ASTM F1828-97(2006)

(Specification)Standard Specification for Ureteral Stents

Standard Specification for Ureteral Stents

ABSTRACT

This specification covers the chemical, mechanical, and metallurgical requirements for wrought titanium-12 molybdenum- 6 zirconium-2 iron alloy for surgical implants to be used in the manufacture of surgical implants. The heat analysis shall conform to the chemical composition requirements prescribed. Ingot analysis may be used for reporting all chemical requirements, except hydrogen. The wrought titanium-12 molybdenum-6 zirconium-2 iron alloy are classified as bar, forging bar and wire. The ultimate tensile strength, yield strength, elongation, and area reduction of the material shall be tested to meet the requirements prescribed.This specification covers the referee test methods for evaluating the performance characteristics of a single-use ureteral stent with retaining means at both ends, during short term use for drainage of urine from the kidney to the bladder. Ureteral stents shall be tested in accordance with the appropriate biological tests to meet the requirements prescribed. Retention strength, break strength, elongation, dynamic frictional force, and radiopacity shall be tested to meet the requirements prescribed.

SCOPE

1.1 This specification covers the referee test methods for evaluating the performance characteristics of a single-use ureteral stent with retaining means at both ends, during short term use for drainage of urine from the kidney to the bladder. These stents are typically available in diameters of 3.7 Fr to 14.0 Fr, and lengths of 8 cm to 30 cm, and are made of silicone, polyurethane, and other polymers. They are provided non-sterile for sterilization and sterile for single-use.

1.2 Exclusions—Long-term indwelling usage (over 30 days) is encountered with this product, but not commonly, and is therefore considered an exception to this specification. Similarly, the use of ureteral stents for non-ureteral applications such as nephrostomy and ileostomy is excluded from the scope of this specification. Non-sterile ureteral stents are also excluded due to the variability of hospital sterilization equipment and processes and the resulting effects on ureteral stent characteristics.

1.3 The following precautionary statement pertains only to the test method portion, Section 5, of this specification:

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:F1828 −97(Reapproved 2006)

Standard Specification for

Ureteral Stents

This standard is issued under the fixed designation F1828; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

INTRODUCTION

The objective of this specification is to describe the test methods used to evaluate the safety and

effectiveness of an indwelling ureteral stent, having retention means at the kidney and bladder ends,

used for urinary drainage of the kidney to the bladder via the ureter.

This specification includes referee test methods that can be used to evaluate the performance

characteristics of ureteral stents. Note that the test methods are not to be construed as production

methods, quality control techniques, or manufacturer’s lot release criteria. The product parameters

addressed by the standard include those determined by the ASTM task group to be pertinent to the

product.

1. Scope 2. Referenced Documents

1.1 This specification covers the referee test methods for 2.1 ASTM Standards:

evaluating the performance characteristics of a single-use D412 Test Methods forVulcanized Rubber andThermoplas-

ureteral stent with retaining means at both ends, during short tic Elastomers—Tension

term use for drainage of urine from the kidney to the bladder. F640 Test Methods for Determining Radiopacity for Medi-

These stents are typically available in diameters of 3.7 Fr to cal Use

14.0Fr,andlengthsof8cmto30cm,andaremadeofsilicone, F748 PracticeforSelectingGenericBiologicalTestMethods

polyurethane, and other polymers. They are provided non- for Materials and Devices

sterile for sterilization and sterile for single-use.

3. Terminology

1.2 Exclusions—Long-termindwellingusage(over30days)

3.1 Definitions of Terms Specific to This Standard:

is encountered with this product, but not commonly, and is

3.1.1 artificial urine—a solution of organic and inorganic

therefore considered an exception to this specification.

compounds that closely simulates the chemical and physical

Similarly, the use of ureteral stents for non-ureteral applica-

properties of normal human urine.Artificial urine will be used

tions such as nephrostomy and ileostomy is excluded from the

asasubstituteforhumanurinetosimulatetheeffectsofhuman

scope of this specification. Non-sterile ureteral stents are also

urine on ureteral stents.

excluded due to the variability of hospital sterilization equip-

ment and processes and the resulting effects on ureteral stent 3.1.2 bladder retention means—physical feature of bladder

end of stent the prevents movement of stent out of bladder.

characteristics.

3.1.3 break strength—peak tensile load required to break

1.3 The following precautionary statement pertains only to

stent.

the test method portion, Section 5, of this specification:

3.1.4 cross section—view of stent tube when cut in a plane

1.4 This standard does not purport to address all of the

perpendicular to length of stent.

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro-

3.1.5 distal—situated away from the point of origin. The

priate safety and health practices and determine the applica-

distal end of a stent is the end that resides in the bladder, also

bility of regulatory limitations prior to use.

known as the bladder end.

