ASTM F1249-90(1995)

(Test Method)Standard Test Method for Water Vapor Transmission Rate Through Plastic Film and Sheeting Using a Modulated Infrared Sensor

Standard Test Method for Water Vapor Transmission Rate Through Plastic Film and Sheeting Using a Modulated Infrared Sensor

SCOPE

1.1 This test method covers a procedure for determining the rate of water vapor transmission through flexible barrier materials. The method is applicable to sheets and films up to 3 mm (0.1 in.) in thickness, consisting of single or multilayer synthetic or natural polymers and foils, including coated materials. It provides for the determination of (1 ) water vapor transmission rate (WVTR), (2) the permeance of the film to water vapor, and (3) for homogeneous materials, water vapor permeability coefficient.

Note 1—Values for water vapor permeance and water vapor permeability must be used with caution. The inverse relationship of WVTR to thickness and the direct relationship of WVTR to the partial pressure differential of water vapor may not always apply.

1.2 This standard does not purport to address all of the safety problems, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn. Contact ASTM

International (www.astm.org) for the latest information.

Designation:F1249–90(Reapproved 1995)

Standard Test Method for

Water Vapor Transmission Rate Through Plastic Film and

Sheeting Using a Modulated Infrared Sensor

This standard is issued under the fixed designation F 1249; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope by Means of Aqueous Solutions

1.1 This test method covers a procedure for determining the

3. Terminology

rate of water vapor transmission through flexible barrier

3.1 Definitions:

materials. The method is applicable to sheets and films up to 3

3.1.1 water vapor permeability coeffıcient—the product of

mm (0.1 in.) in thickness, consisting of single or multilayer

the permeance and the thickness of the film. The permeability

synthetic or natural polymers and foils, including coated

is meaningful only for homogeneous materials, in which case

materials. It provides for the determination of (1) water vapor

it is a property characteristic of bulk material.

transmission rate (WVTR), (2) the permeance of the film to

3.1.1.1 Discussion—Thisquantityshouldnotbeusedunless

water vapor, and (3) for homogeneous materials, water vapor

the relationship between thickness and permeance has been

permeability coefficient.

verified in tests using several thicknesses of the material. An

NOTE 1—Values for water vapor permeance and water vapor perme-

accepted unit of permeability is the metric perm centimeter, or

ability must be used with caution. The inverse relationship of WVTR to 2

1 g/m per day per mm Hg·cm of thickness. The SI unit is the

thickness and the direct relationship of WVTR to the partial pressure

mol/m ·s·Pa·mm. The test conditions (see 3.1) must be stated.

differential of water vapor may not always apply.

3.1.2 water vapor permeance—the ratio of a barrier’s

1.2 This standard does not purport to address all of the

WVTR to the vapor pressure difference between the two

safety concerns, if any, associated with its use. It is the

surfaces.

responsibility of the user of this standard to establish appro-

3.1.2.1 Discussion—An accepted unit of permeance is the

priate safety and health practices and determine the applica- 2

metric perm, or 1 g/m per day per mm Hg. The SI unit is the

bility of regulatory limitations prior to use.

mol/m ·s·Pa. Since the permeance of a specimen is generally a

function of relative humidity and temperature, the test condi-

2. Referenced Documents

tions must be stated.

2.1 ASTM Standards:

3.1.3 water vapor transmission rate (WVTR)—the time rate

D 374 Test Methods for Thickness of Solid Electrical Insu-

of water vapor flow normal to the surfaces, under steady-state

lation

conditions, per unit area.

D 1898 Practice for Sampling of Plastics 2

3.1.3.1 Discussion—An accepted unit ofWVTR is g/m per

D 4204 Practice for Preparing Plastic Film Specimens for a

day. The test conditions of relative humidity and temperature

Round-Robin Study

where the humidity is the difference in relative humidity across

E96 Test Methods for Water Vapor Transmission of Mate-

the specimens, must be stated.

rials

E 104 Practice for Maintaining Constant Relative Humidity

4. Summary of Test Method

4.1 A dry chamber is separated from a wet chamber of

known temperature and humidity by the barrier material to be

This test method is under the jurisdiction ofASTM Committee F-2 on Flexible

tested. The dry chamber and the wet chamber make up a

Barrier Materials and is the direct responsibility of Subcommittee F02.30 on Test

Methods. diffusion cell in which the test film is sealed. The diffusion cell

Current edition approved July 27, 1990. Published September 1990. Originally

is placed in a test station where the dry chamber and the top of

published as F 1249 – 89. Last previous edition F 1249 – 89.

the film are swept with dry air. Water vapor diffusing through

Annual Book of ASTM Standards, Vol 10.01.

