ASTM D2219-97

(Specification)Standard Specification for Poly(Vinyl Chloride) Insulation for Wire and Cable, 60°C Operation

Standard Specification for Poly(Vinyl Chloride) Insulation for Wire and Cable, 60°C Operation

SCOPE

1.1 This specification covers a thermoplastic insulation of poly(vinyl chloride) or the copolymer of vinyl chloride and vinyl acetate. This insulation is recommended for use at conductor temperatures not in excess of 60°C in wet or dry locations at a maximum voltage rating of 600 V for power and control circuits and 5000 V for series lighting circuits.

1.2 The values stated in inch-pound units are the standard. The values stated in parentheses are for information only.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: D 2219 – 97 An American National Standard

Standard Specification for

Poly(Vinyl Chloride) Insulation for Wire and Cable, 60°C

Operation

This standard is issued under the fixed designation D 2219; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

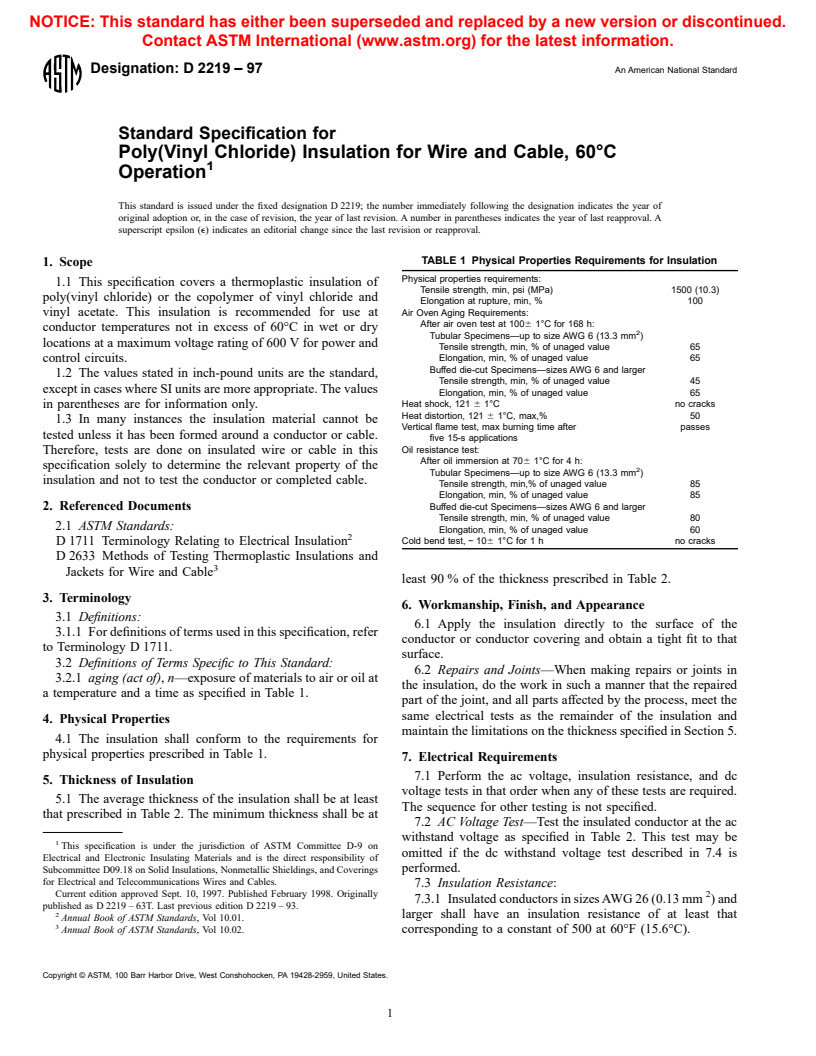

TABLE 1 Physical Properties Requirements for Insulation

1. Scope

Physical properties requirements:

