ASTM D850-99A

(Test Method)Standard Test Method for Distillation of Industrial Aromatic Hydrocarbons and Related Materials

Standard Test Method for Distillation of Industrial Aromatic Hydrocarbons and Related Materials

SCOPE

1.1 This test method covers the distillation of industrial aromatic hydrocarbons and related materials of relatively narrow boiling ranges from 30 to 250°C.

1.2 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.3 The following applies to all specified limits in this test method: for the purposes of determining conformance to this test method, an observed or calculated value shall be rounded off "to the nearest unit" in the last right-hand digit used in expressing the specification limit, in accordance with the rounding-off method of Practice E 29.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. For specific hazard statements, and Section 7.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: D 850 – 99a

AMERICAN SOCIETY FOR TESTING AND MATERIALS

100 Barr Harbor Dr., West Conshohocken, PA 19428

Reprinted from the Annual Book of ASTM Standards. Copyright ASTM

Standard Test Method for

Distillation of Industrial Aromatic Hydrocarbons and Related

Materials

This standard is issued under the fixed designation D 850; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope * Determine the Precision of a Test Method

2.2 Other Document:

1.1 This test method covers the distillation of industrial

OSHA Regulations, 29 CFR, paragraphs 1910.1000 and

aromatic hydrocarbons and related materials of relatively

1910.1200

narrow boiling ranges from 30 to 250°C.

1.2 The values stated in SI units are to be regarded as the

3. Terminology

standard. The values given in parentheses are for information

3.1 Definitions:

only.

3.1.1 See Terminolgy D 4790 for definitions of terms used

1.3 The following applies to all specified limits in this test

in this test method.

method: for the purposes of determining conformance to this

test method, an observed or calculated value shall be rounded

4. Summary of Test Method

off “to the nearest unit” in the last right-hand digit used in

4.1 The distillation of a 100-mL sample of industrial aro-

expressing the specification limit, in accordance with the

matic hydrocarbons and related materials is carried out via a

rounding-off method of Practice E 29.

carefully controlled distillation wherein temperature readings

1.4 This standard does not purport to address all of the

are noted for the first drop of distillate and when 5, 10, and

safety concerns, if any, associated with its use. It is the

each additional 10 up to 90, and 95 % of the sample has

responsibility of the user of this standard to establish appro-

distilled over. The temperature corresponding to the dry point

priate safety and health practices and determine the applica-

is also noted.

bility of regulatory limitations prior to use. For specific hazard

statements, see 6.6 and Section 7.

5. Significance and Use

5.1 This test method is suitable for setting specifications, for

2. Referenced Documents

use as an internal quality control tool, and for use in develop-

2.1 ASTM Standards:

ment or research work on industrial aromatic hydrocarbons and

D 1078 Test Method for Distillation Range of Volatile

2 related materials.

Organic Liquids

5.2 This test method gives a broad indication of general

D 3437 Practice for Sampling and Handling Liquid Cyclic

2 purity and can also indicate presence of excessive moisture. It

Products

will not differentiate between products of similar boiling range.

