ASTM D6521-00

(Practice)Standard Practice for Accelerated Aging of Asphalt Binder Using a Pressurized Aging Vessel (PAV)

Standard Practice for Accelerated Aging of Asphalt Binder Using a Pressurized Aging Vessel (PAV)

SCOPE

1.1 This practice covers the accelerated aging (oxidation) of asphalt binders by means of pressurized air and elevated temperature. This is intended to simulate the type of changes which occur in asphalt binders during in-service oxidative aging but may not accurately simulate the relative rates of aging. It is intended for use with residue from Test Method D 2872 (RTFOT) which is designed to simulate plant aging.Note 1

Modified asphalt binders may phase separate or form skins during oven conditioning in Test Method D 2872 (RTFOT); the results from subsequent testing of this residue may not be representative of modified asphalts short-term aged under field conditions. Phase separation, or formation of skins, or both can also occur during PAV aging. Therefore, the practice may not be suitable for some modified asphalts.Note 2

PAV has not been validated for materials containing particulate materials.

1.2 The aging of asphalt binders during service is affected by ambient temperature and air pressure and by mixture-associated variables such as the volumetric proportions of the mix, the permeability of the mix, properties of the aggregates, and possibly other factors. This conditioning process is intended to provide an evaluation of the relative resistance of different asphalt binders to oxidative aging at selected elevated aging temperatures and pressures but cannot account for mixture variables or provide the relative resistance to aging at in-service conditions.

1.3 The values stated in SI units are to be regarded as the standard.

This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn. Contact ASTM

International (www.astm.org) for the latest information.

Designation:D6521–00

Standard Practice for

Accelerated Aging of Asphalt Binder Using a Pressurized

Aging Vessel (PAV)

This standard is issued under the fixed designation D 6521; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope D 8 Terminology Relating to Materials for Roads and Pave-

ments

1.1 This practice covers the accelerated aging (oxidation) of

D 1754 Test Method for Effect of Heat and Air on Asphalt

asphalt binders by means of pressurized air and elevated

Materials (Thin-Film Oven Test)

temperature. This is intended to simulate the type of changes

D 2872 Test Method for Effect of Heat and Air on Rolling

which occur in asphalt binders during in-service oxidative

Film of Asphalt (Rolling Thin-Film Oven Test)

aging but may not accurately simulate the relative rates of

D 4753 Specification for Evaluating, Selecting and Speci-

aging. It is intended for use with residue from Test Method

fying Balances and Scales for Use in Soil, Rock and

D 2872 (RTFOT) which is designed to simulate plant aging.

Construction Materials Testing

NOTE 1—Modified asphalt binders may phase separate or form skins

E 220 Test Method for Calibration of Thermocouples by

during oven conditioning in Test Method D 2872 (RTFOT); the results

Comparison Techniques

from subsequent testing of this residue may not be representative of

E 1137 Specification for Industrial Platinum Resistance

modified asphalts short-term aged under field conditions. Phase separa-

Thermometers

tion, or formation of skins, or both can also occur during PAV aging.

2.2 AASHTO Standards:

Therefore, the practice may not be suitable for some modified asphalts.

NOTE 2—PAV has not been validated for materials containing particu-

MP1 Provisional Standard Specification for Performance-

late materials.

Graded Asphalt Binder

1.2 The aging of asphalt binders during service is affected

3. Terminology

by ambient temperature and air pressure and by mixture-

3.1 Definitions:

associated variables such as the volumetric proportions of the

3.1.1 Definitionsoftermsusedinthispracticemaybefound

mix, the permeability of the mix, properties of the aggregates,

in Terminology D 8 determined from common English usage,

and possibly other factors. This conditioning process is in-

or combinations of both.

tended to provide an evaluation of the relative resistance of

different asphalt binders to oxidative aging at selected elevated

4. Summary of Practice

aging temperatures and pressures but cannot account for

4.1 Asphalt binder is first aged using Test Method D 2872

mixture variables or provide the relative resistance to aging at

(RTFOT). A specified thickness of residue from the RTFOT is

in-service conditions.

then placed in standard TFOT stainless steel pans and aged at

1.3 The values stated in SI units are to be regarded as the

the specified aging temperature for 20 h in a vessel pressurized

standard.

with air to 2.10 MPa. Aging temperature is selected according

1.4 This standard does not purport to address all of the

to the grade of this asphalt binder. The residue is then vacuum

safety concerns, if any, associated with its use. It is the

degassed.

responsibility of the user of this standard to establish appro-

priate safety and health practices and determine the applica-

5. Significance and Use

bility of regulatory limitations prior to use.