1.1 This specification covers a thermoplastic insulation of

Tensile strength, min, psi (MPa) 1500 (10.3)

poly(vinyl chloride) or the copolymer of vinyl chloride and

Elongation at rupture, min, % 100

Air Oven Aging Requirements:

vinyl acetate. This insulation is recommended for use at

After air oven test at 1006 1°C for 168 h:

conductor temperatures not in excess of 60°C in wet or dry

Tubular Specimens—up to size AWG 6 (13.3 mm )

locations at a maximum voltage rating of 600 V for power and

Tensile strength, min, % of unaged value 65

control circuits. Elongation, min, % of unaged value 65

Buffed die-cut Specimens—sizes AWG 6 and larger

1.2 The values stated in inch-pound units are the standard,

Tensile strength, min, % of unaged value 45

except in cases where SI units are more appropriate. The values

Elongation, min, % of unaged value 65

in parentheses are for information only. Heat shock, 121 6 1°C no cracks

Heat distortion, 121 6 1°C, max,% 50

1.3 In many instances the insulation material cannot be

Vertical flame test, max burning time after passes

tested unless it has been formed around a conductor or cable.

five 15-s applications

Oil resistance test:

Therefore, tests are done on insulated wire or cable in this

After oil immersion at 706 1°C for 4 h:

specification solely to determine the relevant property of the

Tubular Specimens—up to size AWG 6 (13.3 mm )

insulation and not to test the conductor or completed cable.

Tensile strength, min,% of unaged value 85

Elongation, min, % of unaged value 85

2. Referenced Documents Buffed die-cut Specimens—sizes AWG 6 and larger

Tensile strength, min, % of unaged value 80

2.1 ASTM Standards:

Elongation, min, % of unaged value 60

D 1711 Terminology Relating to Electrical Insulation Cold bend test, − 106 1°C for 1 h no cracks

D 2633 Methods of Testing Thermoplastic Insulations and

Jackets for Wire and Cable

least 90 % of the thickness prescribed in Table 2.

3. Terminology

6. Workmanship, Finish, and Appearance

3.1 Definitions:

6.1 Apply the insulation directly to the surface of the

3.1.1 For definitions of terms used in this specification, refer

conductor or conductor covering and obtain a tight fit to that

to Terminology D 1711.

surface.

3.2 Definitions of Terms Specific to This Standard:

6.2 Repairs and Joints—When making repairs or joints in

3.2.1 aging (act of), n—exposure of materials to air or oil at

the insulation, do the work in such a manner that the repaired

a temperature and a time as specified in Table 1.

part of the joint, and all parts affected by the process, meet the

same electrical tests as the remainder of the insulation and

4. Physical Properties

maintain the limitations on the thickness specified in Section 5.

4.1 The insulation shall conform to the requirements for

physical properties prescribed in Table 1.

7. Electrical Requirements

7.1 Perform the ac voltage, insulation resistance, and dc

5. Thickness of Insulation

voltage tests in that order when any of these tests are required.

5.1 The average thickness of the insulation shall be at least

The sequence for other testing is not specified.

that prescribed in Table 2. The minimum thickness shall be at

7.2 AC Voltage Test—Test the insulated conductor at the ac

withstand voltage as specified in Table 2. This test may be

This specification is under the jurisdiction of ASTM Committee D-9 on

omitted if the dc withstand voltage test described in 7.4 is

Electrical and Electronic Insulating Materials and is the direct responsibility of

performed.

Subcommittee D09.18 on Solid Insulations, Nonmetallic Shieldings, and Coverings

for Electrical and Telecommunications Wires and Cables.

7.3 Insulation Resistance:

Current edition approved Sept. 10, 1997. Published February 1998. Originally 2

7.3.1 Insulated conductors in sizes AWG 26 (0.13 mm ) and

published as D 2219 – 63T. Last previous edition D 2219 – 93.

larger shall have an insulation resistance of at least that

Annual Book of ASTM Standards, Vol 10.01.

Annual Book of ASTM Standards, Vol 10.02. correspondi

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.