D 4790 Terminology of Aromatic Hydrocarbons and Re-

lated Chemicals

6. Apparatus

E 1 Specification for ASTM Thermometers

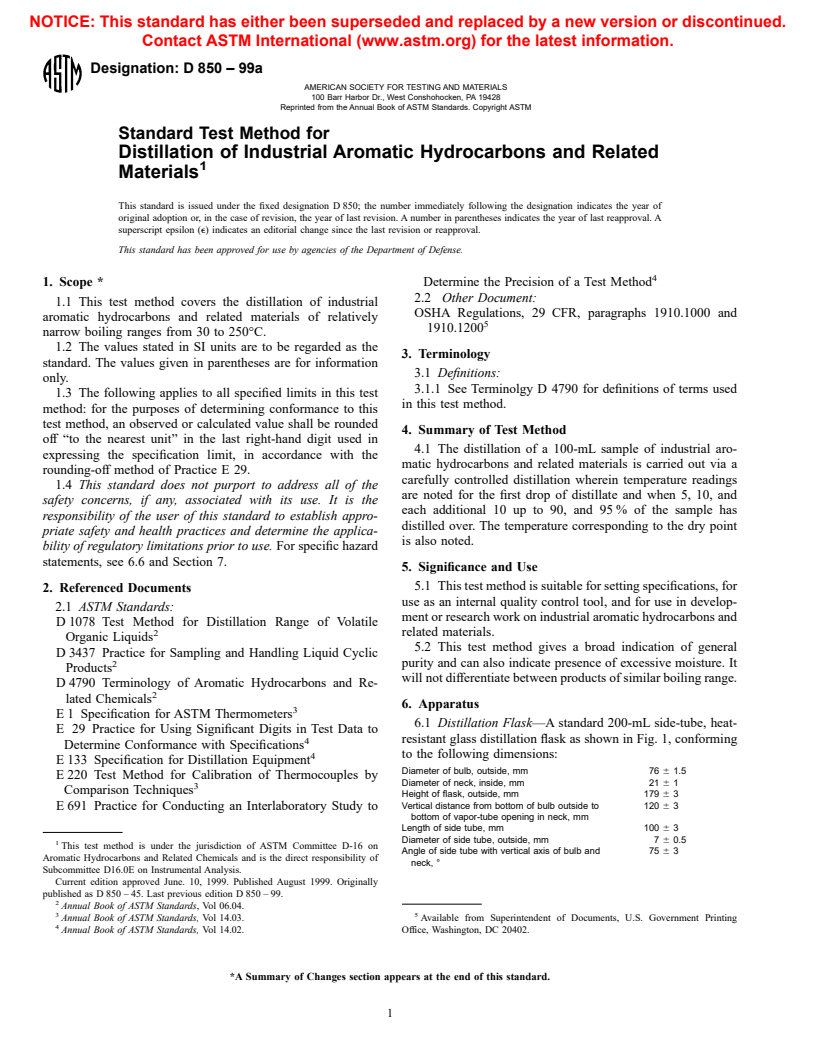

6.1 Distillation Flask—A standard 200-mL side-tube, heat-

E 29 Practice for Using Significant Digits in Test Data to

resistant glass distillation flask as shown in Fig. 1, conforming

Determine Conformance with Specifications

to the following dimensions:

E 133 Specification for Distillation Equipment

Diameter of bulb, outside, mm 76 6 1.5

E 220 Test Method for Calibration of Thermocouples by

Diameter of neck, inside, mm 21 6 1

Comparison Techniques

Height of flask, outside, mm 179 6 3

Vertical distance from bottom of bulb outside to 120 6 3

E 691 Practice for Conducting an Interlaboratory Study to

bottom of vapor-tube opening in neck, mm

Length of side tube, mm 100 6 3

Diameter of side tube, outside, mm 7 6 0.5

This test method is under the jurisdiction of ASTM Committee D-16 on

Angle of side tube with vertical axis of bulb and 75 6 3

Aromatic Hydrocarbons and Related Chemicals and is the direct responsibility of

neck, °

Subcommittee D16.0E on Instrumental Analysis.

Current edition approved June. 10, 1999. Published August 1999. Originally

published as D 850 – 45. Last previous edition D 850 – 99.

Annual Book of ASTM Standards, Vol 06.04.

3 5

Annual Book of ASTM Standards, Vol 14.03. Available from Superintendent of Documents, U.S. Government Printing

Annual Book of ASTM Standards, Vol 14.02. Office, Washington, DC 20402.

*A Summary of Changes section appears at the end of this standard.

