ASTM D7001-06(2011)

(Specification)Standard Specification for Geocomposites for Pavement Edge Drains and Other High-Flow Applications

Standard Specification for Geocomposites for Pavement Edge Drains and Other High-Flow Applications

SCOPE

1.1 This specification covers geocomposite drainage panels used in highway, turf, and other high volume subsurface drainage applications. These products consist of a geotextile wrapped around a polymer core. These products are a minimum of 25 mm (1 in.) thick and are available in 150 mm (6 in.), 300 mm (12 in.), 450 mm (18 in.), and 600 mm (24 in.) widths.

1.2 The requirements of this specification are intended to provide a subsurface drainage geocomposite suitable for drainage of surface and subsurface water, sewerage, and leachates. Products produced in accordance with this specification and intended for pavement drainage applications shall be installed in accordance with Practice D6088.

1.3 The values as stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory requirements prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D7001 −06 (Reapproved 2011)

Standard Specification for

Geocomposites for Pavement Edge Drains and Other High-

Flow Applications

This standard is issued under the fixed designation D7001; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope D2122 Test Method for Determining Dimensions of Ther-

moplastic Pipe and Fittings

1.1 This specification covers geocomposite drainage panels

D3350 Specification for Polyethylene Plastics Pipe and Fit-

used in highway, turf, and other high volume subsurface

tings Materials

drainage applications. These products consist of a geotextile

D4354 Practice for Sampling of Geosynthetics and Rolled

wrapped around a polymer core. These products are a mini-

Erosion Control Products (RECPs) for Testing

mum of 25 mm (1 in.) thick and are available in 150 mm (6

D4355 Test Method for Deterioration of Geotextiles by

in.), 300 mm (12 in.), 450 mm (18 in.), and 600 mm (24 in.)

Exposure to Light, Moisture and Heat in a Xenon Arc

widths.

Type Apparatus

1.2 The requirements of this specification are intended to

D4439 Terminology for Geosynthetics

provide a subsurface drainage geocomposite suitable for drain-

D4491 Test Methods for Water Permeability of Geotextiles

age of surface and subsurface water, sewerage, and leachates.

by Permittivity

Products produced in accordance with this specification and

D4533 Test Method for Trapezoid Tearing Strength of Geo-

intended for pavement drainage applications shall be installed

textiles

in accordance with Practice D6088.

D4632 Test Method for Grab Breaking Load and Elongation

of Geotextiles

1.3 The values as stated in SI units are to be regarded as the

standard. The values given in parentheses are for information D4716 Test Method for Determining the (In-plane) Flow

Rate per Unit Width and Hydraulic Transmissivity of a

only.

Geosynthetic Using a Constant Head

1.4 This standard does not purport to address all of the

D4751 Test Methods for Determining Apparent Opening

safety concerns, if any, associated with its use. It is the

Size of a Geotextile

responsibility of the user of this standard to establish appro-

D4833 Test Method for Index Puncture Resistance of

priate safety, health and environmental practices and deter-

Geomembranes and Related Products

mine the applicability of regulatory limitations prior to use.

D6088 Practice for Installation of Geocomposite Pavement

1.5 This international standard was developed in accor-

Drains

dance with internationally recognized principles on standard-

D6244 Test Method for Vertical Compression of Geocom-

ization established in the Decision on Principles for the

posite Pavement Panel Drains

Development of International Standards, Guides and Recom-

D6364 Test Method for Determining Short-Term Compres-

mendations issued by the World Trade Organization Technical

sion Behavior of Geosynthetics

Barriers to Trade (TBT) Committee.

D6707 Specification for Circular-Knit Geotextile for Use in

Subsurface Drainage Applications

2. Referenced Documents

2 2.2 Other Document:

2.1 ASTM Standards:

AASHTO M288 Geotextile Materials

D1777 Test Method for Thickness of Textile Materials

3. Terminology

This specification is under the jurisdiction of ASTM Committee D35 on

3.1 Definitions:

Geosynthetics and is the direct responsibility of Subcommittee D35.06 on Geosyn-

3.1.1 For definitions of terms relating to geotextiles, refer to

thetic Specifications.

Terminology D4439.

