ASTM D6483-99

(Test Method)Standard Test Method for Evaluation of Diesel Engine Oils in T-9 Diesel Engine

Standard Test Method for Evaluation of Diesel Engine Oils in T-9 Diesel Engine

SCOPE

1.1 This test method is commonly referred to as the Mack T-9. This test method covers an engine test procedure for evaluating diesel engine oils for performance characteristics, including lead corrosion and wear of piston rings and cylinder liners.

1.2 The values stated in either SI or inch-pound units are to be regarded separately as the standard. Within the test method, the inch-pound units are shown in parentheses when combined with SI units.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. See for specific safety precautions.

1.4 Table of ContentsScopeReferenced DocumentsTerminologySummary of Test MethodSignificance of UseApparatus General Description Test Engine Mack T-9 Test Engine Engine Cooling System Engine Oil System Auxiliary Oil System Blowby Meter Air Supply and Filtration Fuel Supply Intake Manifold Temperature ControlEngine Fluids Test Oil Test Fuel Engine Coolant Cleaning MaterialsPreparation of Apparatus at Rebuild Cleaning of Parts Valves, Seats, Guides, and Springs Cylinder Liner, Piston, and Piston Ring Assembly Injectors and Injection Pump Assembly Instructions Measurements System Time ResponsesProcedure Pretest Procedure Engine Start-Up Engine Shutdown Test CycleOil Addition/DrainOil SamplesOil Consumption CalculationsFuel SamplesPeriodic MeasurementsBlowbyCentrifugal Oil Filter Mass GainOil Filter P CalculationInspection of Engine, Fuel, and OilPre-Test MeasurementsPost-Test MeasurementsOil InspectionFuel InspectionsOil ConsumptionLaboratory and Engine Test Stand Calibration/Non-Reference RequirementsCalibration FrequencyCalibration Reference OilsTest NumberingNew Laboratories and New Test StandsTest Stand and Engine CalibrationTest ResultsReference and Non-Reference Oil Test RequirementsNon-Reference Oil Test Result Severity AdjustmentsReportReporting Reference Test ResultsDeviations from Test Operational LimitsElectronic Transmission of Test ResultsPrecision and BiasPrecisionBiasKeywordsAnnexesReport FormsSensor LocationsProcurement of Test MaterialsInstructions for Measuring T-9 Cylinder Sleeves Using the Taylor Hobson Form TalysurfSafety PrecautionsData DictionaryTBN Measurement Procedure for T-9 SamplesTAN Measurement Procedure for T-9 SamplesDetermination of Operational Validity

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

An American National Standard

Designation: D 6483 – 99

Standard Test Method for

Evaluation of Diesel Engine Oils in T-9 Diesel Engine

This standard is issued under the fixed designation D 6483; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope

Injectors and Injection Pump 8.4

Assembly Instructions 8.5

1.1 This test method is commonly referred to as the Mack

Measurements 8.6

T-9. This test method covers an engine test procedure for System Time Responses 8.7

Procedure 9

evaluating diesel engine oils for performance characteristics,

Pretest Procedure 9.1

including lead corrosion and wear of piston rings and cylinder

Engine Start-Up 9.2

liners.

Engine Shutdown 9.3

Test Cycle 9.4

1.2 The values stated in either SI or inch-pound units are to

Oil Addition/Drain 9.5

be regarded separately as the standard. Within the test method,

Oil Samples 9.6

the inch-pound units are shown in parentheses when combined

Oil Consumption Calculations 9.7

Fuel Samples 9.8

with SI units.

Periodic Measurements 9.9

1.3 This standard does not purport to address all of the

Blowby 9.10

safety concerns, if any, associated with its use. It is the Centrifugal Oil Filter Mass Gain 9.11

Oil Filter DP Calculation 9.12

responsibility of the user of this standard to establish appro-

Inspection of Engine, Fuel, and Oil 10

priate safety and health practices and determine the applica-

Pre-Test Measurements 10.1

bility of regulatory limitations prior to use. See Annex A5 for Post-Test Measurements 10.2

Oil Inspection 10.3

specific safety precautions.

