ASTM C796-97

(Test Method)Standard Test Method for Foaming Agents for Use in Producing Cellular Concrete Using Preformed Foam

Standard Test Method for Foaming Agents for Use in Producing Cellular Concrete Using Preformed Foam

SCOPE

1.1 This test method furnishes a way of measuring, in the laboratory, the performance of a foaming chemical to be used in producing foam (air cells) for making cellular concrete.

1.2 This test method includes the following:

1.2.1 Manufacture of laboratory quantities of cellular concrete.

1.2.2 Determination of the air content of the freshly prepared cellular concrete and of the hardened concrete after handling in conventional machinery.

1.2.3 Determination of the following properties of the hardened concrete: compressive strength, tensile splitting strength, density, and water absorption. It may not be necessary to study all of the above properties in all cases, depending on the proposed use of the material.

1.3 The values stated in inch-pound units are to be regarded as the standard.

1.4 This standard does not purport to address all of the safety problems, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:C796–97

Standard Test Method for

Foaming Agents for Use in Producing Cellular Concrete

Using Preformed Foam

This standard is issued under the fixed designation C 796; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope weight Insulating Concrete

C 496 Test Method for Splitting Tensile Strength of Cylin-

1.1 This test method furnishes a way of measuring, in the

drical Concrete Specimens

laboratory, the performance of a foaming chemical to be used

C 511 Specification for Moist Cabinets, Moist Rooms, and

in producing foam (air cells) for making cellular concrete.

Water Storage Tanks Used in the Testing of Hydraulic

1.2 This test method includes the following:

Cements and Concretes

1.2.1 Manufacture of laboratory quantities of cellular con-

C 869 Specification for Foaming Agents Used in Making

crete.

Preformed Foam for Cellular Concrete

1.2.2 Determination of the air content of the freshly pre-

pared cellular concrete and of the hardened concrete after

3. Terminology

handling in conventional machinery.

3.1 Definitions:

1.2.3 Determination of the following properties of the

3.1.1 cellular concrete—a lightweight product consisting of

hardened concrete: compressive strength, tensile splitting

portland cement, cement-silica, cement-pozzolan, lime-

strength,density,andwaterabsorption.Itmaynotbenecessary

pozzolan, or lime-silica pastes, or pastes containing blends of

to study all of the above properties in all cases, depending on

these ingredients and having a homogeneous void or cell

the proposed use of the material.

structure, attained with gas-forming chemicals or foaming

1.3 The values stated in inch-pound units are to be regarded

agents (for cellular concretes containing binder ingredients

as the standard.

other than, or in addition to portland cement, autoclave curing

1.4 This standard does not purport to address all of the

is usually employed). In cellular concrete the density control

safety concerns, if any, associated with its use. It is the

is achieved by substituting macroscopic air cells for all or part

responsibility of the user of this standard to establish appro-

of the fine aggregate. Normal-weight coarse aggregate is

priate safety and health practices and determine the applica-

usually not used but lightweight aggregates, both fine and

bility of regulatory limitations prior to use.

coarse, are often utilized in cellular concrete.

1.5 The text of this standard references notes and footnotes

3.2 Symbols:

which provide explanatory material. These notes and footnotes

(excluding those in tables and figures) shall not be considered

as requirements of the standard.

D 5 experimental density of the concrete before

ex1

3 3

pumping, lb/ft (kg/m )

2. Referenced Documents

D 5 experimental density of the concrete after pump-

ex2

3 3

2.1 ASTM Standards:

ing, lb/ft (kg/m )

C 88 Test Method for Soundness of Aggregates by Use of

D 5 theoretical density of the plastic mix based on

th

3 3

Sodium Sulfate or Magnesium Sulfate

absolute volume, lb/ft (kg/m )

3 3

C 150 Specification for Portland Cement

D 5 design density of the text mixture, lb/ft (kg/m )

d

C 192 Practice for Making and Curing ConcreteTest Speci-

SGC 5 specific gravity of cement 5 3.15

mens in the Laboratory

T 5 time required to overfill the container, min

3 3

T 5 time required to generate 1 ft (1 m ) of foam, min

C 495 Test Method for Compressive Strength of Light-

3 3

V 5 volume of foam container, ft (m )

3 3

V 5 volume of air required in the test batch, ft (m )

a

3 3

V 5 volume of test specimen (cylinder), ft (m )

c

ThistestmethodisunderthejurisdictionofASTMCommitteeC-9onConcrete

andConcreteAggregatesandisthedirectresponsibilityofSubcommitteeC09.23on

Chemical Admixtures.