Current edition approved Oct. 1, 2011. Published November 2011. Originally

approved in 2004. Last previous edition approved in 2006 as D7001 – 06. DOI: 3.1.2 geocomposite, n—a product composed of two or more

10.1520/D7001-06R11.

materials, at least one of which is a geosynthetic. D4439

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on Available from American Association of State Highway and Transportation

the ASTM website. Officials (AASHTO), 444 N. Capitol St., NW, Suite 249, Washington, DC 20001.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D7001−06 (2011)

TABLE 2 Geotextile Properties

3.1.3 geosynthetic, n—a planar product manufactured from

polymeric material used with foundation, soil, rock, earth, or Minimum Value Minimum Value

Property Test Method Class A Class B

any other geotechnical engineering related material as an

Geocomposite Geocomposite

integral part of a man-made project, structure, or system.

Grab Strength Test Method D4632 700 N 500 N

D4439

Elongation Test Method D4632 >50 % >50 %

Seam Strength Test Method D4632 630 N 450 N

4. Classification Puncture Strength Test Method D4833 250 N 180 N

Trapezoidal Tear Test Method D4533 250 N 180 N

-1 -1

4.1 General—Thisspecificationcoversgeocompositedrain-

Permittivity Test Methods D4491 0.5 s 0.5 s

AOS Test Method D4751 0.25 mm 0.25 mm

age products or structures intended for high flow volume

(max. avg. roll (max. avg. roll

subsurfacedrainageapplications.Twodistinctlydifferentprod-

value) value)

uct designs are included in this specification, a ClassAproduct

Ultraviolet Test Method D4355 50 % retained 50 % retained

Degradation Breaking Strength at 500 h at 500 h

composed of a cuspated or sheet and post core wrapped with a

geotextile serving as the outer boundary and a drainage fabric,

NOTE 1—These properties are for the geotextile for the finished product

andaClassBproductcomposedofaseriesofsmallroundpipe

as applied to the core, including the effects of any resin bonding or

connected together or a flat pipe design consisting of a full

calendaring done to the material. If circular knit geotextile is used, it shall

circumference core with the geotextile acting only as a meet the requirements of Specification D6707. Geotextile properties for

Class A cores are listed as Class 2 in AASHTO M288; and for Class B

drainage fabric.

cores are Class 3 as in AASHTO M288.

4.1.1 Fittings covered by this application are normally

molded. Fittings may be fabricated from sections of the

drainage core by thermal welding.

4.1.2 Fittings intended to outlet these products often transi-

6.1.3 Geotextile Materials—Fibers used in the manufacture

tion into pipe systems. These transition fittings are included,

of geotextiles shall consist of long-chain synthetic polymers

but the pipe is not.

composed of at least 95 percent by weight of polyolefins or

polyesters.

5. Ordering Information

6.2 Manufacture and Assembly—The geocomposite shall be

5.1 When ordering material in accordance with this

assembled from the permitted core structures and the geotex-

specification, the following should be specified:

tile.

5.1.1 The product size (150 mm, 300 mm, 450 mm, or 600

6.2.1 Core—The core structure shall be manufactured by

mm) (6 in., 12 in., 18 in., or 24 in.).

continuous extrusion and forming and cut to size.

5.1.2 The geocomposite class (Table 2 and Table 3).

6.2.2 Fittings—The core fittings shall be blow molded,

5.1.3 The geotextile component class (Table 2).

injection molded, rotational molded, thermoformed, or fabri-

5.1.4 Fittings required. Fittings may be required to couple

cated by extrusion or hot plate welding.

sections together and to provide outlets, typically transitioning

6.2.3 Geotextile—The geotextile may be knitted, needle-

to round pipe.

punched non-woven, or spun-bonded non-woven.

6.2.4 Assembly—The geotextile must be attached to the

6. Materials and Manufacture

Class A core by heat bonding or gluing; or, for Class B cores,

6.1 Basic Materials—These products are composites of two

may be formed into a sleeve and placed around the core. The

or more materials, typically a drainage core and a geotextile

geotextile sleeve may be seamed by sewing, gluing, or thermal

filter.

bonding, or may be a tubular knit.

