ASTM F1837M-97(2023)

(Specification)Standard Specification for Heat-Shrink Cable Entry Seals (Metric)

Standard Specification for Heat-Shrink Cable Entry Seals (Metric)

ABSTRACT

This specification covers the general requirements for heat-shrink cable entry seals. Cable entry seals are intended for making electrical cable penetrations into connection boxes, bulkheads, or other enclosures. Heat-shrink cable entry seals shall be of the following types: Type I (Types I-1, I-2, I-3, I-4, I-5, and I-6); Type II (Types II-1, II-2, II-3, and II-4); Type III; and Type IV. The rigid plastic parts shall be made from polyamide (nylon), or polyester material, or both. The following tests shall be performed: conformance testing; mechanical abuse test; and level of effectiveness.

SCOPE

1.1 This specification covers the general requirements for heat-shrink cable entry seals. Cable entry seals are intended for making electrical cable penetrations into connection boxes, bulkheads, or other enclosures. These devices are suitable for both thin wall enclosures up to 5 mm (3/16 in.) thick and thick-wall enclosures of 5 mm to 19 mm (3/16 in. to 3/4 in.) thick.

1.2 Cable entry seals shall have factory-applied adhesive that provides the seal to wire and cable jackets.

1.3 The values stated in SI units are to be regarded as standard. The values given in parentheses are mathematical conversions to inch-pound units that are provided for information only and are not considered standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: F1837M − 97 (Reapproved 2023) An American National Standard

Standard Specification for

Heat-Shrink Cable Entry Seals (Metric)

This standard is issued under the fixed designation F1837M; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope D412 Test Methods for Vulcanized Rubber and Thermoplas-

tic Elastomers—Tension

1.1 This specification covers the general requirements for

D570 Test Method for Water Absorption of Plastics

heat-shrink cable entry seals. Cable entry seals are intended for

D635 Test Method for Rate of Burning and/or Extent and

making electrical cable penetrations into connection boxes,

Time of Burning of Plastics in a Horizontal Position

bulkheads, or other enclosures. These devices are suitable for

D747 Test Method for Apparent Bending Modulus of Plas-

both thin wall enclosures up to 5 mm ( ⁄16 in.) thick and

tics by Means of a Cantilever Beam (Withdrawn 2019)

3 3

thick-wall enclosures of 5 mm to 19 mm ( ⁄16 in. to ⁄4 in.) thick.

D792 Test Methods for Density and Specific Gravity (Rela-

1.2 Cable entry seals shall have factory-applied adhesive

tive Density) of Plastics by Displacement

that provides the seal to wire and cable jackets.

D2240 Test Method for Rubber Property—Durometer Hard-

1.3 The values stated in SI units are to be regarded as ness

D2671 Test Methods for Heat-Shrinkable Tubing for Elec-

standard. The values given in parentheses are mathematical

conversions to inch-pound units that are provided for informa- trical Use

D2863 Test Method for Measuring the Minimum Oxygen

tion only and are not considered standard.

Concentration to Support Candle-Like Combustion of

1.4 This standard does not purport to address all of the

Plastics (Oxygen Index)

safety concerns, if any, associated with its use. It is the

D3149 Specification for Crosslinked Polyolefin Heat-

responsibility of the user of this standard to establish appro-

Shrinkable Tubing for Electrical Insulation (Withdrawn

priate safety, health, and environmental practices and deter-

2020)

mine the applicability of regulatory limitations prior to use.

D4066 Classification System for Nylon Injection and Extru-

1.5 This international standard was developed in accor-

sion Materials (PA)

dance with internationally recognized principles on standard-

D4732 Specification for Cool-Application Filling Com-

ization established in the Decision on Principles for the

pounds for Telecommunications Wire and Cable

Development of International Standards, Guides and Recom-

2.2 ASME Standard:

mendations issued by the World Trade Organization Technical

ASME B1.1 Unified Inch Screw Threads (UN and UNR

Barriers to Trade (TBT) Committee.

Thread Form)

2. Referenced Documents 2.3 NEMA Standard:

2 NEMA 250 Enclosures for Electrical Equipment (1000 Volts

2.1 ASTM Standards:

Max)

D149 Test Method for Dielectric Breakdown Voltage and

2.4 IEC Standard:

Dielectric Strength of Solid Electrical Insulating Materials

IEC 68-2-6 Environmental Testing–Part 2: Tests–Test FC:

at Commercial Power Frequencies

Vibration (Sinusoidal), Sixth Edition

D257 Test Methods for DC Resistance or Conductance of

Insulating Materials

3. Terminology

3.1 Definitions of Terms Specific to This Standard:

1 3

This specification is under the jurisdiction of ASTM Committee F25 on Ships The last approved version of this historical standard is referenced on

and Marine Technology and is the direct responsibility of Subcommittee F25.10 on www.astm.org.