Annual Book of ASTM Standards, Vol 08.01.

Annual Book of ASTM Standards, Vol 08.02.

5 6

Annual Book of ASTM Standards, Vol 04.06. Annual Book of ASTM Standards, Vol 11.03.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn. Contact ASTM

International (www.astm.org) for the latest information.

F1249–90 (1995)

6.1.1.1 Diffusion Cell O–Ring—An appropriately-sized

groove machined into the humid chamber side of the diffusion

cellretainsaneopreneO–ring.Thetestareaisconsideredtobe

the area established by the inside contact diameter of the

compressed O–ring when the diffusion cell is clamped shut

against the test specimen.

6.1.1.2 Diffusion Cell Sealing Surface, a flat rim around the

dry side of the diffusion cell. This is a critical sealing surface

against which the test specimen is pressed; it shall be smooth

and without radial scratches.

6.1.1.3 Diffusion Cell Air Passages, two holes in the dry

half of the diffusion cell. These shall incorporate O–rings

suitable for sealing the diffusion cell to the test chamber

pneumatic fittings for the introduction and exhaust of air

without significant loss or leakage.

NOTE 2—Use of Multiple Diffusion Cells—Experience has shown that

arrangements using multiple diffusion cells are a practical way to increase

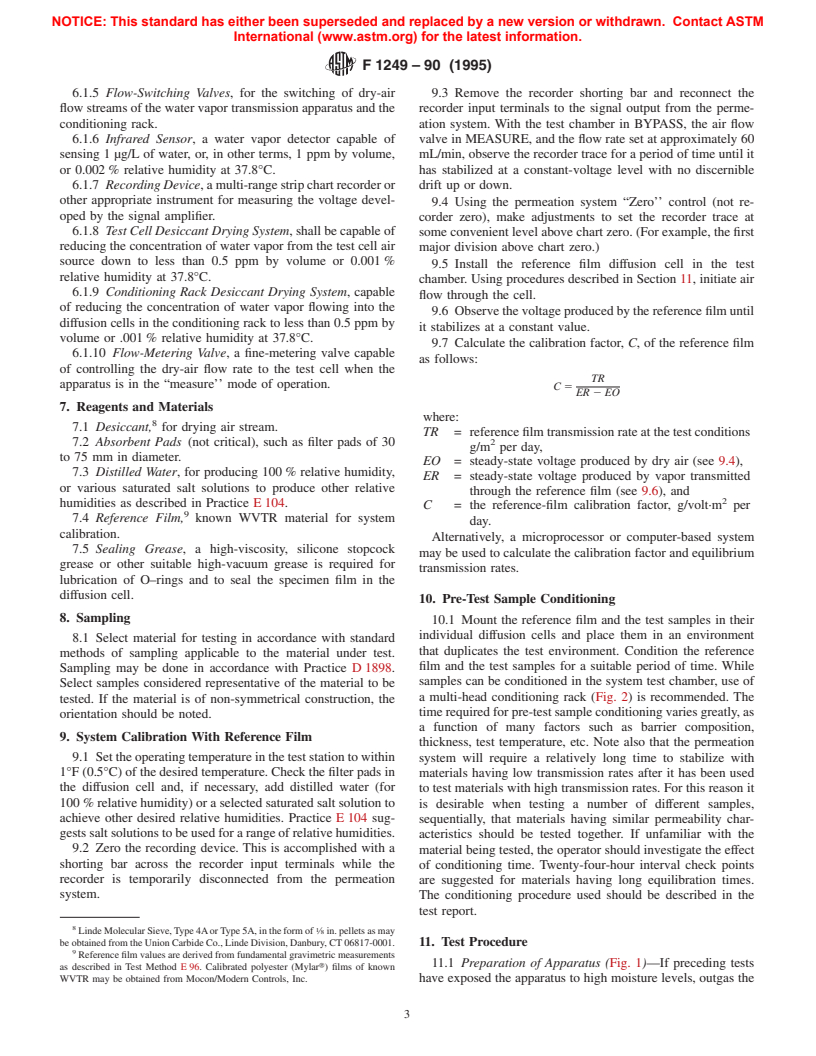

FIG. 1 Measuring System

the number of measurements which can be obtained in a given time. A

separateconditioningrack(Fig.2)containsamanifoldwhichconnectsthe

dry-chamber side of each individual diffusion cell to a dry-air source. Dry

airiscontinuallypurgingthedrychamberofthosecellsthatareconnected

the film mixes with the air and is carried into a pressure-

to the conditioning rack while the humid chamber side is held at a specific

modulatedinfraredsensor.Thissensormeasuresthefractionof

relative humidity by distilled water or a saturated-salt solution. It is

infrared energy absorbed by the water vapor and produces an

desirable to thermostatically control the temperature of the conditioning

electrical signal, the amplitude of which is proportional to

rack as described in 6.1.3.

water vapor concentration. The amplitude of the electrical

6.1.2 Test Chamber, a cavity into which the diffusion cell is

signal produced by the test film is then compared to the signal

inserted. The test chamber shall incorporate means for clamp-

produced by measurement of a calibration film of known

ing the diffusion cell in accurate registration with pneumatic

transmission rate.This information is then used to calculate the

system openings to the dry-air source and the infrared detector.

rateatwhichmoistureistransmittedthroughthematerialbeing

The chamber shall also provide a thermometer well for the

tested.

measurement of temperature.

6.1.3 Test Station Temperature Control—It is desirable to

5. Significance and Use

