

arrangements of cathode, dynodes, and anodes.

Annual Book of ASTM Standards, Vol 03.05.

Copyright © ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959, United States.

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

E 520

FIG. 2 Electrostatic Dynode Structures

FIG. 1 Envelope Configurations

4.3.1 Photocathode—A typical photomultiplier of the

conduction bands of semiconducting or conducting materials if

end-on configuration possesses a semitransparent to opaque

the surface of the material is exposed to electromagnetic

layer of photoemissive material that is deposited on the inner

radiation having a photon energy higher than that required by

surface of the window segment in an evacuated glass envelope.

the photoelectric work-function threshold. The number of

In the side-on window types, the cathode layer is on a reflective

electrons emitted per incident photon, that is, the quantum

substrate within the evacuated tube or on the inner surface of

efficiency, is likely to be less than unity and typically less than

the window.

0.3.

4.3.2 Dynodes and Anode—Secondary-electron multiplica-

tion systems are designed so that the electrons strike a dynode

5.2.1 Spectral Response—The spectral response of a pho-

at a region where the electric field is directed away from the

tocathode is the relative rate of photoelectron production as a

surface and toward the next dynode. Six of these configurations

function of wavelength of the incident radiation of constant

are shown in Fig. 2. Ordinarily a photomultiplier uses from 4

flux density and solid angle. Spectral response is measured at

to 16 dynodes. There are several different configurations of

the cathode with a simple anode or at the anode of a

anodes including multianodes and cross wire anodes for

secondary-electron photomultiplier. Usually, this wavelength-

position sensitivity.

dependent response is expressed in amperes per watt at anode.

4.3.3 Rigidness of Structural Components— The standard

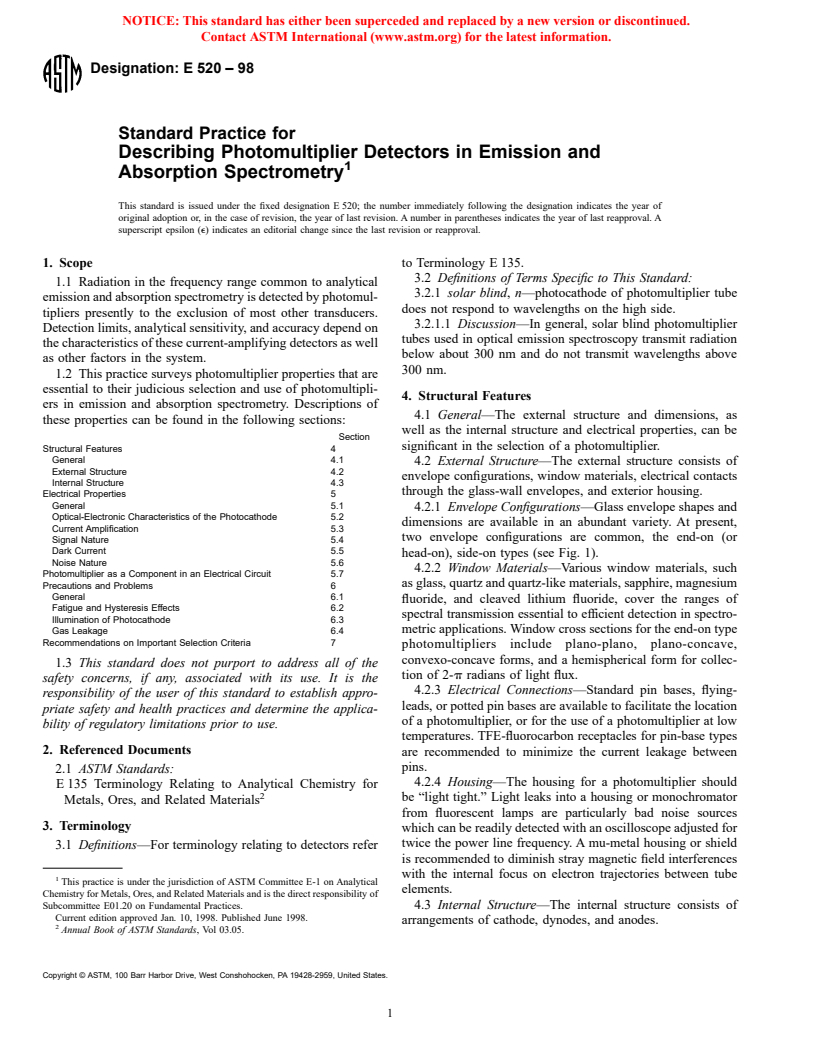

5.2.1.1 Spectral response curves for several common stan-

structural components generally will not endure exceptional

dard cathode-types are shown in Fig. 3. The S-number is a

mechanical shocks. However, specifically constructed photo-

standard industrial reference number for a given cathode type

multipliers (ruggedized) that are resistant to damage by me-

and spectral response. Some of the common cathode surface

chanical shock and stress are available for special applications,

compositions are listed below. Semiconductive photocathodes,

such as geophysical uses or in mobile laboratories.

for example, GaAs(Cs) and InGaAs(Cs), as well as red-

5. Electrical Properties

enhanced multialkali photocathodes (S-25) are also available.