Fuel Inspections 10.4

1.4 Table of Contents:

Oil Consumption 10.5

Lab and Engine Test Stand Calibration/Non-Ref Requirements 11

Scope 1

Calibration Frequency 11.1

Referenced Documents 2

Calibration Reference Oils 11.2

Terminology 3

Test Numbering 11.3

Summary of Test Method 4

New Laboratories and New Test Stands 11.4

Significance of Use 5

Test Stand and Engine Calibration 11.5

Apparatus 6

Test Results 11.6

General Description 6.1

Reference and Non-Reference Oil Test Requirements 11.7

Test Engine 6.2

Non-Reference Oil Test Result Severity Adjustments 11.8

Mack T-9 Test Engine 6.2.1

Report 12

Engine Cooling System 6.2.2

Reporting Reference Test Results 12.1.1

Engine Oil System 6.2.3

Deviations from Test Operational Limits 12.1.2

Auxiliary Oil System 6.2.4

Electronic Transmission of Test Results 12.1.3

Blowby Meter 6.2.5

Precision and Bias 13

Air Supply and Filtration 6.2.6

Precision 13.1

Fuel Supply 6.2.7

Bias 13.2

Intake Manifold Temperature Control 6.2.8

Keywords 14

Engine Fluids 7

Annexes

Test Oil 7.1

Report Forms Annex A1

Test Fuel 7.2

Sensor Locations Annex A2

Engine Coolant 7.3

Procurement of Test Materials Annex A3

Cleaning Materials 7.4

Instructions for Measuring T-9 Cylinder Sleeves Using the Taylor Annex A4

Preparation of Apparatus at Rebuild 8

Hobson Form Talysurf

Cleaning of Parts 8.1

Safety Precautions Annex A5

Valves, Seats, Guides, and Springs 8.2

Data Dictionary Annex A6

Cylinder Liner, Piston, and Piston Ring Assembly 8.3

TBN Measurement Procedure for T-9 Samples Annex A7

TAN Measurement Procedure for T-9 Samples Annex A8

Determination of Operational Validity Annex A9

This test method is under the jurisdiction of ASTM Committee D02 on

2. Referenced Documents

Petroleum Products and Lubricants and is the direct responsibility of Subcommittee

D02.B0 on Automotive Lubricants.

2.1 ASTM Standards:

Current edition approved Dec. 10, 1999. Published March 2000.

D 86 Test Method for Distillation of Petroleum Products

The ASTM Test Monitoring Center will update changes in this test method by

means of Information Letters. This edition includes all Information Letters through

99-1. Information Letters may be obtained from ASTM Test Monitoring Center,

6555 Penn Avenue, Pittsburgh, PA 15206-4489, Attention: Administrator. Annual Book of ASTM Standards, Vol 05.01.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

D6483–99

D 93 Test Methods for Flash Point by Pensky-Martens 2.2 SAE Standards:

Closed Tester

SAE J1995 Engine Power Test Code - Spark Ignition and

D 97 Test Method for Pour Point of Petroleum Products

Compression Ignition - Gross Power Rating

D 129 Test Method for Sulfur in Petroleum Products (Gen-

eral Bomb Method)

3. Terminology

D 130 Test Method for Detection of Copper Corrosion from

3.1 Definitions:

Petroleum Products by the Copper Strip Tarnish Test

3.1.1 blind reference oil, n—a reference oil, the identity of

D 287 Test Method for API Gravity of Crude Petroleum and

which is unknown by the test facility. D 5844

Petroleum Products (Hydrometer Method)

3.1.1.1 Discussion—This is a coded reference oil that is

D 445 Test Method for Kinematic Viscosity of Transparent

submitted by a source independent from the test facility.

and Opaque Liquids (the Calculation of Dynamic Viscos-

3 3.1.2 blowby, n—in internal combustion engines, the com-

ity)

bustion products and unburned air-and-fuel mixture that enter

D 482 Test Method for Ash from Petroleum Products

the crankcase. D 5302

D 524 Test Method for Ramsbottom Carbon Residue of

3 3.1.3 calibrate, v—to determine the indication or output of

Petroleum Products

3 a measuring device with respect to that of a standard. E 344

D 613 Test Method for Cetane Number of Diesel Fuel Oil

3.1.4 candidate oil, n—an oil that is intended to have the

D 664 Test Method for Acid Number of Petroleum Products

3 performance characteristics necessary to satisfy a specification

by Potentiometric Titration

and is intended to be tested against that specification.

