ASTM D2290-08

(Test Method)Standard Test Method for Apparent Hoop Tensile Strength of Plastic or Reinforced Plastic Pipe by Split Disk Method

Standard Test Method for Apparent Hoop Tensile Strength of Plastic or Reinforced Plastic Pipe by Split Disk Method

SIGNIFICANCE AND USE

Split disk tension tests, properly interpreted, provide reasonably accurate information with regard to the apparent tensile strength of plastic pipe when employed under conditions approximating those under which the tests are made.

Tension tests may provide data for research and development, engineering design, quality control, acceptance or rejection under specifications, and for special purposes. The test cannot be considered significant for applications differing widely from the load-time scale of the standard test.

Note 1—Procedure C has been used on polyethylene and polybutylene pipe to produce results equivalent to Quick Burst results (Test Method D 1599) for 4 in. to 8 in. pipes.

SCOPE

1.1 This test method covers the determination of the comparative apparent tensile strength of most plastic products utilizing a split disk test fixture, when tested under defined conditions of pretreatment, temperature, humidity, and test machine speed. This test method is applicable to reinforced-thermosetting resin pipe regardless of fabrication method. This test method also is applicable to extruded and molded thermoplastic pipe.

Procedure A is used for reinforced-thermosetting resin pipe; Procedure B is used for thermoplastic pipe of any size; Procedure C is used for thermoplastic pipe with nominal diameter of 4½ in. and greater.

1.2 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D2290 − 08 AnAmerican National Standard

Standard Test Method for

Apparent Hoop Tensile Strength of Plastic or Reinforced

1

Plastic Pipe by Split Disk Method

This standard is issued under the fixed designation D2290; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope 3. Summary of Test Method

3.1 The test specimen is loaded through the suggested

1.1 This test method covers the determination of the com-

self-aligning split disk test fixture (Fig. 1) which applies tensile

parative apparent tensile strength of most plastic products

stress to the test ring. An apparent tensile strength rather than

utilizing a split disk test fixture, when tested under defined

a true tensile strength is obtained in this test because of a

conditions of pretreatment, temperature, humidity, and test

bending moment imposed during test at the split between the

machine speed. This test method is applicable to reinforced-

split disk test fixture. This moment is induced by the change in

thermosetting resin pipe regardless of fabrication method. This

contour of the ring between the two disk sections as they

test method also is applicable to extruded and molded thermo-

separate. The test fixture is designed to minimize the effect of

plastic pipe.

this bending moment.

Procedure A is used for reinforced-thermosetting resin pipe;

Procedure B is used for thermoplastic pipe of any size;

4. Significance and Use

Procedure C is used for thermoplastic pipe with nominal

1

diameter of 4 ⁄2 in. and greater.

4.1 Split disk tension tests, properly interpreted, provide

reasonably accurate information with regard to the apparent

1.2 The values stated in inch-pound units are to be regarded

tensile strength of plastic pipe when employed under condi-

as standard. The values given in parentheses are mathematical

tions approximating those under which the tests are made.

conversions to SI units that are provided for information only

and are not considered standard.

4.2 Tension tests may provide data for research and

development, engineering design, quality control, acceptance

1.3 This standard does not purport to address all of the

or rejection under specifications, and for special purposes. The

safety concerns, if any, associated with its use. It is the

test cannot be considered significant for applications differing

responsibility of the user of this standard to establish appro-

widely from the load-time scale of the standard test.

priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use.

NOTE 1—Procedure C has been used on polyethylene and polybutylene

pipe to produce results equivalent to Quick Burst results (Test Method

D1599) for 4 in. to 8 in. pipes.

2. Referenced Documents

2

2.1 ASTM Standards:

5. Apparatus

D618 Practice for Conditioning Plastics for Testing

5.1 Micrometers—Suitable ball-type micrometers, reading

D1599 Test Method for Resistance to Short-Time Hydraulic

to at least 0.001 in., for measuring the width and thickness of

Pressure of Plastic Pipe, Tubing, and Fittings

the test specimens.

