ASTM E749-96

(Practice)Standard Practice for Acoustic Emission Monitoring During Continuous Welding

Standard Practice for Acoustic Emission Monitoring During Continuous Welding

SCOPE

1.1 This practice provides recommended guidelines for acoustic emission (AE) monitoring of weldments during and immediately following their fabrication by continuous welding processes. The technique is in a developmental stage and is not used routinely on production welding. Depending on the results of ongoing research and preproduction weld monitoring experience, these procedures are subject to change before routine implementation on production welds.

1.2 The procedure described in this practice is applicable to the detection and location of AE sources in weldments and in their heat-affected zone during fabrication, particularly in those cases where the time duration of welding is such that fusion and solidification take place while welding is still in progress.

1.3 The effectiveness of acoustic emission to detect discontinuities in the weldment and the heat-affected zone is dependent on the design of the AE system, the calibration procedure, the weld process, and the material type. Materials that have been monitored include low-carbon steels, low-alloy steels, stainless steels, and some aluminum alloys. The system performance must be verified for each application by demonstrating that the defects of concern can be detected with the desired reliability.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: E 749 – 96 An American National Standard

Standard Practice for

Acoustic Emission Monitoring During Continuous Welding

This standard is issued under the fixed designation E 749; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope 2.2 ASNT Standards:

SNT-TC-1A Recommended Practice for Nondestructive

1.1 This practice provides recommended guidelines for

Testing Personnel Qualification and Certification

acoustic emission (AE) monitoring of weldments during and

ANSI/ASNT CP-189 Standard for Qualification and Certi-

immediately following their fabrication by continuous welding

fication of Nondestructive Testing Personnel

processes. The technique is in a developmental stage and is not

2.3 Military Standard:

used routinely on production welding. Depending on the

MIL-STD-410 Nondestructive Testing Personnel Qualifica-

results of ongoing research and preproduction weld monitoring

tion and Certification

experience, these procedures are subject to change before

routine implementation on production welds.

3. Terminology

1.2 The procedure described in this practice is applicable to

3.1 Definitions—For definitions of terms relating to acoustic

the detection and location of AE sources in weldments and in

emission testing, see Section B of Terminology E 1316.

their heat-affected zone during fabrication, particularly in those

cases where the time duration of welding is such that fusion

4. Significance and Use

and solidification take place while welding is still in progress.

4.1 Detection and location of AE sources in weldments

1.3 The effectiveness of acoustic emission to detect discon-

during fabrication may provide information related to the

tinuities in the weldment and the heat-affected zone is depen-

integrity of the weld. Such information may be used to direct

dent on the design of the AE system, the calibration procedure,

repair procedures on the weld or as a guide for application of

the weld process, and the material type. Materials that have

other nondestructive evaluation (NDE) methods. A major

been monitored include low-carbon steels, low-alloy steels,

attribute of applying AE for in-process monitoring of welds is

stainless steels, and some aluminum alloys. The system per-

the ability of the method to provide immediate real-time

formance must be verified for each application by demonstrat-

information on weld integrity. This feature makes the method

ing that the defects of concern can be detected with the desired

useful to lower weld costs by repairing defects at the most

reliability.

convenient point in the production process. The AE activity

1.4 This standard does not purport to address all of the

from discontinuities in the weldment is stimulated by the

safety concerns, if any, associated with its use. It is the

thermal stresses from the welding process. The AE activity

responsibility of the user of this standard to establish appro-

resulting from this stimulation is detected by AE sensors in the

priate safety and health practices and determine the applica-

vicinity of the weldment which convert the acoustic signals

bility of regulatory limitations prior to use.

into electronic signals. The AE instrumentation similar to that

described in Practice E 569 processes signals and may provide

2. Referenced Documents

means for immediate display or indication of AE activity and

2.1 ASTM Standards:

for permanent recordings of the data.

E 543 Practice for Evaluating Agencies that Perform Non-

2 4.2 Items to be considered in preparation and planning for

destructive Testing

monitoring should include but not be limited to the following:

E 569 Practice for Acoustic Emission Monitoring of Struc-

2 4.2.1 Description of the system or object to be monitored or

tures During Controlled Stimulation

examined,

E 650 Guide for Mounting Piezoelectric Acoustic Emission

2 4.2.2 Extent of monitoring, that is, entire weld, cover passes

Sensors

2 only, and so forth,

E 1316 Terminology for Nondestructive Examinations

4.2.3 Limitations or restrictions on the sensor mounting

procedures, if applicable,

This practice is under the jurisdiction of ASTM Committee E-7 on Nonde-

structive Testing and is the direct responsibility of Subcommittee E07.04 on

Acoustic Emission. Available from American Society of Nondestructive Testing, 1711 Arlingate

Current edition approved May 10, 1996. Published July 1996. Originally Plaza, P. O. Box 28518, Columbus, OH 43228-0518.

e1 4

published as E 749 – 80. Last previous edition E 749 – 80 (1991) . Available from Standardization Documents Order Desk, Bldg. 4 Section D, 700

Annual Book of ASTM Standards, Vol 03.03. Robbins Ave., Philadelphia, PA 19111-5094, Attn: NPODS.

