ASTM E1045-00(2010)

(Specification)Standard Specification for Pipet, Sahli Hemoglobin

Standard Specification for Pipet, Sahli Hemoglobin

ABSTRACT

This specification covers reusable Sahli hemoglobin pipets. The pipets shall be made of common spirit bore white back tubing. Pipet design shall be straight and of one-piece construction. Pipet delivery tips shall be made with a gradual or concave taper. Pipet dimensions shall be within tolerance limit indicated in this specification. The pipet shall have markings which include graduation line, volumetric designation, identification, and capacity deviation. Testing methods include capacity test, capacity deviation, pigmentation test, and strain free test.

SCOPE

1.1 This specification covers reusable pipets calibrated “to contain” 20 cmm of whole blood and used for hemoglobin determinations.

1.2 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:E1045 −00(Reapproved 2010)

Standard Specification for

1

Pipet, Sahli Hemoglobin

This standard is issued under the fixed designation E1045; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

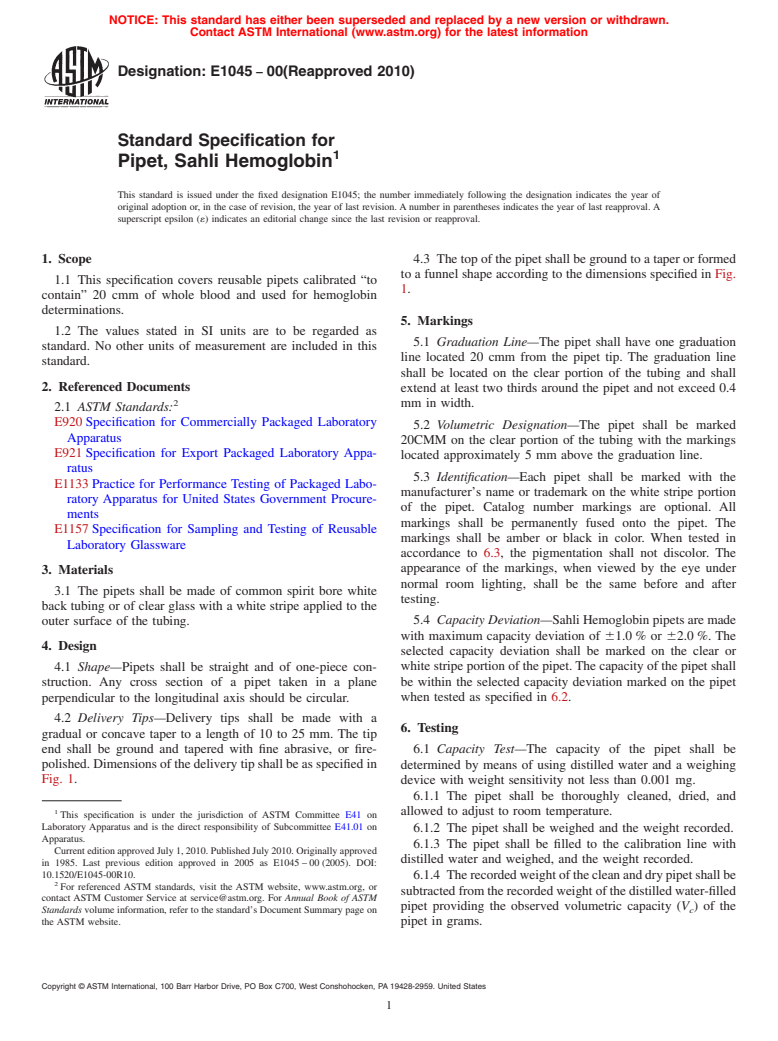

1. Scope 4.3 Thetopofthepipetshallbegroundtoataperorformed

to a funnel shape according to the dimensions specified in Fig.

1.1 This specification covers reusable pipets calibrated “to

1.

contain” 20 cmm of whole blood and used for hemoglobin

determinations.