A “solar blind” response cathode of CsI, not shown in Fig. 3,

5.1 General—The electrical properties of a photomultiplier

provides a low-noise signal in the 160 to 300-nm region of the

are a complex function of the cathode, dynodes, and the

spectrum. Intensity measurements at wavelengths below 100

voltage divider bridge used for gain control.

nm can be made with a windowless, gold-cathode photomul-

5.2 Optical-Electronic Characteristics of the

Photocathode—Electrons are ejected into a vacuum from the tiplier.

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

E 520

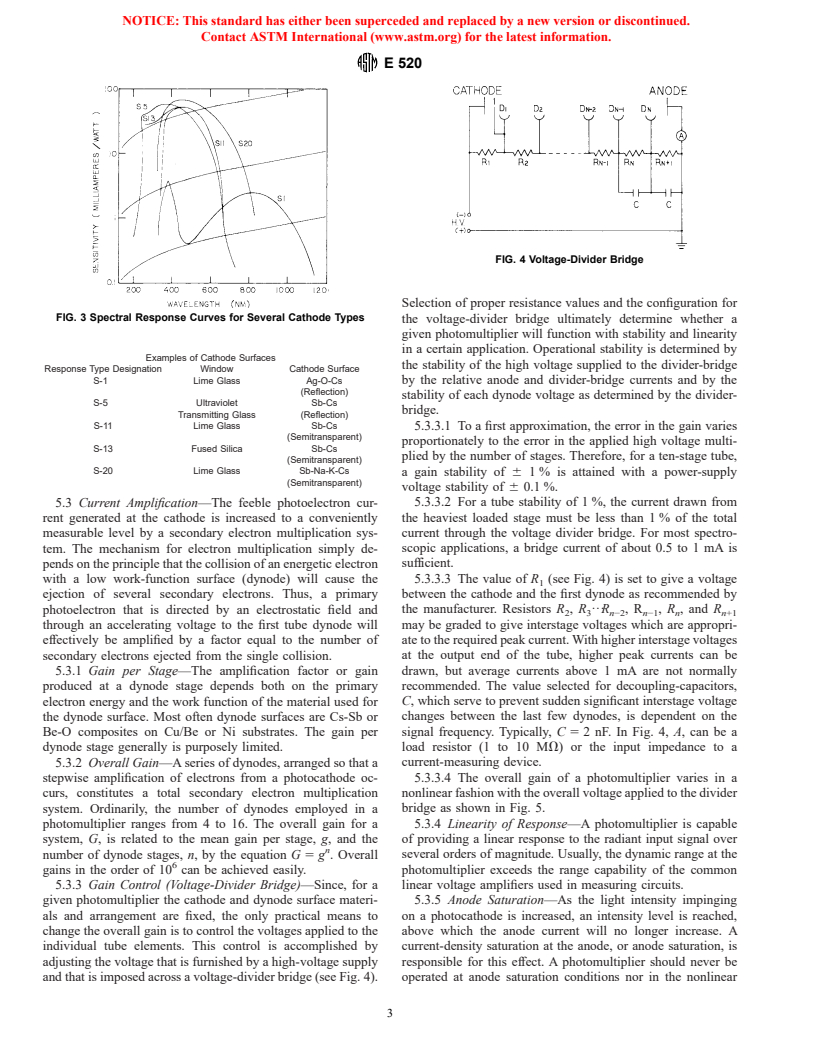

FIG. 4 Voltage-Divider Bridge

Selection of proper resistance values and the configuration for

FIG. 3 Spectral Response Curves for Several Cathode Types

the voltage-divider bridge ultimately determine whether a

given photomultiplier will function with stability and linearity

in a certain application. Operational stability is determined by

Examples of Cathode Surfaces

the stability of the high voltage supplied to the divider-bridge

Response Type Designation Window Cathode Surface

S-1 Lime Glass Ag-O-Cs by the relative anode and divider-bridge currents and by the

(Reflection)

stability of each dynode voltage as determined by the divider-

S-5 Ultraviolet Sb-Cs

bridge.

Transmitting Glass (Reflection)

S-11 Lime Glass Sb-Cs

5.3.3.1 To a first approximation, the error in the gain varies

(Semitransparent)

proportionately to the error in the applied high voltage multi-

S-13 Fused Silica Sb-Cs

plied by the number of stages. Therefore, for a ten-stage tube,

(Semitransparent)

S-20 Lime Glass Sb-Na-K-Cs

a gain stability of 6 1 % is attained with a power-supply

(Semitransparent)

voltage stability of 6 0.1 %.