E4 Practices for Force Verification of Testing Machines

5.2 Testing Machine—A universal testing machine of the

constant-rate-of-cross-head-movement type and comprising

1 essentially the following:

This test method is under the jurisdiction of ASTM Committee F17 on Plastic

Piping Systems and is the direct responsibility of Subcommittee F17.40 on Test

5.2.1 Drive Mechanism—A drive mechanism for imparting

Methods.

to the crosshead a uniform controlled velocity with respect to

Current edition approved Nov. 1, 2008. Published November 2008. Originally

the base, this velocity to be regulated as specified in Section 9.

approved in 1964. Last previous edition approved in 2004 as D2290 – 04. DOI:

10.1520/D2290-08.

5.2.2 Load Indicator—A load-indicating mechanism ca-

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

pable of showing the total tensile load carried by the test

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

specimen. This mechanism shall be essentially free from

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. inertia lag at the specified rate of testing and shall indicate the

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D2290 − 08

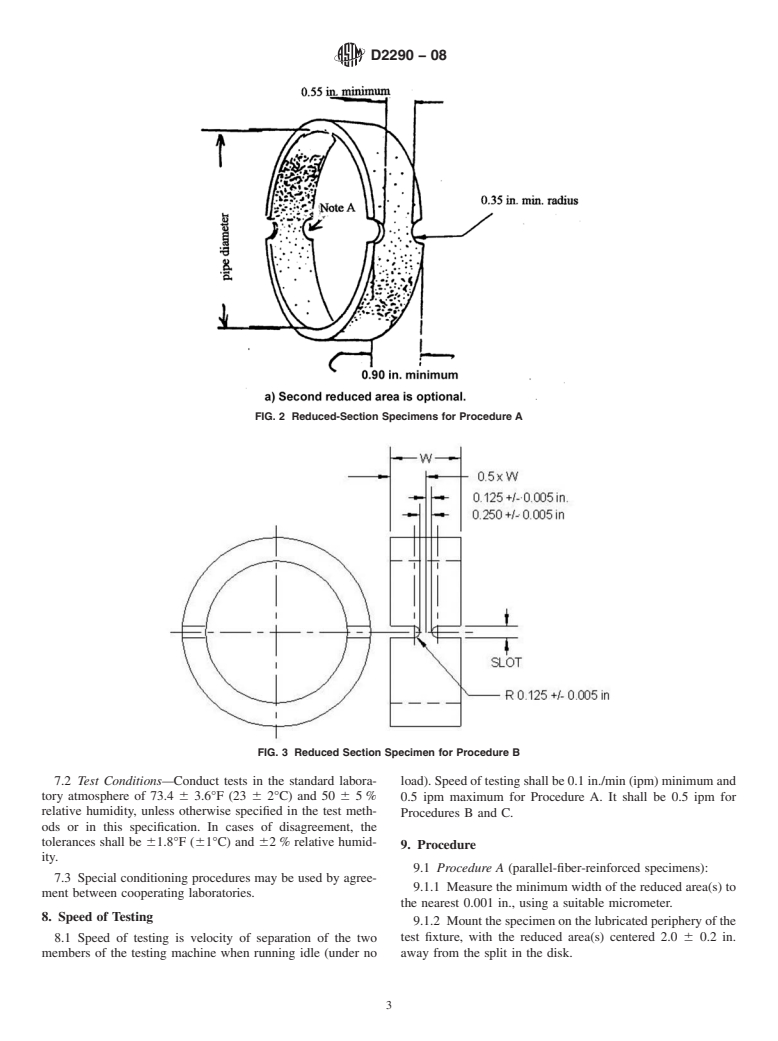

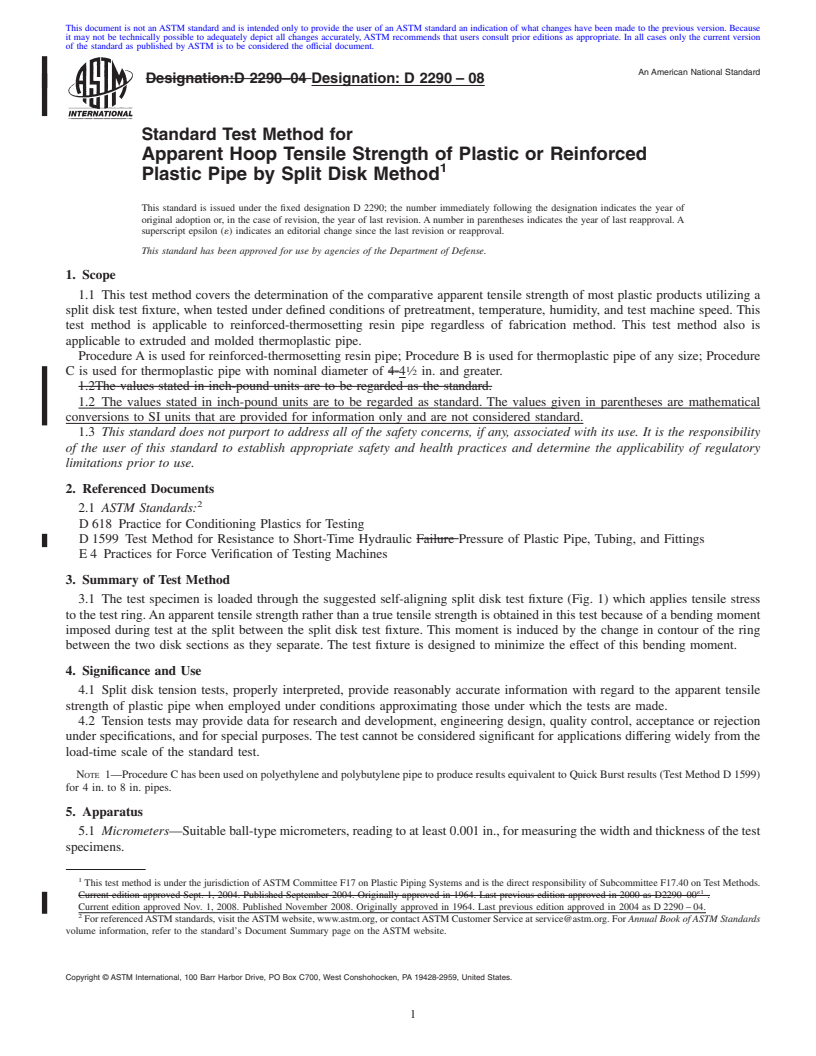

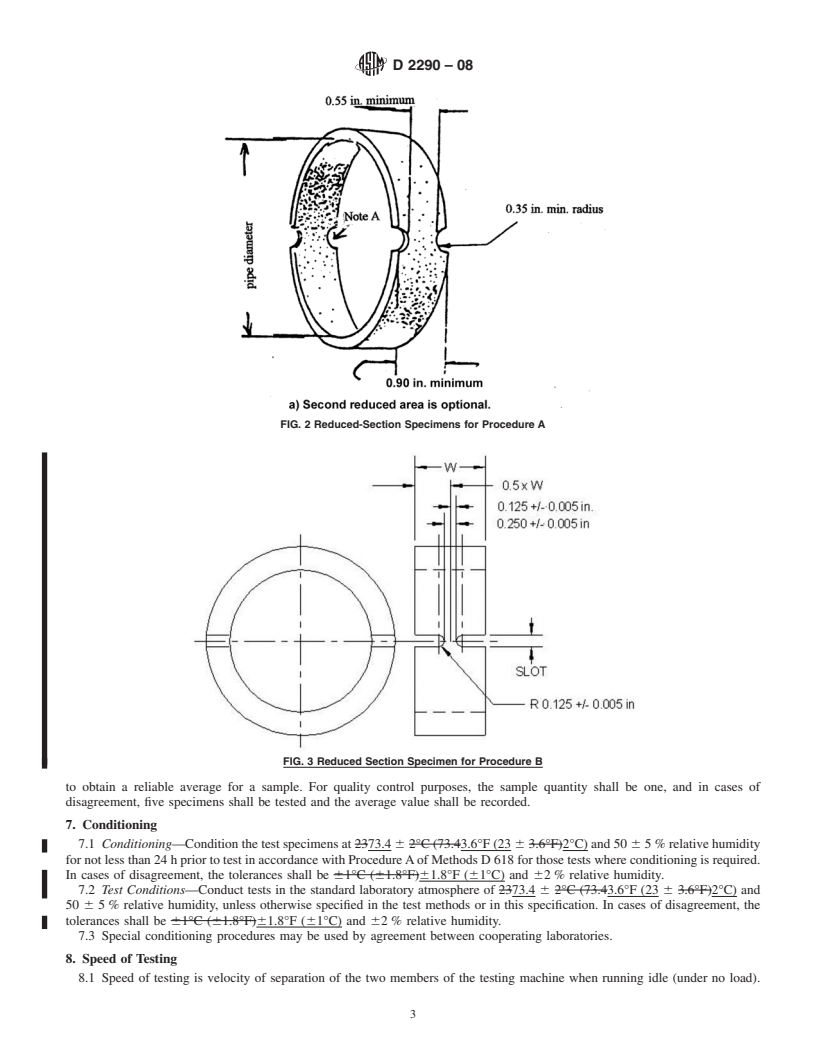

FIG. 1 Test Fixture: Typical

load with an accuracy

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

An American National Standard

Designation:D 2290–04 Designation:D 2290–08

Standard Test Method for

Apparent Hoop Tensile Strength of Plastic or Reinforced

1

Plastic Pipe by Split Disk Method

This standard is issued under the fixed designation D 2290; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope

