ASTM F493-14

(Specification)Standard Specification for Solvent Cements for Chlorinated Poly(Vinyl Chloride) (CPVC) Plastic Pipe and Fittings

Standard Specification for Solvent Cements for Chlorinated Poly(Vinyl Chloride) (CPVC) Plastic Pipe and Fittings

ABSTRACT

This specification covers requirements for solvent cements for chlorinated poly(vinyl chloride) (CPVC) plastic pipe, tubing, and socket-type fittings. Solvent cement shall be a CPVC resin-based solution, shall be free-flowing, shall show no gelation or stratification, and shall not contain lumps or any foreign matter. Other requirements include resin content, dissolution, viscosity, shelf stability, hydrostatic burst strength, and hydrostatic sustained pressure strength. Test procedures for solid contents, inert filler determination, viscosity, hydrostatic burst strength, and hydrostatic sustained pressure strength are included in this specification.

SCOPE

1.1 This specification provides requirements for chlorinated poly(vinyl chloride) (CPVC) solvent cements to be used in joining chlorinated poly(vinyl chloride) pipe, tubing, and socket-type fittings.

1.2 CPVC solvent cements are used with CPVC 41 chlorinated poly(vinyl chloride) pipe, tubing, and fittings, which meet Class 23447 as defined in Specification D1784.

1.3 A recommended procedure for joining CPVC pipe and fittings is given in Appendix X1.

1.4 The text of this specification references notes, footnotes, and appendixes which provide explanatory material. These notes and footnotes (excluding those in tables and figures) shall not be considered as requirements of the specification.

1.5 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.6 The following safety hazards caveat pertains only to the test methods portion, Section 6, of this specification: This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:F493 −14 An American National Standard

Standard Specification for

Solvent Cements for Chlorinated Poly(Vinyl Chloride)

1

(CPVC) Plastic Pipe and Fittings

ThisstandardisissuedunderthefixeddesignationF493;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginal

adoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscript

epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope* D1599Test Method for Resistance to Short-Time Hydraulic

Pressure of Plastic Pipe, Tubing, and Fittings

1.1 This specification provides requirements for chlorinated

D1784Specification for Rigid Poly(Vinyl Chloride) (PVC)

poly(vinyl chloride) (CPVC) solvent cements to be used in

Compounds and Chlorinated Poly(Vinyl Chloride)

joining chlorinated poly(vinyl chloride) pipe, tubing, and

(CPVC) Compounds

socket-type fittings.

D2846/D2846MSpecification for Chlorinated Poly(Vinyl

1.2 CPVC solvent cements are used with CPVC 41 chlori-

Chloride) (CPVC) Plastic Hot- and Cold-Water Distribu-

nated poly(vinyl chloride) pipe, tubing, and fittings, which

tion Systems

meet Class 23447 as defined in Specification D1784.

F402 Practice for Safe Handling of Solvent Cements,

Primers, and Cleaners Used for Joining Thermoplastic

1.3 A recommended procedure for joining CPVC pipe and

fittings is given in Appendix X1. Pipe and Fittings

F412Terminology Relating to Plastic Piping Systems

1.4 Thetextofthisspecificationreferencesnotes,footnotes,

F439Specification for Chlorinated Poly (Vinyl Chloride)

and appendixes which provide explanatory material. These

(CPVC) Plastic Pipe Fittings, Schedule 80

notesandfootnotes(excludingthoseintablesandfigures)shall

2.2 NSF Standards:

not be considered as requirements of the specification.

Standard No. 14for Plastic Piping Components and Related

1.5 The values stated in inch-pound units are to be regarded 3

Materials

as standard. The values given in parentheses are mathematical

StandardNo.61forDrinkingWaterSystemsComponents—

conversions to SI units that are provided for information only 3

Health Effects

and are not considered standard.

