ASTM D880-92(1997)

(Test Method)Standard Test Method for Impact Testing for Shipping Containers and Systems

Standard Test Method for Impact Testing for Shipping Containers and Systems

SCOPE

1.1 This test method covers two procedures for conducting impact tests on loaded containers or shipping units (pallet loads), as follows:

1.1.1 Procedure A , to test the ability of a container or shipping unit to withstand impacts, and

1.1.2 Procedure B , to test the ability of a container or shipping unit or interior packing, or both, to provide protection to the contents, when subjected to impacts.

1.2 either of these two procedures may be used to evaluate different designs of containers of the same size and carrying the same load. These procedures are suitable for testing various types of containers such as boxes, crates, barrels, drums, kegs, bags, sacks, or pails made of various materials or combinations of materials and for shipping units such as pallet loads or palletized units.

1.3 The procedures described in this test method are particularly suitable for testing large or heavily loaded containers.

1.4 The values stated in inch-pound units are to be regarded as the standard. The SI units given in parentheses are for information only.

1.5 This standard does not purport to address all of the safety problems, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.> Specific precautionary statements are given in Note 1 and Section 7.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: D 880 – 92 (Reapproved 1997)

Standard Test Method for

Impact Testing for Shipping Containers and Systems

This standard is issued under the fixed designation D 880; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope Measure of Quality for a Lot or Process

2.2 ISO Standard:

1.1 This test method covers two procedures for conducting

ISO 2244 Horizontal Impact Test (Horizontal or Incline

impact tests on loaded containers or shipping units (pallet

Plane Test: Pendulum Test)

loads), as follows:

1.1.1 Procedure A, to test the ability of a container or

3. Terminology

shipping unit to withstand impacts, and

3.1 Definitions—For definitions of terms applicable to this

1.1.2 Procedure B, to test the ability of a container or

test method see Terminology D 996.

shipping unit or interior packing, or both, to provide protection

3.2 Definitions of Terms Specific to This Standard:

to the contents, when subjected to impacts.

3.2.1 hazard— removable solid object of any size or shape

1.2 Either of these two procedures may be used to evaluate

placed on an impact surface (backstop) so as to contact a test

different designs of containers of the same size and carrying the

specimen at any desired location during the impact of the

same load. These procedures are suitable for testing various

specimen into the impact surface (backstop).

types of containers such as boxes, crates, barrels, drums, kegs,

bags, sacks, or pails made of various materials or combinations

4. Summary of Test Method

of materials and for shipping units such as pallet loads or

4.1 An apparatus having a guided carriage capable of

palletized units.

holding a test container or shipping unit impacts into a rigid

1.3 The procedures described in this test method are par-

impact surface (backstop) with or without hazards at a prede-

ticularly suitable for testing large or heavily loaded containers.

termined impact velocity. When testing the ability of a con-

1.4 The values stated in inch-pound units are to be regarded

tainer or shipping unit to withstand impact (Procedure A)

as the standard. The SI units given in parentheses are for

multiple tests with the same impact velocity or increasing

information only.

impact velocities may be conducted until failure occurs. When

1.5 This standard does not purport to address all of the

testing the ability of the container, shipping unit, or interior

safety concerns, if any, associated with its use. It is the

packing, or combination thereof, to provide protection to the

responsibility of the user of this standard to establish appro-

contents (Procedure B), a predetermined number of impacts, at

priate safety and health practices and determine the applica-

predetermined velocities, are applied and the container(s) and

bility of regulatory limitations prior to use. Specific precau-

contents are then inspected.

tionary statements are given in Note 1 and Section 7.

5. Significance and Use

2. Referenced Documents

5.1 The impact test has been found useful in laboratory

2.1 ASTM Standards:

simulation of impacts such as those encountered in manual and

D 996 Terminology of Packaging and Distribution Environ-

2 mechanical handling and transportation. The impact test simu-

ments

lates some types of shocks that could occur in the handling of

D 4003 Test Method for Programmable Horizontal Impact

2 packages or shipping units and helps evaluate the ability of the

Test for Shipping Containers and Systems

package to protect the contents against these shocks. The test

D 4332 Practice for Conditioning Containers, Packages, or

2 may also permit observation of progressive failure of a package

Packaging Components for Testing

and damage to the contents.

D 5277 Test Methods for Performing Programmed Hori-

2 5.2 The test results within a given laboratory using this test

zontal Impacts Using an Inclined Impact Tester

method may be useful for evaluating and comparing packages.

E 122 Practice for Choice of Sample Size to Estimate a

However, because of the variability of test machines that have

been used in the past, especially the impact surface (backstop),

This test method is under the jurisdiction of ASTM Committee D-10 on

Packaging and is the direct responsibility of Subcommittee D10.22 on Handling and

Transportation.

Current edition approved Aug. 15, 1992. Published November 1992. Originally

Annual Book of ASTM Standards, Vol 14.02.

published as D 880 – 68. Last previous edition D 880 – 86.

Available from American National Standards Institute, 11 W. 42nd Street, 13th

Annual Book of ASTM Standards, Vol 15.09.

Floor, New York, NY 10036.

Copyright © ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959, United States.

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

D 880

it has been found that interlaboratory correlation of test results be cleared prior to each test. Stop the test immediately if a

has been poor. dangerous condition should develop. The testing of hazardous

5.3 These procedures are not intended to simulate rail car materials or products may require special precautions that must

coupling environment. Refer to Test Method D 4003 and Test be observed. Safety equipment may be required and its use

Methods D 5277. must be understood before starting the test.

5.4 This test method fulfills the requirement of ISO 2244.

8. Sampling

NOTE 1—ISO 2244 may not meet the requirements for this test method.