5.3 Current Amplification—The feeble photoelectron cur- 5.3.3.2 For a tube stability of 1 %, the current drawn from

rent generated at the cathode is increased to a conveniently the heaviest loaded stage must be less than 1 % of the total

measurable level by a secondary electron multiplication sys- current through the voltage divider bridge. For most spectro-

tem. The mechanism for electron multiplication simply de- scopic applications, a bridge current of about 0.5 to 1 mA is

pends on the principle that the collision of an energetic electron sufficient.

with a low work-function surface (dynode) will cause the 5.3.3.3 The value of R (see Fig. 4) is set to give a voltage

ejection of several secondary electrons. Thus, a primary between the cathode and the first dynode as recommended by

photoelectron that is directed by an electrostatic field and the manufacturer. Resistors R , R ···R ,R , R , and R

2 3 n−2 n−1 n n+1

through an accelerating voltage to the first tube dynode will may be graded to give interstage voltages which are appropri-

ate to the required peak current. With higher interstage voltages

effectively be amplified by a factor equal to the number of

secondary electrons ejected from the single collision. at the output end of the tube, higher peak currents can be

drawn, but average currents above 1 mA are not normally

5.3.1 Gain per Stage—The amplification factor or gain

produced at a dynode stage depends both on the primary recommended. The value selected for decoupling-capacitors,

C, which serve to prevent sudden significant interstage voltage

electron energy and the work function of the material used for

the dynode surface. Most often dynode surfaces are Cs-Sb or changes between the last few dynodes, is dependent on the

signal frequency. Typically, C 5 2 nF. In Fig. 4, A, can be a

Be-O composites on Cu/Be or Ni substrates. The gain per

dynode stage generally is purposely limited. load resistor (1 to 10 MV) or the input impedance to a

current-measuring device.

5.3.2 Overall Gain—A series of dynodes, arranged so that a

stepwise amplification of electrons from a photocathode oc- 5.3.3.4 The overall gain of a photomultiplier varies in a

nonlinear fashion with the overall voltage applied to the divider

curs, constitutes a total secondary electron multiplication

system. Ordinarily, the number of dynodes employed in a bridge as shown in Fig. 5.

photomultiplier ranges from 4 to 16. The overall gain for a 5.3.4 Linearity of Response—A photomultiplier is capable

system, G, is related to the mean gain per stage, g, and the of providing a linear response to the radiant input signal over

n

number of dynode stages, n, by the equation G 5 g . Overall several orders of magnitude. Usually, the dynamic range at the

gains in the order of 10 can be achieved easily. photomultiplier exceeds the range capability of the common

5.3.3 Gain Control (Voltage-Divider Bridge)—Since, for a linear voltage amplifiers used in measuring circuits.

given photomultiplier the cathode and dynode surface materi- 5.3.5 Anode Saturation—As the light intensity impinging

als and arrangement are fixed, the only practical means to on a photocathode is increased, an intensity level is reached,

change the overall gain is to control the voltages applied to the above which the anode current will no longer increase. A

individual tube elements. This control is accomplished by current-density saturation at the anode, or anode saturation, is

adjusting the voltage that is furnished by a high-voltage supply responsible for this effect. A photomultiplier should never be

and that is imposed across a voltage-divider bridge (see Fig. 4). operated at anode saturation conditions nor in the nonlinear

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

E 520

an approximate factor of ten for each 20 K temperature

decrease.

5.6 Noise Nature—Since noise power is an additive circuit

property, a consideration of the major sources of noise in a

photomultiplier is important. The four principal noise sources

of concern are shot noise, thermionic emission noise, field

emission noise, and leakage-current noise. Johnson noise is a

property of the anode load resistor in a measuring circuit and

will not be treated here.

(a) The shot-noise equation describes the maximum shot-

effect noise as follows:

1/2

i 5 ~2qIDf! (1)

rms

A. Venetian Blind-15 Dynodes

where:

B. Box and Grid-11 Dynodes

i 5 root-mean-square (quadratic) noise current,

rms

C. Venetian Blind-11 Dynodes

q 5 charge on each carrier, C,

FIG. 5 Overall Gain Dependence on Applied Voltage (SbCs

I 5 total current through tube, A, and

Cathode)

Df 5 band pass, Hz.

The shot-noise component is inversely proportional to the

response region approaching saturation because of possible

cathode radiant sensitivity.

damage to the tube.

(b) The Nyquist equation describes the thermal noise as

5.4 Signal Nature—The current through a photomultiplier is

follows:

composed of discrete charge carriers. Each effective photoelec-

1/2

i 5 @~4kTDf/R!# (2)

tron is randomly emitted from the cathode and travels a

rms

distance to the first dynode where a small packet of electrons

where:

is generated. This packet of electrons then travels to the next

R 5 resistance of a conducting element, V,

dynode where yet a larger bunch of electrons is produced, and

−23

k 5 Boltzmann constant (1.38 3 10 J/K), and

this process c

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.