1.6 The following safety hazards caveat pertains only to the 3. Terminology

test methods portion, Section 6, of this specification: This

3.1 Definitions—The definitions in this specification are in

standard does not purport to address all of the safety concerns,

accordance with Terminology F412.

if any, associated with its use. It is the responsibility of the user

of this standard to establish appropriate safety and health

4. General Requirements

practices and determine the applicability of regulatory limita-

4.1 ThesolventcementshallbeasolutionofthebaseCPVC

tions prior to use.

resin used to make Class 23447, chlorinated poly(vinyl chlo-

ride) molding or extrusion compound as defined in Specifica-

2. Referenced Documents

tion D1784.

2

2.1 ASTM Standards:

4.2 When rework material is used, the manufacturer shall

D1084Test Methods for Viscosity of Adhesives

use only his own clean rework material that is compatible with

D1598Test Method for Time-to-Failure of Plastic Pipe

virgin material and produces a cement that meets the require-

Under Constant Internal Pressure

ments of this specification.

4.3 The cement shall be free-flowing and shall not contain

1

This specification is under the jurisdiction ofASTM Committee F17 on Plastic

Piping Systems and is the direct responsibility of Subcommittee F17.20 on Joining. lumps, undissolved resin, or any foreign matter that will

Current edition approved Nov. 1, 2014. Published December 2014. Originally

adversely affect the ultimate joint strength or chemical resis-

approved in 1977. Last previous edition approved in 2010 as F493–10. DOI:

tance of the cement.

10.1520/F0493-14.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

3

Standards volume information, refer to the standard’s Document Summary page on Available from NSF International, P.O. Box 130140, 789 N. Dixboro Rd.,Ann

the ASTM website. Arbor, MI 48113-0140, http://www.nsf.org.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

F493−14

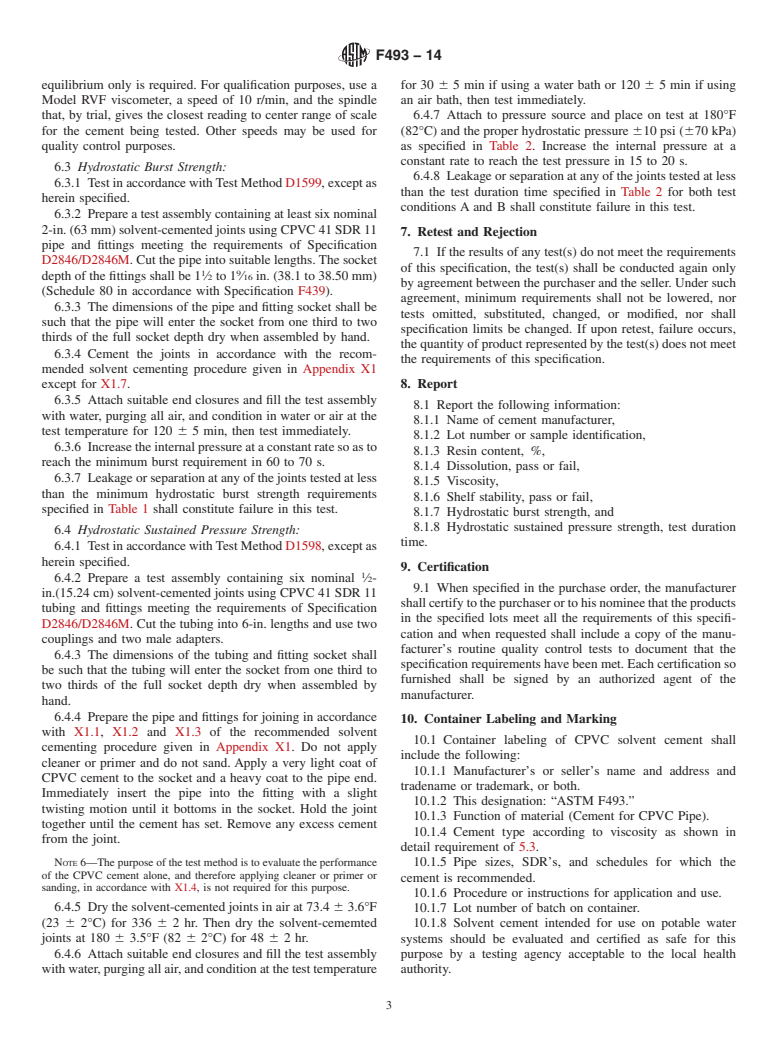

TABLE 2 Minimum Hydrostatic Sustained Pressure Requirements

4.4 The cement shall show no gelation or stratification that

1

for Nominal ⁄2 in. CPVC Solvent-Cemented Joints Tested in

cannot be removed by stirring.

