ASTM B880-14(2019)

(Specification)Standard Specification for General Requirements for Chemical Check Analysis Limits for Nickel, Nickel Alloys and Cobalt Alloys

Standard Specification for General Requirements for Chemical Check Analysis Limits for Nickel, Nickel Alloys and Cobalt Alloys

ABSTRACT

This specification details the limits of variation for determining the chemical check analysis limits of cast or wrought nickel, nickel alloy and cobalt alloy parts and/or supplied material.

SCOPE

1.1 This specification covers limits of variation for determining acceptability of the chemical composition of cast or wrought nickel, nickel alloy, and cobalt alloy parts and/or material supplied by a producer. Check analysis limits for elements or for ranges of elements not currently listed herein shall be as specified in the applicable material specification or as agreed upon by purchaser and supplier.

1.2 In case of any conflicting requirements, the requirements of the purchase order, the individual material specification, and this general specification shall prevail in the sequence named.

1.3 When specifically referenced in the material specification, the buyer may elect to apply check analysis limits to determine acceptability at his final acceptance or verification procedures. Check analysis limits are not permitted or are to be used by the producer for their own ladle or ingot analysis acceptance testing.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation:B880 −14 (Reapproved 2019)

Standard Specification for

General Requirements for Chemical Check Analysis Limits

for Nickel, Nickel Alloys and Cobalt Alloys

This standard is issued under the fixed designation B880; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope E55 Practice for Sampling Wrought Nonferrous Metals and

Alloys for Determination of Chemical Composition

1.1 This specification covers limits of variation for deter-

E88 Practice for Sampling Nonferrous Metals and Alloys in

mining acceptability of the chemical composition of cast or

Cast Form for Determination of Chemical Composition

wrought nickel, nickel alloy, and cobalt alloy parts and/or

E1473 Test Methods for Chemical Analysis of Nickel, Co-

material supplied by a producer. Check analysis limits for

balt and High-Temperature Alloys

elements or for ranges of elements not currently listed herein

shall be as specified in the applicable material specification or 2.2 SAE Standards:

as agreed upon by purchaser and supplier. AMS 2269 Chemical Check Analysis Limits Nickel, Nickel

Alloys and Cobalt Alloys

1.2 In case of any conflicting requirements, the require-

ments of the purchase order, the individual material

3. Terminology

specification, and this general specification shall prevail in the

sequence named.

3.1 Definitions:

3.1.1 check (product or verification) analysis, n—analysis

1.3 When specifically referenced in the material

made by buyer of parts and materials to verify conformity to

specification, the buyer may elect to apply check analysis

specification, or to determine variations in compositions within

limits to determine acceptability at his final acceptance or

a heat or lot.

verification procedures. Check analysis limits are not permitted

3.1.1.1 Discussion—Heat or lot acceptance or rejection of

or are to be used by the producer for their own ladle or ingot

parts and materials may be made by applying check limits as

analysis acceptance testing.

described in 3.1.2. Check limits of finished parts or material do

1.4 This standard does not purport to address all of the

not apply to elements whose percentage can be varied by

safety concerns, if any, associated with its use. It is the

fabricating techniques employed unless the sample is taken in

responsibility of the user of this standard to establish appro-

such a manner as to exclude such variations.

priate safety, health, and environmental practices and deter-

mine the applicability of regulatory limitations prior to use. 3.1.2 variation limit, under minimum or over maximum,

n—it is the amount of variation for a specified element, which

1.5 This international standard was developed in accor-

dance with internationally recognized principles on standard- may vary either under or over the specified composition limit

during an individual check analysis.

ization established in the Decision on Principles for the

Development of International Standards, Guides and Recom-

3.1.2.1 Discussion—In no case shall the reported determi-

mendations issued by the World Trade Organization Technical nations of any element in a heat, using the same analytical

Barriers to Trade (TBT) Committee.

procedure, vary both above and below the specified range.

3.1.3 remainder or balance, n—refers to main element,

2. Referenced Documents

which forms the basis of that particular alloy and from which

2.1 ASTM Standards:

the alloy is made.