Copyright © ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959, United States.

E 749

4.2.4 Performance parameters to be established and main-

tained during the calibration procedure (sensitivity, locational

accuracy, and so forth),

4.2.5 Maximum time interval between system calibration

checks,

4.2.6 Performance criteria for purchased equipment,

4.2.7 Requirements for permanent records of the AE re-

FIG. 1 Typical Sensor Placement for Single Channel AE

sponse, if applicable,

Monitoring of a Linear Weld

4.2.8 Content and format of testing report, if required, and

4.2.9 Operator qualification and certification, if required.

5. Basis of Application

5.1 Personnel Qualification:

5.1.1 Nondestructive Testing (NDT) personnel shall be

qualified in accordance with a nationally recognized NDT

personnel qualification practice or standard such as ANSI/

FIG. 2 Typical Sensor Placement for Two-Channel AE Monitoring

ASNT CP-189, SNT-TC-1A, MIL-STD-410, or similar docu-

of a Linear Weld

ment. The practice or standard used and its applicable revision

shall be specified in the contractual agreement between the

using parties.

5.1.2 In those cases in which AE monitoring is restricted to

use as a production tool to facilitate immediate repair, moni-

toring during welding may be performed by production per-

sonnel lacking the necessary certification; however, certified

personnel should verify that proper procedures are imple-

mented.

5.2 Qualification of Nondestructive Agencies—If specified

FIG. 3 Typical Sensor Placement for Three-Channel AE

in the contractual agreement, NDT agencies shall be qualified

Monitoring of a Circular Weld

and evaluated as described in Practice E 543. The applicable

edition of Practice E 543 shall be specified in the contractual

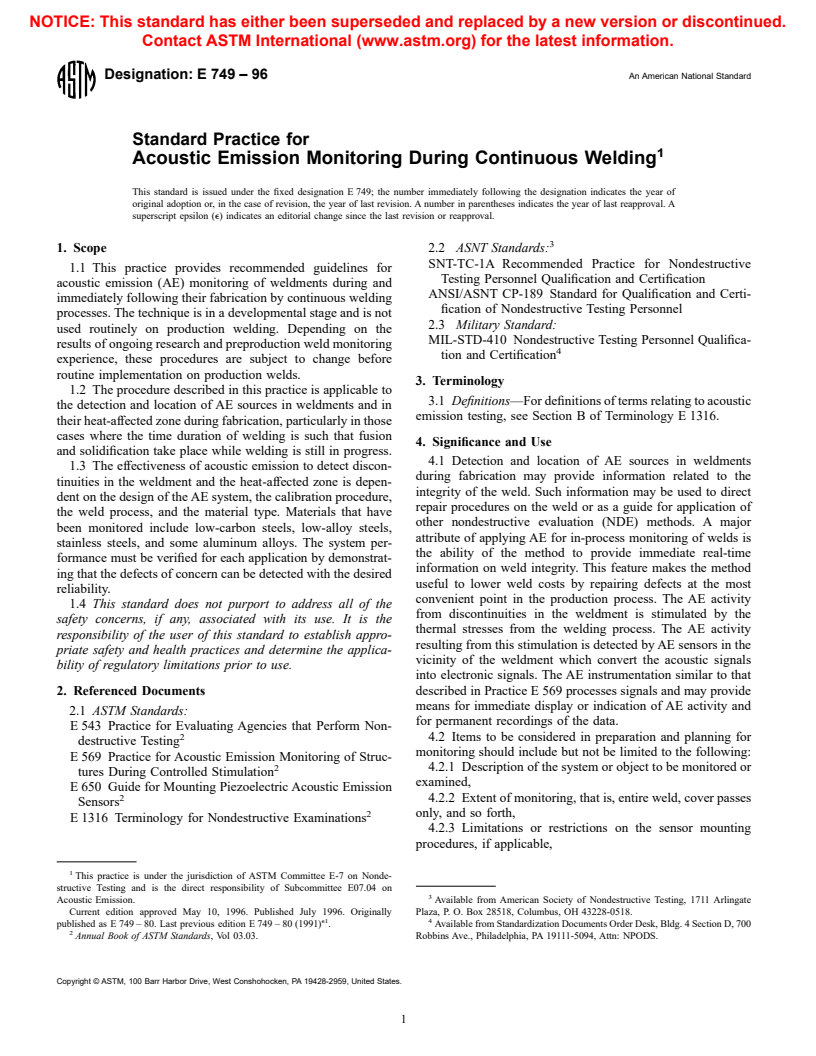

Fig. 4 shows side and top views of a typical configuration for

agreement.

moving sensors.