Electrical. Available from American Society of Mechanical Engineers (ASME), ASME

Current edition approved Dec. 1, 2023. Published December 2023. Originally International Headquarters, Two Park Ave., New York, NY 10016-5990, http://

approved in 1997. Last previous edition approved in 2018 as F1837M – 97 (2018). www.asme.org.

DOI: 10.1520/F1837M-97R23. Available from National Electrical Manufacturers Association (NEMA), 1300

For referenced ASTM standards, visit the ASTM website, www.astm.org, or N. 17th St., Suite 900, Arlington, VA 22209, http://www.nema.org.

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Available from International Electrotechnical Commission (IEC), 3, rue de

Standards volume information, refer to the standard’s Document Summary page on Varembé, 1st floor, P.O. Box 131, CH-1211, Geneva 20, Switzerland, https://

the ASTM website. www.iec.ch.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

F1837M − 97 (2023)

3.1.1 heat-shrink cable entry seal, n—heat-shrinkable tube 5.1.1 Part Number (see Figs. 1-6).

making a watertight, fume-tight seal where cable connections 5.1.2 Quantity (per each part).

boxes, bulkheads, or other enclosures.

6. Materials and Manufacture

3.1.2 polyolefin, n—a polymer made by the polymerization

of hydrocarbon olefins or copolymerization olefins.

6.1 The rigid plastic parts shall be made from polyamide

(nylon), or polyester material, or both. The material shall be

4. Classification

Group 1, Class 8, Grade 1 as specified in Specification D4066.

4.1 Heat-shrink cable entry seals shall be of the following

6.1.1 Threads shall be unified form UN 2A or 2B or taper

types:

pipe thread (NPT) as specified in ASME B1.1.

4.1.1 Type 1, standard cable entry seals for thin-wall enclo-

6.2 The heat-shrinkable tubing shall be of a crosslinked

sures shall consist of the three part assembly; a rigid plastic

polyolefin in accordance with Type III of Specification D3149.

nut, O-ring, and heat-shrinkable molded area.

4.1.1.1 Type I–1, molded area configured with one opening 6.3 The adhesive shall be general purpose high-bond-

strength adhesive sealant that provides stain relief and envi-

for a single wire or cable entry.

4.1.1.2 Type I–2, molded area configured with two equal ronmental sealing of heat-shrink tubing to cable jackets.

size openings to seal two wires or cables.

6.4 O-rings shall be made of a material conforming to Type

4.1.1.3 Type I–3, molded area configured with three equal

II of Specification D4732.

size openings to seal three wires or cables.

6.5 The polyolefin heat-shrinkable tubing shall met require-

4.1.1.4 Type I–4, molded area configured with four equal

ments of Test Methods D2671.

size openings to seal four wires or cables.

4.1.1.5 Type I–5, molded area configured with six equal size

7. Other Requirements

openings to seal six wires or cables.

4.1.1.6 Type I–6, molded area configured with eight equal

7.1 Dimensional Requirements—Cable-entry seals shall

size openings to seal eight wires or cables.

