ASTM E810-03(2008)

(Test Method)Standard Test Method for Coefficient of Retroreflection of Retroreflective Sheeting Utilizing the Coplanar Geometry

Standard Test Method for Coefficient of Retroreflection of Retroreflective Sheeting Utilizing the Coplanar Geometry

SIGNIFICANCE AND USE

Measurements made by this test method are related to visual observations of retroreflective sheeting as seen by the human eye when illuminated by tungsten-filament light sources such as a motor vehicle headlamp.

The values determined relate to the visual effects for a given geometric configuration as specified by the user of the test method. This test method has been found useful for tests at observation angles between 0.1 and 2.0° (observation angles between 0.1° and 0.2° may be achieved by careful design of source and receiver aperture configuration), and at entrance angles up to 60°. It has been used to determine coefficient of retroreflection values as low as 0.1 cd·lx−1· m−2, but for values less than 1 cd·lx−1· m−2 special attention must be given to the responsivity of the receiver and to the elimination of very small amounts of stray light.

SCOPE

1.1 This test method describes an instrument measurement of the retroreflective performance of retroreflective sheeting.

1.2 The user of this test method must specify the entrance and observation angles to be used, and may specify the rotation angles.

1.3 This test method is intended as a laboratory test and requires a facility that can be darkened sufficiently so that stray light does not affect the test results. The testing apparatus must be able to achieve the coplanar geometry.

1.4 Portable and bench retroreflection measuring equipment may be used to determine RA values provided the geometry and appropriate substitution standard reference panels, measured in accordance with this test method, are utilized. In this case the methods of Procedure B in Practice E 809 apply. Additional information on the use of portable retroreflectometers may be found in Test Method E 1709.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:E810 −03(Reapproved2008)

Standard Test Method for

Coefficient of Retroreflection of Retroreflective Sheeting

Utilizing the Coplanar Geometry

This standard is issued under the fixed designation E810; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope E809Practice for Measuring Photometric Characteristics of

Retroreflectors

1.1 This test method describes an instrument measurement

E1709Test Method for Measurement of Retroreflective

of the retroreflective performance of retroreflective sheeting.

Signs Using a Portable Retroreflectometer at a 0.2 Degree

1.2 The user of this test method must specify the entrance

Observation Angle

andobservationanglestobeused,andmayspecifytherotation

2.2 Other Document:

angles.

CIE Publication No 54 Retroreflection—Definition and

1.3 This test method is intended as a laboratory test and Measurement

requiresafacilitythatcanbedarkenedsufficientlysothatstray

3. Terminology

light does not affect the test results.The testing apparatus must

be able to achieve the coplanar geometry.

3.1 The terms and definitions in Terminology E284 and

Practice E808 apply to this test method.

1.4 Portable and bench retroreflection measuring equipment

maybeusedtodetermine R valuesprovidedthegeometryand

A 3.2 Definitions:

appropriatesubstitutionstandardreferencepanels,measuredin

3.2.1 coeffıcient of retroreflection, R —of a plane retrore-

A

accordance with this test method, are utilized. In this case the

flecting surface, the ratio of the coefficient of luminous

methods of Procedure B in Practice E809 apply. Additional

intensity(R )tothearea(A),expressedincandelasperluxper

I

−1 −2

information on the use of portable retroreflectometers may be

square metre (cd·lx ·m ). R = R/A.

A I

found in Test Method E1709.

3.2.1.1 Discussion—The equivalent inch–pound units for

coefficient of retroreflection are candelas per foot-candle per

1.5 This standard does not purport to address all of the

−1 −2

square foot (cd·fc ·ft ). The SI and inch pound units are

safety concerns, if any, associated with its use. It is the

numerically equal, because the units of R reduce to 1/sr. An

responsibility of the user of this standard to establish appro-

A

equivalenttermusedforcoefficientofretroreflectionisspecific

priate safety and health practices and determine the applica-

intensity per unit area, with symbol SIAor the CIE symbol R'.

bility of regulatory limitations prior to use.

