ASTM B909-00(2006)

(Guide)Standard Guide for Plane Strain Fracture Toughness Testing of Non-Stress Relieved Aluminum Products

Standard Guide for Plane Strain Fracture Toughness Testing of Non-Stress Relieved Aluminum Products

SCOPE

1.1 This guide covers supplementary guidelines for plane-strain fracture toughness testing of aluminum products for which complete stress relief is not practicable. Guidelines for recognizing when residual stresses may be significantly biasing test results are presented, as well as methods for minimizing the effects of residual stress during testing. This guide also provides guidelines for correction and interpretation of data produced during the testing of these products. Test Method E 399 is the standard test method to be used for plane-strain fracture toughness testing of aluminum alloys.

This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:B909–00 (Reapproved 2006)

Standard Guide for

Plane Strain Fracture Toughness Testing of Non-Stress

Relieved Aluminum Products

This standard is issued under the fixed designation B909; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 3. Terminology

1.1 This guide covers supplementary guidelines for plane- 3.1 Definitions—Terminology in Test Method E399 and

strain fracture toughness testing of aluminum products for Terminology E1823 are applicable herein.

which complete stress relief is not practicable. Guidelines for 3.2 Definitions of Terms Specific to This Standard:

recognizingwhenresidualstressesmaybesignificantlybiasing 3.2.1 corrected plane-strain fracture toughness— a test

test results are presented, as well as methods for minimizing result, designated K (corrected), which has been corrected for

q

the effects of residual stress during testing. This guide also residual stress bias by one of the methods outlined in this

provides guidelines for correction and interpretation of data guide.ThecorrectedresultisanestimationoftheK orK that

q Ic

produced during the testing of these products. Test Method would have been obtained in a residual stress free specimen.

E399 is the standard test method to be used for plane-strain The corrected result may be obtained from a test record which

fracture toughness testing of aluminum alloys. yielded either an invalid K or valid K , but for which there is

q Ic

1.2 This standard does not purport to address all of the evidence that significant residual stress is present in the test

safety concerns, if any, associated with its use. It is the coupon.

responsibility of the user of this standard to establish appro- 3.2.2 invalid plane-strain fracture toughness— a test result,

priate safety and health practices and determine the applica- designated K , that does not meet one or more validity

q

bility of regulatory limitations prior to use. requirements in Test Method E399 or ISO 12737 and may or

may not be significantly influenced by residual stress.

2. Referenced Documents

3.2.3 valid plane-strain fracture toughness— a test result,

2.1 ASTM Standards:

designated K , meeting the validity requirements in Test

Ic

E399 Test Method for Linear-Elastic Plane-Strain Fracture

Method E399 or ISO 12737 that may or may not be signifi-

Toughness K of Metallic Materials cantly influenced by residual stress.

Ic

E561 Test Method for K-R Curve Determination

4. Significance and Use

E1823 Terminology Relating to Fatigue and Fracture Test-

ing 4.1 The property K , determined by Test Method E399 or

Ic

2.2 ANSI Standard: ISO 12737, characterizes a material’s resistance to fracture in

ANSI H35.1 Alloy and Temper Designations for Alumi- a neutral environment and in the presence of a sharp crack

num subjected to an applied opening force or moment within a field

2.3 ISO Standard: of high constraint to lateral plastic flow (plane strain condi-

ISO 12737 Metallic Materials–Determination of Plane tion).AK value is considered to be a lower limiting value of

Ic

Strain Fracture Toughness fracture toughness associated with the plane strain state.

4.1.1 Thermal quenching processes used with precipitation

hardened aluminum alloy products can introduce significant

This guide is under the jurisdiction ofASTM Committee B07 on Light Metals

residual stresses in the product. Mechanical stress relief pro-

and Alloys and is the direct responsibility of Subcommittee B07.05 on Testing.

cedures (stretching, compression) are commonly used to re-

Current edition approved Sept. 1, 2006. Published September 2006. Originally

approved in 2000. Last previous edition approved in 2000 as B909 – 00. DOI:

lieve these residual stresses in products with simple shapes.

10.1520/B0909-00R06.