5.3 Procedures and Techniques—The procedures and tech-

6.1.2 Position and route the signal cables connecting the

niques to be used shall be as described in this practice unless

sensor(s) to the AE instrumentation to avoid contacting the hot

otherwise specified. Specific techniques may be specified in the

weld bead or entangling the welding and positioning equip-

contractual agreement.

ment.

6.1.3 Adjustment of Apparatus:

6. Examination Preparation

6.1.3.1 After all sensors are mounted, connected, and op-

6.1 The following preparatory procedures should be com-

erational (without objectionable background noise), the AE

pleted before initiating AE monitoring:

monitoring system can then be adjusted using an AE simulator.

6.1.1 Select the location(s) where the sensor(s) will be

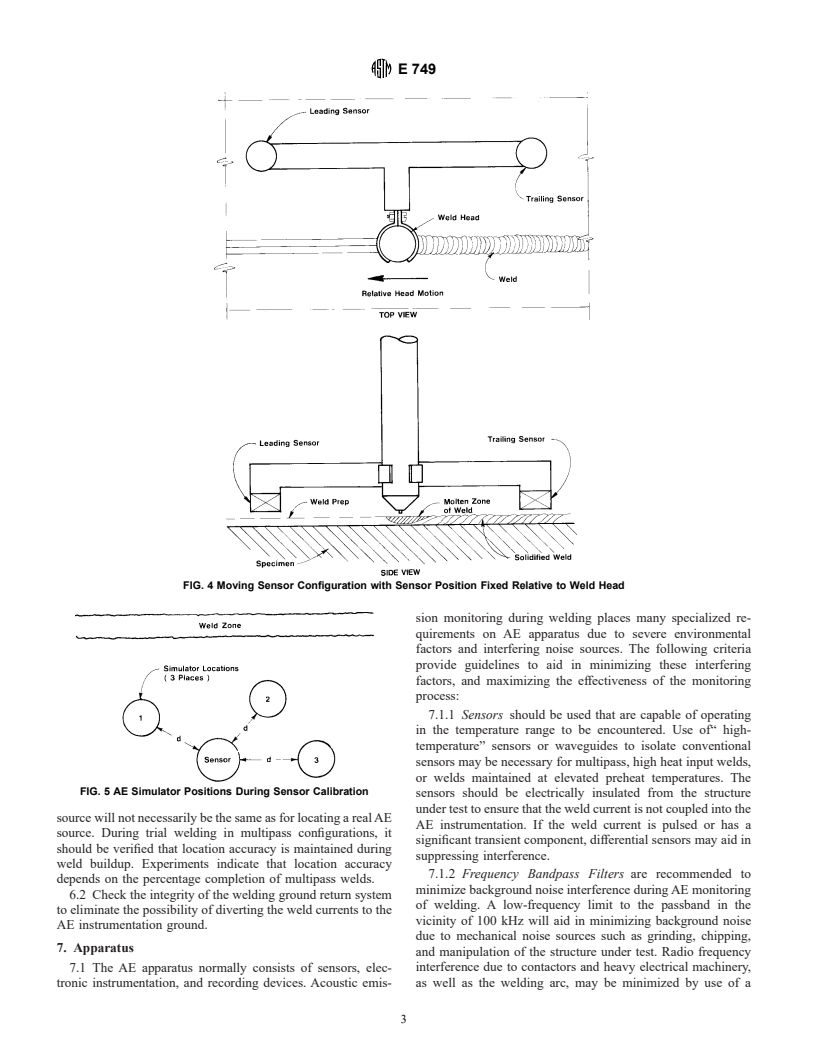

6.1.3.2 Gain Adjustment—To set the gain for a channel,

acoustically coupled. The sensor(s) should be centrally located

locate the acoustic emission simulator at a selected distance

near the weldment to provide for optimal AE response from all

adjacent to the sensor. Monitor the response to the simulated

portions of the weld. If the sensor(s) are piezoelectric, this

emission, and adjust the channel gain to a specified amplitude

location should be such that the maximum temperature stays

level. Repeat this procedure two times, placing the simulator at

substantially below the Curie temperature of the sensor(s).

the same distance from the sensor but at different azimuthal

Take care in selecting the sensor mounting locations to avoid

positions relative to the original simulator positions (see Fig.

contact or disturbance, or both, of the sensor by any of the

5). Record the average gain for the three simulator positions.

welding or structural positioning equipment. Typical distances

Repeat the entire procedure for each AE sensor on the

from 6 in. to 1 ft (150 to 300 mm) from the heat-affected zone

structure, and adjust the gains. The average gains for all

of the weld are usually satisfactory. Typical fixed sensor

channels should give responses to the simulator that have peak

placement patterns that have been successfully used are shown voltages identical to within 63 dB.

in Figs. 1-3.

6.1.4 Determination of Source-Location Accuracy—Check

6.1.1.1 If a fixed contact sensor(s) is used, clean the area(s) the operation of the AE source-location function by analyzing

where attachment will be made to eliminate loose scale,

simulated AE signals from several random locations in the

welding

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.