Thetermcoefficientofretroreflectionandthesymbol R along

A

with the SI units of candelas per lux per square meter

2. Referenced Documents

−1 −2

2 (cd·lx ·m ) are recommended by ASTM.

2.1 ASTM Standards:

3.2.1.2 Discussion—R is a useful engineering quantity for

A

E284Terminology of Appearance

determining the photometric performance of such retroreflec-

E308PracticeforComputingtheColorsofObjectsbyUsing

tive surfaces as highway delineators or warning devices. R

A

the CIE System

may also be used to determine the minimum area of retrore-

E691Practice for Conducting an Interlaboratory Study to

flective sheeting necessary for a desired level of photometric

Determine the Precision of a Test Method

performance. R has been used extensively in the specification

A

E808Practice for Describing Retroreflection

of retroreflective sheeting.

3.2.2 coplanar geometry, n—retroreflection geometry in

whichtheretroreflectoraxis,illuminationaxis,andobservation

This test method is under the jurisdiction of ASTM Committee E12 on Color

and Appearance and is the direct responsibility of Subcommittee E12.10 on

axis lie in one plane.

Retroreflection.

3.2.2.1 Discussion—In the coplanar geometry: the second

Current edition approved Feb. 1, 2008. Published February 2008. Originally

entrance angle component, β , is equal to 0°; presentation

approved in 1981. Last previous edition approved in 2003 as E810–03. DOI: 2

10.1520/E0810-03R08.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM AvailablefromU.S.NationalCommitteeoftheCIE(InternationalCommission

Standards volume information, refer to the standard’s Document Summary page on on Illumination), C/o Thomas M. Lemons, TLA-Lighting Consultants, Inc., 7 Pond

the ASTM website. St., Salem, MA 01970, http://www.cie-usnc.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

E810−03(2008)

angle, γ, is equal to either 0° or 180°; orientation angle, ω,is illumination;forexample,thedirectionoftheroadonwhichor

s

equal to either the rotation angle, ε,orto ε + 180° or ε − 180°. with respect to which the retroreflector is intended to be

positioned. The retroreflector axis usually coincides with the

3.2.3 datum axis, n—adesignatedhalf-linefromtheretrore-

axis of symmetry of the retroreflector. For retroreflective

flector center perpendicular to the retroreflector axis.

sheetingthenormaltothesurfaceischosenastheretroreflector

3.2.4 datum mark, n—anindicationontheretroreflector,off

axis.

the retroreflector axis, that establishes the direction of the

3.2.16 retroreflector center, n—the point on or near a ret-

datum axis.

roreflector that is designated to be the location of the device.

3.2.5 entrance angle, β,n—the angle between the illumina-

3.2.17 rotation angle,ε,n—theangleinaplaneperpendicu-

tion axis and the retroreflector axis.

lar to the retroreflector axis from the observation half-plane to

3.2.5.1 Discussion—The entrance angle is usually no larger

the datum axis, measured counterclockwise from a viewpoint

than 90°, but for completeness its full range is defined as 0° ≤

on the retroreflector axis.

β≤180°.IntheCIE(goniometersystem)βisresolvedintotwo

3.2.17.1 Discussion—Range:−180° <ε≤ 180°. The defini-

componentsβ andβ .Sincebydefinitionβisalwayspositive,

1 2

tion is applicable when entrance angle and viewing angle are

the common practice of referring to the small entrance angles

less than 90°. More generally, rotation angle is the angle from

that direct specular reflections away from the photoreceptor as

the positive part of second axis to the datum axis, measured

anegativevalueisdeprecatedbyASTM.Therecommendation

counterclockwise from a viewpoint on the retroreflector axis.

is to designate such negative values as belonging to β .

