ASTM D2517-00

(Specification)Standard Specification for Reinforced Epoxy Resin Gas Pressure Pipe and Fittings

Standard Specification for Reinforced Epoxy Resin Gas Pressure Pipe and Fittings

SCOPE

1.1 This specification covers requirements and methods of test for materials, dimensions and tolerances, hydrostatic-burst strength, chemical resistance, and longitudinal tensile properties, for reinforced epoxy resin pipe and fittings for use in gas mains and services for direct burial and insertion applications. The pipe and fittings covered by this specification are intended for use in the distribution of natural gas, petroleum fuels (propane-air and propane-butane vapor mixtures), manufactured and mixed gases where resistance to gas permeation, toughness, resistance to corrosion, aging, and deterioration from water, gas, and gas additives are required. Methods of marking are also given. Design considerations are discussed in Appendix X1.

1.2 The values in SI units are to be regarded as the standard.

1.3 The following safety hazards caveat pertains only to the test method portion, Section 8, of this specification: This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

There is no similar or equivalent ISO standard.

1.4 A recommended inplant quality control program is given in Appendix X2.

General Information

Relations

Standards Content (Sample)

An American National Standard

Designation: D 2517 – 00

Standard Specification for

Reinforced Epoxy Resin Gas Pressure Pipe and Fittings

This standard is issued under the fixed designation D 2517; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope* D 1598 Test Method for Time-to-Failure of Plastic Pipe

Under Constant Internal Pressure

1.1 This specification covers requirements and methods of

D 1599 TestMethodforShort-TimeHydraulicFailurePres-

test for materials, dimensions and tolerances, hydrostatic-burst

sure of Plastic Pipe, Tubing, and Fittings

strength, chemical resistance, and longitudinal tensile proper-

D 1898 Practice for Sampling of Plastics

ties, for reinforced epoxy resin pipe and fittings for use in gas

D 2105 Test Method for Longitudinal Tensile Properties of

mains and services for direct burial and insertion applications.

“Fiberglass” (Glass-Fiber-Reinforced Thermosetting-

The pipe and fittings covered by this specification are intended

Resin) Pipe and Tube

for use in the distribution of natural gas, petroleum fuels

D 2143 Test Method for Cyclic Pressure Strength of Rein-

(propane–air and propane–butane vapor mixtures), manufac-

forced, Thermosetting Plastic Pipe

tured and mixed gases where resistance to gas permeation,

D 2290 Test Method for Apparent Tensile Strength of Ring

toughness, resistance to corrosion, aging, and deterioration

or Tubular Plastics and Reinforced Plastics by Split Disk

from water, gas, and gas additives are required. Methods of

Method

marking are also given. Design considerations are discussed in

D 2412 Test Method for Determination of External Loading

Appendix X1.

Characteristics of Plastic Pipe by Parallel-Pipe Loading

1.2 The values in SI units are to be regarded as the standard.

D 2924 Test Method for External Pressure Resistance of

1.3 The following safety hazards caveat pertains only to the

“Fiberglass’’ (Glass-Fiber-Reinforced Thermosetting

test method portion, Section 8, of this specification: This

Resin) Pipe

standard does not purport to address all of the safety concerns,

D 2992 Practice for Obtaining Hydrostatic or Pressure De-

if any, associated with its use. It is the responsibility of the user

sign Basis for “Fiberglass’’ (Glass-Fiber-Reinforced

of this standard to establish appropriate safety and health

Thermosetting-Resin) Pipe and Fittings

practices and determine the applicability of regulatory limita-

D 2996 Specification for Filament Wound “Fiberglass’’

tions prior to use.

(Glass-Fiber-Reinforced Thermosetting-Resin) Pipe

NOTE 1—There is no similar or equivalent ISO standard.