Water or Air External Environment at 180 ± 3.6°F (82 ± 2°C)

4.5 When inert fillers and colorants are added, the resulting

Test Hydrostatic Test P

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: F493 − 10 F493 − 14 An American National Standard

Standard Specification for

Solvent Cements for Chlorinated Poly(Vinyl Chloride)

1

(CPVC) Plastic Pipe and Fittings

This standard is issued under the fixed designation F493; the number immediately following the designation indicates the year of original

adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A superscript

epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope*

1.1 This specification provides requirements for chlorinated poly(vinyl chloride) (CPVC) solvent cements to be used in joining

chlorinated poly(vinyl chloride) pipe, tubing, and socket-type fittings.

1.2 CPVC solvent cements are used with CPVC 41 chlorinated poly(vinyl chloride) pipe, tubing, and fittings, which meet Class

23447 as defined in Specification D1784.

1.3 A recommended procedure for joining CPVC pipe and fittings is given in Appendix X1.

1.4 The text of this specification references notes, footnotes, and appendixes which provide explanatory material. These notes

and footnotes (excluding those in tables and figures) shall not be considered as requirements of the specification.

1.5 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical

conversions to SI units that are provided for information only and are not considered standard.

1.6 The following safety hazards caveat pertains only to the test methods portion, Section 6, of this specification: This standard

does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this

standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

2. Referenced Documents

2

2.1 ASTM Standards:

D1084 Test Methods for Viscosity of Adhesives

D1598 Test Method for Time-to-Failure of Plastic Pipe Under Constant Internal Pressure

D1599 Test Method for Resistance to Short-Time Hydraulic Pressure of Plastic Pipe, Tubing, and Fittings

D1784 Specification for Rigid Poly(Vinyl Chloride) (PVC) Compounds and Chlorinated Poly(Vinyl Chloride) (CPVC)

Compounds

D2846/D2846M Specification for Chlorinated Poly(Vinyl Chloride) (CPVC) Plastic Hot- and Cold-Water Distribution Systems

F402 Practice for Safe Handling of Solvent Cements, Primers, and Cleaners Used for Joining Thermoplastic Pipe and Fittings

F412 Terminology Relating to Plastic Piping Systems

F439 Specification for Chlorinated Poly (Vinyl Chloride) (CPVC) Plastic Pipe Fittings, Schedule 80

2.2 NSF Standards:

3

Standard No. 14 for Plastic Piping Components and Related Materials

3

Standard No. 61 for Drinking Water Systems Components—Health Effects

3. Terminology

3.1 Definitions—The definitions in this specification are in accordance with Terminology F412.

4. General Requirements

4.1 The solvent cement shall be a solution of the base CPVC resin used to make Class 23447, chlorinated poly(vinyl chloride)

molding or extrusion compound as defined in Specification D1784.

1

This specification is under the jurisdiction of ASTM Committee F17 on Plastic Piping Systems and is the direct responsibility of Subcommittee F17.20 on Joining.

Current edition approved Aug. 1, 2010Nov. 1, 2014. Published September 2010December 2014. Originally approved in 1977. Last previous edition approved in 20042010

as F493 – 04.F493 – 10. DOI: 10.1520/F0493-10.10.1520/F0493-14.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

3

Available from NSF International, P.O. Box 130140, 789 N. Dixboro Rd., Ann Arbor, MI 48113-0140, http://www.nsf.org.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

F493 − 14

4.2 When rework material is used, the manufacturer shall use only his own clean rework material that is compatible with virgin

material and produces a cement that meets the requirements of this specification.

4.3 The cement shall be free-flowing and shall not contain lumps, undissolved resin, or any foreign matter that will adversely

affect

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.