ASTM E2110-11

(Terminology)Standard Terminology for Exterior Insulation and Finish Systems (EIFS)

Standard Terminology for Exterior Insulation and Finish Systems (EIFS)

SCOPE

1.1 This terminology covers terms and definitions pertaining to materials and processes used in the design and application of exterior insulation and finish systems (EIFS).

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: E2110 − 11

Standard Terminology for

1

Exterior Insulation and Finish Systems (EIFS)

This standard is issued under the fixed designation E2110; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope dry, v—to develop the ultimate properties of a wet-state

material solely by evaporation of volatile ingredients.

1.1 This terminology covers terms and definitions pertain-

ing to materials and processes used in the design and applica-

durability, n—the capability of a building assembly,

tion of exterior insulation and finish systems (EIFS).

component, product, or construction to maintain serviceabil-

ity over not less than a specified time.

2. Referenced Documents

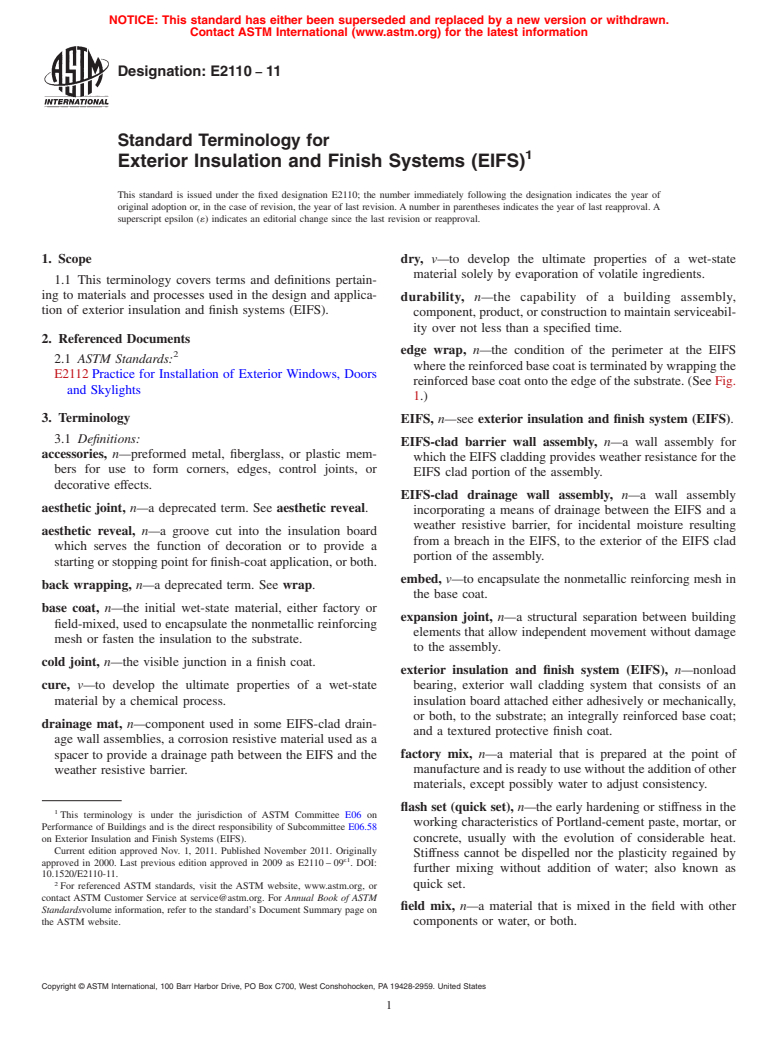

edge wrap, n—the condition of the perimeter at the EIFS

2

2.1 ASTM Standards:

where the reinforced base coat is terminated by wrapping the

E2112 Practice for Installation of Exterior Windows, Doors

reinforced base coat onto the edge of the substrate. (See Fig.

and Skylights

1.)

3. Terminology EIFS, n—see exterior insulation and finish system (EIFS).

3.1 Definitions:

EIFS-clad barrier wall assembly, n—a wall assembly for

accessories, n—preformed metal, fiberglass, or plastic mem-

which the EIFS cladding provides weather resistance for the

bers for use to form corners, edges, control joints, or

EIFS clad portion of the assembly.

decorative effects.

EIFS-clad drainage wall assembly, n—a wall assembly

aesthetic joint, n—a deprecated term. See aesthetic reveal.

incorporating a means of drainage between the EIFS and a

weather resistive barrier, for incidental moisture resulting

aesthetic reveal, n—a groove cut into the insulation board

from a breach in the EIFS, to the exterior of the EIFS clad

which serves the function of decoration or to provide a

portion of the assembly.

starting or stopping point for finish-coat application, or both.

embed, v—to encapsulate the nonmetallic reinforcing mesh in

back wrapping, n—a deprecated term. See wrap.

the base coat.

base coat, n—the initial wet-state material, either factory or

expansion joint, n—a structural separation between building

field-mixed, used to encapsulate the nonmetallic reinforcing

elements that allow independent movement without damage

mesh or fasten the insulation to the substrate.

to the assembly.

cold joint, n—the visible junction in a finish coat.