D 850

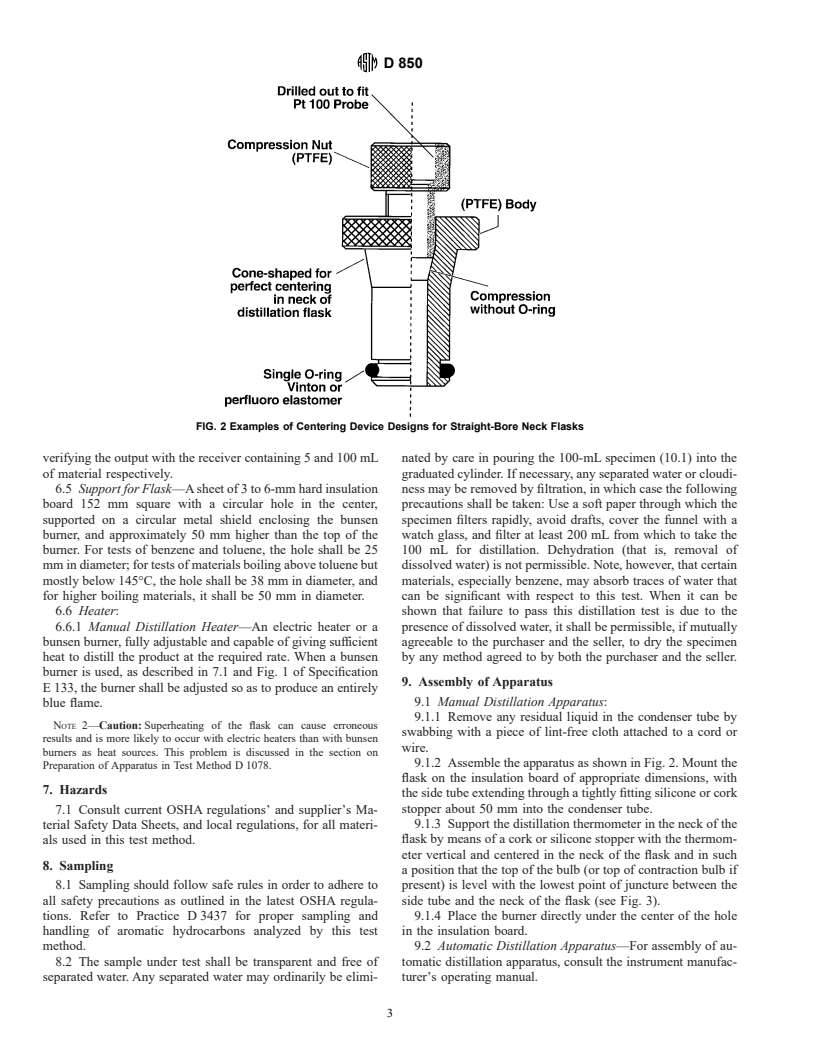

sensor in the neck of the flask. The use of a cork or silicone

stopper with a hole drilled through the center is not acceptable

for this purpose. Examples of acceptable centering devices are

shown in Fig. 2.

6.2.2.2 The electronic circuitry or algorithms, or both, used

shall include the capability to simulate the temperature lag of

a mercury-in-glass thermometer.

6.2.2.3 Alternatively, the sensor can also be placed in a

casing with the tip of the sensor covered, so that the assembly,

because of its adjusted thermal mass and conductivity, has a

temperature lag similar to that of a mercury-in-glass thermom-

eter.

NOTE 1—In a region where the temperature is changing rapidly during

the distillation, the temperature lag of a thermometer can be as much as 3

s.

6.3 Condenser and Cooling Bath:

FIG. 1 Distillation Flask

6.3.1 Manual Distillation Condenser and Cooling Bath:

6.3.1.1 The manual distillation condenser and cooling bath

shall be as specified in Section 5, and Fig. 1 of Specification

The flask does not comply with Flask C of Specification

E 133.

E 133.