3.2.17.2 Discussion—Rotation of the sample about the ret-

3.2.6 goniometer, n—an instrument for measuring or setting

roreflector axis while the source and receiver remain fixed in

angles.

space changes the rotation angle (ε) and the orientation angle

(ω ) equally.

3.2.7 illumination axis, n—thehalf-linefromtheretroreflec-

s

tor center through the source point.

3.2.18 rotationally uniform, adj—having substantially con-

stant R , when rotated about the retroreflector axis, while the

3.2.8 observation angle, α,n—the angle between the illu-

A

source, receiver, retroreflector center and retroreflector axis all

mination axis and the observation axis.

remain in a fixed spatial relation.

3.2.8.1 Discussion—The observation angle is never nega-

3.2.18.1 Discussion—The degree of rotational uniformity

tive and is almost always less than 10° and usually no more

can be specified numerically.

than 2°. The full range is defined as 0°≤α < 180°.

3.2.19 source, n—an object that produces light or other

3.2.9 observation axis, n—the half-line from the retroreflec-

radiant flux.

tor center through the observation point.

3.2.10 receiver, n— the portion of a photometric instrument

4. Summary of Test Method

that receives the viewing beam from the specimen, including a

4.1 This test method involves the use of a light projector

collector such as an integrating sphere, if used, often the

source,areceiver,adevicetopositionthereceiverwithrespect

monochromator or spectral filters, the detector, and associated

to the source and a test specimen holder in a suitable darkened

optics and electronics.

area.Thespecimenholderisseparatedfromthelightsourceby

3.2.11 retroreflection, n—reflection in which the reflected

15 m.

rays are preferentially returned in directions close to the

opposite of the direction of the incident rays, this property

4.2 Thegeneralprocedureinvolvedistodeterminetheratio

being maintained over wide variations of the direction of the of the light retroreflected from the test surface to that incident

B

incident rays. [CIE]

on the test surface.

3.2.12 retroreflective material, n—a material that has a thin

4.3 The photometric quantity, coefficient of retroreflection,

continuous layer of small retroreflective elements on or very

is calculated from these measurements.

near its exposed surface (for example, retroreflective sheeting,

retroreflective fabrics, transfer films, beaded paint, highway

5. Significance and Use

surface signs, or pavement striping).

5.1 Measurements made by this test method are related to

3.2.13 retroreflective sheeting—a retroreflective material

visual observations of retroreflective sheeting as seen by the

preassembled as a thin film ready for use.

humaneyewhenilluminatedbytungsten-filamentlightsources

such as a motor vehicle headlamp.

3.2.14 retroreflector, n—a reflecting surface or device from

which, when directionally irradiated, the reflected rays are

5.2 The values determined relate to the visual effects for a

preferentiallyreturnedindirectionsclosetotheoppositeofthe

given geometric configuration as specified by the user of the

direction of the incident rays, this property being maintained

testmethod.Thistestmethodhasbeenfoundusefulfortestsat

over wide variations of the direction of the incident rays. [CIE,

observation angles between 0.1 and 2.0° (observation angles

B

1982]

between 0.1° and 0.2° may be achieved by careful design of

3.2.15 retroreflector axis, n—adesignatedhalf-linefromthe

source and receiver aperture configuration), and at entrance

retroreflector center. angles up to 60°. It has been used to determine coefficient of

−1 −2

3.2.15.1 Discussion—Thedirectionoftheretroreflectoraxis retroreflection values as low as 0.1 cd·lx ·m , but for values

−1 −2

is usually chosen centrally among the intended directions of less than 1 cd·lx ·m special attention must be given to the

E810−03(2008)

responsivityofthereceiverandtotheeliminationofverysmall 6.2.5 Thestabilityofthereceivershallbesuchthatreadings

amounts of stray light. from a constant source do not vary any more than 1% for the

duration of the test.