5.1 This method is designed to simulate the type of in-

2. Referenced Documents

service oxidative aging that occurs in asphalt binders during

2.1 ASTM Standards:

Annual Book of ASTM Standards, Vol 04.03.

1 3

This practice is under the jurisdiction of ASTM Committee D04 on Road and Annual Book of ASTM Standards, Vol 04.08.

Paving Materials and is the direct responsibility of Subcommittee D04.46 on Annual Book of ASTM Standards, Vol 14.03.

Durability and Distillation Test. Available fromAASHTO, National Institute of Std. &Tech., Gaithersburg, MD

Current edition approved Jan. 10, 2000. Published April 2000. 20899.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn. Contact ASTM

International (www.astm.org) for the latest information.

D6521

pavement service. Residue from this conditioning practice may a set of asphalts at PAV conditions may differ significantly

be used to estimate the physical or chemical properties of from the actual in-service relative rates at lower temperatures

asphalt binders after several years of in-service aging in the and pressures.

field.

6. Apparatus

5.2 Binders aged using this standard are used to determine

specification properties in accordance AASHTO MP1. The 6.1 An equipment system consisting of a pressure vessel,

binder is aged using the RTFOT test prior to this conditioning pressure controlling devices, temperature controlling devices,

pressureandtemperaturemeasuringdevices,andatemperature

step. Unaged asphalt binders, RTFOT residues, and PAV

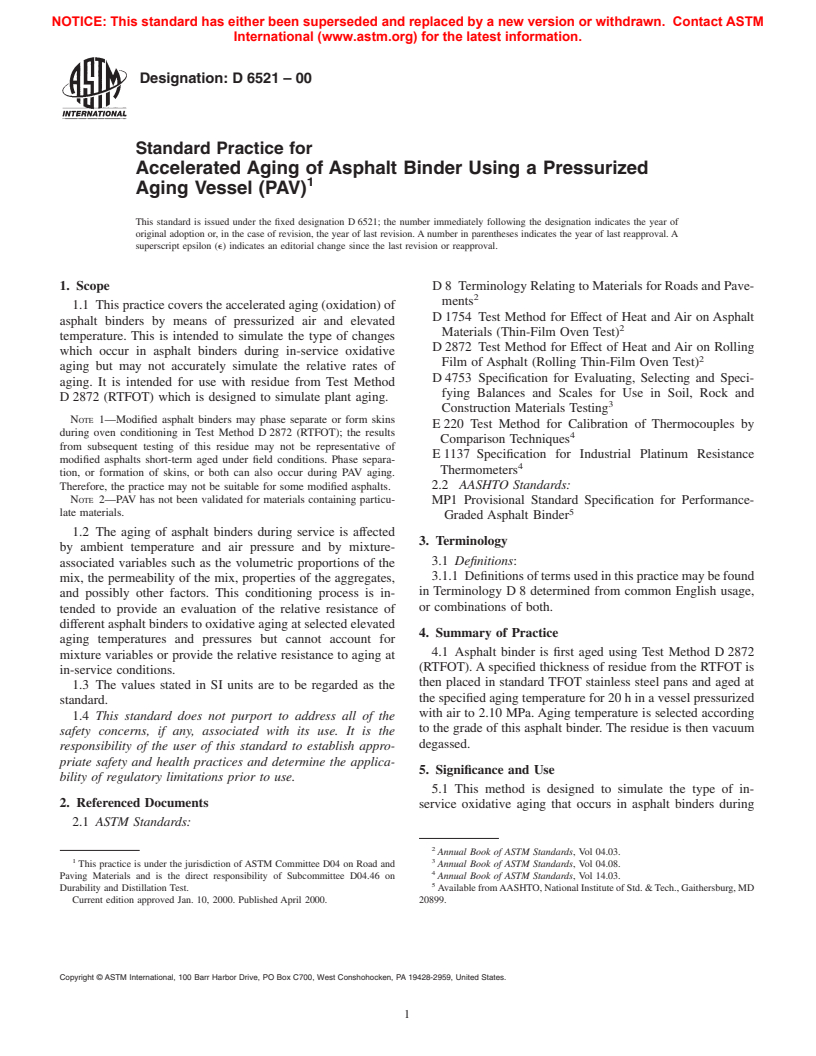

and pressure recording system (see Fig. 1).

residues are used to determine specification properties in

6.1.1 Pressure Vessel—A stainless steel pressure vessel

accordance with MP1.

designed to operate at 2.1 6 0.1 MPa between 90 and 110°C

5.3 For asphalt binders of different grades or from different

with interior dimensions adequate to hold ten TFOT pans and

sources, there is no unique correlation between the aging time

a pan holder. The pressure vessel shall contain a pan holder

and temperature in this conditioning practice and in-service

capableofholdingtenTFOTstainlesssteelpansinahorizontal

pavement age and temperature. Therefore, for a given set of

(level) position such that the asphalt binder film thickness is

in-service climatic conditions, it is not possible to select a

reasonably uniform. The holder shall be designed for easy

single PAV aging time and elevated temperature and pressure

insertion and removal from the vessel when the holder, pans,

that will predict the properties or the relative rankings of the

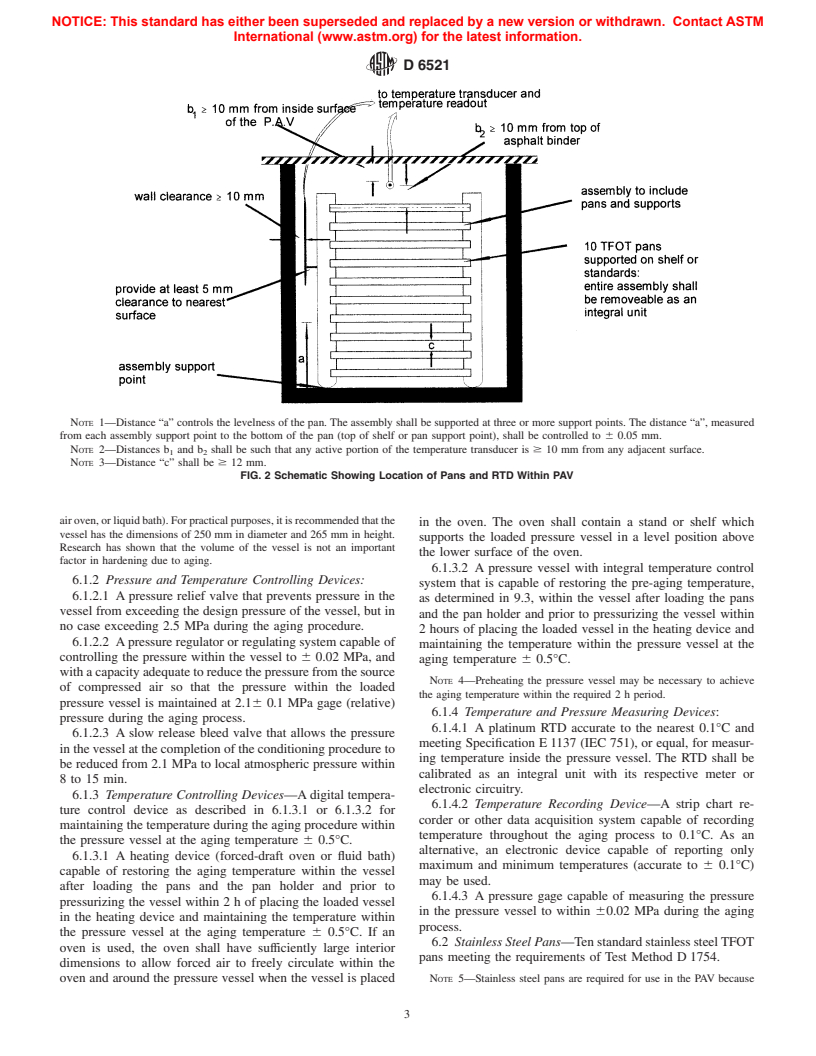

and asphalt binder are at the aging temperature. A schematic

properties of all asphalt binders after a specific set of in-service

showing a possible configuration of the vessel, pan holder and

exposure conditions.

