ASTM B752-06(2011)e2

(Specification)Standard Specification for Castings, Zirconium-Base, Corrosion Resistant, for General Application

Standard Specification for Castings, Zirconium-Base, Corrosion Resistant, for General Application

ABSTRACT

This specification covers zirconium and zirconium-alloy castings for general corrosion-resistant and industrial applications. Material for this specification shall be melted by conventional processes used for reactive metals. Typical methods include the consumable electrode and inductoslag melting processes. The material shall conform to the required chemical composition for zirconium, hafnium, iron, chromium, hydrogen, nitrogen, carbon, oxygen, phosphorus, tin, and niobium. Product analysis and heat treatment shall be performed on the material, and shall conform within the specified check analysis tolerances.

SCOPE

1.1 This specification covers zirconium and zirconium-alloy castings for general corrosion-resistant and industrial applications.

1.2 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

´2

Designation:B752 −06(Reapproved 2011)

Standard Specification for

Castings, Zirconium-Base, Corrosion Resistant, for General

Application

This standard is issued under the fixed designation B752; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

´ NOTE—Method E 142 was removed editorially from Section 2 and X1.1.2 was corrected in April 2011.

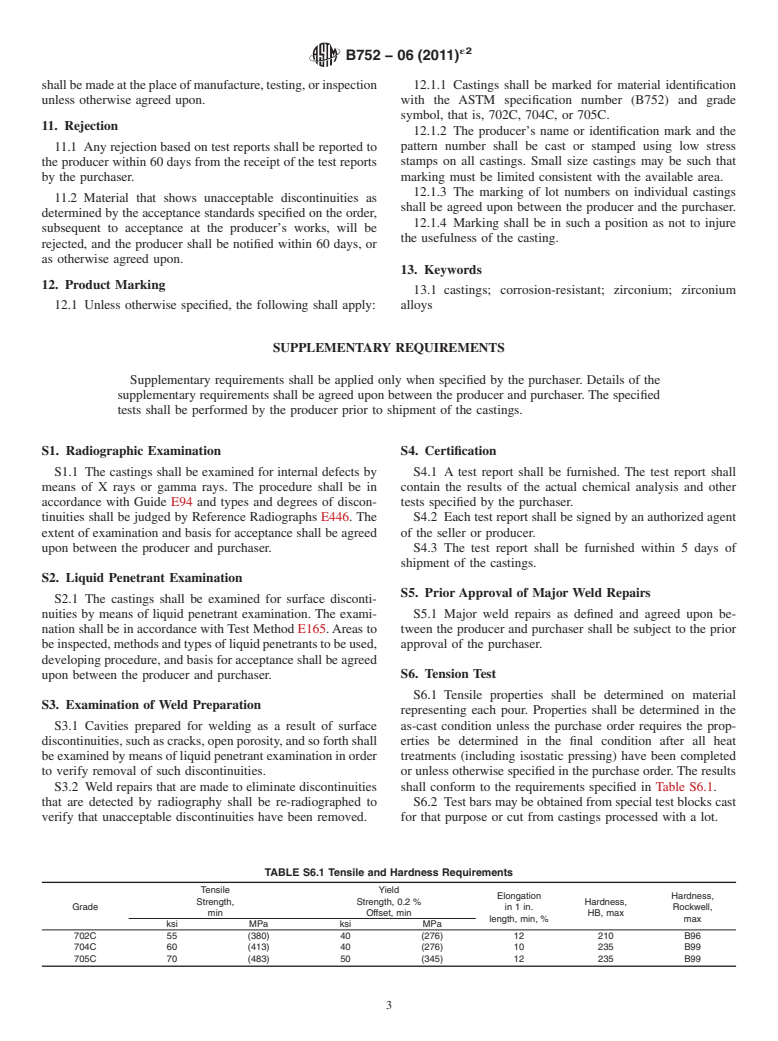

´ NOTE—SI units were removed editorially from Elongation heading in Table S6.1 in March 2012.