exterior insulation and finish system (EIFS), n—nonload

cure, v—to develop the ultimate properties of a wet-state bearing, exterior wall cladding system that consists of an

material by a chemical process. insulation board attached either adhesively or mechanically,

or both, to the substrate; an integrally reinforced base coat;

drainage mat, n—component used in some EIFS-clad drain-

and a textured protective finish coat.

age wall assemblies, a corrosion resistive material used as a

spacer to provide a drainage path between the EIFS and the factory mix, n—a material that is prepared at the point of

weather resistive barrier. manufacture and is ready to use without the addition of other

materials, except possibly water to adjust consistency.

flash set (quick set), n—the early hardening or stiffness in the

1

This terminology is under the jurisdiction of ASTM Committee E06 on

working characteristics of Portland-cement paste, mortar, or

Performance of Buildings and is the direct responsibility of Subcommittee E06.58

on Exterior Insulation and Finish Systems (EIFS). concrete, usually with the evolution of considerable heat.

Current edition approved Nov. 1, 2011. Published November 2011. Originally

Stiffness cannot be dispelled nor the plasticity regained by

ε1

approved in 2000. Last previous edition approved in 2009 as E2110 – 09 . DOI:

further mixing without addition of water; also known as

10.1520/E2110-11.

2

quick set.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

field mix, n—a material that is mixed in the field with other

Standardsvolume information, refer to the standard’s Document Summary page on

the ASTM website. components or water, or both.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

E2110 − 11

NOTE 1—Not to scale.

FIG. 1 Example of an Edge Wrap (At Door Jam)

finish coat, n—the final wet-state material, which provides running bond, n—pattern used when installing the thermal

color and texture, applied over the reinforced base coat.

insulation board, to offset the vertical insulation board joints

from joints in previo

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

´1

Designation:E2110–09 Designation: E2110 – 11

Standard Terminology for

1

Exterior Insulation and Finish Systems (EIFS)

This standard is issued under the fixed designation E2110; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1

´ NOTE—Term EIFS editorially added in September 2010.

1. Scope

1.1 This terminology covers terms and definitions pertaining to materials and processes used in the design and application of

exterior insulation and finish systems (EIFS).

2. Referenced Documents

2

2.1 ASTM Standards:

E2112 Practice for Installation of Exterior Windows, Doors and Skylights

3. Terminology

3.1 Definitions:

accessories, n—preformedmetal,fiberglass,orplasticmembersforusetoformcorners,edges,controljoints,ordecorativeeffects.

aesthetic joint, n—a deprecated term. See aesthetic reveal.

aesthetic reveal, n—a groove cut into the insulation board which serves the function of decoration or to provide a starting or

stopping point for finish-coat application, or both.

back wrapping, n—a deprecated term. See wrap.

base coat, n—the initial wet-state material, either factory or field-mixed, used to encapsulate the nonmetallic reinforcing mesh or

fasten the insulation to the substrate.

cold joint, n—the visible junction in a finish coat.

cure, v—to develop the ultimate properties of a wet-state material by a chemical process.

drainage mat, n—component used in some EIFS-clad drainage wall assemblies, a corrosion resistive material used as a spacer

to provide a drainage path between the EIFS and the weather resistive barrier.

dry, v—to develop the ultimate properties of a wet-state material solely by evaporation of volatile ingredients.

durability, n—the capability of a building assembly, component, product, or construction to maintain serviceability over not less

than a specified time.

edge wrap, n—the condition of the perimeter at the EIFS where the reinforced base coat is terminated by wrapping the reinforced

base coat onto the edge of the substrate. (See Fig. 1.)

EIFS, n—see exterior insulation and finish system (EIFS).

EIFS-clad barrier wall assembly, n—a wall assembly for which the EIFS cladding provides weather resistance for the EIFS clad

portion of the assembly.

EIFS-clad drainage wall assembly, n—a wall assembly incorporating a means of drainage between the EIFS and a weather

resistive barrier, for incidental moisture resulting from a breach in the EIFS, to the exterior of the EIFS clad portion of the

assembly.

embed, v—to encapsulate the nonmetallic reinforcing mesh in the base coat.

expansion joint, n—a structural separation between building elements that allow independent movement without damage to the

assembly.

exterior insulation and finish system (EIFS), n—nonload bearing, exterior wall cladding system that consists of an insulation

1

This terminology is under the jurisdiction of ASTM Committee E06 on Performance of Buildings and is the direct responsibility of Subcommittee E06.58 on Exterior

Insulation and Finish Systems (EIFS).

Current edition approved April 15, 2009. Published May 2009. Originally approved in 2000. Last previous edition approved in 2003 as E2110–03. DOI:

10.1520/E2110-09E01.

´1

Current edition approved Nov. 1, 2011. Published November 2011. Originally approved in 2000. Last previous edition approved in 2009 as E2110 – 09 . DOI:

10.1520/E2110-11.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standardsvolume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

E2110 – 11

NOTE 1—Not to scale.

FIG. 1 Example of an Edge Wrap (At Door Jam)

board attached either adhesively or mechanically, or both, to the substrate; an integrally reinforced base coat; and a textured

protective finish coat.

factory mix, n—a material that is prepared at the point of manufacture and is ready to use without the addition of other materials,

except possibly water to adjust consistency.

flash set (quick set), n—the early hardening or stiffness in the working characteristics of Portland-cement paste, mortar, or

concrete, usually with the evoluti

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.