3.1.6 drainage holes—holes in wall of stent tubing that

allow flow of urine into and out of lumen of stent.

This specification is under the jurisdiction of ASTM Committee F04 on

Medical and Surgical Materials and Devices and is the direct responsibility of

Subcommittee F04.34 on Urological Materials and Devices. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved March 1, 2006. Published April 2006. Originally contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

approved in 1997. Last previous edition approved in 1997 as F1828 – 97. DOI: Standards volume information, refer to the standard’s Document Summary page on

10.1520/F1828-97R06. the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

F1828−97 (2006)

3.1.7 dynamic frictional force—resistancetorelativemotion The manufacturer need not use this referee test method for

between two surfaces during motion. This force is defined as inspection and quality control.

the coefficient of kinetic friction multiplied by the force acting

3.1.16 retention strength—force required to overcome the

on the surface of the material in a plane perpendicular to the

retaining means on a stent.

surface.

3.1.17 sterility—the state of being free of microorganisms.

3.1.8 elongation—expressed as a percent, is equal to the

For purposes of this specification, sterility is defined as

change in length of a sample of tubing at failure divided by its

freedom from microorganisms when tested according to the

original length. Stretching of the tubing is produced by tensile

methodology defined by the USP for nonparenteral devices.

loading.

3.1.18 tolerances—the allowable deviation from a standard

3.1.9 French size—Scale used to indicate size of tubular

size. The tolerance for the length of a ureteral stent is 60.5 cm

devices, each unit being approximately equal to 0.013 in. or

(0.197 in). the tolerance for the specified French size of a

0.33 mm in diameter.Typical label French sizes are as follows:

ureteral stent is 60.01 mm (0.004 in), or approximately ⁄3

French Size Outside Diameter

French.

in. mm

3.1.19 ureteral stent—an indwelling tubular device that

3.7 0.050,1.23

resides in the kidney, ureter, and bladder containing means for

4.5 0.060,1.50

retaining ends of tube in kidney and bladder.

4.7 0.061,1.57

6.0 0.079,2.00

7.0 0.092,2.33

4. Requirements

8.0 0.105,2.67

8.5 0.112,2.83

4.1 Biocompatibility—Ureteral stents shall be tested in ac-

10.0 0.131,3.33

cordance with the appropriate biological tests contained in

14.0 0.183,4.66

Specification F748 or similar guidance established by the U. S.

3.1.10 kidney retention means—physical feature of kidney

Food and Drug Administration or International Organization

end of stent that prevents movement of stent out of the kidney.

for Standardization (ISO).

3.1.11 length—length of stent is defined as the distance

between the most proximal portion of the bladder retention

5. Special Precautions

means and the most distal portion of the kidney retention

5.1 The following cautionary comments recognize the sen-

means when the stent is laying on a flat surface with the

sitivity of the materials of construction to potential environ-

mainshaft straight. (See Fig. 1).

mental conditions. These are outlined here to point out poten-

3.1.12 lumen—the channel within a tube.

tialsituationsthatcouldadverselyaffecttheperformanceofthe

3.1.13 proximal—situated toward the point of origin. In the

stent during testing.

urinary tract, the kidney is considered to be the point of origin.

5.1.1 Care should be taken during testing and use to prevent

The proximal end of a stent is the end that resides in the renal

damage to the stents. Such damage can be caused by abrasion

pelvis, also known as the kidney end.

and contact with sharp objects or chemical products.

3.1.14 radiopacity—property indicating ability of device to

5.1.2 Stents should be kept away from generators, electric

absorbx-rayenergy,allowingdevicetobeseeninaradiograph

motors,diathermymachines,andfluorescentlightsbecausethe

or fluoroscopic screen.

ozone produced may attack elastomeric materials. This applies

to both storage and handling.

3.1.15 referee test method—the method cited in the pub-

lished specification for the device. This method will be used 5.1.3 To help avoid contamination of the stents proper

when the performance of the ureteral stent is to be evaluated. handling precautions should be observed.