1. Scope 3.2 Lot Definitions:

3.2.1 castings, n—alotshallconsistofallcastingsproduced

1.1 Thisspecificationcoverszirconiumandzirconium-alloy

from the same pour.

castings for general corrosion-resistant and industrial applica-

tions.

4. Ordering Information

1.2 The values stated in inch-pound units are to be regarded

4.1 Orders for castings to this specification shall include the

as standard. The values given in parentheses are mathematical

following, as required to describe the requirements adequately.

conversions to SI units that are provided for information only

4.1.1 Description of the castings by pattern number or

and are not considered standard.

drawing (dimensional tolerances shall be included on the

casting drawing),

2. Referenced Documents

4.1.2 Quantity,

2.1 ASTM Standards:

4.1.3 Grade Designation (see Table 1),

A802/A802M Practice for Steel Castings, Surface Accep-

4.1.4 Options in the specification, and

tance Standards, Visual Examination

4.1.5 Supplementary requirements desired, including the

E8 Test Methods for Tension Testing of Metallic Materials

standards of acceptance.

E10 Test Method for Brinell Hardness of Metallic Materials

E18 Test Methods for Rockwell Hardness of Metallic Ma-

5. Materials and Manufacture

terials

5.1 Material for this specification shall be melted by con-

E23 Test Methods for Notched Bar Impact Testing of Me-

ventional processes used for reactive metals. Typical methods

tallic Materials

include the consumable electrode and inductoslag melting

E94 Guide for Radiographic Examination

processes.

E165 Practice for Liquid Penetrant Examination for General

Industry

6. Chemical Composition

E446 Reference Radiographs for Steel Castings Up to 2 in.

(50.8 mm) in Thickness

6.1 Pour Analysis—An analysis of each pour shall be made

by the producer from a sample such as a casting or test bar that

3. Terminology

is representative of the pour. The chemical composition deter-

mined shall conform to the requirements specified for the

3.1 Definitions of Terms Specific to This Standard:

relevant grade in Table 1.

3.1.1 pour, n—shallconsistofallmaterialmeltedandcastat

6.1.1 The elements listed in Table 1 are intentional alloying

one time.

additions of elements which are inherent to the manufacture of

primaryzirconium,zirconiumsponge,millproductorcastings.

6.1.1.1 Elements other than those listed in Table 1 are

This specification is under the jurisdiction of ASTM Committee B10 on

deemed to be capable of occurring in the grades listed in Table

Reactive and Refractory Metals and Alloys and is the direct responsibility of

Subcommittee B10.02 on Zirconium and Hafnium.

1 by and only by way of unregulated or unanalyzed scrap

Current edition approved April 1, 2011. Published April 2011. Originally

additions to the pour.Therefore, pour analysis for elements not

approved in 1985. Last previous edition approved in 2006 as B752 – 06. DOI:

listedinTable1shallbeconsideredtobeinexcessoftheintent

10.1520/B0752-06R11E02.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or of this specification.

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

6.2 When agreed upon by producer and purchaser and

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. requested by the purchaser in his written purchase order,

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

´2

B752−06(2011)

A

TABLE 1 Chemical Requirements

7.2 Ifpost-weldheattreatmentisrequired,itshallconsistof

Grade Designation,

a stress relief performed at 1050 6 50°F (565 6 25°C) for a

Composition, %

1 1

minimum of ⁄2 h at temperature plus an additional ⁄2hat

702C 704C 705C

temperature per inch of thickness for section sizes greater than

Zirconium and hafnium, 98.8 97.1 95.1

1 in. (25 mm). After heat treatment, the castings should be

min.

cooled in air or in the furnace to ambient temperature unless

Hafnium, max 4.5 4.5 4.5

Iron and chro- 0.3 0.3 0.3

otherwise agreed upon between the purchaser and producer.