3.1.3.1 Discussion—It is assumed to be present in an

amount approximately equal to the difference between 100 %

This specification is under the jurisdiction of Committee B02 on Nonferrous

Metals and Alloys and is the direct responsibility of Subcommittee B02.07 on

and the sum percentage of the alloying elements and listed

Refined Nickel and Cobalt and Their Alloys.

impurities or residual elements. It need not be analyzed or need

Current edition approved April 1, 2019. Published May 2019. Originally

an actual percentage figure for reporting purposes.

approved in 1998. Last previous edition approved in 2014 as B880 – 14. DOI:

10.1520/B0880-14R19.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on Available from SAE International (SAE), 400 Commonwealth Dr.,Warrendale,

the ASTM website. PA 15096, http://www.sae.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

B880−14 (2019)

3.1.4 residual elements, n—specified or unspecified 3.1.5.1 Discussion—It is not the intention of 3.1.5 that an

elements, not intentionally added, which may be present, due analysis is required for any unspecified element.

to their presence in starting raw materials or manufacturing

3.1.5.2 Discussion—A chemical analysis for the remainder

processes.

or balance element is not required. The manufacturer is

3.1.4.1 Discussion—Producers will not normally analyze

permitted to report the analysis of the element as “balance” or

for such elements, unless specifically asked for in the specifi-

“remainder” and need not report the result of the actual

cation or purchase order.

arithmetic calculation, unless requested by the purchaser in the

3.1.4.2 Discussion—Reporting analyses of unspecified ele-

purchase order.

ments is permitted.

4. Technical Requirements

3.1.5 remainder or balance, n—the element comprising the

major portion of an alloy’s composition, determined by sub-

4.1 Analytical Procedures—Refereeanalysisshallbebyany

tracting the sum of the amounts of all analyzed elements

method acceptable to purchaser and vendor.

(specifiedelements,andwhenmeasured,unspecifiedelements)

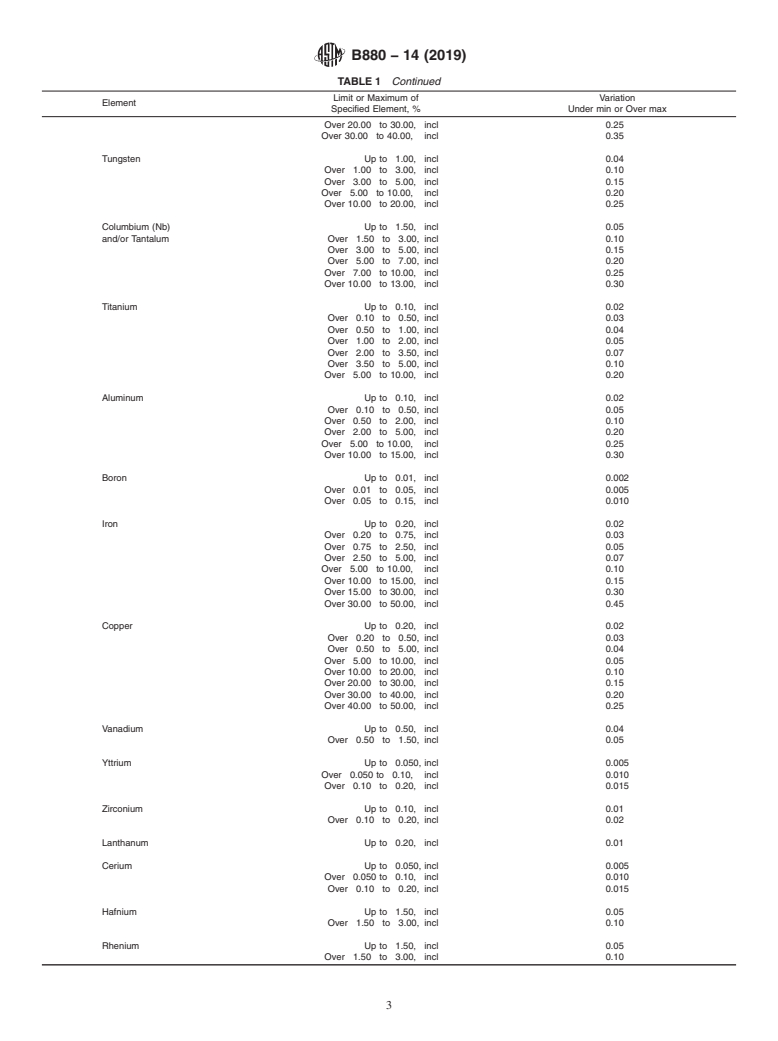

4.2 Check Analysis Limits—Shall be as shown in Table 1.

from 100 %.

TABLE 1 Check Analys

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.