ASTM D4388-13

(Specification)Standard Specification for Nonmetallic Semi-Conducting and Electrically Insulating Rubber Tapes

Standard Specification for Nonmetallic Semi-Conducting and Electrically Insulating Rubber Tapes

ABSTRACT

This specification covers nonmetallic semi-conducting and electrically insulating rubber tapes designed for the splicing and repair of electrical wire and cables operating at specified phase to phase voltages. The tapes, which are classified into five types (Types I, II, III, IV, and V), shall conform to physical property requirements such as tensile strength, elongation at break, dielectric strength, dissipation factor, permittivity, volume resistivity, behavior during fusion test, ozone resistance, heat exposure, and UV resistance.

SCOPE

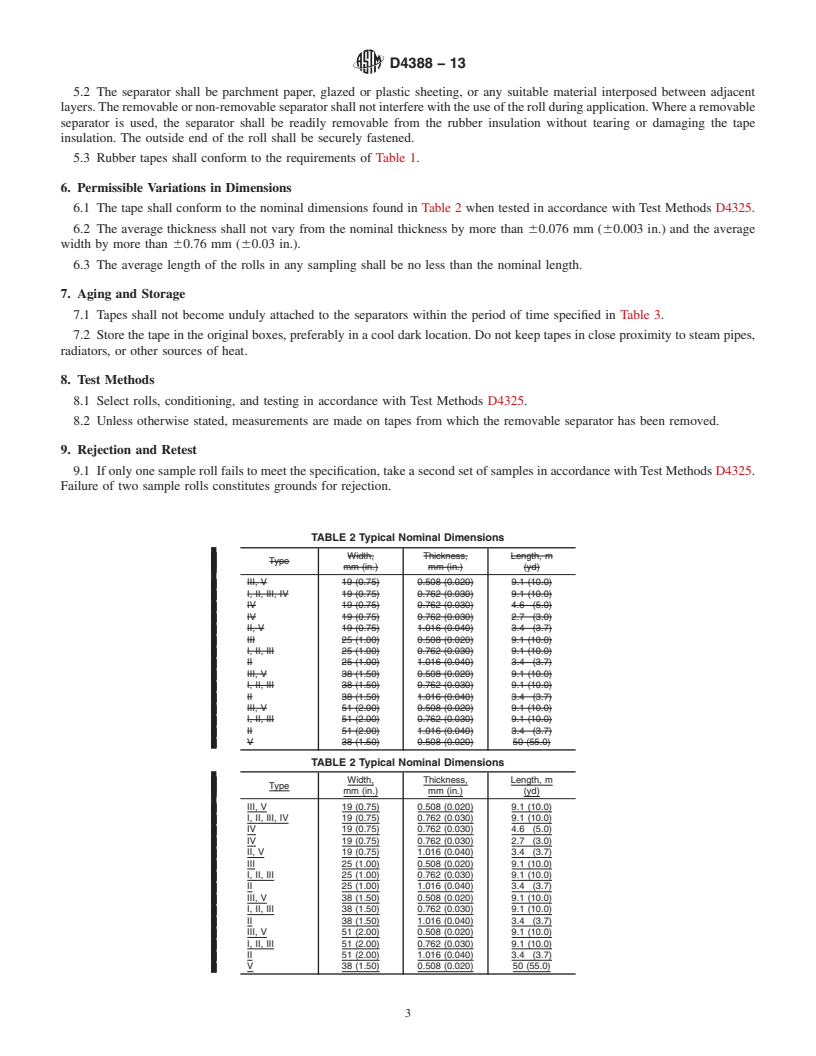

1.1 This specification covers nonmetallic semi-conducting and electrical insulating tapes designed for the splicing and repair of electrical wire and cables operating at voltages up to 325 kV, phase to phase.

1.2 The SI values are the standard. The values stated in inch-pound units given in parentheses are for information purposes only.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D4388 −13

Standard Specification for

Nonmetallic Semi-Conducting and Electrically Insulating

1

Rubber Tapes

This standard is issued under the fixed designation D4388; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope* overwrap. Apply the tape to the wire or cable within an

ambient temperature range of−10 and 40 °C (14 and 104 °F).

1.1 This specification covers nonmetallic semi-conducting

4.1.2 Type II—A medium voltage, ozone-resistant, rubber

and electrical insulating tapes designed for the splicing and

insulating tape designed for use with wires and cables operat-

repair of electrical wire and cables operating at voltages up to

ing up to 35 000 V phase to phase in either wet or dry

325 kV, phase to phase.

locationswithconductortemperaturesupto90°C(194°F)for

1.2 The SI values are the standard. The values stated in

continuous operation, up to 130 °C (266 °F) for emergency

inch-pound units given in parentheses are for information

overloadconditions,andupto250°C(482°F)forshort-circuit

purposes only.

conditions when installed in accordance with the manufactur-

er’s instruction. For wet or dry outdoor use, protect the tape

2. Referenced Documents

from ultraviolet radiation by the use of a suitable overwrap.

2

2.1 ASTM Standards:

Apply the tape to the wire or cable within an ambient

D1711Terminology Relating to Electrical Insulation

temperature range of−10 and 40 °C (14 and 104 °F).

D4325Test Methods for Nonmetallic Semi-Conducting and

4.1.3 Type III—A high voltage, ozone-resistant, rubber in-

Electrically Insulating Rubber Tapes

sulating tape designed for use with wires and cables operating

up to 138 000 V phase to phase in either wet or dry locations

3. Terminology

with conductor temperatures up to 90 °C (194 °F) for continu-

3.1 Definitions—Use Terminology D1711 for definitions of

ous operation, up to 130 °C (266 °F) for emergency overload

terms used in these test methods and associated with electrical

conditions, and up to 250 °C (482 °F) for short-circuit

or electronic insulation materials.

conditions when installed in accordance with the manufactur-

er’s instructions. This tape is suitable for wet or dry outdoor

4. Classification

use. Apply the tape to the wire or cable within an ambient

4.1 Types:

temperature range of−10 and 40 °C (14 and 104 °F).

