ASTM E855-90(2000)

(Test Method)Standard Test Methods for Bend Testing of Metallic Flat Materials for Spring Applications Involving Static Loading

Standard Test Methods for Bend Testing of Metallic Flat Materials for Spring Applications Involving Static Loading

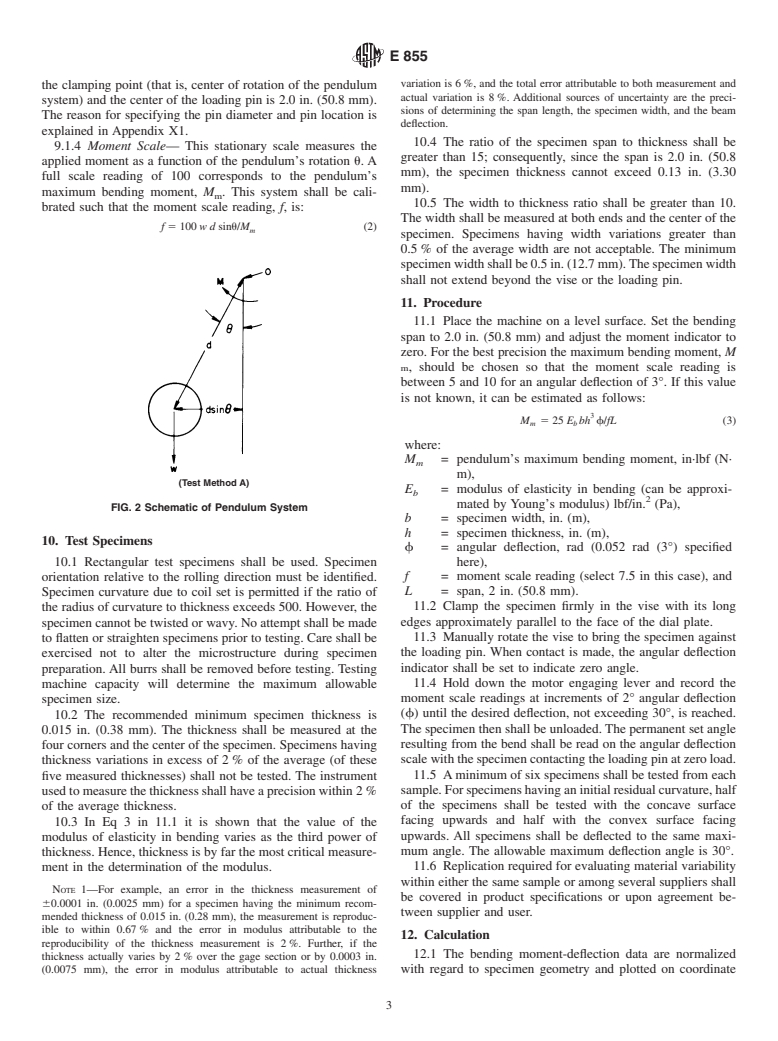

SIGNIFICANCE AND USE

Measurements of bending strength and modulus of elasticity in bending should be made for materials whose principal stressing mode is bending. For many materials, the tensile and compressive moduli are somewhat different. Since the bending modulus is a combination of the tensile and compressive moduli, it is often different from each of them.

Precise measurements of the modulus of elasticity in bending and bending strength require due regard for numerous variables that may affect their determination. These include (1) characteristics such as specimen orientation with respect to the rolling direction, grain size, residual stresses, previous strain history, dimensions and specimen preparation, orientation of deformed grains relative to the direction of the normal stress; and (2) test conditions, such as tem-

perature, temperature variations, condition of the test equipment and adherence to the recommended test procedure.

SCOPE

1.1 This standard describes three test methods for determining the modulus of elasticity in bending and the bending strength of metallic strips or sheets intended for the use in flat springs:

1.1.1 Test Method A--a cantilever beam,

1.1.2 Test Method B--a three-point loaded beam (that is, a beam resting on two supports and centrally loaded), and

1.1.3 Test Method Ca four-point loaded beam (that is, a beam resting on two supports and loaded at two points equally spaced from each support).