pans and specifying dimensional requirements is shown in Fig.

5.4 The relative degree of hardening of different asphalt

2.

binders varies with aging temperatures and pressures in the

NOTE 3—The vessel may be a separate unit to be placed in a forced

PAV. Therefore, two asphalt binders may age at a similar rate

draft oven for conditioning the asphalt binders or an integral part of the

at one condition of temperature and pressure, but age differ-

temperature control system (for example, by direct heating of the vessel or

entlyatanothercondition.Hence,therelativeratesofagingfor by surrounding the vessel with a permanently affixed heating unit, forced

FIG. 1 Schematic of PAV Test System

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn. Contact ASTM

International (www.astm.org) for the latest information.

D6521

NOTE 1—Distance “a” controls the levelness of the pan. The assembly shall be supported at three or more support points. The distance “a”, measured

from each assembly support point to the bottom of the pan (top of shelf or pan support point), shall be controlled to 6 0.05 mm.

NOTE 2—Distances b and b shall be such that any active portion of the temperature transducer is$ 10 mm from any adjacent surface.

1 2

NOTE 3—Distance “c” shall be$ 12 mm.

FIG. 2 Schematic Showing Location of Pans and RTD Within PAV

airoven,orliquidbath).Forpracticalpurposes,itisrecommendedthatthe

in the oven. The oven shall contain a stand or shelf which

vessel has the dimensions of 250 mm in diameter and 265 mm in height.

supports the loaded pressure vessel in a level position above

Research has shown that the volume of the vessel is not an important

the lower surface of the oven.

factor in hardening due to aging.

6.1.3.2 A pressure vessel with integral temperature control

6.1.2 Pressure and Temperature Controlling Devices:

system that is capable of restoring the pre-aging temperature,

6.1.2.1 A pressure relief valve that prevents pressure in the

as determined in 9.3, within the vessel after loading the pans

vessel from exceeding the design pressure of the vessel, but in

and the pan holder and prior to pressurizing the vessel within

no case exceeding 2.5 MPa during the aging procedure.

2 hours of placing the loaded vessel in the heating device and

6.1.2.2 Apressure regulator or regulating system capable of

maintaining the temperature within the pressure vessel at the

controlling the pressure within the vessel to 6 0.02 MPa, and

aging temperature 6 0.5°C.

withacapacityadequatetoreducethepressurefromthesource

NOTE 4—Preheating the pressure vessel may be necessary to achieve

of compressed air so that the pressure within the loaded

the aging temperature within the required 2 h period.

pressure vessel is maintained at 2.16 0.1 MPa gage (relative)

6.1.4 Temperature and Pressure Measuring Devices:

pressure during the aging process.

6.1.4.1 A platinum RTD accurate to the nearest 0.1°C and

6.1.2.3 A slow release bleed valve that allows the pressure

meeting Specification E 1137 (IEC 751), or equal, for measur-

in the vessel at the completion of the conditioning procedure to

ing temperature inside the pressure vessel. The RTD shall be

be reduced from 2.1 MPa to local atmospheric pressure within

calibrated as an integral unit with its respective meter or

8 to 15 min.

electronic circuitry.