6. Apparatus 6.2.6 The field of view shall be limited by use of light

baffles or a field aperture on the instrument so that the entire

6.1 Light Source—The light source shall be of the projector

testsampleisfullywithinthefieldofview,rejectingstraylight

typeandshallmeetthefollowingrequirements(anilluminance

asmuchaspractical.Abackgroundlightlevel m lessthan5%

b

at the 15 m specimen distance of about 10 lx is commonly

of the smallest m reading is acceptable.

available within these restrictions):

6.2.7 The receiver aperture shall be a standard circular

6.1.1 The spectral energy distribution of the source shall be

aperture as defined in Practice E809. For measurements at

proportional to CIE standard Source A (a correlated color

observation angles (α) of 0.2°≤α≤ 2.0°, the receiver shall be

temperature of 2856 K, see Practice E308). The projection

provided with an entrance aperture 26 mm (62 mm) in

lamp together with the projection optics shall be operated such

diameter.Thiscorrespondsto0.1°angularapertureat15mtest

that it illuminates the test specimen with this spectral power

distance. For measurements at observation angles (α) of 0.1° ≤

distribution.

α < 0.2°, the receiver shall be provided with an entrance

6.1.2 An unpolarizing light source shall be used.

aperture 13 mm (61 mm) in diameter. This corresponds to a

6.1.3 The source aperture shall be a standard circular

0.05° angular aperture at 15 m test distance. The size of the

aperture as defined in Practice E809. For measurements at

entrance aperture stop must be small so that the receiver may

observation angles (α) of 0.2°≤α≤ 2.0°, the exit aperture of

be positioned physically close to the source exit aperture

the source shall be uniformly radiant, circular and 26 mm (62

without shadowing any of the illuminating light beam.