D 1319 Test Method for Hydrocarbon Types in Liquid

3 D 5844

Petroleum Products by Fluorescent Indicator Absorbtion

3 3.1.5 heavy-duty, adj—in internal combustion engine opera-

D 2500 Test Method for Cloud Point of Petroleum Oils

tion, characterized by average speeds, power output, and

D 2622 Test Method for Sulfur in Petroleum Products by

3 internal temperatures that are close to the potential maximums.

X-Ray Spectrometry

D 4485

D 2709 Test Method for Water and Sediment in Middle

3.1.6 heavy-duty engine, n—in internal combustion engines,

Distillate Fuels by Centrifuge

one that is designed to allow operation continuously at or close

D 2896 Test Method for Base Number of Petroleum Prod-

3 to its peak output. D 4485

ucts by Potentiometric Perchloric Acid Titration

3.1.7 non-reference oil, n—any oil other than a reference

D 4052 Test Method for Density and Relative Density of

oil, such as a research formulation, commercial oil, or candi-

Liquids by Digital Density Meter

date oil. D 5844

D 4485 Specification for Performance of Engine Oils

3.1.8 non-standard test, n—a test that is not conducted in

D 4737 Test Method for Calculated Cetane Index by Four

conformance with the requirements in the standard test

Variable Equation

method, such as running on an uncalibrated test stand, using

D 4739 Test Method for Base Number Determination by

different test equipment, applying different equipment assem-

Potentiometric Titration

bly procedures, or using modified operating conditions.

D 5185 Test Method for Determination of Additive Ele-

D 5844

ments, Wear Metals, and Contaminants in Used Lubricat-

3.1.9 oxidation, n—of engine oil, the reaction of the oil with

ing Oils and Determination of Selected Elements in Base

an electron acceptor, generally oxygen, that can produce

Oils by Inductively Coupled Plasma Atomic Emission

deleterious acidic or resinous materials often manifested as

Spectrometry (ICP-AES)

sludge formation, varnish formation, viscosity increase, or

D 5302 Test Method for Evaluation of Automotive Engine

corrosion, or combination thereof. Sub. B Glossary

Oils for Inhibition of Deposit Formation and Wear in a

3.1.10 reference oil, n—an oil of known performance char-

Spark-Ignition Internal Combustion Engine Fueled with

acteristics, used as a basis for comparison. D 5844

Gasoline and Operated Under Low-Temperature, Light-

Duty Conditions 3.1.10.1 Discussion—Reference oils are used to calibrate

testing facilities, to compare the performance of other oils, or

D 5844 Test Method for Evaluation of Automotive Engine

Oils for Inhibition of Rusting (Sequence IID) to evaluate other materials (such as seals) that interact with

oils.

D 5967 Test Method for Evaluation of Diesel Engine Oils in

T-8 Diesel Engine 3.1.11 sludge, n—in internal combustion engines, a deposit,

principally composed of insoluble resins and oxidation prod-

E 29 Practice for Using Significant Digits in Test Data to

Determine Conformance with Specifications ucts from fuel combustion and lubricant, that does not drain

from engine parts but can be removed by wiping with a cloth.

E 178 Practice for Dealing With Outlying Observations

E 344 Terminology Relating to Thermometry and Hydro- D 5302

mometry

Available from Society of Automotive Engineers, 400 Commonwealth Drive,

Annual Book of ASTM Standards, Vol 05.02. Warrendale, PA 15096.

