ASTM D6483-03

(Test Method)Standard Test Method for Evaluation of Diesel Engine Oils in T-9 Diesel Engine

Standard Test Method for Evaluation of Diesel Engine Oils in T-9 Diesel Engine

SCOPE

1.1 This test method covers an engine test procedure for evaluating diesel engine oils for performance characteristics, including lead corrosion and wear of piston rings and cylinder liners. This test method is commonly referred to as the Mack T-9.

1.2 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. See Annex A5 for specific safety precautions.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

An American National Standard

Designation:D6483–03

Standard Test Method for

1

Evaluation of Diesel Engine Oils in T-9 Diesel Engine

This standard is issued under the fixed designation D 6483; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope

Preparation of Apparatus at Rebuild 8

Cleaning of Parts 8.1

1.1 This test method covers an engine test procedure for

Valves, Seats, Guides, and Springs 8.2

evaluating diesel engine oils for performance characteristics,

Cylinder Liner, Piston, and Piston Ring Assembly 8.3

Injectors and Injection Pump 8.4

including lead corrosion and wear of piston rings and cylinder

Assembly Instructions 8.5

2

liners. This test method is commonly referred to as the Mack

Measurements 8.6

T-9.

System Time Responses 8.7

Procedure 9

1.2 The values stated in SI units are to be regarded as the

Pretest Procedure 9.1

standard. The values given in parentheses are for information

Engine Start-Up 9.2

only. Engine Shutdown 9.3

Test Cycle 9.4

1.3 This standard does not purport to address all of the

Oil Addition/Drain 9.5

safety concerns, if any, associated with its use. It is the

Oil Samples 9.6

responsibility of the user of this standard to establish appro- Oil Consumption Calculations 9.7

