ASTM F2028-00

(Test Method)Standard Test Methods for the Dynamic Evaluation of Glenoid Loosening or Disassociation

Standard Test Methods for the Dynamic Evaluation of Glenoid Loosening or Disassociation

SCOPE

1.1 These test methods measure how much a prosthetic glenoid component rocks or pivots following cyclic displacement of the humeral head to opposing glenoid rims (for example, superior-inferior or anterior-posterior). Performance is judged by the tensile displacement opposite each loaded rim after dynamic rocking.

1.2 The same setup can be used to test the locking mechanism of modular glenoid components, for example, for disassociation.

1.3 The test method covers shoulder replacement designs with both monolithic and modular humeral and glenoid components with either cemented or noncemented fixation.

1.4 The values stated in SI units are to be regarded as the standard. The values given in parentheses are provided for information purposes only.

General Information

Standards Content (Sample)

Designation: F 2028 – 00

Standard Test Methods for

the Dynamic Evaluation of Glenoid Loosening or

1

Disassociation

This standard is issued under the fixed designation F 2028; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope proximal humerus or humeral head and articulates with the

natural glenoid fossa or a prosthetic replacement.

1.1 These test methods measure how much a prosthetic

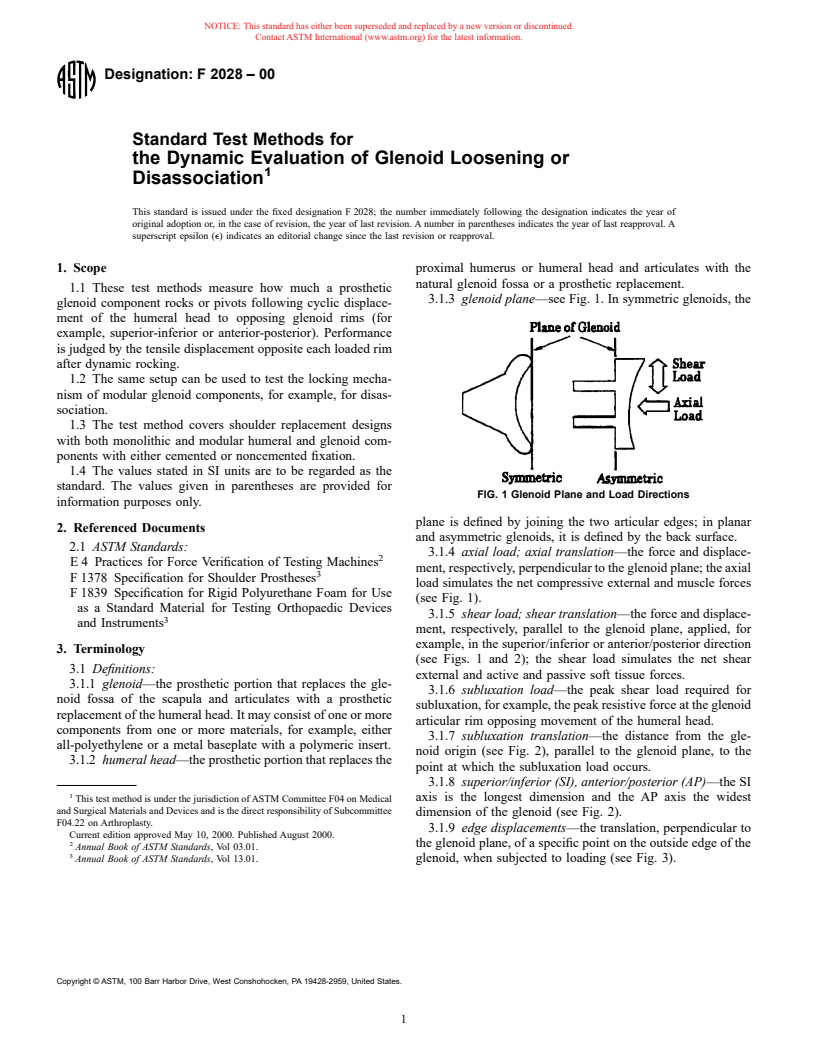

3.1.3 glenoid plane—see Fig. 1. In symmetric glenoids, the

glenoid component rocks or pivots following cyclic displace-

ment of the humeral head to opposing glenoid rims (for

example, superior-inferior or anterior-posterior). Performance

is judged by the tensile displacement opposite each loaded rim

after dynamic rocking.

1.2 The same setup can be used to test the locking mecha-

nism of modular glenoid components, for example, for disas-

sociation.

1.3 The test method covers shoulder replacement designs

with both monolithic and modular humeral and glenoid com-

ponents with either cemented or noncemented fixation.

1.4 The values stated in SI units are to be regarded as the

standard. The values given in parentheses are provided for

FIG. 1 Glenoid Plane and Load Directions

information purposes only.

plane is defined by joining the two articular edges; in planar

2. Referenced Documents

and asymmetric glenoids, it is defined by the back surface.

2.1 ASTM Standards:

3.1.4 axial load; axial translation—the force and displace-

2

E 4 Practices for Force Verification of Testing Machines

ment, respectively, perpendicular to the glenoid plane; the axial

3

F 1378 Specification for Shoulder Prostheses

load simulates the net compressive external and muscle forces

F 1839 Specification for Rigid Polyurethane Foam for Use

(see Fig. 1).

as a Standard Material for Testing Orthopaedic Devices

3.1.5 shear load; shear translation—the force and displace-

3

and Instruments

ment, respectively, parallel to the glenoid plane, applied, for

example, in the superior/inferior or anterior/posterior direction

3. Terminology

(see Figs. 1 and 2); the shear load simulates the net shear

3.1 Definitions:

external and active and passive soft tissue forces.