5. Markings

1.2 The values stated in SI units are to be regarded as

5.1 Graduation Line—The pipet shall have one graduation

standard. No other units of measurement are included in this

line located 20 cmm from the pipet tip. The graduation line

standard.

shall be located on the clear portion of the tubing and shall

2. Referenced Documents

extend at least two thirds around the pipet and not exceed 0.4

2

mm in width.

2.1 ASTM Standards:

E920Specification for Commercially Packaged Laboratory

5.2 Volumetric Designation—The pipet shall be marked

Apparatus

20CMM on the clear portion of the tubing with the markings

E921Specification for Export Packaged Laboratory Appa-

located approximately 5 mm above the graduation line.

ratus

5.3 Identification—Each pipet shall be marked with the

E1133Practice for Performance Testing of Packaged Labo-

manufacturer’s name or trademark on the white stripe portion

ratory Apparatus for United States Government Procure-

of the pipet. Catalog number markings are optional. All

ments

markings shall be permanently fused onto the pipet. The

E1157Specification for Sampling and Testing of Reusable

markings shall be amber or black in color. When tested in

Laboratory Glassware

accordance to 6.3, the pigmentation shall not discolor. The

appearance of the markings, when viewed by the eye under

3. Materials

normal room lighting, shall be the same before and after

3.1 The pipets shall be made of common spirit bore white

testing.

back tubing or of clear glass with a white stripe applied to the

5.4 Capacity Deviation—SahliHemoglobinpipetsaremade

outer surface of the tubing.

with maximum capacity deviation of 61.0% or 62.0%. The

4. Design

selected capacity deviation shall be marked on the clear or

4.1 Shape—Pipets shall be straight and of one-piece con- whitestripeportionofthepipet.Thecapacityofthepipetshall

be within the selected capacity deviation marked on the pipet

struction. Any cross section of a pipet taken in a plane

perpendicular to the longitudinal axis should be circular. when tested as specified in 6.2.

4.2 Delivery Tips—Delivery tips shall be made with a

6. Testing

gradual or concave taper to a length of 10 to 25 mm. The tip

end shall be ground and tapered with fine abrasive, or fire- 6.1 Capacity Test—The capacity of the pipet shall be

polished.Dimensionsofthedeliverytipshallbeasspecifiedin

determined by means of using distilled water and a weighing

Fig. 1. device with weight sensitivity not less than 0.001 mg.

6.1.1 The pipet shall be thoroughly cleaned, dried, and

1

allowed to adjust to room temperature.

This specification is under the jurisdiction of ASTM Committee E41 on

Laboratory Apparatus and is the direct responsibility of Subcommittee E41.01 on

6.1.2 The pipet shall be weighed and the weight recorded.

Apparatus.

6.1.3 The pipet shall be filled to the calibration line with

CurrenteditionapprovedJuly1,2010.PublishedJuly2010.Originallyapproved

distilled water and weighed, and the weight recorded.

in 1985. Last previous edition approved in 2005 as E1045–00(2005). DOI:

10.1520/E1045-00R10.

6.1.4 Therecordedweightofthecleananddrypipetshallbe

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

subtractedfromtherecordedweightofthedistilledwater-filled

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

pipet providing the observed volumetric capacity (V)ofthe

Standards volume information, refer to the standard’s Document Summary page on c

the ASTM website. pipet in grams.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

E1045−00 (2010)

FIG. 1 Pipet, Sahli Hemoglobin

6.1.5 The observed volumetric capacity (V) shall then be Cr O 2H O),1000mLofwater,and1500mLofsulfuricacid

t 2 7 2

corrected to actual volumetric capacity at 20°C (V ), deter- (H SO , ACS Reagent—95 to 98%). Immerse the pipets in

c 2 4

mined by: thechromicacidsolution.Letstandatroomtemperature(20to

25°C) for 15 min. Remove the pipets from the solution and

V

t

V 5 (1)

thoroughly rinse in distilled water. Dry the pip

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.