conform to the dimensional requirements of Tables 1-6. Type I

4.1.2 Type II, cable entry seal for threaded hole applications

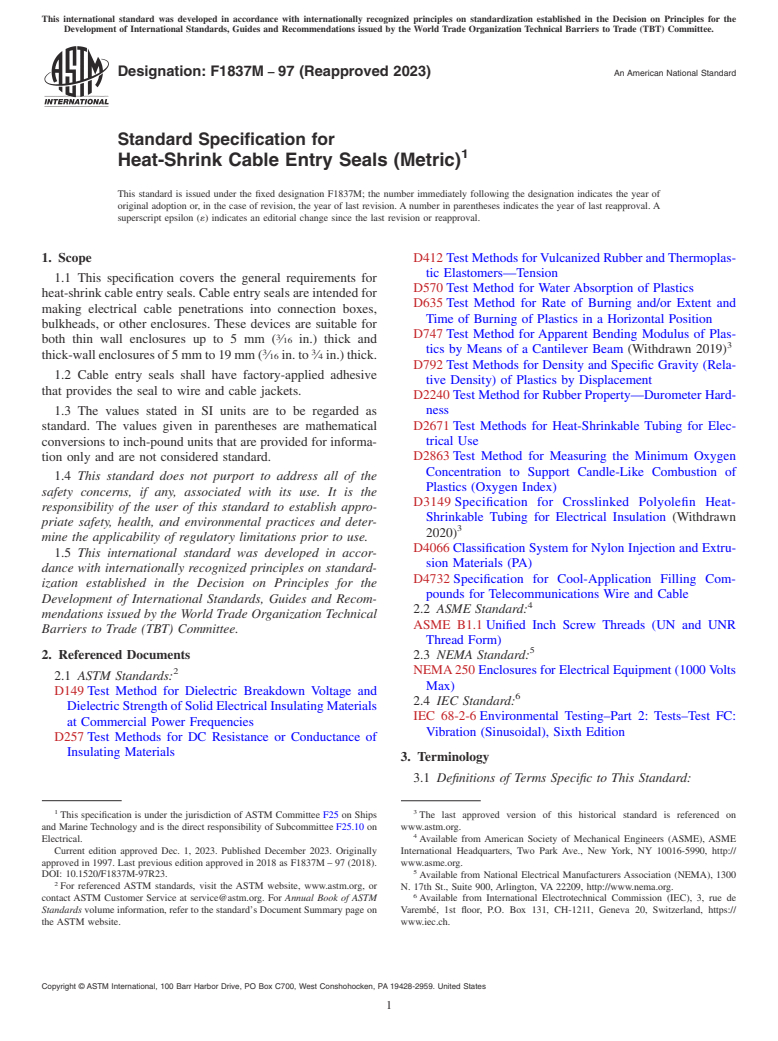

cable-entry seals are presented in Fig. 1 and Fig. 2. Type II

shall consist of a one-part assembly that combines a tapered

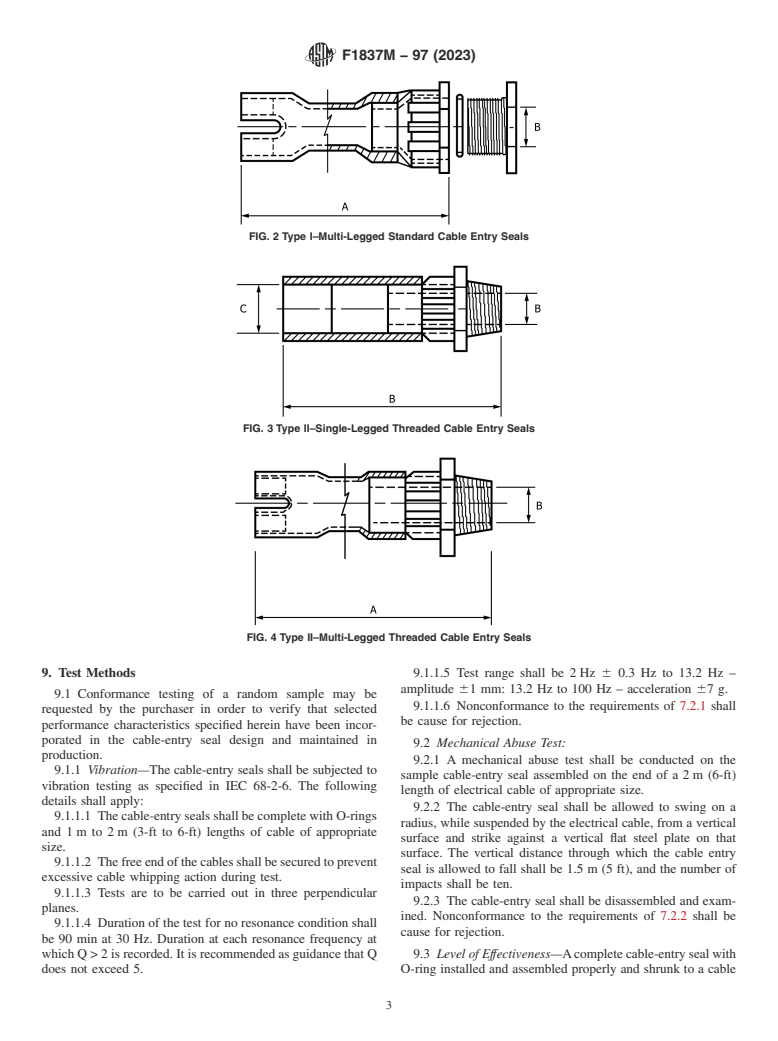

cable-entry seals are presented in Fig. 3 and Fig. 4. Right-angle

national pipe thread (NPT) in rigid plastic with heat-shrinkable

cable-entry seals (Types III and IV) are presented in Fig. 5 and

molded area.