mm) in diameter. This corresponds to 0.1° angular aperture at

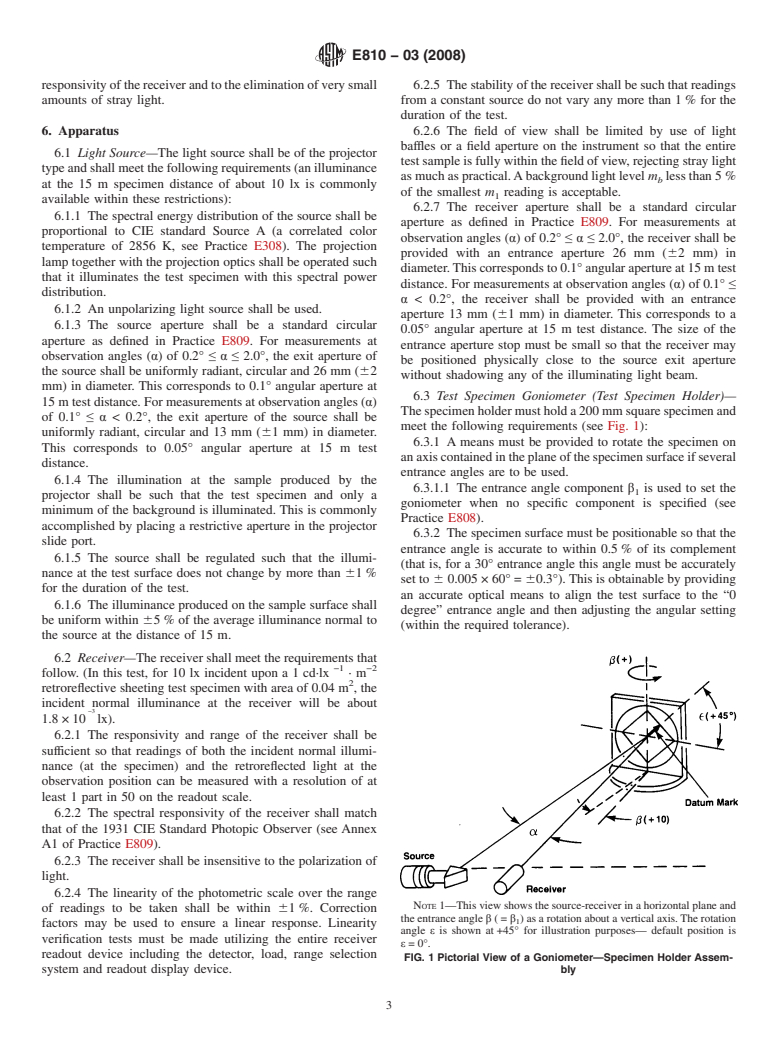

6.3 Test Specimen Goniometer (Test Specimen Holder)—

15mtestdistance.Formeasurementsatobservationangles(α)

Thespecimenholdermustholda200mmsquarespecimenand

of 0.1°≤α < 0.2°, the exit aperture of the source shall be

meet the following requirements (see Fig. 1):

uniformly radiant, circular and 13 mm (61 mm) in diameter.

6.3.1 A means must be provided to rotate the specimen on

This corresponds to 0.05° angular aperture at 15 m test

anaxiscontainedintheplaneofthespecimensurfaceifseveral

distance.

entrance angles are to be used.

6.1.4 The illumination at the sample produced by the

6.3.1.1 The entrance angle component β is used to set the

projector shall be such that the test specimen and only a

goniometer when no specific component is specified (see

minimum of the background is illuminated. This is commonly

Practice E808).

accomplished by placing a restrictive aperture in the projector

6.3.2 The specimen surface must be positionable so that the

slide port.

entrance angle is accurate to within 0.5% of its complement

6.1.5 The source shall be regulated such that the illumi-

(that is, for a 30° entrance angle this angle must be accurately

nance at the test surface does not change by more than 61%

set to 6 0.005 × 60°= 60.3°).This is obtainable by providing

for the duration of the test.

an accurate optical means to align the test surface to the “0

6.1.6 The illuminance produced on the sample surface shall

degree” entrance angle and then adjusting the angular setting

be uniform within 65% of the average illuminance normal to

(within the required tolerance).

the source at the distance of 15 m.

6.2 Receiver—The receiver shall meet the requirements that

−1 −2

follow. (In this test, for 10 lx incident upon a 1 cd·lx ·m

retroreflective sheeting test specimen with area of 0.04 m , the

incident normal illuminance at the receiver will be about

−3

1.8×10 lx).

6.2.1 The responsivity and range of the receiver shall be

sufficient so that readings of both the incident normal illumi-

nance (at the specimen) and the retroreflected light at the

observation position can be measured with a resolution of at

least 1 part in 50 on the readout scale.

6.2.2 The spectral responsivity of the receiver shall match

that of the 1931 CIE Standard Photopic Observer (see Annex

A1 of Practice E809).

6.2.3 The

...

This document is not anASTM standard and is intended only to provide the user of anASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:E810–01 Designation: E 810 – 03 (Reapproved 2008)

Standard Test Method for

Coefficient of Retroreflection of Retroreflective Sheeting

Utilizing the Coplanar Geometry

This standard is issued under the fixed designation E810; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This test method describes an instrument measurement of the retroreflective performance of retroreflective sheeting.

1.2 The user of this test method must specify the entrance and observation angles to be used, and may specify the rotation

angles.

1.3 This test method is intended as a laboratory test and requires a facility that can be darkened sufficiently so that stray light

does not affect the test results. The testing apparatus must be able to achieve the coplanar geometry.

