ASTM F1244-89(1999)

(Specification)Standard Specification for Berths, Marine

Standard Specification for Berths, Marine

SCOPE

1.1 This specification covers the construction of marine berths for officers, crew, and passengers.

1.2 The values stated in inch-pound units are to be regarded as the standard. The values given in parentheses are for information only.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

An American National Standard

Designation: F 1244 – 89 (Reapproved 1999)

Standard Specification for

Berths, Marine

This standard is issued under the fixed designation F 1244; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope 3.1.6 hand—the berth may be right hand, left hand, or

finished both sides for use in the middle of the room. Right

1.1 This specification covers the construction of marine

hand is defined as follows: the berth is right hand if the head of

berths for officers, crew, and passengers.

the berth is on the right hand end when the berth is viewed

1.2 The values stated in inch-pound units are to be regarded

from the front. Left hand is opposite. See Fig. 1 and Fig. 2 and

as the standard. The values given in parentheses are for

Table 1 and Table 2 for elevations of left-handed berths. A

information only.

berth finished on both sides is not shown, but it is one that is

2. Referenced Documents accessible from either side, has the head of the berth against a

bulkhead, and is not handed.

2.1 ASTM Standards:

3.1.7 lee rail—a guard to inhibit a person from rolling out of

A 366/A 366M Specification for Commercial Steel (CS)

bed because of ship motion. In this specification, the lee rail is

Sheet, Carbon, (0.15 Maximum Percent) Cold-Rolled

a raised pine railing.

A 512 Specification for Cold-Drawn Buttweld Carbon Steel

3.1.8 mattress—a fabric-covered, box-type unit containing

Mechanical Tubing

springs and cushioning material that supports the sleeping

F 825 Specification for Drawers, Furniture, Marine, Steel

surface.

F 1085 Specification for Mattress and Box Springs, Berths

3.1.9 pan section—the section of the berth designed to

2.2 American Institute of Steel Construction Manual:

support the mattress and box spring.