6.3.1.2 As an alternative, the condenser tube may consist of

6.2 Temperature Measurement Devices:

a straight glass tube 600 to 610 mm in length and 12 mm in

6.2.1 Manual Distillation Thermometer— The ASTM Sol-

inside diameter, of standard wall thickness (about 1.25 mm)

vents Distillation Thermometer used in the test shall be as

with the exit end cut off square and ground flat. It shall be set

prescribed in the specifications for the material being tested. If

in a cooling trough so that at least 380 mm of the tube is in

no thermometer is specified in the material specification, select

contact with the water. Clearance between the condenser tube

one from Table 1 with the smallest graduations that will cover

and any parallel side of the trough shall be not less than 19 mm.

the entire distillation range of the material being tested. Table

The water in the cooling trough shall be maintained at 10 to

1 lists several ASTM solvents distillation thermometers which

20°C. This may be done by adding ice to the water or by

are suitable for testing industrial aromatic hydrocarbons, and

circulating chilled water through the trough. The trough shall

which meet the requirements of Specification E 1.

be so mounted that the condenser tube is set at an angle of 75°

6.2.2 Automatic Distillation Temperature Sensor—

with the vertical.

Temperature measurement systems using thermocouples or

6.3.2 Automatic Distillation and Cooling Bath—The auto-

resistance thermometers, otherwise referred to as the “tempera-

ture measuring devices,” must exhibit the same temperature lag matic distillation and cooling bath shall be as specified in

Section 5, Fig. 2 of Specification E 133.

and accuracy as the equivalent mercury glass thermometer.

Confirmation of the calibration of these temperature sensors is 6.4 Distillation Receiver:

to be done at regular intervals. This may be accomplished as 6.4.1 Manual Distillation Receiver—A graduate of the cy-

prescribed in Test Method E 220, or some similar means using lindrical type, of uniform diameter, with a pressed or molded

a precision resistance decade box. Another technique is to base and a lipped top. The cylinder shall be marked to contain

distill pure toluene and compare the temperature indicated by 100 mL, and the 0 to 100 mL receiver portion shall be not less

the thermocouple or resistance thermometer with that shown than 178 nor more than 203 mm in length. It shall be graduated

by the thermometer. in single millilitres and each fifth mark shall be distinguished

by a longer line. It shall be numbered from the bottom up at

6.2.2.1 Automatic Distillation Temperature Sensor Center-

ing Device—The temperature sensor shall be mounted through intervals of 10 mL. The overall height of the receiver shall not

be less than 248 nor more than 260 mm. The graduations shall

a snug-fitting device designed to mechanically center the

not be in error by more than 1 mL at any point on the scale. The

bottom 1-mL graduation may be omitted. The receiver com-

TABLE 1 ASTM Thermometers for Distillation Test of Industrial

Aromatic Hydrocarbons plies with Section 9, Graduate B Fig. 4, of Specification E 133.

6.4.2 Automatic Distillation Receiver—A receiver to be

ASTM

Ther- Subdivision,

used with measurements in accordance with the instrument

Name Range, °C

mometer °C

manufacturer and conform to the physical specifications de-

No.

scribed in this section, with the exception of the graduations.

39C solvents distillation 48 to 102 0.2

6.4.2.1 Automatic Distillation Level Follower—For auto-

40C solvents distillation 72 to 126 0.2

41C solvents distillation 98 to 152 0.2

matic apparatus, the level follower or recording mechanism of

42C solvents distillation 95 to 255 0.5

the apparatus will have a resolution of 0.1 mL with an accuracy

102C solvents distillation 123 to 177 0.2

of 6 1 mL. The calibration of the assembly should be

103C solvents distillation 148 to 202 0.2

104C solvents distillation 173 to 227 0.2

confirmed according to the manufacturer’s instructions at

105C solvents distillation 198 to 252 0.2

regular intervals. The typical calibration procedure involves

D 850

FIG. 2 Examples of Centering Device Designs for Straight-Bore Neck Flasks

verifying the output with the receiver containing 5 and 100 mL nated by care in pouring the 100-mL specimen (10.1) into the

of material respectively. graduated cylinder. If necessary, any separated water or cloudi-

6.5 Support for Flask—A sheet of 3 to 6-mm hard insulation ness may be removed by filtration, in which case the following

board 152 mm square with a circular hole in the center, precautions shall be taken: Use a soft paper through which the

supported on a circular metal shield enclosing the bunsen specimen filters rapidly, avoid drafts, cover the funnel with a

burner, and approximately 50 mm higher than the top of the watch glass, and filter at least 200 mL from which to take the

burner. For tests of benzene and toluene, the hole shall be 25 100 mL for distillation. Dehydration (that is, removal of

mm in diameter; for tests of materials boiling above toluene but dissolved water) is not permissible. Note, however, that certain

mostly below 145°C, the hole shall be 38 mm in diameter, and materials, especially benzene, may absorb traces of water that

can be significant with respect to this test. When it can be

for higher boiling materials, it shall be 50 mm in diameter.