1.2 Values stated in inch-pound units are to be regarded as the standard. SI units are provided for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:E855–90(Reapproved 2000)

Standard Test Methods for

Bend Testing of Metallic Flat Materials for Spring

1

Applications Involving Static Loading

This standard is issued under the fixed designation E855; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope 3.1.2 bend properties—those properties of a material that

2 are associated with elastic and inelastic behavior when a

1.1 This standard describes three test methods for deter-

bending force is applied, or that involve the relationship

mining the modulus of elasticity in bending and the bending

between bending stress and strain.

strength of metallic strips or sheets intended for the use in flat

−2

3.1.3 bending stress at outer fiber (FL )—the nominal

springs:

stressintheouterfibersofabeamresultingfromapplicationof

1.1.1 Test Method A—a cantilever beam,

a bending load.

1.1.2 Test Method B—a three-point loaded beam (that is, a

−2

3.1.4 elastic limit in bending (FL )—the greatest bending

beam resting on two supports and centrally loaded), and

stress that a material is capable of sustaining without perma-

1.1.3 Test Method C—a four-point loaded beam (that is, a

nent strain remaining after complete release of the bending

beam resting on two supports and loaded at two points equally

moment.

spaced from each support).

−2

3.1.5 modulus of elasticity in bending (FL )—the ratio of

1.2 Values stated in inch-pound units are to be regarded as

bendingstresstocorrespondingstrainbelowtheelasticlimitin

the standard. SI units are provided for information only.

bending.

1.3 This standard does not purport to address all of the

3.1.6 span length (L)—the distance between supports.

safety concerns, if any, associated with its use. It is the

3.1.7 uniform bending moment (FL)—a bending moment

responsibility of the user of this standard to establish appro-

thatproducesauniformstrainattheouterfibersthroughoutthe

priate safety and health practices and determine the applica-

gage length of the specimen.

bility of regulatory limitations prior to use.

−2

3.1.8 bending proof strength (FL )—the nominal stress in

2. Referenced Documents the outer fibers of a beam that results in a specific permanent

strain in the outer fibers upon unloading.

2.1 The following documents of the issue in effect on date

−2

3.1.9 cyclic bending yield strength (FL )—the maximum

of use of these test methods form a part of these test methods

nominalstressinuniformcyclicbendingresultingfromagiven

to the extent referenced herein:

plastic deformation in the outer fibers of a beam.

2.2 ASTM Standards:

−2

3

3.1.10 offset yield strength in bending (FL )—the nominal

E4 Practices for Force Verification of Testing Machines

stress in the outer fibers of a beam in bending at which a

E6 Terminology Relating to Methods of Mechanical Test-

3

specified limiting deviation from proportionality of bending

ing

stresstobendingstrainisexhibited.Thedeviationisexpressed

E111 TestMethodforYoung’sModulus,TangentModulus,

3

in terms of strain.

and Chord Modulus

4. Significance and Use

3. Terminology

4.1 Measurements of bending strength and modulus of

3.1 Definitions of Terms Specific to This Standard:

elasticity in bending should be made for materials whose

3.1.1 In addition to the terms in Terminology E6, the

principal stressing mode is bending. For many materials, the

following descriptions of terms apply in connection with these

tensile and compressive moduli are somewhat different. Since

test methods for determining bend properties:

the bending modulus is a combination of the tensile and

compressive moduli, it is often different from each of them.

1

These test methods are under the jurisdiction of ASTM Committee E28 on

4.2 Precise measurements of the modulus of elasticity in

Mechanical Testing and are the direct responsibility of Subcommittee E28.02 on

bending and bending strength require due regard for numerous

Ductility and Flexure Testing.

Current edition approved March 30, 1990. Published May 1990. Originally variablesthatmayaffecttheirdetermination.Theseinclude(1)

published as E855–81. Last previous edition E855–84.

characteristics such as specimen orientation with respect to the

2

MethodD,whichappearedinthelastpreviousedition,wasdroppedbecauseof

rolling direction, grain size, residual stresses, previous strain

the unavailability of commercial testing equipment.

3

history, dimensions and specimen preparation, orientation of

Annual Book of ASTM Standards, Vol 03.01.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ------------

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.