6.1.1 Core Materials—Compounds used in the manufacture

of the drainage core and fittings shall be polyethylene with a

7. Physical Properties

minimum cell classification of 424420C as defined and de-

7.1 The geocomposite materials covered by this specifica-

scribed in Specification D3350. Compounds that have a higher

tion shall have a nominal thickness of 25 mm (1 in.) and a

cell classification in one or more properties are acceptable,

nominal width of 150 mm, 300 mm, 450 mm, and 600 mm (6

except for density, which must be cell Class 4, provided the

in., 12 in., 18 in., and 24 in.) wide. Product length shall be as

product requirements are met.

agreed to by the customer and the manufacturer.

6.1.2 Reworked Materials—Clean rework material, gener-

7.2 The geocomposite products covered by this standard are

ated from the manufacturer’s own production, may be used by

available in two distinctly different forms, an open core with a

the manufacturer provided that the core and fittings produced

geotextile wrap that acts as part of the structure as well as a

meet all requirements of this specification.

filter, listed as Class A; and a fully enclosed core with a

geotextile wrap that acts only as a filter, listed as Class B.

TABLE 1 Core Properties

Property Test Method Minimum Value

8. Mechanical and Performance Requirements

Overall Thickness Test Method D1777 $ 25 mm (1 in.) (Nomi-

8.1 The drainage core shall have the properties shown in

(mm) nal)

Compression Strength Test Method D6364 $ 210 kPa (30 psi) (90°)

Table 1.

(kPa) $ 140 kPa (20 psi) (50°)

8.2 The geotextile shall have the properties shown in Table

NOTE 1—Table 1 applies to both Class A and Class B cores. 2.

D7001−06 (2011)

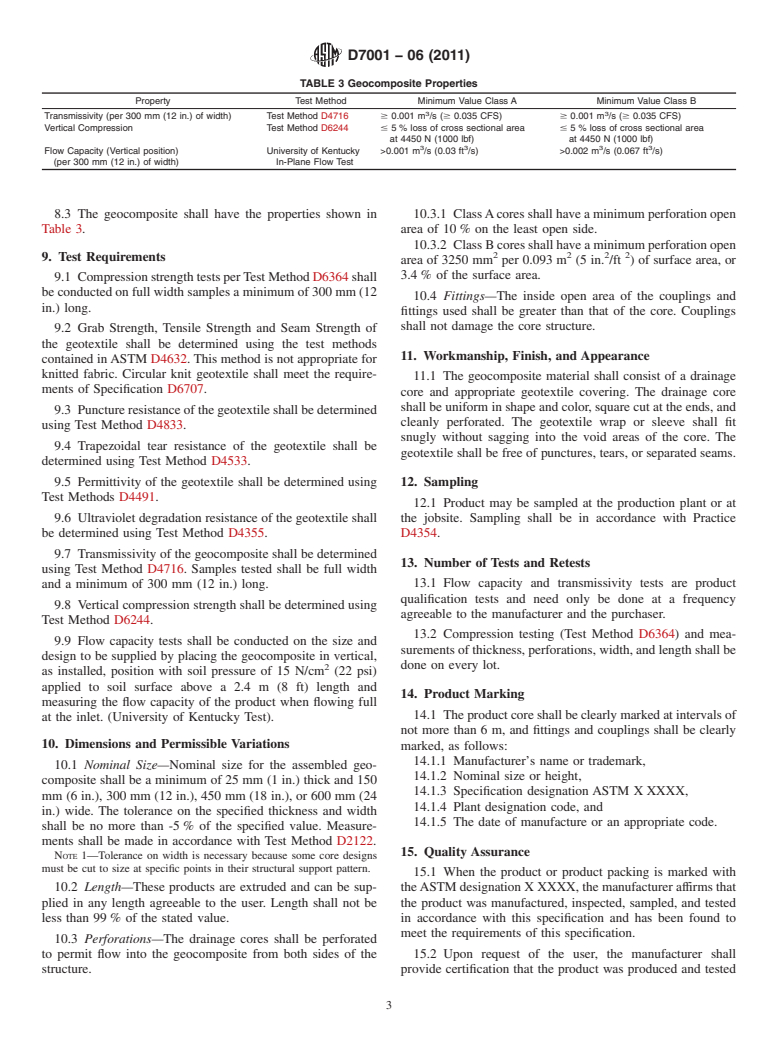

TABLE 3 Geocomposite Properties

Property Test Method Minimum Value Class A Minimum Value Class B

3 3

Transmissivity (per 300 mm (12 in.) of width) Test Method D4716 $ 0.001 m /s ($ 0.035 C

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.