FIG. 1Determine of Stent Length

F1828−97 (2006)

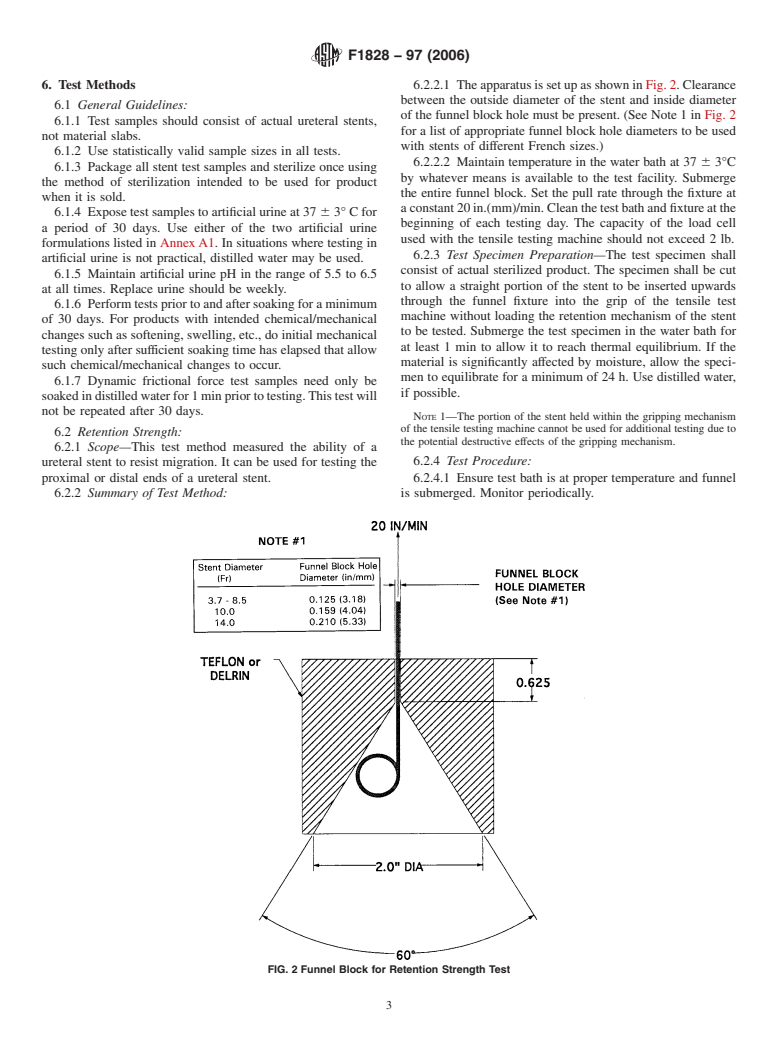

6. Test Methods 6.2.2.1 TheapparatusissetupasshowninFig.2.Clearance

between the outside diameter of the stent and inside diameter

6.1 General Guidelines:

of the funnel block hole must be present. (See Note 1 in Fig. 2

6.1.1 Test samples should consist of actual ureteral stents,

for a list of appropriate funnel block hole diameters to be used

not material slabs.

with stents of different French sizes.)

6.1.2 Use statistically valid sample sizes in all tests.

6.2.2.2 Maintain temperature in the water bath at 37 6 3°C

6.1.3 Package all stent test samples and sterilize once using

by whatever means is available to the test facility. Submerge

the method of sterilization intended to be used for product

the entire funnel block. Set the pull rate through the fixture at

when it is sold.

aconstant20in.(mm)/min.Cleanthetestbathandfixtureatthe

6.1.4 Expose test samples to artificial urine at 37 6 3° C for

beginning of each testing day. The capacity of the load cell

a period of 30 days. Use either of the two artificial urine

used with the tensile testing machine should not exceed 2 lb.

formulations listed in AnnexA1. In situations where testing in

6.2.3 Test Specimen Preparation—The test specimen shall

artificial urine is not practical, distilled water may be used.

consist of actual sterilized product. The specimen shall be cut

6.1.5 Maintain artificial urine pH in the range of 5.5 to 6.5

to allow a straight portion of the stent to be inserted upwards

at all times. Replace urine should be weekly.

through the funnel fixture into the grip of the tensile test

6.1.6 Performtestspriortoandaftersoakingforaminimum

machine without loading the retention mechanism of the stent

of 30 days. For products with intended chemical/mechanical

to be tested. Submerge the test specimen in the water bath for

changes such as softening, swelling, etc., do initial mechanical

at least 1 min to allow it to reach thermal equilibrium. If the

testing only after sufficient soaking time has elapsed that allow

material is significantly affected by moisture, allow the speci-

such chemical/mechanical changes to occur.

men to equilibrate for a minimum of 24 h. Use distilled water,

6.1.7 Dynamic frictional force test samples need only be

if possible.

soakedindistilledwaterfor1minpriortotesting.Thistestwill

not be repeated after 30 days.

NOTE 1—The portion of the stent held within the gripping mechanism

of the tensile testing machine cannot be used for additional testing due to

6.2 Retention Strength:

the potential destructive effects of the gripping mechanism.

6.2.1 Scope—This test method measured the ability of a

6.2.4 Test Procedure:

ureteral stent to resist migration. It can be used for testing the

proximal or distal ends of a ureteral stent. 6.2.4.1 Ensure test bath is at proper temperature and funnel

6.2.2 S

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.