Fuel Samples 9.8

priate safety and health practices and determine the applica-

Periodic Measurements 9.9

bility of regulatory limitations prior to use. See Annex A5 for

Blowby 9.10

specific safety precautions. Centrifugal Oil Filter Mass Gain 9.11

Oil Filter DP Calculation 9.12

1.4 Table of Contents:

Inspection of Engine, Fuel, and Oil 10

Scope 1

Pre-Test Measurements 10.1

Referenced Documents 2

Post-Test Measurements 10.2

Terminology 3

Oil Inspection 10.3

Summary of Test Method 4

Fuel Inspections 10.4

Significance of Use 5

Oil Consumption 10.5

Apparatus 6

Lab and Engine Test Stand Calibration/Non-Ref Requirements 11

General Description 6.1

Calibration Frequency 11.1

Test Engine 6.2

Calibration Reference Oils 11.2

Mack T-9 Test Engine 6.2.1

Test Numbering 11.3

Engine Cooling System 6.2.2

New Laboratories and New Test Stands 11.4

Engine Oil System 6.2.3

Test Stand and Engine Calibration 11.5

Auxiliary Oil System 6.2.4

Test Results 11.6

Blowby Meter 6.2.5

Reference and Non-Reference Oil Test Requirements 11.7

Air Supply and Filtration 6.2.6

Non-Reference Oil Test Result Severity Adjustments 11.8

Fuel Supply 6.2.7

Report 12

Intake Manifold Temperature Control 6.2.8

Reporting Reference Test Results 12.1.1

Engine Fluids 7

Deviations from Test Operational Limits 12.1.2

Test Oil 7.1

Electronic Transmission of Test Results 12.1.3

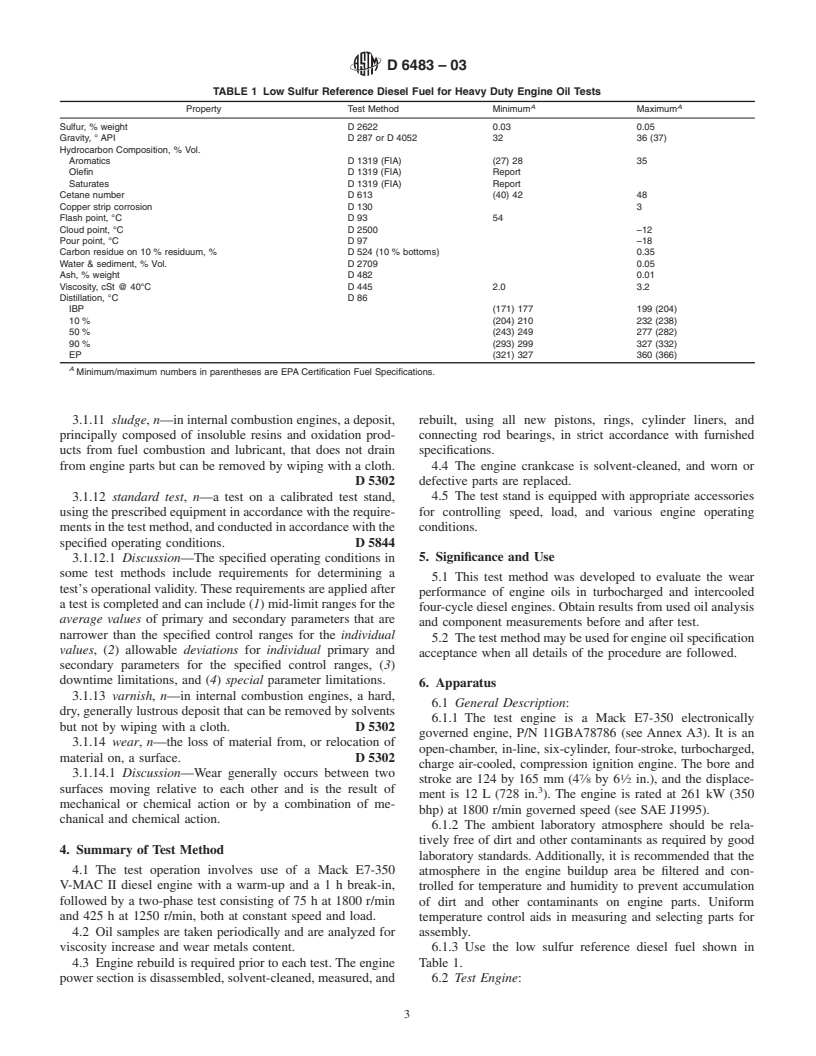

Test Fuel 7.2

Precision and Bias 13

Engine Coolant 7.3

Precision 13.1

Cleaning Materials 7.4

Bias 13.2

Keywords 14

Annexes

Report Forms Annex A1

1

This test method is under the jurisdiction of ASTM Committee D02 on

Sensor Locations Annex A2

Petroleum Products and Lubricants and is the direct responsibility of Subcommittee

Procurement of Test Materials Annex A3

D02.B0 on Automotive Lubricants.

Instructions for Measuring T-9 Cylinder Sleeves Using the Taylor Annex A4

Current edition approved May 10, 2003. Published July 2003. Originally Hobson Form Talysurf

approved in 1999. Last previous edition approved in 1999 as D 6483–99. Safety Precautions Annex A5

2

TheASTM Test Monitoring Center will update changes in this test method by Data Dictionary Annex A6

TBN Measurement Procedure for T-9 Samples Annex A7

means of Information Letters. This edition includes all Information Letters through

TAN Measurement Procedure for T-9 Samples Annex A8

02-1. Information Letters may be obtained from ASTM Test Monitoring Center,

6555 Penn Avenue, Pittsburgh, PA 15206-4489, Attention: Administrator.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

D6483–03

D 5967 TestMethodforEvaluationofDieselEngineOilsin

Determination of Operational Validity Annex A9

T-8 Diesel Engine

2. Referenced Documents

E 29 Practice for Using Significant Digits in Test Data to

3

Determine Conformance with Specifications

2.1 ASTM Standards:

E 178 Practice for Dealing With Outlying Observations

D 86 Test Method for Distillation of Petroleum Products at

E 344 Terminology Relating to Thermometry and Hydro-

Atmospheric Pressure

mometry

D 93 Test Methods for Flash Point by Pensky-Martens

5

2.2 SAE Standards:

Closed Cup Tester

SAE J1995 Engine Power Test Code - Spark Ignition and

D 97 Test Method for Pour Point of Petroleum Products

Compression Ignition - Gross Power Rating

D 129 Test Method for Sulfur in Petrole

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.