Current edition approved Nov. 10, 1997. Published October 1998. Originally

published as C 796 – 74 T. Last previous edition C 796 – 87a (1993). ACI Committee 116, “Cement and ConcreteTerminology,”American Concrete

Annual Book of ASTM Standards, Vol 04.02. Institute, Publication SP-19, 1967, p. 144.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

C796

3 3 1

6.6 Strike-Off Plate for Molds—A ⁄4-in. (6-mm) thick, flat

V 5 volume of foam in the test batch, ft (m )

f

steel plate at least 8 in. (200 mm) longer and 2 in. (50 mm)

V 5 volume of water absorbed by test specimen in 24

w

3 3

wider than the diameter of the mold.

h, ft (m )

W 5 net weight of foam in overfilled container before 6.7 Scales—Scales and weights shall be accurate to within

0.1 % of the weight of the material being measured.

striking off, lb (kg)

W 5 net weight of foam in container after striking off,

6.8 Compression Machines—Compression testing ma-

lb (kg) chines used for compressive strength tests and tensile-splitting

W 5 weight of cement in the test batch, lb (kg)

strength tests shall conform to the requirements of Test

c

W 5 weight of foam in the test batch, lb (kg)

Methods C 495 and C 496, respectively.

f

W 5 total weight of water in the test batch, including

TW

6.9 Drying Oven—The drying oven shall be as described in

weight of foam, lb (kg)

Test Method C 88.

3 3

W 5 density of foam, lb/ft (kg/m )

uf

6.10 Compressed Air—A source of compressed air capable

W 5 weight of water added to test batch at mixer, lb

w

of maintaining pressures in the range of 60 to 100 psi (0.4 to

(kg)

0.7 MPa) to 61 psi (60.007 MPa).

6.11 Weighing Container for Concrete— A machined-steel

3 3

4. Summary of Test Method

container of 0.5 ft (0.014 m ) volume with a flat smooth rim.

4.1 This test method includes the following:

6.12 Strike-Off Plate for Weighing Container—A ⁄4-in.

4.1.1 Manufacture of laboratory quantities of cellular con- (6-mm)thick,flatsteelplate,atleast8in.(200mm)longerand

crete.

2 in. (50 mm) wider than the diameter of the rim of the

4.1.2 Determination of the air content of freshly prepared weighing container.

cellular concrete and of hardened concrete after handling in

6.13 Stop Watch—A stop watch graduated in seconds and

conventional machinery. minutes.

4.1.3 Determination of the following properties of hardened

6.14 Calipers—Calipers to span 3, 6, and 12 in. (76, 152,

concrete: compressive strength, tensile splitting strength, den-

and 305 mm).

sity, and water absorption. It may not be necessary to study all

6.15 Foam Weighing Container—A lightweight vessel of

3 3

of the above properties in all cases, depending on the proposed

approximately 2 ft (0.06 m ) capacity, with a smooth rim for

use of the material.

striking off.

6.16 Strike-Off Plate for Foam Weighing Container—A

5. Significance and Use

⁄4-in. (6-mm) thick, flat steel plate at least 8 in. (200 mm)

longer and 2 in. (50 mm) wider than the diameter of the rim of

5.1 This test method is used to develop data for comparison

the container.

or compliance with the requirements of Specification C 869.

6.17 Small Tools—Small tools such as a rubber-headed

hammer and a trowel shall be provided.

6. Apparatus

6.1 Mixer—The mixer shall be a power-driven paddle-type

7. Materials and Proportions

3 3

mixer with a capacity of at least 4 ft (0.12 m ), an operating

7.1 Cement—The cement used shall be Type I or Type III

speed of 40 to 45 r/min (0.24 to 0.27 kHz), and equipped with

portland cement meeting the requirements of Specification

rubber wiper blades.

C 150.

6.2 Foam Generator—The foam generator shall be a

7.2 Water-Cement Ratio—The water requirement will vary

laboratory-sizedgeneratorapprovedbythemanufacturerofthe

with the type and source of cement. For the purpose of these

foam being used and shall be similar to the type used in the

tests, w/c 5 0.58forTypeIcementand w/c 5 0.64forTypeIII

field.

cement shall be used. However, if a particular cement or

6.3 Pump—Thepumpshallbeanopenorclosedthroat-type

4 foaming agent used with these values of w/c does not produce

pump and shall be run at 450 r/min (2.7 kHz).The pump shall

3 3 a satisfactory mix, a trial mix or mixes may be made using the

be equipped with a 4.5-ft (0.13-m )“ feed” reservoir and 50 ft

cement and foaming agent in question. Pump the trial mix (see

(15 m) of open-end 1-in. (25-mm) inside diameter rubber hose

8.7.1)andrevisethe w/cif D ,theunitweightoftheconcrete

ex2

on the pump discharge, the exit end of the hose being at the

afterpumping,ismorethan10 %differentfromthedesignunit

same height as the pump.

3 3

weight of 40 lb/ft (641 kg/m ).