8.1 The number of test specimens depends on the desired

6. Apparatus degree of precision and the availability of specimens. Practice

E 122 provides guidance on the choice of sample size. It is

6.1 Testing Machine:

recommended that at least three representative test specimens

6.1.1 The test machine shall consist of a guided test carriage

be used.

with a flat test specimen mounting surface and an impact

surface (backstop) with the plane of the face perpendicular

9. Test Specimens

within 630 min ( ⁄2°) to the direction of movement of the

9.1 When the specimen is being tested by Procedure A to

carriage at impact.

determine the ability of the container or shipping unit to

6.1.2 There shall be an impact surface (backstop) that is

withstand impact stresses, either the actual contents or a

integral with a solid mass at least 50 times the maximum mass

dummy load simulating such contents can be used. When the

of the test specimen. The impact surface firmly attached to the

1 specimen is being tested by Procedure B to determine the

mass, shall be a steel plate not less than ⁄2 in. (13 mm) thick.

ability of the container or shipping unit or interior packing, or

The impact surface (backstop) must have dimensions greater

both, to provide protection to the contents, actual contents shall

than those of the impacting surface of the test specimen to

be used. For both procedures closing, strapping, or sealing

permit full contact with the shipping container.

should be the same as will be used in actual shipment.

NOTE 2—The purpose of the apparatus is to provide an impact surface

NOTE 4—Certain contents or ingredients of the objects under test may

(backstop) and mass that will improve interlaboratory correlation of test

be replaced by inert materials of approximately the same weight and

results and the accuracy of tests between laboratories. The test can be

characteristics.

conducted on apparatus that does not meet the requirements of 6.1.2,

provided it is clearly stated in 14.1.1.

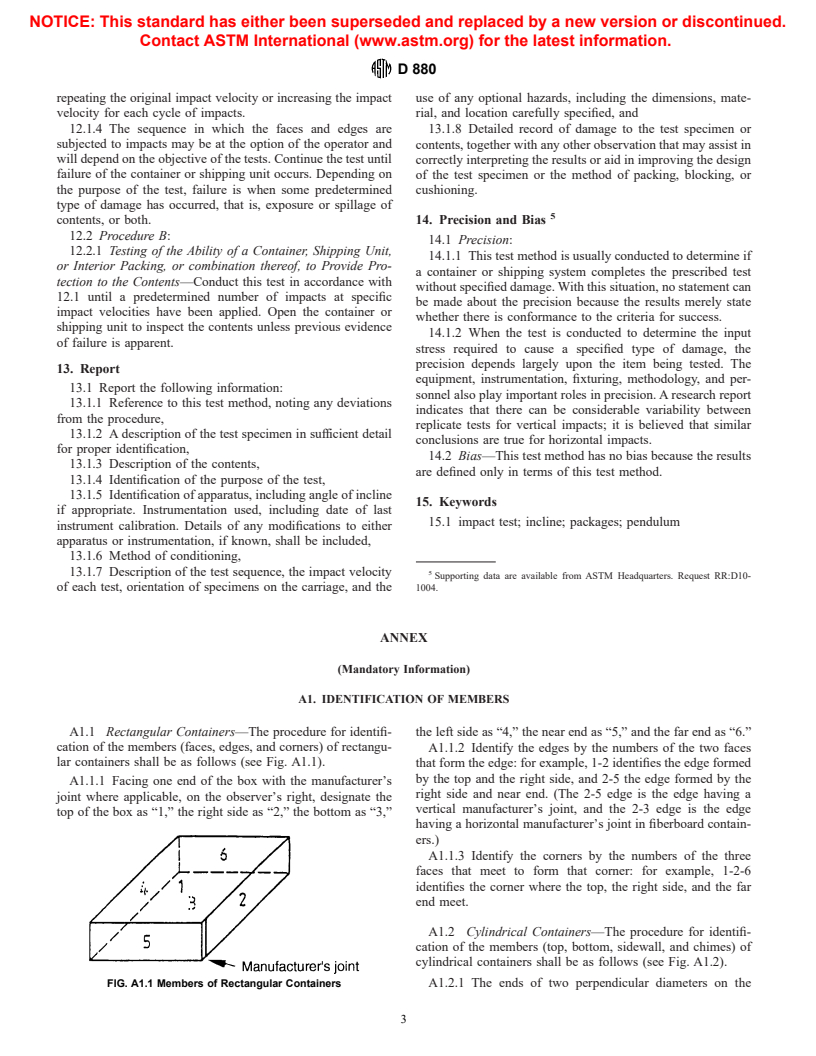

9.2 Identification of Members—See Annex A1.

6.1.3 The test machine shall provide some means of moving

10. Calibration

the test carriage to obtain the desired impact velocity. This may

be the result of mechanical or pneumatic means, gravity

10.1 Calibrate the impact carriage so that the desired impact

through the use of a 10 ° (nominal) incline, or a pendulum

velocity (65 %) may be achieved.

device.

10.2 Make the calibration using the carriage with a load

simulating actual contents equivalent to the package/product’s

NOTE 3—Depending upon the configuration of the test machine there

weight. Measure the velocity of the carriage just before impact.

may be other forces acting before, during, or after the impact that may

affect the test results.

11. Conditioning

6.1.4 The test machine should preferably have a means of

11.1 It is recommended that atmospheres for conditioning

preventing multiple impacts.

be selected from those shown in Practice D 4332. Unless

6.1.5 The test carriage shall provide surface friction such

otherwise specified, precondition and condition fiberboard and

that the test specimen does not move during the period from

other paperboard containers in accordance with the standard

rest to impact, but will move freely upon impact.

atmosphere specified in Practice D 4332.

6.1.6 The impact surface (backstop) ma

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.