mium, max

Hydrogen, max 0.005 0.005 0.005

Nitrogen, max 0.03 0.03 0.03 8. Workmanship, Finish, and Appearance

Carbon, max 0.1 0.1 0.1

8.1 Allcastingsshallbemadeinaworkmanlikemannerand

Oxygen, max 0.25 0.3 0.3

Phosphorus, max 0.01 0.01 0.01

shall conform to the dimensions in drawings furnished by the

Tin . 1.0 to 2.0 .

purchaser before manufacturing is started. If the pattern is

Niobium . . 2.0 to 3.0

supplied by the purchaser, the dimensions of the casting shall

A

By agreement between the purchaser and the producer, analysis may be

be as predicted by the pattern.

required and limits established for elements and compounds not specified in this

table.

8.2 The surface of the casting shall be free of adhering mold

material, scale, cracks, and hot tears as determined by visual

examination.Othersurfacediscontinuitiesshallmeetthevisual

acceptance standards specified in the order. Practice A802/

chemical analysis shall be completed for specific residual

A802M or other visual standards may be used to define

elements not listed in this specification.

acceptable surface discontinuities and finish. Unacceptable

surface discontinuities shall be removed, and their removal

6.3 Product Analysis—A product analysis may be made by

verified by visual examination of the resultant cavities.

the purchaser on a representative casting from any lot. Because

of the possibility of oxygen or other interstitial contamination,

9. Repair by Welding

samples for oxygen, carbon, hydrogen, and nitrogen analysis

shall be taken no closer than ⁄4 in. (6.3 mm) to a cast surface

9.1 If repairs are required, these shall be made using a

except that castings too thin for this shall be analyzed on

welding procedure and operators certified to quality require-

representative material. The chemical composition determined

ments established by the producer. The procedures developed

shall conform to the analysis in Table 1 within the check

shall be consistent with standard practices recommended for

analysis variations shown in Table 2 or shall be subject to

reactive metal alloys. The producer shall maintain documenta-

rejection by the purchaser.

tion on procedure and welder qualifications. Procedure modi-

fications or special arrangements shall be as agreed upon

6.4 In the event of disagreement between the manufacturer

between the producer and purchaser.

and the purchaser on the conformance of the material to the

requirements of this specification or any special test specified

9.2 Weld repairs shall be considered major in the case of a

by the purchase, a mutually acceptable referee shall perform

casting that has leaked on a hydrostatic test or when the depth

thetestsinquestion.Theresultsofthereferee’stestingshallbe

of the cavity after preparation for repair exceeds 20 % of the

used in determining conformance of the material to this

actual wall thickness or 1 in. (25 mm), whichever is smaller, or

specification.

when the surface area of the cavity exceeds approximately 10

2 2

in. (6500 mm ). All other weld repairs shall be considered

7. Heat Treatment

minor. Major and minor repairs shall be subject to the same

7.1 Unless otherwise specified in the contract, all castings

quality standards as are used to inspect the castings.

willbesuppliedintheas-castconditionexceptwhenpost-weld

9.3 The composition of the deposited weld metal shall be

heat treatment is required.

within the chemical requirements for each grade established in

Table 1.

9.4 All castings with major weld repairs shall be stress

TABLE 2 Check Analysis Tolerances

relieved after repair in accordance with 7.2. Stress relief after

Permissible

minor repairs is not required for grades 702C and 704C except

Maximum

Variation

Element of Range,

by agreement between the producer and the purchaser. Grade

in Check

Weight, %

Analysis 705C must be stress relieved after any weld repair.

Nitrogen 0.03 +0.006

Carbon 0.10 +0.02

10. Inspection

Hydrogen 0.005 +0.001

Iron and chromium 0.30 +0.06

10.1 The producer shall afford the purchaser’s inspector all

Oxygen 0.25 +0.05

reasonable facilities necessary to satisfy him that the m

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.