Fig. 6.

4.1.2.1 Type II–1, molded area configured with one opening

7.2 Performance Requirements:

for a single wire or cable entry.

7.2.1 Vibration Resistance—When cable-entry seals are

4.1.2.2 Type II–2, molded area configured with two equal

tested as specified in 9.1, there shall be no evidence of cracking

size openings to seal two wires or cables.

or loosening of parts.

4.1.2.3 Type II–3, molded area configured with three equal

7.2.2 Ruggedness—When cable-entry seals are subjected to

size openings to seal three wires or cables.

a mechanical abuse test as specified in 9.2, there shall be no

4.1.2.4 Type II–4, molded area configured with four equal

cracking, breaking, distortion, or damage to the sample.

size openings to seal four wires or cables.

7.2.3 Effectiveness of Seal—When cable-entry seals are

4.1.3 Type III, right angle cable entry seal for thin-wall

tested as specified in 9.3, there shall be no evidence of leakage

enclosure shall consist of a three part assembly; a rigid plastic

through or around the cable entry seals.

nut, O-ring, and heat-shrinkable molded area.

4.1.4 Type IV, right angle cable entry seal for threaded hole

8. Workmanship, Finish, and Appearance

application shall consist of a one-part assembly that combines

a tapered national pipe thread (NPT) in rigid plastic with a 8.1 Cable-entry seals shall be free from warp, cracks,

chipped edges, or surfaces, blisters, uneven surfaces, scratches,

heat-shrinkable molded area.

dents, and flow lines. They shall be free from fins, burrs, and

5. Ordering Information

unsightly finish caused by chipping, filling, or grinding without

subsequent buffing or polishing. All molded parts shall be

5.1 Orders for cable entry seals under this specification shall

include the following: cleaned thoroughly of annealing mediums.

FIG. 1 Type I–Single-Legged Standard Cable Entry Seals

F1837M − 97 (2023)

FIG. 2 Type I–Multi-Legged Standard Cable Entry Seals

FIG. 3 Type II–Single-Legged Threaded Cable Entry Seals

FIG. 4 Type II–Multi-Legged Threaded Cable Entry Seals

9. Test Methods 9.1.1.5 Test range shall be 2 Hz 6 0.3 Hz to 13.2 Hz –

amplitude 61 mm: 13.2 Hz to 100 Hz – acceleration 67 g.

9.1 Conformance testing of a random sample may be

9.1.1.6 Nonconformance to the requirements of 7.2.1 shall

requested by the purchaser in order to verify that selected

be cause for rejection.

performance characteristics specified herein have been incor-

porated in the cable-entry seal design and maintained in

9.2 Mechanical Abuse Test:

production.

9.2.1 A mechanical abuse test shall be conducted on the

9.1.1 Vibration—The cable-entry seals shall be subjected to

sample cable-entry seal assembled on the end of a 2 m (6-ft)

vibration testing as specified in IEC 68-2-6. The following

length of electrical cable of appropriate size.

details shall apply:

9.2.2 The cable-entry seal shall be allowed to swing on a

9.1.1.1 The cable-entry seals shall be complete with O-rings

radius, while suspended by the electrical cable, from a vertical

and 1 m to 2 m (3-ft to 6-ft) lengths of cable of appropriate

surface and strike against a vertical flat steel plate on that

size.

surface. The vertical distance through which the cable entry

9.1.1.2 The free end of the cables shall be secured to prevent

seal is allowed to fall shall be 1.5 m (5 ft), and the number of

excessive cable whipping action during test.

impacts shall be ten.

9.1.1.3 Tests are to be carried out in three perpendicular

9.2.3 The cable-entry seal shall be disassembled and exam-

planes.

ined. Nonconformance to the requirements of 7.2.2 shall be

9.1.1.4 Duration of the test for no resonance condition shall

cause for rejection.

be 90 min at 30 Hz. Duration at each resonance frequency at

which Q > 2 is recorded. It is recommended as guidance that Q 9.3 Level of Effectiveness—A complete cable-entry seal with

does not exceed 5. O-ring installed and assembled properly and shrunk to a cable

F1837M − 97 (2023)

FIG. 5 Type III–Right-Angle Cable Entry Seals

FIG. 6 Type IV–Right-Angle Cable Entry Seals

or with a plug installed shall conform to the performance 11. Certification

requirements of NEMA 250. The NEMA enclosure type

11.1 Material Certification—Material certification shall be

designation (4, 4X, 6, 6P) shall establish the appropriate

required from the manufacturers of the plastic material and

environmental capability required of the installed cable-entry

shirk-tubing to ensure the materials were manufactured,

seal.

sampled, tested, and inspected in accordance with Specifica-

9.3.1 Nonconformance to the requirements of 7.2.3 shall be

tions D4066 and D3149. Material identity traceable to this

cause for rejection.

certification shall be maintained throughout the manufacturing

process.