thermostatically control the temperature of the test station. A

5.1 The purpose of this test method is to obtain reliable

simple resistive heater attached to the station in such a manner

values for the WVTR of barrier materials.

as to ensure good thermal contact is adequate for this purpose.

5.2 WVTR is an important property of packaging materials

A thermistor sensor and an appropriate control circuit will

and can be directly related to shelf life and packaged product

serve to regulate the temperature unless measurements are

stability.

beingmadeclosetoambienttemperature.Inthatcaseitmaybe

5.3 Data from this test method is suitable as a referee

necessary to provide cooling coils to remove some of the heat.

method of testing, provided that the purchaser and seller have

6.1.4 Flowmeter—A means for regulating the flow of dry

agreed on sampling procedures, standardization procedures,

air within an operating range of 5 to 100 cc/min is required.

test conditions, and acceptance criteria.

6. Apparatus

6.1 This method utilizes water vapor transmission appara-

tus (Fig. 1) comprised of the following:

6.1.1 Diffusion Cell, an assembly consisting of two metal

halves which, when closed upon the test specimen, will

accurately define a circular area.Atypical acceptable diffusion

cell area is 50 cm . The volume enclosed by each cell half,

when clamped, is not critical; it should be small enough to

allow for rapid gas exchange, but not so small that an

unsupported film which happens to sag or buckle will contact

the top or bottom of the cell. A depth of approximately 6 mm

(0.250 in.) has been found to be satisfactory for 50-cm cells.

Suitable apparatus can be obtained from Mocon/Modern Controls, Inc., 6820

Shingle Creek Parkway, Minneapolis, MN 55430. FIG. 2 Conditioning System

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn. Contact ASTM

International (www.astm.org) for the latest information.

F1249–90 (1995)

6.1.5 Flow-Switching Valves, for the switching of dry-air 9.3 Remove the recorder shorting bar and reconnect the

flow streams of the water vapor transmission apparatus and the recorder input terminals to the signal output from the perme-

conditioning rack. ation system. With the test chamber in BYPASS, the air flow

6.1.6 Infrared Sensor, a water vapor detector capable of valve in MEASURE, and the flow rate set at approximately 60

sensing 1 µg/L of water, or, in other terms, 1 ppm by volume, mL/min, observe the recorder trace for a period of time until it

or 0.002 % relative humidity at 37.8°C. has stabilized at a constant-voltage level with no discernible

6.1.7 Recording Device,amulti-rangestripchartrecorderor drift up or down.

other appropriate instrument for measuring the voltage devel-

9.4 Using the permeation system “Zero’’ control (not re-

oped by the signal amplifier.