1.4 Portable and bench retroreflection measuring equipment may be used to determine R values provided the geometry and

A

appropriate substitution standard reference panels, measured in accordance with this test method, are utilized. In this case the

methods of Procedure B in Practice E809 apply.Additional information on the use of portable retroreflectometers may be found

in Test Method E1709.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2.1 ASTM Standards:

E284 Terminology of Appearance

E308 Practice for Computing the Colors of Objects by Using the CIE System

E691 Practice for Conducting an Interlaboratory Study to Determine the Precision of a Test Method

E808 Practice for Describing Retroreflection

E809 Practice for Measuring Photometric Characteristics of Retroreflectors

E1709 Test Method for Measurement of Retroreflective Signs Using a Portable Retroreflectivemeter Retroreflectometer

2.2 Other Document:

CIE Publication No54 Retroreflection—Definition and Measurement

3. Terminology

3.1 The terms and definitions in Terminology E284 and Practice E808 apply to this test method.

3.2 Definitions:

3.2.1 coeffıcient of retroreflection, R —of a plane retroreflecting surface, the ratio of the coefficient of luminous intensity (R )

A I

−1 −2

to the area ( A), expressed in candelas per lux per square metre (cd·lx ·m ). R = R/A.

A I

3.2.1.1 Discussion—The equivalent inch–pound units for coefficient of retroreflection are candelas per foot-candle per square

−1 −2

foot (cd·fc ·ft ). The SI and inch pound units are numerically equal, because the units of R reduce to 1/sr.An equivalent term

A

usedforcoefficientofretroreflectionisspecificintensityperunitarea,withsymbolSIAortheCIEsymbolR8.Thetermcoefficient

−1 −2

of retroreflection and the symbol R along with the SI units of candelas per lux per square meter (cd·lx ·m ) are recommended

A

by ASTM.

3.2.1.2 Discussion—R is a useful engineering quantity for determining the photometric performance of such retroreflective

A

surfacesashighwaydelineatorsorwarningdevices. R mayalsobeusedtodeterminetheminimumareaofretroreflectivesheeting

A

ThistestmethodisunderthejurisdictionofASTMCommitteeE12onColorandAppearanceandisthedirectresponsibilityofSubcommitteeE12.10onRetroreflection.

Current edition approved June 10, 2001. Published August 2001. Originally published as E810–81. Last previous edition E810–94(2000).

Current edition approved Feb. 1, 2008. Published February 2008. Originally approved in 1981. Last previous edition approved in 2003 as E810–03.

ForreferencedASTMstandards,visittheASTMwebsite,www.astm.org,orcontactASTMCustomerServiceatservice@astm.org.For Annual Book of ASTM Standards

, Vol 06.01.volume information, refer to the standard’s Document Summary page on the ASTM website.

Annual Book of ASTM Standards, Vol 14.02.

Available from U.S. National Committee of the CIE (International Commission on Illumination), C/o Thomas M. Lemons, TLA-Lighting Consultants, Inc., 7 Pond St.,

Salem, MA 01970, http://www.cie-usnc.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

E 810 – 03 (2008)

necessary for a desired level of photometric performance. R has been used extensively in the specification of retroreflective

A

sheeting.

3.2.2 coplanar geometry, n—retroreflection geometry in which the retroreflector axis, illumination axis, and observation axis

lie in one plane.

3.2.2.1 Discussion—In the coplanar geometry: the second entrance angle component, b , is equal to 0°; presentation angle, g,

is equal to either 0° or 180°; orientation angle, v , is equal to either the rotation angle, e,orto e + 180° or e − 180°.

s

3.2.3 datum axis, n—a designated half-line from the retroreflector center perpendicular to the retroreflector axis.

3.2.4 datum mark, n— an indication on the retroreflector, off the retroreflector axis, that establishes the direction of the datum

axis.

3.2.5 entrance angle, b, n—the angle between the illumination axis and the retroreflector axis.

3.2.5.1 Discussion—The entrance angle is usually no larger than 90°, but for completeness its full range is defined as 0°# b

# 180°. In the CIE (goniometer system) b is resolved into two components b and b . Since by definition b is always positive,

1 2

the common practice of referring to the small entrance angles that direct specular reflections away from the photoreceptor as a

negative value is deprecated by ASTM. The recommendation is to designate such negative values as belonging to b .