6.6 Heater: shown that failure to pass this distillation test is due to the

6.6.1 Manual Distillation Heater—An electric heater or a presence of dissolved water, it shall be permissible, if mutually

bunsen burner, fully adjustable and capable of giving sufficient agreeable to the purchaser and the seller, to dry the specimen

heat to distill the product at the required rate. When a bunsen by any method agreed to by both the purchaser and the seller.

burner is used, as described in 7.1 and Fig. 1 of Specification

9. Assembly of Apparatus

E 133, the burner shall be adjusted so as to produce an entirely

9.1 Manual Distillation Apparatus:

blue flame.

9.1.1 Remove any residual liquid in the condenser tube by

NOTE 2—Caution: Superheating of the flask can cause erroneous

swabbing with a piece of lint-free cloth attached to a cord or

results and is more likely to occur with electric heaters than with bunsen

wire.

burners as heat sources. This problem is discussed in the section on

9.1.2 Assemble the apparatus as shown in Fig. 2. Mount the

Preparation of Apparatus in Test Method D 1078.

flask on the insulation board of appropriate dimensions, with

7. Hazards

the side tube extending through a tightly fitting silicone or cork

stopper about 50 mm into the condenser tube.

7.1 Consult current OSHA regulations’ and supplier’s Ma-

terial Safety Data Sheets, and local regulations, for all materi- 9.1.3 Support the distillation thermometer in the neck of the

flask by means of a cork or silicone stopper with the thermom-

als used in this test method.

eter vertical and centered in the neck of the flask and in such

8. Sampling

a position that the top of the bulb (or top of contraction bulb if

8.1 Sampling should follow safe rules in order to adhere to present) is level with the lowest point of juncture between the

all safety precautions as outlined in the latest OSHA regula- side tube and the neck of the flask (see Fig. 3).

tions. Refer to Practice D 3437 for proper sampling and 9.1.4 Place the burner directly under the center of the hole

handling of aromatic hydrocarbons analyzed by this test in the insulation board.

method. 9.2 Automatic Distillation Apparatus—For assembly of au-

8.2 The sample under test shall be transparent and free of tomatic distillation apparatus, consult the instrument manufac-

separated water. Any separated water may ordinarily be elimi- turer’s operating manual.

D 850

FIG. 3 Position of Thermometer in Measuring Device in Distillation Flask

NOTE 3—The centering device must be as stated in 6.2.2.1 (Fig. 2).

prevent loss by spattering; then adjust the heater to continue the

distillation at the rate of 5 to 7 mL/min (about 2 drops/s).

9.3 Carefully measure a 100-mL specimen of the material to

Maintain this rate, and continue the distillation to dryness. The

be tested in the 100-mL graduated cylinder at room tempera-

total yield of distillate when testing close boiling benzenes,

ture and transfer to the distillation flask, draining the cylinder

toluenes, and xylenes shall be not less than 97 %, and when

at least 15 s. This is preferably done before mounting the flask

in position, in order to prevent liquid from entering the side testing wider boiling refined products and light oils, shall be

arm. Do not rinse out the graduated cylinder used to measure not less than 95 %; otherwise, the test shall be repeated.

the sample for distillation, but place under the lower end of the

10.1.3 Take the temperature reading when the first drop of

condenser tube to receive the distillate.

distillate falls into the receiving cylinder and report as the

9.4 Fit the flask vapor tube, provided with a snug fitting

initial boiling point (IBP). If necessary, take additional r

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.