corder zero), make adjustments to set the recorder trace at

6.1.8 Test Cell Desiccant Drying System, shall be capable of

some convenient level above chart zero. (For example, the first

reducing the concentration of water vapor from the test cell air

major division above chart zero.)

source down to less than 0.5 ppm by volume or 0.001 %

9.5 Install the reference film diffusion cell in the test

relative humidity at 37.8°C.

chamber. Using procedures described in Section 11, initiate air

6.1.9 Conditioning Rack Desiccant Drying System, capable

flow through the cell.

of reducing the concentration of water vapor flowing into the

9.6 Observe the voltage produced by the reference film until

diffusion cells in the conditioning rack to less than 0.5 ppm by

it stabilizes at a constant value.

volume or .001 % relative humidity at 37.8°C.

9.7 Calculate the calibration factor, C, of the reference film

6.1.10 Flow-Metering Valve, a fine-metering valve capable

as follows:

of controlling the dry-air flow rate to the test cell when the

TR

apparatus is in the “measure’’ mode of operation.

C 5

ER 2 EO

7. Reagents and Materials

where:

7.1 Desiccant, for drying air stream.

TR = reference film transmission rate at the test conditions

7.2 Absorbent Pads (not critical), such as filter pads of 30 2

g/m per day,

to 75 mm in diameter.

EO = steady-state voltage produced by dry air (see 9.4),

7.3 Distilled Water, for producing 100 % relative humidity,

ER = steady-state voltage produced by vapor transmitted

or various saturated salt solutions to produce other relative

through the reference film (see 9.6), and

humidities as described in Practice E 104.

C = the reference-film calibration factor, g/volt·m per

7.4 Reference Film, known WVTR material for system

day.

calibration.

Alternatively, a microprocessor or computer-based system

7.5 Sealing Grease, a high-viscosity, silicone stopcock

may be used to calculate the calibration factor and equilibrium

grease or other suitable high-vacuum grease is required for

transmission rates.

lubrication of O–rings and to seal the specimen film in the

diffusion cell.

10. Pre-Test Sample Conditioning

8. Sampling

10.1 Mount the reference film and the test samples in their

individual diffusion cells and place them in an environment

8.1 Select material for testing in accordance with standard

that duplicates the test environment. Condition the reference

methods of sampling applicable to the material under test.

film and the test samples for a suitable period of time. While

Sampling may be done in accordance with Practice D 1898.

samples can be conditioned in the system test chamber, use of

Select samples considered representative of the material to be

a multi-head conditioning rack (Fig. 2) is recommended. The

tested. If the material is of non-symmetrical construction, the

timerequiredforpre-testsampleconditioningvariesgreatly,as

orientation should be noted.

a function of many factors such as barrier composition,

9. System Calibration With Reference Film

thickness, test temperature, etc. Note also that the permeation

9.1 Settheoperatingtemperatureintheteststationtowithin

system will require a relatively long time to stabilize with

1°F (0.5°C) of the desired temperature. Check the filter pads in

materials having low transmission rates after it has been used

the diffusion cell and, if necessary, add distilled water (for

to test materials with high transmission rates. For this reason it

100 % relative humidity) or a selected saturated salt solution to

is desirable when testing a number of different samples,

achieve other desired relative humidities. Practice E 104 sug-

sequentially, that materials having similar permeability char-

gestssaltsolutionstobeusedforarangeofrelativehumidities.

acteristics should be tested together. If unfamiliar with the

9.2 Zero the recording device. This is accomplished with a

material being tested, the operator should investigate the effect

shorting bar across the recorder input terminals while the

of conditioning time. Twenty-four-hour interval check points

recorder is temporarily disconnected from the permeation

are suggested for materials having long equilibration times.

system.

The conditioning procedure used should be described in the

test report.

LindeMolecularSieve,Type4AorType5A,intheformof ⁄8in.pelletsasmay

be obtained from the Union Carbide Co., Linde Division, Danbury, CT06817-0001. 11. Test Procedure

Reference film values are derived from fundamental gravimetric measurements

11.1 Preparation of Apparatus (Fig. 1)—If preceding tests

as described in Test Method E96. Calibrated polyester (Mylart) films of known

WVTR may be obtained from Mocon/Modern Controls, Inc. have exposed the apparatus to high moisture levels, outgas the

NOTICE: This standard has either been supersed

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.