3.1.1 glenoid—the prosthetic portion that replaces the gle-

3.1.6 subluxation load—the peak shear load required for

noid fossa of the scapula and articulates with a prosthetic

subluxation, for example, the peak resistive force at the glenoid

replacement of the humeral head. It may consist of one or more

articular rim opposing movement of the humeral head.

components from one or more materials, for example, either

3.1.7 subluxation translation—the distance from the gle-

all-polyethylene or a metal baseplate with a polymeric insert.

noid origin (see Fig. 2), parallel to the glenoid plane, to the

3.1.2 humeral head—the prosthetic portion that replaces the

point at which the subluxation load occurs.

3.1.8 superior/inferior (SI), anterior/posterior (AP)—the SI

1

axis is the longest dimension and the AP axis the widest

This test method is under the jurisdiction of ASTM Committee F04 on Medical

and Surgical Materials and Devices and is the direct responsibility of Subcommittee

dimension of the glenoid (see Fig. 2).

F04.22 on Arthroplasty.

3.1.9 edge displacements—the translation, perpendicular to

Current edition approved May 10, 2000. Published August 2000.

2

the glenoid plane, of a specific point on the outside edge of the

Annual Book of ASTM Standards, Vol 03.01.

3

Annual Book of ASTM Standards, Vol 13.01. glenoid, when subjected to loading (see Fig. 3).

Copyright © ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

F 2028

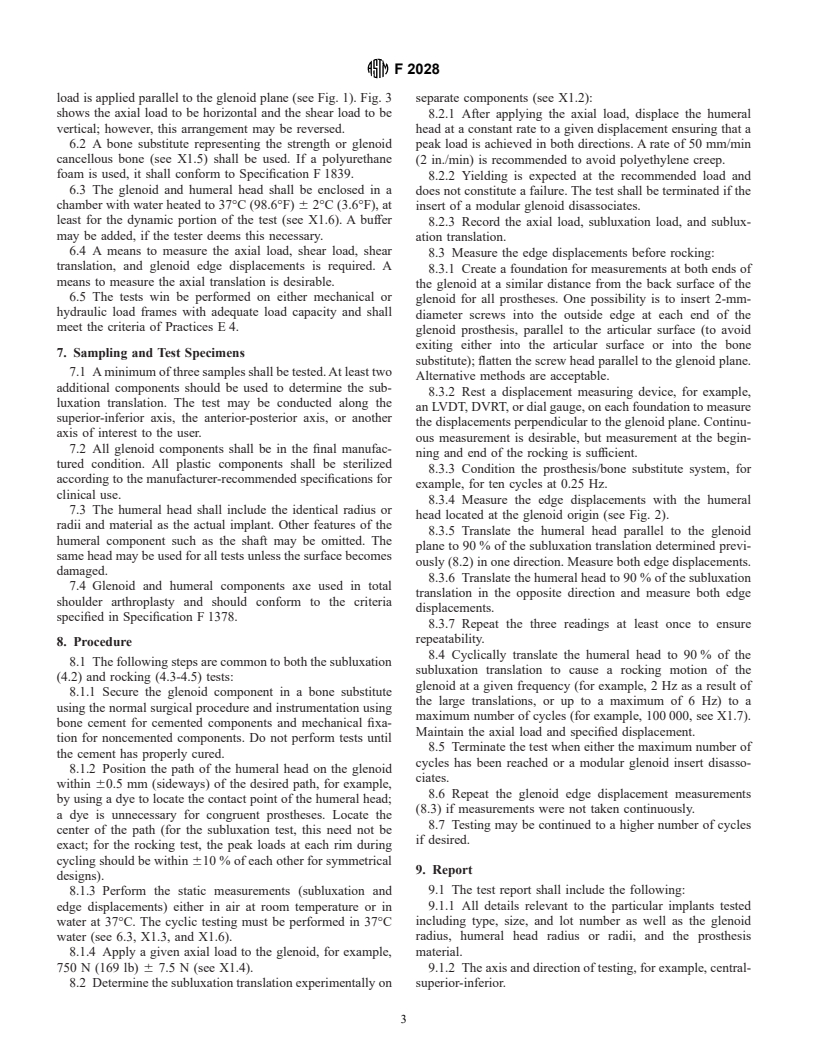

FIG. 2 Glenoid Axes and Origin

FIG. 3 Biaxial Testing Apparatus

GLENOID LOOSENING TEST METHOD

4. Summary of Test Method 4.4 The humeral head is cycled to 90 % of the subluxation

distance for a fixed number of cycles.

4.1 The prosthetic glenoid component is fixed into a bone

4.5 The edge displacements (4.3) are either repeated follow-

substitute using the normal surgical technique.

ing the cycling or measured continuously during the cycling.

4.2 The subluxation translation is determined experimen-

tally on additional components. This is accomplished, using a

5. Significance and Use

biaxial apparatus (see Fig. 3). by applying an axial load

5.1 This test method is intended to investigate the resistance

perpendicular to the glenoid, then translating the humeral head

of a glenoid component to loosening. Glenoid loosening is the

parallel to the glenoid plane until encountering a peak shear

most common clinical complication in total shoulder arthro-

load. This is performed in both directions, corresponding to the

plasty (see X1.1). The method assumes that loosening occurs

dire

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.