D 3567 Practice for Determining Dimensions of “Fiber-

1.4 A recommended inplant quality control program is glass’’ (Glass-Fiber-Reinforced Thermosetting Resin)

given in Appendix X2. Pipe and Fittings

D 3839 Practice for Underground Installation of “Fiber-

2. Referenced Documents

glass’’ (Glass-Fiber-Reinforced Thermosetting Resin)

2.1 ASTM Standards: Pipe

D 396 Specification for Fuel Oils

D 3892 Practice for Packaging/Packing of Plastics

D 543 Test Method for Resistance of Plastics to Chemical D 5685 Specification for “Fiberglass” (Glass-Fiber-

Reagents

Reinforced Thermosetting-Resin) Pressure Pipe Fittings

D 618 Practice for Conditioning Plastics and Electrical

3. Terminology

Insulating Materials for Testing

D 883 Terminology Relating to Plastics 3.1 Definitions:

3.1.1 General—Definitions are in accordance with Termi-

nology D 883 or F 412. Abbreviations are in accordance with

Terminology D 1600, unless otherwise indicated. The abbre-

This specification is under the jurisdiction of ASTM Committee D20 on

Plastics and is the direct responsibility of Subcommittee D20.23 on Reinforced

viation for fiberglass pipe is RTRP and the abbreviation for

Plastic Piping Systems.

fiberglass fittings is RTRF.

Current edition approved July 10, 2000. Published September 2000. Originally

published as D2517 – 66. Last previous edition D2517 – 94.

Annual Book of ASTM Standards, Vol 05.01.

3 4

Annual Book of ASTM Standards, Vol 08.01. Subcommittee D 20.23 has Annual Book of ASTM Standards, Vol 08.04.

completed work to develop methods which are adapted for RTRP. Annual Book of ASTM Standards, Vol 08.02.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D 2517 – 00

3.1.2 The gas industry technology used in this specification injurious defects. The pipe and fittings shall be as uniform as

is in accordance with definitions given in The Department of commercially practicable in color, opacity, density, and other

Transportation of Natural and Other Gas by Pipeline Minimum physical properties.

Safety Standards.

6.2 Pipe Dimensions and Tolerances:

3.1.3 Standards Reinforced Thermosetting Resin Pipe Ma-

6.2.1 Diameters—The outside diameter of the pipe shall be

terials Designation Code—The pipe material designation code

in accordance with Table 1 when measured in accordance with

shall consist of the abbreviation RTRP followed by type and

8.4.1.

grade in arabic numerals, class by a capital letter and the long

6.2.2 Wall Thickness—The wall thickness of the pipe shall

term steady pressure strength by a second capital letter. The

meet the requirements given in Table 1 when measured in

fittings material designation shall consist of the abbreviation

accordance with 8.4.1.

RTRF followed by type (method of manufacture), grade

6.2.3 Lengths—The pipe shall be in lengths as specified on

(general type of resin), class (configuration of joining system),

the purchase order when measured in accordance with 8.4.1.

and pressure rating.

NOTE 3—Either threaded adaptors or bonded joints are acceptable.

4. Classification

Jointers of up to 5 % of the shipment are acceptable to meet the length

requirements. No section less than 1.5 m (5 ft) long can be used to make

4.1 Pipe—The pipe covered in this specification is made by

a joint and only one jointer can be used in a length.

the filament winding process and is described in Specification

D 2996.Requirementsofthispipearebasedonshort-termtests

6.3 Fittings Dimensions and Tolerances— The fittings di-

defined in this specification.

mensions shall enable the pipe and fittings to be joined and

4.2 Fittings—This specification covers reinforced epoxy shall be measured in accordance with 8.4.2.

resin fittings described in specification D 5685 and made of the

NOTE 4—Subcommittee D 20.23 is working towards development of

type of materials covered in Section 5, which are capable of

dimensional requirements for fittings; however, it will be some time

being joined to the pipe and will provide a suitable gas

before the requirements are available.Therefore, the method of measuring

distribution system.

is provided only to have a standard method of measuring fittings

dimensions for inspection purposes.