3.2.6 goniometer, n—an instrument for measuring or setting angles.

3.2.7 illumination axis, n—the half-line from the retroreflector center through the source point.

3.2.8 observation angle, a, n—the angle between the illumination axis and the observation axis.

3.2.8.1 Discussion—The observation angle is never negative and is almost always less than 10° and usually no more than 2°.

The full range is defined as 0°# a < 180°.

3.2.9 observation axis, n—the half-line from the retroreflector center through the observation point.

3.2.10 receiver, n— the portion of a photometric instrument that receives the viewing beam from the specimen, including a

collector such as an integrating sphere, if used, often the monochromator or spectral filters, the detector, and associated optics and

electronics.

3.2.11 retroreflection, n—reflection in which the reflected rays are preferentially returned in directions close to the opposite of

B

the direction of the incident rays, this property being maintained over wide variations of the direction of the incident rays. [CIE]

3.2.12 retroreflective material, n—a material that has a thin continuous layer of small retroreflective elements on or very near

its exposed surface (for example, retroreflective sheeting, retroreflective fabrics, transfer films, beaded paint, highway surface

signs, or pavement striping).

3.2.13 retroreflective sheeting—a retroreflective material preassembled as a thin film ready for use.

3.2.14 retroreflector, n—a reflecting surface or device from which, when directionally irradiated, the reflected rays are

preferentially returned in directions close to the opposite of the direction of the incident rays, this property being maintained over

B

wide variations of the direction of the incident rays. [CIE, 1982]

3.2.15 retroreflector axis, n—a designated half-line from the retroreflector center.

3.2.15.1 Discussion—The direction of the retroreflector axis is usually chosen centrally among the intended directions of

illumination;forexample,thedirectionoftheroadonwhichorwithrespecttowhichtheretroreflectorisintendedtobepositioned.

The retroreflector axis usually coincides with the axis of symmetry of the retroreflector. For retroreflective sheeting the normal to

the surface is chosen as the retroreflector axis.

3.2.16 retroreflector center, n—the point on or near a retroreflector that is designated to be the location of the device.

3.2.17 rotation angle, e, n—the angle in a plane perpendicular to the retroreflector axis from the observation half-plane to the

datum axis, measured counterclockwise from a viewpoint on the retroreflector axis.

3.2.17.1 Discussion— Range:−180° < e# 180°. The definition is applicable when entrance angle and viewing angle are less

than 90°. More generally, rotation angle is the angle from the positive part of second axis to the datum axis, measured

counterclockwise from a viewpoint on the retroreflector axis.

3.2.17.2 Discussion—Rotation of the sample about the retroreflector axis while the source and receiver remain fixed in space

changes the rotation angle (e) and the orientation angle (v ) equally.

s

3.2.18 rotationally uniform, adj—havingsubstantiallyconstantR ,whenrotatedabouttheretroreflectoraxis,whilethesource,

A

receiver, retroreflector center and retroreflector axis all remain in a fixed spatial relation.

3.2.18.1 Discussion—The degree of rotational uniformity can be specified numerically.

3.2.19 source, n—an object that produces light or other radiant flux.

4. Summary of Test Method

4.1 This test method involves the use of a light projector source, a receiver, a device to position the receiver with respect to the

source and a test specimen holder in a suitable darkened area. The specimen holder is separated from the light source by 15 m.

4.2 The general procedure involved is to determine the ratio of the light retroreflected from the test surface to that incident on

the test surface.

4.3 The photometric quantity, coefficient of retroreflection, is calculated from these measurements.

5. Significance and Use

5.1 Measurements made by this test method are related to visual observations of retroreflective sheeting as seen by the human

E 810 – 03 (2008)

eye when illuminated by tungsten-filament light sources such as a motor vehicle headlamp.