4.1.1 Type I—Alowvoltagerubberinsulatingtapedesigned

4.1.4 Type IV—A nonmetallic semi-conducting tape de-

for use on wires and cables operating up to 2000 V phase to

signed for shielding various portions of joints and terminations

phaseindrylocationswithconductortemperaturesupto80°C

in electrical wires and cables operating at any voltage under

(176 °F) for continuous operation, up to 95 °C (203 °F) for

wet or dry conditions with conductor temperatures up to 90 °C

emergency overload conditions, and up to 150 °C (302 °F) for

(194°F)forcontinuousoperation,orupto130°C(266°F)for

short-circuit conditions. For outdoor use, protect the tape from

emergencyoverloadconditions.Thistapeissuitableforwetor

ozone attack and ultraviolet radiation by the use of a suitable

dry outdoor use.Apply the tape to the wire or cable within an

ambient temperature range of−10 and 40 °C (14 and 104 °F).

1

This specification is under the jurisdiction of ASTM Committee D09 on 4.1.5 Type V—A higher voltage, ozone-resistant, rubber

Electrical and Electronic Insulating Materials and is the direct responsibility of

insulating tape designed for use with wires and cables operat-

Subcommittee D09.07 on Flexible and Rigid Insulating Materials.

ing up to 325 000 V phase to phase in either wet or dry

Current edition approved Nov. 1, 2013. Published December 2013. Originally

locationswithconductortemperaturesupto90°C(194°F)for

approved in 1984. Last previous edition approved in 2008 as D4388–08. DOI:

10.1520/D4388-13.

continuous operation, up to 130 °C (266 °F) for emergency

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

overload, and up to 250 °C (482 °F) short-circuit conditions

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

when installed in accordance with the manufacturer’s instruc-

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. tions.Thistapeissuitableforwetordryoutdooruse.Applythe

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page:

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: D4388 − 08 D4388 − 13 An American National Standard

Standard Specification for

Nonmetallic Semi-Conducting and Electrically Insulating

1

Rubber Tapes

This standard is issued under the fixed designation D4388; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope*

1.1 This specification covers nonmetallic semi-conducting and electrical insulating tapes designed for the splicing and repair of

electrical wire and cables operating at voltages up to 325 kV, phase to phase.

1.2 The SI values are the standard. The values stated in inch-pound units given in parentheses are for information purposes only.

2. Referenced Documents

2

2.1 ASTM Standards:

D1711 Terminology Relating to Electrical Insulation

D4325 Test Methods for Nonmetallic Semi-Conducting and Electrically Insulating Rubber Tapes

3. Terminology

3.1 Definitions—Use Terminology D1711 for definitions of terms used in these test methods and associated with electrical or

electronic insulation materials.

4. Classification

4.1 Types:

4.1.1 Type I—A low voltage rubber insulating tape designed for use on wires and cables operating up to 2000 V phase to phase

in dry locations with conductor temperatures up to 80 °C (176 °F) for continuous operation, up to 95 °C (203 °F) for emergency

overload conditions, and up to 150 °C (302 °F) for short-circuit conditions. For outdoor use, protect the tape from ozone attack

and ultraviolet radiation by the use of a suitable overwrap. Apply the tape to the wire or cable within an ambient temperature range

of − 10 and 40 °C (14 and 104 °F).

4.1.2 Type II—A medium voltage, ozone-resistant, rubber insulating tape designed for use with wires and cables operating up

to 35 000 V phase to phase in either wet or dry locations with conductor temperatures up to 90 °C (194 °F) for continuous

operation, up to 130 °C (266 °F) for emergency overload conditions, and up to 250 °C (482 °F) for short-circuit conditions when

installed in accordance with the manufacturer’s instruction. For wet or dry outdoor use, protect the tape from ultraviolet radiation

by the use of a suitable overwrap. Apply the tape to the wire or cable within an ambient temperature range of − 10 and 40 °C (14

and 104 °F).

4.1.3 Type III—A high voltage, ozone-resistant, rubber insulating tape designed for use with wires and cables operating up to

138 000 V phase to phase in either wet or dry locations with conductor temperatures up to 90 °C (194 °F) for continuous operation,

up to 130 °C (266 °F) for emergency overload conditions, and up to 250 °C (482 °F) for short-circuit conditions when installed

in accordance with the manufacturer’s instructions. This tape is suitable for wet or dry outdoor use. Apply the tape to the wire or

cable within an ambient temperature range of − 10 and 40 °C (14 and 104 °F).

4.1.4 Type IV—A nonmetallic semi-conducting tape designed for shielding various portions of joints and terminations in

electrical wires and cables operating at any voltage under wet or dry conditions with conductor temperatures up to 90 °C (194 °F)

1

This specification is under the jurisdiction of ASTM Committee D09 on Electrical and Electronic Insulating Materials and is the direct responsibility of Subcommittee

D09.07 on Flexible and Rigid Insulating Materials.

Current edition approved May 1, 2008Nov. 1, 2013. Published June 2008December 2013. Originally approved in 1984. Last previous edition approved in 20022008 as

D4388 – 02.D4388 – 08. DOI: 10.1520/D4388-08.10.1520/D4388-13.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D4388 − 13

for continuous operation, or up to 130 °C (266 °F) for emergency overload conditions. This tape is suitable for wet or dry outdoor

use. Apply the tape to the wire or cable within an ambient temperature range of − 10 and 40 °C (14 and

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.