5. Materials

6.4 Short-Term Rupture Strength (Burst Pressure)—The

5.1 The resins and reinforcements used to make pipe shall

minimum hoop stress at burst for pipe covered by this

be as specified in 5.1.1.

specification shall be as listed in Table 2 when tested in

5.1.1 This specification covers glass fiber reinforced epoxy

accordance with 8.5. The minimum burst requirements for

resin pipe and fittings as defined in Specification D 2996—

fittings covered by this specification shall be 4.82 MPa (700

RTRP 11 AU and RTRP 11 CU and fittings as defined in

psi) internal pressure or 27.5 MPa (4000 psi) hoop tensile

specification D 5685-RTRF 11A1D, RTRF 21A1D, RTRF

stress, whichever is greater, when tested in accordance with 8.5

11F2D and RTRF 21A2D.

at temperatures of 23°C (73.4°F) and 65.6°C (150°F), and

calculated using the equation listed in Test Method D 1599 for

NOTE 2—The particular reinforced thermosetting resin included ini-

tially in this specification for gas pressure piping was selected on the basis hoop stress. The calculations shall use the fittings wall thick-

of engineering test studies made by Battelle Memorial Institute, experi-

ness and diameter at a point where the wall thickness is at a

mental use in field installations, and technical data supplied by the

minimum and which is also in the section of the fittings which

manufacturers of the plastics materials used to make the pipe and fittings.

is not reinforced by the pipe.

It is the intent of ASTM Committee D-20 on Plastics to consider for

6.5 Crush Strength—The minimum stiffness factor at 5 %

inclusion other resins and reinforcements in this specification when

deflection of the pipe shall be as shown in Table 2 when tested

evidence is presented to show that they are suitable for gas service.

Minimum requirements are an ASTM pipe specification and long-term

in accordance with Test Method D 2412.

strength determined in accordance with Test Method D 2992, Procedure

6.6 Chemical Resistance—The pipe shall not change more

B, in addition to the requirements of this specification.

than 612 % in apparent tensile strength when measured in

accordance with 8.7.

6. Requirements

6.1 Workmanship—The pipe and fittings shall be free of

NOTE 5—Asuitable chemical resistance test for fittings is not available

visible cracks, holes, foreign inclusions, blisters, and other at the present time and will be added when available.

TABLE 1 Pipe Dimensions, mm (in.)

Nominal Outside Diameter Tolerance Minimum Wall Thickness

2 60.325 (2.375) +1.524, −0.457 (+0.060, −0.018) 1.524 (0.060)

3 88.900 (3.500) +1.524, −0.457 (+0.060, −0.018) 1.524 (0.060)

4 114.300 (4.500) +1.524, −0.457 (+0.060, −0.018) 1.780 (0.070)

6 168.275 (6.625) +1.678, −0.711 (+0.066, −0.028) 2.540 (0.100)

8 219.075 (8.625) +2.184, −1.016 (+0.086, −0.040) 3.227 (0.125)

10 273.050 (10.750) +2.743, −1.219 (+0.108, −0.048) 3.830 (0.150)

12 323.850 (12.750) +3.251, −1.422 (+0.128, −0.056) 4.215 (0.175)