6.1.3 Temperature Controlling Devices—Adigital tempera-

6.1.4.2 Temperature Recording Device—A strip chart re-

ture control device as described in 6.1.3.1 or 6.1.3.2 for

corder or other data acquisition system capable of recording

maintaining the temperature during the aging procedure within

temperature throughout the aging process to 0.1°C. As an

the pressure vessel at the aging temperature 6 0.5°C.

alternative, an electronic device capable of reporting only

6.1.3.1 A heating device (forced-draft oven or fluid bath)

maximum and minimum temperatures (accurate to 6 0.1°C)

capable of restoring the aging temperature within the vessel

may be used.

after loading the pans and the pan holder and prior to

6.1.4.3 A pressure gage capable of measuring the pressure

pressurizing the vessel within2hof placing the loaded vessel

in the pressure vessel to within 60.02 MPa during the aging

in the heating device and maintaining the temperature within

process.

the pressure vessel at the aging temperature 6 0.5°C. If an

6.2 Stainless Steel Pans—Ten standard stainless steelTFOT

oven is used, the oven shall have sufficiently large interior

pans meeting the requirements of Test Method D 1754.

dimensions to allow forced air to freely circulate within the

oven and around the pressure vessel when the vessel is placed NOTE 5—Stainless steel pans are required for use in the PAV because

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn. Contact ASTM

International (www.astm.org) for the latest information.

D6521

they provide a safer environment for hydrocarbons under elevated

temperature at which to apply pressure to the vessel for

temperatures and pressures.

performing the aging procedure. This information will be

useful in 10.9.

6.3 Balance—A balance conforming to the requirements of

Specification D 4753, Class G2.

10. Procedure

6.4 Vacuum Oven—A vacuum oven capable of maintaining

10.1 Condition the asphalt binder in accordance with Test

temperature up to 180°C with an accuracy of 6 5°C and

Method D 2872 (RTFOT).

vacuum of 15 6 1.0 kPa absolute shall be used. The pressure

10.2 Combine the hot residue from the RTFOT bottles into

vessel itself may be used in lieu of a vacuum oven if it is

a single container, stir to blend, then transfer to TFOT pans in

capable of maintaining a temperature of 180°C and a vacuum

accordance with 10.4 for PAV conditioning or allow the hot

of 15.0 kPa.

residue in the container to cool to room temperature and cover

6.5 Vacuum System—A vacuum system capable of generat-

and store at room temperature for PAV conditioning at a later

ing and maintaining pressure below 15 kPa absolute. Suitable

date. If conditioned asphalt binder is allowed to cool to room

vacuum systems include a vacuum pump, an air aspirator, or a

temperature, heat it until it is sufficiently fluid to pour and stir

house vacuum system.

it before pouring it into the TFOT pans.

7. Materials 10.3 Place the pan holder inside the pressure vessel. If an

oven is used, place the pressure vessel inside the oven, select

7.1 Commercial bottled air or equivalent.

an aging temperature, and preheat the pressure vessel to the

aging temperature selected. If an integrated temperature con-

8. Hazards

trol pressure vessel is used, one should select an aging

8.1 Use standard laboratory safety procedures in handling

temperature and follow the manufacturer’s instructions for

the hot asphalt binder when preparing aging specimens and

preheating the pressure vessel.

removing the residue from the pressure vessel. Use special

precaution when lifting the pressure vessel. NOTE 8—If conditioning asphalt binders for conformance to AASHTO

MP1, select the appropriate aging temperature from Table 1 of MP1.

NOTE 9—For vessels placed in an oven, preheating the vessel 10 to

9. Calibration and Standardization

15°C above the aging temperature can be used to reduce the drop in PAV

9.1 Temperature Detector—Verify the calibration of the

temperature during the loading process and minimize the time required to

RTD and its respective meter or electronic circuitry to 0.1°C at

stabilize the system, after loading, to attain the required temperature.

least every six months using a calibrated temperature indicator

NOTE 10—Aging temperature in the PAV is selected to account for

traceable to a national standard. different climatic regions.Temperatures in excess of approximately 115°C

can change the chemistry of asphalt binders using an accelerated aging

NOTE 6—The RTD or thermistor and its meter may be calibrated by the

practice and should be avoided.

manufacturer or a commercial vendor. One suggested method is to

10.4 Place the TFOT pan on a balance and add 50 6 0.5 g

perform the following steps: (1) Select a partial immersion mercury-in-

glass thermometer with an appropriate ran

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.