AISC Wire and Sheet Metal Gages-Equivalent Thicknesses

in Decimals of an Inch, U.S. Standard Gage for Uncoated,

4. Classification

Hot and Cold Rolled Sheets

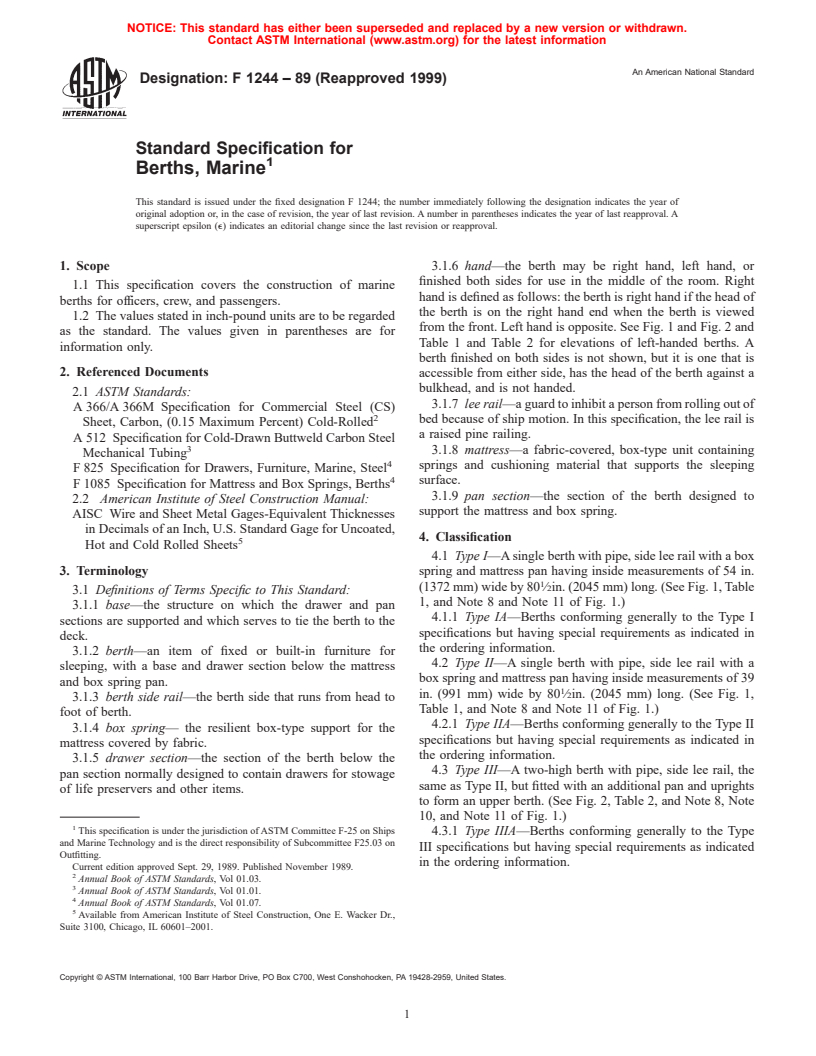

4.1 Type I—A single berth with pipe, side lee rail with a box

3. Terminology spring and mattress pan having inside measurements of 54 in.

(1372 mm) wide by 80 ⁄2in. (2045 mm) long. (See Fig. 1, Table

3.1 Definitions of Terms Specific to This Standard:

1, and Note 8 and Note 11 of Fig. 1.)

3.1.1 base—the structure on which the drawer and pan

4.1.1 Type IA—Berths conforming generally to the Type I

sections are supported and which serves to tie the berth to the

specifications but having special requirements as indicated in

deck.

the ordering information.

3.1.2 berth—an item of fixed or built-in furniture for

4.2 Type II—A single berth with pipe, side lee rail with a

sleeping, with a base and drawer section below the mattress

box spring and mattress pan having inside measurements of 39

and box spring pan.

in. (991 mm) wide by 80 ⁄2in. (2045 mm) long. (See Fig. 1,

3.1.3 berth side rail—the berth side that runs from head to

Table 1, and Note 8 and Note 11 of Fig. 1.)

foot of berth.

4.2.1 Type IIA—Berths conforming generally to the Type II

3.1.4 box spring— the resilient box-type support for the

specifications but having special requirements as indicated in

mattress covered by fabric.

the ordering information.

3.1.5 drawer section—the section of the berth below the

4.3 Type III—A two-high berth with pipe, side lee rail, the

pan section normally designed to contain drawers for stowage

same as Type II, but fitted with an additional pan and uprights

of life preservers and other items.

to form an upper berth. (See Fig. 2, Table 2, and Note 8, Note

10, and Note 11 of Fig. 1.)

This specification is under the jurisdiction of ASTM Committee F-25 on Ships

4.3.1 Type IIIA—Berths conforming generally to the Type

and Marine Technology and is the direct responsibility of Subcommittee F25.03 on

III specifications but having special requirements as indicated

Outfitting.

in the ordering information.

Current edition approved Sept. 29, 1989. Published November 1989.

Annual Book of ASTM Standards, Vol 01.03.

Annual Book of ASTM Standards, Vol 01.01.

Annual Book of ASTM Standards, Vol 01.07.

Available from American Institute of Steel Construction, One E. Wacker Dr.,

Suite 3100, Chicago, IL 60601–2001.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

