ASTM D5267-97(2005)

(Test Method)Standard Test Method for Determination of Extrudability of Cartridge Adhesives

Standard Test Method for Determination of Extrudability of Cartridge Adhesives

SIGNIFICANCE AND USE

Cartridge adhesives are typically used at job sites in a wide variety of temperature ranges. These products may be exposed to cold temperatures, where one of the limiting application factors is whether the product can be extruded from the cartridge.

The test method quantitatively measures the force necessary to extrude a cartridge adhesive at a given temperature. This provides the formulator with results that can assist in formulation development and the end user with information for use in selecting a product for general usage.

By measuring (the ease of) extrusion from the cartridge, the test method can also be used as a quality control tool to measure the shelf life stability of a product.

SCOPE

1.1 This test method covers a means of measuring the amount of force necessary to extrude an adhesive from a cartridge at a given temperature.

1.2 The values stated in inch-pound units are to be regarded as the standard. The values given in parentheses are for information only.

1.3 This standard does not purport to address all of the safety problems, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D5267–97(Reapproved2005)

Standard Test Method for

Determination of Extrudability of Cartridge Adhesives

This standard is issued under the fixed designation D5267; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 3. Terminology

1.1 This test method measures the amount of force neces- 3.1 Definitions—Many terms in this test method are defined

sary to extrude an adhesive from a cartridge at a given in Terminology D907.

temperature.

4. Significance and Use

1.2 The values stated in inch-pound units are to be regarded

as the standard. The values given in parentheses are for 4.1 Cartridge adhesives are typically used at job sites in a

wide variety of temperature ranges. These products may be

information only.

1.3 This standard does not purport to address all of the exposed to cold temperatures, where one of the limiting

application factors is whether the product can be extruded from

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro- the cartridge.

4.2 The test method quantitatively measures the force nec-

priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use. essary to extrude a cartridge adhesive at a given temperature.

This provides the formulator with results that can assist in

2. Referenced Documents

formulation development and the end user with information for

2.1 ASTM Standards: use in selecting a product for general usage.

D907 Terminology of Adhesives 4.3 By measuring (the ease of) extrusion from the cartridge,

the test method can also be used as a quality control tool to

measure the shelf life stability of a product.

This test method is under the jurisdiction of ASTM Committee D14 on

Adhesives and is the direct responsibility of Subcommittee D14.10 on Working

5. Apparatus

Properties.

Current edition approved Oct. 1, 2005. Published November 2005. Originally

5.1 The test fixture is shown in Fig. 1. Details are shown in

approved in 1992. Last previous edition approved in 1997 as D5267 – 97. DOI:

10.1520/D5267-97R05.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

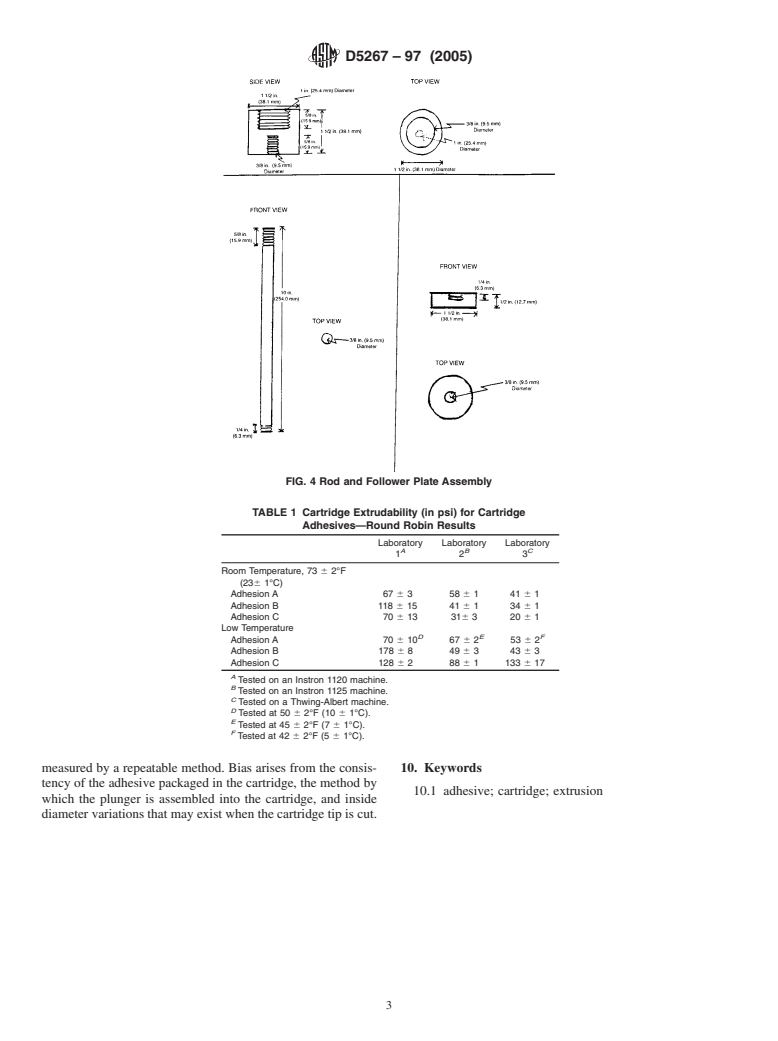

D5267–97 (2005)

FIG. 3 Cartridge Brace and Rear Support Assembly

FIG. 2 Base Support for Test Fixture

second value is the force needed to extrude the adhesive from

Figs. 2-4. Make the framework from aluminum. Make the rod

the cartridge continuously.

and plunger combination from steel.

5.2 The test fixture is designed to be fitted onto a test

8. Report

machine capable of measuring compressive strength.

8.1 Report the following information:

6. Conditioning 8.1.1 Complete identification of the adhesive, including

type, source, date of test, etc.

6.1 Before measuring extrudability, condition the cartridge

8.1.2 Complete identification of the cartridge, including

filled with adhesive until it reaches the desired constant

type, composition, liner used, plunger design, source, size, etc.

temperature.

8.1.3 Temperature of adhesive.

8.1.4 Crosshead speed used for extrusion.

7. Procedure

8.1.5 Force (in psi) used initially to extrude the adhesive

7.1 Mount the test fixture to the test machine for stability.

from the cartridge and the average to maintain a constant flow

7.2 After conditi

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.