5.2 The values determined relate to the visual effects for a given geometric configuration as specified by the user of the test

method. This test method has been found useful for tests at observation angles between 0.1 and 2.0° (observation angles between

0.1° and 0.2° may be achieved by careful design of source and receiver aperture configuration), and at entrance angles up to 60°.

−1 −2 −1

It has been used to determine coefficient of retroreflection values as low as 0.1 cd·lx ·m , but for values less than 1 cd·lx ·

−2

m special attention must be given to the responsivity of the receiver and to the elimination of very small amounts of stray light.

6. Apparatus

6.1 Light Source—The light source shall be of the projector type and shall meet the following requirements (an illuminance at

the 15-m15 m specimen distance of about 10 lx is commonly available within these restrictions):

6.1.1 The spectral energy distribution of the source shall be proportional to CIE standard Source A (a correlated color

temperature of 2856 K, see Practice E308). The projection lamp together with the projection optics shall be operated such that

it illuminates the test specimen with this spectral power distribution.

6.1.2 An unpolarizing light source shall be used.

6.1.3At observation angles between 0.2° and 2.0°, the exit aperture of the source shall be uniformly radiant, circular and 26 mm

(62 mm) in diameter. This corresponds to a 0.1° angular aperture at the 15 m test distance. At observation angles between 0.1°

and 0.2°, the exit aperture of the source shall be uniformly radiant, circular and 13 mm (61 mm) in diameter. This corresponds

to a 0.05° angular aperture at the 15 m test distance.

6.1.3 The source aperture shall be a standard circular aperture as defined in Practice E809. For measurements at observation

angles(a)of0.2°# a#2.0°,theexitapertureofthesourceshallbeuniformlyradiant,circularand26mm(62mm)indiameter.

This corresponds to 0.1° angular aperture at 15 m test distance. For measurements at observation angles (a) of 0.1°# a < 0.2°,

the exit aperture of the source shall be uniformly radiant, circular and 13 mm (61 mm) in diameter. This corresponds to 0.05°

angular aperture at 15 m test distance.

6.1.4 The illumination at the sample produced by the projector shall be such that the test specimen and only a minimum of the

background is illuminated. This is commonly accomplished by placing a restrictive aperture in the projector slide port.

6.1.5 The source shall be regulated such that the illuminance at the test surface does not change by more than 61% for the

duration of the test.

6.1.6 The illuminance produced on the sample surface shall be uniform within 65% of the average illuminance normal to the

source at the distance of 15 m.

−1 −2

6.2 Receiver—The receiver shall meet the requirements that follow. (In this test, for 10 lx incident upon a 1 cd·lx ·m

retroreflective sheeting test specimen with area of 0.04 m , the incident normal illuminance at the receiver will be about 1.8 310

−3lx).

6.2.1 The responsivity and range of the receiver shall be sufficient so that readings of both the incident normal illuminance (at

the specimen) and the retroreflected light at the observation position can be measured with a resolution of at least 1 part in 50 on

the readout scale.

6.2.2 The spectral responsivity of the receiver shall match that of the 1931 CIE Standard Photopic Observer (seeAnnexA1 of

Practice E809).

6.2.3 The receiver shall be insensitive to the polarization of light.

6.2.4 Thelinearityofthephotometricscaleovertherangeofreadingstobetakenshallbewithin 61%.Correctionfactorsmay

be used to ensure a linear response. Linearity verification tests must be made utilizing the entire receiver readout device including

the detector, load, range selection system and readout display device.

6.2.5 The stability of the receiver shall be such that readings from a constant source do not vary any more than 1% for the

duration of the test.

6.2.6 The field of view shall be limited by use of light baffles or a field aperture on the instrument so that the entire test sample

isfullywithinthefieldofview,rejectingstraylightasmuchaspractical.Abackgroundlightlevel m lessthan5%ofthesmallest

b

m reading is acceptable.

6.2.7 The receiver aperture shall be a standard circular aperture as defined in Practice E809. For measurements at observation

anglesbetween(a)of0.2°an

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.