5 9

Annual Book of ASTM Standards, Vol 05.03. Available from the secretary of the ASTM D02.B0 Subcommittee: J. L.

Annual Book of ASTM Standards, Vol 14.02. Newcombe, Infineum USA, 26777 Central Park Blvd., Ste. 300, Southfield, MI

Annual Book of ASTM Standards, Vol 14.03. 48076-4172.

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

D6483–99

3.1.12 standard test, n—a test on a calibrated test stand, 4.5 The test stand is equipped with appropriate accessories

using the prescribed equipment in accordance with the require- for controlling speed, load, and various engine operating

ments in the test method, and conducted in accordance with the conditions.

specified operating conditions. D 5844

3.1.12.1 Discussion—The specified operating conditions in 5. Significance and Use

some test methods include requirements for determining a

5.1 This test method was developed to evaluate the wear

test’s operational validity. These requirements are applied after

performance of engine oils in turbocharged and intercooled

a test is completed and can include (1) mid-limit ranges for the

four-cycle diesel engines. Obtain results from used oil analysis

average values of primary and secondary parameters that are

and component measurements before and after test.

narrower than the specified control ranges for the individual

5.2 The test method may be used for engine oil specification

values,(2) allowable deviations for individual primary and

acceptance when all details of the procedure are followed.

secondary parameters for the specified control ranges, (3)

downtime limitations, and (4) special parameter limitations.

6. Apparatus

3.1.13 varnish, n—in internal combustion engines, a hard,

6.1 General Description:

dry, generally lustrous deposit that can be removed by solvents

but not by wiping with a cloth. D 5302 6.1.1 The test engine is a Mack E7-350 electronically

governed engine, P/N 11GBA78786 (see Annex A3). It is an

3.1.14 wear, n—the loss of material from, or relocation of

open-chamber, in-line, six-cylinder, four-stroke, turbocharged,

material on, a surface. D 5302

charge air-cooled, compression ignition engine. The bore and

3.1.14.1 Discussion—Wear generally occurs between two

7 1

stroke are 124 by 165 mm (4 ⁄8 by 6 ⁄2in.), and the

surfaces moving relative to each other and is the result of

displacement is 12 L (728 in. ). The engine is rated at 261 kW

mechanical or chemical action or by a combination of me-

(350 bhp) at 1800 r/min governed speed (see SAE J1995).

chanical and chemical action.

6.1.2 The ambient laboratory atmosphere should be rela-

4. Summary of Test Method tively free of dirt and other contaminants as required by good

laboratory standards. Additionally, it is recommended that the

4.1 The test operation involves use of a Mack E7-350

atmosphere in the engine buildup area be filtered and con-

V-MAC II diesel engine with a warm-up anda1h break-in,

trolled for temperature and humidity to prevent accumulation

followed by a two-phase test consisting of 75 h at 1800 r/min

of dirt and other contaminants on engine parts. Uniform

and 425 h at 1250 r/min, both at constant speed and load.

temperature control aids in measuring and selecting parts for

4.2 Oil samples are taken periodically and are analyzed for

assembly.

viscosity increase and wear metals content.