1.1 This test method covers the determination of the comparative apparent tensile strength of most plastic products utilizing a

split disk test fixture, when tested under defined conditions of pretreatment, temperature, humidity, and test machine speed. This

test method is applicable to reinforced-thermosetting resin pipe regardless of fabrication method. This test method also is

applicable to extruded and molded thermoplastic pipe.

Procedure A is used for reinforced-thermosetting resin pipe; Procedure B is used for thermoplastic pipe of any size; Procedure

1

C is used for thermoplastic pipe with nominal diameter of 4-4 ⁄2 in. and greater.

1.2The values stated in inch-pound units are to be regarded as the standard.

1.2 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical

conversions to SI units that are provided for information only and are not considered standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2

2.1 ASTM Standards:

D 618 Practice for Conditioning Plastics for Testing

D 1599 Test Method for Resistance to Short-Time Hydraulic Failure Pressure of Plastic Pipe, Tubing, and Fittings

E 4 Practices for Force Verification of Testing Machines

3. Summary of Test Method

3.1 The test specimen is loaded through the suggested self-aligning split disk test fixture (Fig. 1) which applies tensile stress

to the test ring.An apparent tensile strength rather than a true tensile strength is obtained in this test because of a bending moment

imposed during test at the split between the split disk test fixture. This moment is induced by the change in contour of the ring

between the two disk sections as they separate. The test fixture is designed to minimize the effect of this bending moment.