10. Inspection

11.2 When specified in the purchase order or contract, the

10.1 Visual and Dimensional Examination—Samples shall

be examined visually to verify that the materials, design, purchaser shall be furnished certification that samples repre-

construction, physical dimensions, marking, and workmanship senting each lot have been either tested or inspected as directed

are as specified in the applicable requirements. in this specification and the requirements have been met. When

F1837M − 97 (2023)

A

TABLE 1 Type 1—Single Legged Standard Cable Entry Seals

C B A

Tubing

Expanded I.D. Recovered I.D. Overall Nominal

B

(min) (max) I.D. (min) Recovered Recommended Part No.

Length Hole Diameter

13.0 (0.50) 3.0 (0.12) 19.0 (0.75) 89.0 (3.50) 25.5 (1.00) CES S 1-1

19.0 (0.75) 6.5 (0.25) 19.0 (0.75) 89.0 (3.50) 25.5 (1.00) CES S 1-2

19.0 (0.75) 6.5 (0.25) 19.0 (0.75) 32.0 (1.25) 25.5 (1.00) CES S 1-3

28.5 (1.20) 13.0 (0.50) 28.0 (1.10) 95.0 (3.75) 35.0 (1.38) CES S 1-4

35.0 (1.38) 13.0 (0.50) 28.0 (1.10) 95.0 (3.75) 44.5 (1.75) CES S 1-5

40.0 (1.70) 19.0 (0.75) 40.0 (1.60) 120.0 (4.75) 51.0 (2.00) CES S 1-6

70.0 (2.75) 19.0 (0.75) 53.0 (2.10) 102.0 (4.00) 60.0 (2.36) CES S 1-7

70.0 (2.75) 36.0 (1.43) 74.0 (2.90) 178.0 (7.00) 89.0 (3.50) CES S 1-8

A

Dimensions shown are nominal and in millimetres (inches).

B

Part numbers were established in the following way:

CES—cable entry seal,

S or T—standard or threaded, and

1-1—number preceding hyphen represents number legs; number following hyphen represents size type.

A

TABLE 2 Type 1—Multi-Legged Standard Cable Entry Seals

B A

Multi-Leg Boot

Expanded I.D. Recovered I.D.

Min. Max. Overall Nominal

(Each Leg) (Each Leg) I.D. (min) Recovered Recommended

B

No. of Legs Length Hole Diameter Part No.

2 10.0 (0.40) 3.0 (0.11) 19.0 (0.75) 89.0 (3.50) 25.5 (1.00) CES S 2-1

2 15.0 (0.60) 4.5 (0.17) 28.0 (1.10) 95.0 (3.75) 35.0 (1.38) CES S 2-2

2 23.0 (0.90) 7.5 (0.30) 40.0 (1.60) 120.0 (4.75) 51.0 (2.00) CES S 2-3

3 10.0 (0.40) 3.0 (0.11) 19.0 (0.75) 89.0 (3.50) 25.5 (1.00) CES S 3-1

3 15.0 (0.60) 4.5 (0.17) 28.0 (1.10) 95.0 (3.75) 35.01 (1.38) CES S 3-2

3 23.0 (0.90) 7.5 (0.30) 40.0 (1.60) 120.0 (4.75) 51.0 (2.00) CES S 3-3

3 32.0 (1.25) 13.0 (0.50) 74.0 (2.90) 178.0 (7.00) 89.0 (3.50) CES S 3-4

4 10.0 (0.40) 3.0 (0.11) 19.0 (0.75) 89.0 (3.50) 25.5 (1.00) CES S 4-1

4 15.0 (0.60) 4.5 (0.17) 28.0 (1.10) 95.0 (3.75) 35.0 (1.38) CES S 4-2

4 23.0 (0.90) 7.5 (0.30) 40.0 (1.60) 120.0 (4.75) 51.0 (2.00) CES S 4-3

4 32.0 (1.25) 13.0 (0.5

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.