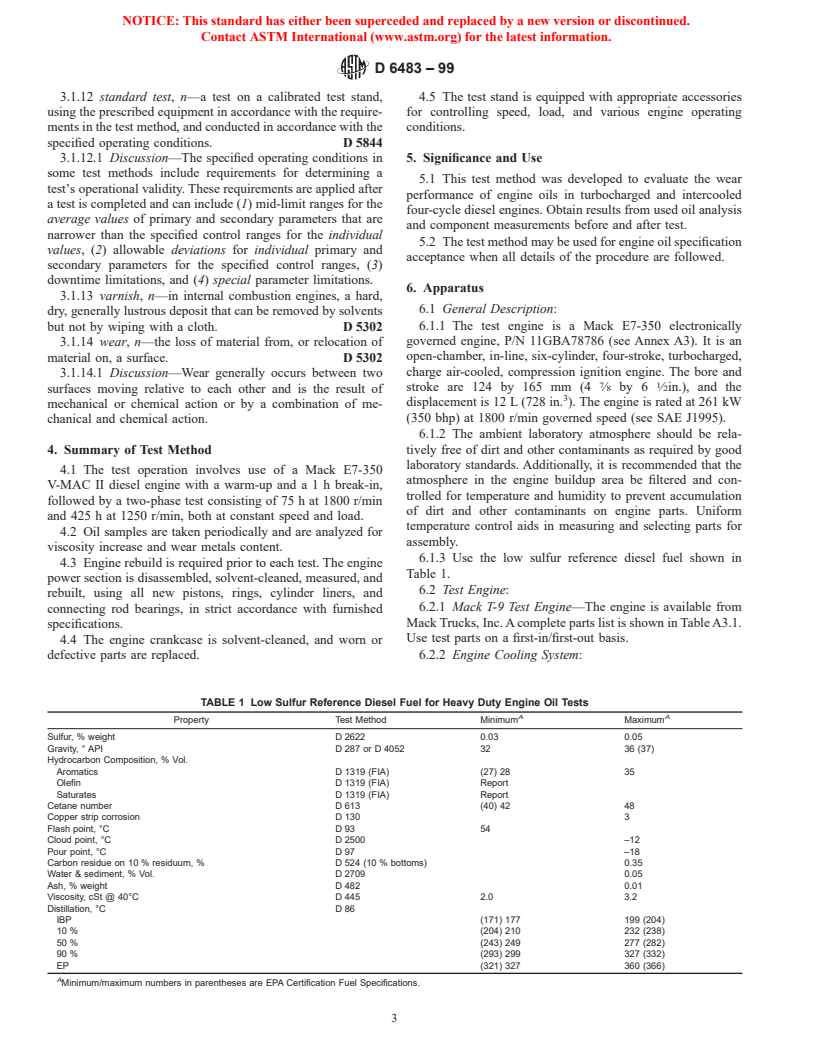

6.1.3 Use the low sulfur reference diesel fuel shown in

4.3 Engine rebuild is required prior to each test. The engine

Table 1.

power section is disassembled, solvent-cleaned, measured, and

6.2 Test Engine:

rebuilt, using all new pistons, rings, cylinder liners, and

6.2.1 Mack T-9 Test Engine—The engine is available from

connecting rod bearings, in strict accordance with furnished

specifications. Mack Trucks, Inc. A complete parts list is shown in Table A3.1.

Use test parts on a first-in/first-out basis.

4.4 The engine crankcase is solvent-cleaned, and worn or

defective parts are replaced. 6.2.2 Engine Cooling System:

TABLE 1 Low Sulfur Reference Diesel Fuel for Heavy Duty Engine Oil Tests

A A

Property Test Method Minimum Maximum

Sulfur, % weight D 2622 0.03 0.05

Gravity, ° API D 287 or D 4052 32 36 (37)

Hydrocarbon Composition, % Vol.

Aromatics D 1319 (FIA) (27) 28 35

Olefin D 1319 (FIA) Report

Saturates D 1319 (FIA) Report

Cetane number D 613 (40) 42 48

Copper strip corrosion D 130 3

Flash point, °C D 93 54

Cloud point, °C D 2500 –12

Pour point, °C D 97 –18

Carbon residue on 10 % residuum, % D 524 (10 % bottoms) 0.35

Water & sediment, % Vol. D 2709 0.05

Ash, % weight D 482 0.01

Viscosity, cSt @ 40°C D 445 2.0 3.2

Distillation, °C D 86

IBP (171) 177 199 (204)

10 % (204) 210 232 (238)

50 % (243) 249 277 (282)

90 % (293) 299 327 (332)

EP (321) 327 360 (366)

A

Minimum/maximum numbers in parentheses are EPA Certification Fuel Specifications.

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

D6483–99

6.2.2.1 Use a new Mack coolant conditioner shown in Table use antifreeze solutions). It is permissible to use Pencool

A3.1, every test, to limit scaling in the cooling system. 3000 coolant additive at the manufactu

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.