However, in the case of mill products with thick cross-sections

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

(for example, heavy gage plate or large hand forgings) or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on complex shapes (for example, closed die forgings, complex

the ASTM website.

open die forgings, stepped extrusions, castings), complete

Available fromAmerican National Standards Institute (ANSI), 25 W. 43rd St.,

mechanical stress relief is not always possible. In other

4th Floor, New York, NY 10036, http://www.ansi.org.

instances residual stresses may be unintentionally introduced

Available from International Organization for Standardization (ISO), 1 rue de

Varembé, Case postale 56, CH-1211, Geneva 20, Switzerland, http://www.iso.ch.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

B909–00 (2006)

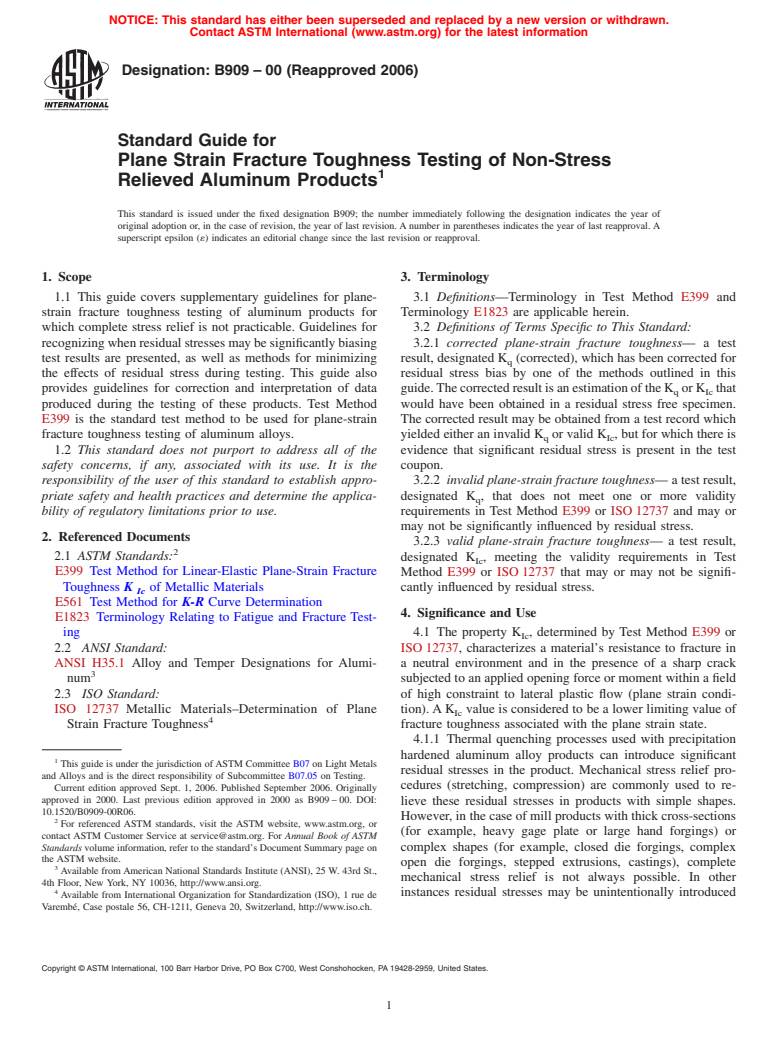

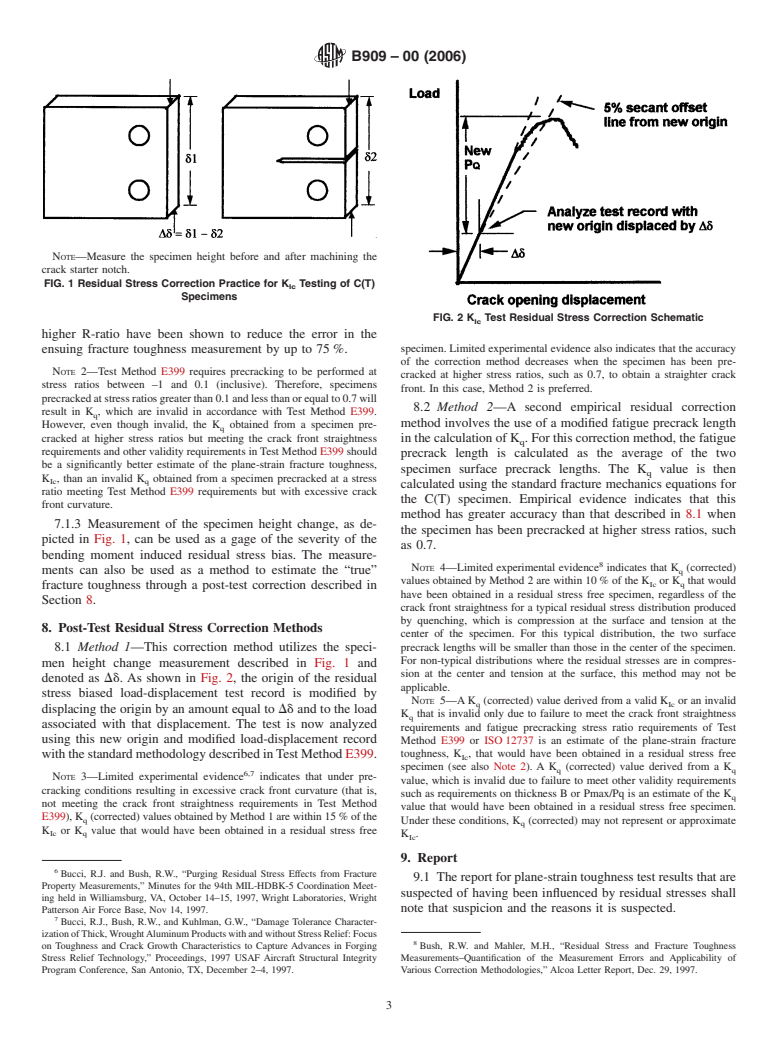

into a product during fabrication operations such as straight- length to width ratio (a /W) of 0.45, a difference in the height

o

ening, forming, or welding operations. measured before and after machining the notch equal to or

4.1.2 Specimens taken from such products that contain greater than 0.003 in. (0.076 mm) is an indicator that the

residual stress will likewise themselves contain residual stress. ensuing test result will be significantly influenced by residual

While the act of specimen extraction in itself partially relieves stress.

and redistributes the pattern of original stress, the remaining 5.1.3 Excessive fatigue precrack front curvature not meet-

magnitude can still be appreciable enough to cause significant ing the crack-front straightness requirements in Test Method

error in the ensuing test result. E399 or ISO 12737.

4.1.3 Residual stress is superimposed on the applied stress 5.1.4 Unusually high loads or number of cycles required for

andresultsinanactualcrack-tipstressintensitythatisdifferent precracking relative to the same or similar alloy/products.

from that based solely on externally applied forces or displace- 5.1.5 A significant change in fracture toughness that is

ments. greater than that typically observed upon changing specimen

4.1.4 Teststhatutilizedeepedge-notchedspecimenssuchas configuration (for example, from C(T) to three point bend bar)

thecompacttensionC(T)areparticularlysensitivetodistortion or upon changing specimen plan size that cannot be explained

during specimen machining when influential residual stress is by other means. For example, if residual stress is biasing