4. Significance and Use

4.1 Split disk tension tests, properly interpreted, provide reasonably accurate information with regard to the apparent tensile

strength of plastic pipe when employed under conditions approximating those under which the tests are made.

4.2 Tension tests may provide data for research and development, engineering design, quality control, acceptance or rejection

under specifications, and for special purposes. The test cannot be considered significant for applications differing widely from the

load-time scale of the standard test.

NOTE 1—Procedure C has been used on polyethylene and polybutylene pipe to produce results equivalent to Quick Burst results (Test Method D 1599)

for 4 in. to 8 in. pipes.

5. Apparatus

5.1 Micrometers—Suitable ball-type micrometers, reading to at least 0.001 in., for measuring the width and thickness of the test

specimens.

1

This test method is under the jurisdiction ofASTM Committee F17 on Plastic Piping Systems and is the direct responsibility of Subcommittee F17.40 on Test Methods.

´1

Current edition approved Sept. 1, 2004. Published September 2004. Originally approved in 1964. Last previous edition approved in 2000 as D2290–00 .

Current edition approved Nov. 1, 2008. Published November 2008. Originally approved in 1964. Last previous edition approved in 2004 as D 2290 – 04.

2

For referencedASTM standards, visit theASTM website, www.astm.org, or contactASTM Customer Service at service@astm.org. For Annual Book ofASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

D 2290–08

FIG. 1 Test Fixture: Typical

5.2 Testing Machine—A universal testing machine of the constant-rate-of-cros

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.