ASTM A959-04

(Guide)Standard Guide for Specifying Harmonized Standard Grade Compositions for Wrought Stainless Steels

Standard Guide for Specifying Harmonized Standard Grade Compositions for Wrought Stainless Steels

SCOPE

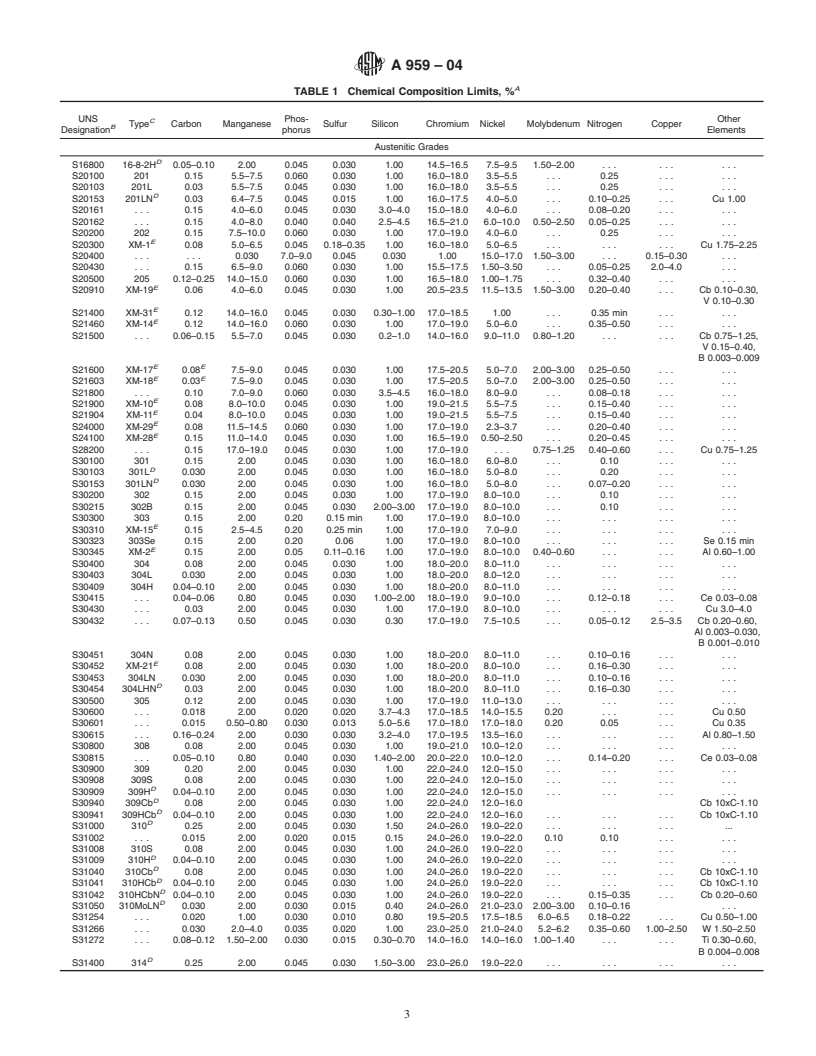

1.1 This standard provides a guide to ASTM Subcommittees A01.06, A01.10, A01.17, A01.22, and A01.28 for specifying chemical composition limits of wrought stainless steels. It is intended that these recommended grade composition limits be suitable for adoption by other standardization bodies that prepare standards for stainless steel products.

1.2 Included in this guide are the recommendations for determining the number of significant figures for specifying chemical composition from Test Methods, Practices and Terminology A 751.

1.3 All stainless steel UNS numbers and the stainless steel grades in all standards overseen by the aforementioned ASTM subcommittees have been included, except those grades applicable to restricted special end uses and alloys containing less than 10.5 % minimum chromium.

1.4 Not addressed are minor composition modifications which a specific product subcommittee may find necessary to accommodate effects of normal processing or to enhance fabricability by the producer or user, or both.

1.5 Also not generally addressed (except when established by ASTM product subcommittees) is a complete rationalization of all limits, especially when such would conflict with long-standing practices and is not justified by special technical effect.