F 1244

5. Ordering Information 6. Materials and Manufacture

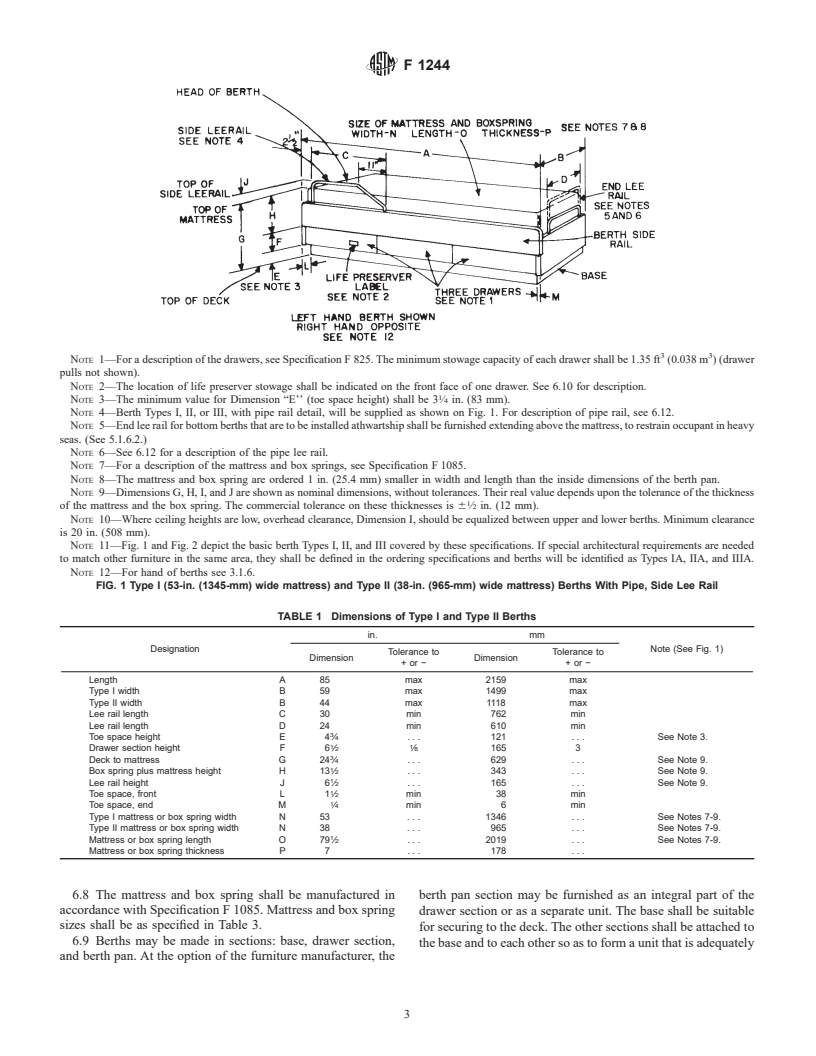

6.1 For berth details, see Fig. 1 and Fig. 2 and Table 1 and

5.1 Orders for items purchased under this specification shall

Table 2.

include the following:

6.2 Sheet Metal:

5.1.1 Type of berth.

6.2.1 Sheet metal shall be steel in accordance with Specifi-

5.1.1.1 Type I, IA; II, IIA; or III, IIIA.

cation A 366/A 366M.

5.1.1.2 Hand—Right, left, or finished both sides.

6.2.2 Minimum steel sheet metal thicknesses shall be as

5.1.2 Quantity—The quantity of right hand, left hand, or

follows:

finished both sides for each type.

6.2.2.1 Drawer section 18 USSG (0.0478 in. or 1.21 mm).

5.1.3 Mattress and Box Spring—Shall be furnished in ac-

6.2.2.2 Pan section 18 USSG (0.0478 in. or 1.21 mm).

cordance with Specification F 1085.

6.2.2.3 Base frame 16 USSG (0.0598 in. or 1.52 mm).

5.1.4 Paint:

6.3 Welding:

5.1.4.1 Color—The purchaser shall pick from manufactur-

6.3.1 Metal components shall be joined by welding.

er’s samples or submit a sample chip of the color desired.

6.3.2 Welding shall be adequate to prevent racking of berth

5.1.4.2 The manufacturer’s standard baked enamel will be

components during handling.

furnished unless otherwise required and specified by the

6.3.3 Spotwelds shall be spaced approximately 3 to 5 in. (76

purchaser.

to 127 mm) on centers.

5.1.5 Weights—If the total weight of the berth assembly is

6.3.4 Spotwelds, on exposed surfaces, higher than the gen-

required, it shall be requested by the purchaser.

eral surface of the adjacent metal, shall be ground flush.

5.1.6 Options:

6.3.5 Spotweld depressions, on exposed surfaces, shall be

5.1.6.1 If a special architectural appearance or finish is

spot filled and sanded.

required for these berths to match other furniture in the same

6.4 Side and end panels shall be suitably stiffened to prevent

space, it shall be defined in the ordering documents.

buckling or oil-canning.

5.1.6.2 The pipe lee rail at the foot of all berths shall be

6.5 Sound deadening shall be vermin proof and applied to

furnished extending above the mattress, to restrain occupants

unstiffened areas where needed, and in thickness required, to

in heavy sea.

sound deaden berth.

5.1.6.3 Normally, on berths installed in a corner, the head of 6.6 Drawers shall be manufactured in accordance with

the berth is installed against one of the bulkheads. On some Specification F 825. Minimum stowage capacity for each

3 3

smaller ships, the trim of the vessel is such that this configu- drawer shall be 1.35 ft (0.038 m ).

ration would place the foot of the berth higher than the head. In 6.7 A furniture base shall be provided suitable for securing

such cases, the head and foot shall be reversed, and this berth to deck. Base shall be equipped with means for leveling

requirement shall be so noted in the ordering document. when installed aboard ship.

F 1244

3 3

NOTE 1—For a description of the drawers, see Specification F 825. The minimum stowage capacity of each drawer shall be 1.35 ft (0.038 m ) (drawer

pulls not shown).

NOTE 2—The location of life preserver stowage shall be indicated on the front face of one drawer. See 6.10 for description.

NOTE 3—The minimum value for Dimension “E’’ (toe space height) shall be 3 ⁄4 in. (83 mm).

NOTE 4—Berth Types I, I

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.