6.4 Curing Cabinet—The curing cabinet shall be as de-

7.3 Batch Quantities—The quantities of materials described

scribed in Specification C 511.

in Table 1 shall be used in the test batch.

6.5 Molds—The cylindrical molds for compression test

7.3.1 The foaming solution in the foam will be considered

specimens shall be as described in the Apparatus section of

as part of the total mixing water. The quantities listed in Table

Test Method C 495. The molds for all other test specimens

shall conform to the cylinder molds in theApparatus section of

Method C 192.

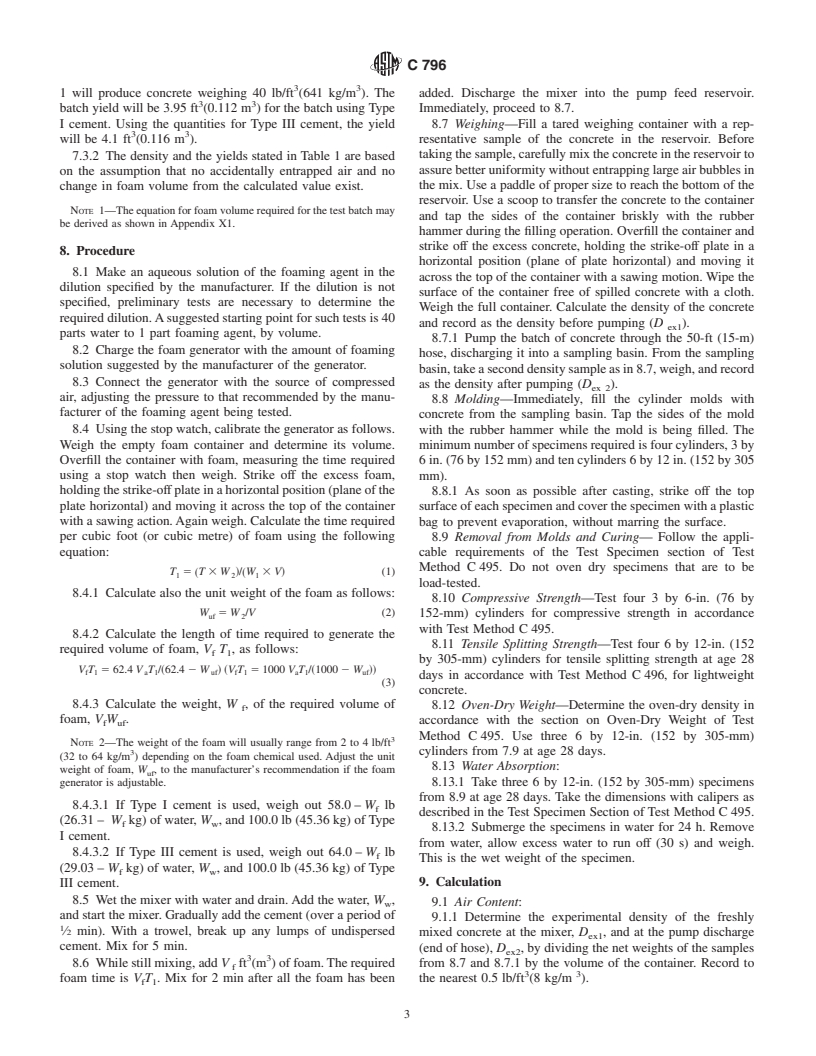

TABLE 1 Materials for the Test Batch

Type of Cement, Total Water, Foam,

3 3

Cement lb (kg) lb (kg) ft (m )

I 100.0 (45.36) 58.0 (26.31) 156.62/(62.4 − W ) (71.0/(1000 − W ))

uf uf

The Moyno Type CDR, Frame 2JC4 or 2L4 pump, or equivalent, has been III 100.0 (45.36) 64.0 (29.03) 160.37/(62.4 − W ) (73.0/(1000 − W ))

uf uf

found satisfactory for this purpose.

C796

3 3

1 will produce concrete weighing 40 lb/ft (641 kg/m ). The added. Discharge the mixer into the pump feed reservoir.

3 3

batch yield will be 3.95 ft (0.112 m ) for the batch using Type Immediately, proceed to 8.7.

I cement. Using the quantities for Type III cement, the yield 8.7 Weighing—Fill a tared weighing container with a rep-

3 3

will be 4.1 ft (0.116 m ). resentative sample of the concrete in the reservoir. Before

takingthesample,carefullymixtheconcreteinthereservoirto

7.3.2 The density and the yields stated in Table 1 are based

assure better uniformity without entrapping large air bubbles in

on the assumption that no accidentally entrapped air and no

the mix. Use a paddle of proper size to reach the bottom of the

change in foam volume from the calculated value exist.

reservoir. Use a scoop to transfer the concrete to the container

NOTE 1—The equation for foam volume required for the test batch may

and tap the sides of the container briskly with the rubber

be d

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.