1.6 Excluded from this guide are cast material and welding filler metal.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:A959–04

Standard Guide for

Specifying Harmonized Standard Grade Compositions for

1

Wrought Stainless Steels

This standard is issued under the fixed designation A 959; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope* J 1086 Recommended Practice for Numbering Metals and

3

Alloys

1.1 This document provides a guide to ASTM Subcommit-

HS-1086 Metals and Alloys in the Unified Numbering

tees A01.06, A01.10, A01.17, A01.22, and A01.28 for speci-

3

System

fying chemical composition limits of wrought stainless steels.

Itisintendedthattheserecommendedgradecompositionlimits

3. Terminology

be suitable for adoption by other standardization bodies that

3.1 Definitions of Terms Specific to This Standard:

prepare standards for stainless steel products.

3.1.1 austenitic grade, n—metallurgical term meaning that

1.2 Included in this guide are the recommendations for

the material is usually predominantly face-centered cubic in

determining the number of significant figures for specifying

structure and hardenable only by cold working.

chemical composition from Test Methods, Practices, and Ter-

3.1.2 austenitic-ferritic (duplex) grade, n—metallurgical

minology A 751.

term meaning that the material is a mixture of austenitic and

1.3 All stainless steel UNS numbers and the stainless steel

ferritic structures, with at least one-fourth of the lesser phase,

grades in all standards overseen by the aforementionedASTM

and hardenable only by cold working.

subcommittees have been included, except those grades appli-

3.1.3 ferritic grade, n—metallurgical term meaning that the

cable to restricted special end uses and alloys containing less

material is body-centered cubic in structure (with little, if any,

than 10.5 % minimum chromium.

tempered martensite) and hardenable only slightly by cold

1.4 Not addressed are minor composition modifications

working (responding little or only slightly to conventional heat

which a specific product subcommittee may find necessary to

treatment by quenching and tempering).

accommodate effects of normal processing or to enhance

3.1.4 martensitic grade, n—metallurgicaltermmeaningthat

fabricability by the producer or user, or both.

the material is capable of being produced in a distorted

1.5 Also not generally addressed (except when established

body-centered cubic structure by conventional heat treating

byASTMproductsubcommittees)isacompleterationalization

and quenching, and that the quenched structure is capable of

of all limits, especially when such would conflict with long-

conventionaltempering.Martensiticgradesaredeliveredinthe

standing practices and is not justified by special technical

annealed (ferritic) condition or the hardened and tempered

effect.

(martensitic) condition.

1.6 Excluded from this guide are cast material and welding

3.1.5 precipitation hardening grade, n—metallurgical term

filler metal.

meaning that the material may be basically austenitic or

2. Referenced Documents martensitic in structure and hardenable by precipitation hard-

2 ening (sometimes called age hardening).

2.1 ASTM Standards:

3.1.6 standard stainless steel grade, n—listed chemical

A 751 Test Methods, Practices, and Terminology for

composition associated with a stainless steel grade identified

Chemical Analysis of Steel Products

by a particular UNS number appearing in SAE publication

E 527 Practice for Numbering Metals and Alloys (UNS)

HS-1086, except as modified by an ASTM subcommittee

2.2 SAE Standards:

having oversight of a wrought stainless steel product where

such a modification is justified by a specific technical effect.

1

This guide is under the jurisdiction of ASTM Committee A01 on Steel,

4. Significance and Use

Stainless Steel and Related Alloys and is the direct responsibility of Subcommittee

A01.17 on Flat-Rolled and Wrought Stainless Steel. 4.1 It is anticipated that the ASTM Subcommittees A01.06,

Current edition approved Sept. 1, 2004. Published September 2004. Originally

A01.10, A01.17, A01.22, and A01.28 will use the standard

approved in 1996. Last previous edition approved in 2003 as A 959-03.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

3

Standards volume information, refer to the standard’s Document Summary page on Available from Society of Automotive Engineers (SAE), 400 Commonwealth

the ASTM website. Dr., Warrendale, PA 15096-0001.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.