present.Ingeneral,forthosecaseswheresuchresidualstresses fracture toughness tests results, then increasing the specimen

are thermal quench induced, the resulting K or K result is plan size typically results in increasing K values.

Ic q q

typically biased upward (that is, K is higher than that which

q

NOTE 1—Otherfactors,suchasasteeplyrisingR-curve(PracticeE561)

would have been achieved in a residual stress free specimen).

in high toughness alloy/products, may also be responsible for K values

q

The inflated values result from the combination of specimen

increasing with increasing specimen plan size.

distortionandbendingmomentscausedbytheredistributionof

5.1.6 A nonlinear load-COD trace during the initial elastic

residual stress during specimen machining and excessive

portion of the test record. This result is indicative of the

fatigue precrack from curvature .

residual stress clamping that is being overcome to open the

4.2 This guide can serve the following purposes:

crack under the progressively increasing applied load.

4.2.1 Provide warning signs that the measured value of K

Ic

has been biased by residual stresses and may not be a lower

6. Minimizing Effects of Residual Stress on Fracture

limit value of fracture toughness.

Toughness Measurements

4.2.2 Provide experimental methods by which to minimize

6.1 When testing aluminum products that have not been

the effect of residual stress on measured fracture toughness

stress relieved, there are two approaches available to minimize

values.

or eliminate the effects of residual stress on fracture toughness

4.2.3 Suggest methods that can be used to correct residual

measurements. The first approach involves the use of one or

stress influenced values of fracture toughness to values that

more experimental methods designed to minimize the residual

approximate a fracture toughness value representative of a test

stress in test specimens. The second approach involves the use

performed without residual stress bias.

of post-test correction methods to estimate the fracture tough-

ness K or K that would have been obtained had the test

q Ic

5. Warning Signs

specimen been free of residual stress.

5.1 There are a number of warning signs that test measure-

ments are or might be biased by the presence of residual stress.

7. Experimental Methods to Minimize Effects of Residual

If any one or more of the following conditions exist, residual

Stress

stress bias of the ensuing plane strain fracture toughness test

7.1 The following considerations can be used to minimize

resultshouldbe

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.