D 2517 – 00

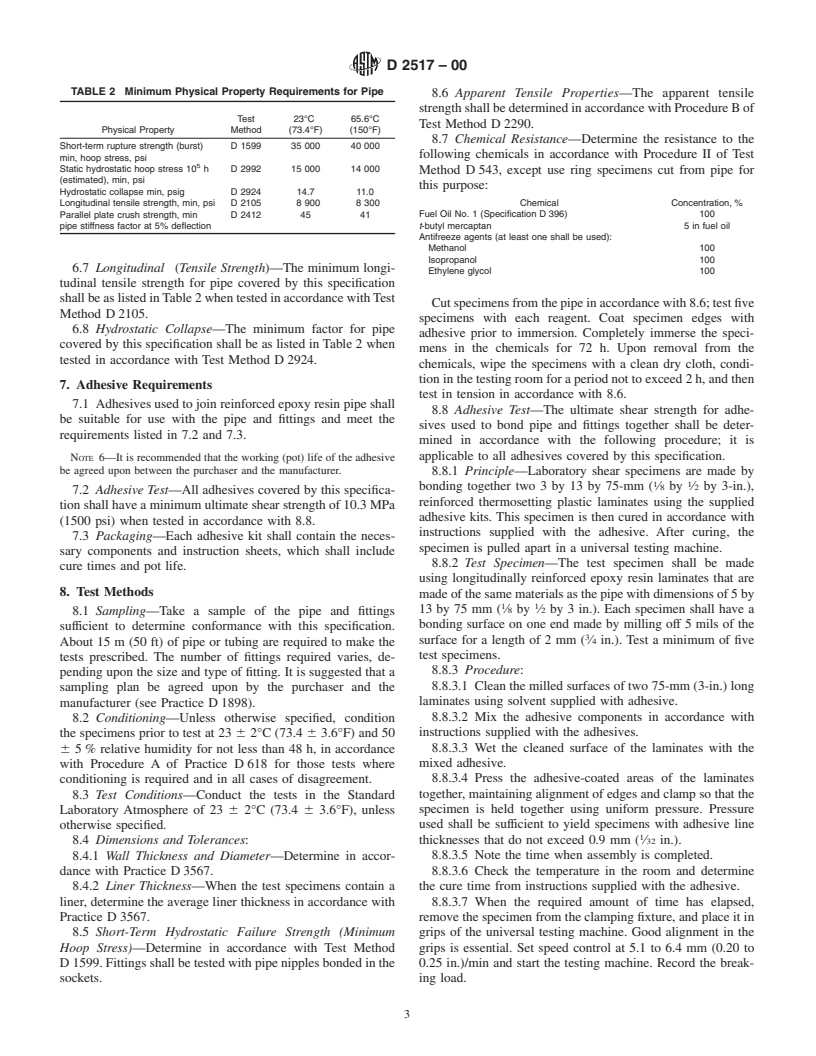

TABLE 2 Minimum Physical Property Requirements for Pipe

8.6 Apparent Tensile Properties—The apparent tensile

strengthshallbedeterminedinaccordancewithProcedureBof

Test 23°C 65.6°C

Test Method D 2290.

Physical Property Method (73.4°F) (150°F)

8.7 Chemical Resistance—Determine the resistance to the

Short-term rupture strength (burst) D 1599 35 000 40 000

following chemicals in accordance with Procedure II of Test

min, hoop stress, psi

Static hydrostatic hoop stress 10 h D 2992 15 000 14 000

Method D 543, except use ring specimens cut from pipe for

(estimated), min, psi

this purpose:

Hydrostatic collapse min, psig D 2924 14.7 11.0

Longitudinal tensile strength, min, psi D 2105 8 900 8 300 Chemical Concentration, %

Fuel Oil No. 1 (Specification D 396) 100

Parallel plate crush strength, min D 2412 45 41

pipe stiffness factor at 5% deflection t-butyl mercaptan 5 in fuel oil

Antifreeze agents (at least one shall be used):

Methanol 100

Isopropanol 100

6.7 Longitudinal (Tensile Strength)—The minimum longi-

Ethylene glycol 100

tudinal tensile strength for pipe covered by this specification

shallbeaslistedinTable2whentestedinaccordancewithTest

Cutspecimensfromthepipeinaccordancewith8.6;testfive

Method D 2105.

specimens with each reagent. Coat specimen edges with

6.8 Hydrostatic Collapse—The minimum factor for pipe

adhesive prior to immersion. Completely immerse the speci-

covered by this specification shall be as listed in Table 2 when

mens in the chemicals for 72 h. Upon removal from the

tested in accordance with Test Method D 2924.

chemicals, wipe the specimens with a clean dry cloth, condi-

tion in the testing room for a period not to exceed 2 h, and then

7. Adhesive Requirements

test in tension in accordance with 8.6.

7.1 Adhesives used to join reinforced epoxy resin pipe shall

8.8 Adhesive Test—The ultimate shear strength for adhe-

be suitable for use with the pipe and fittings and meet the

sives used to bond pipe and fittings together shall be deter-

requirements listed in 7.2 and 7.3.

mined in accordance with the following procedure; it is

applicable to all adhesives covered by this specification.

NOTE 6—It is recommended that the working (pot) life of the adhesive

be agreed upon between the purchaser and the manufacturer.

8.8.1 Principle—Laboratory shear specimens are made by

1 1

bonding together two 3 by 13 by 75-mm ( ⁄8 by ⁄2 by 3-in.),

7.2 Adhesive Test—All adhesives covered by this specifica-

reinforced thermosetting plastic laminates using the supplied

tion shall have a minimum ultimate shear strength of 10.3 MPa

adhesive kits. This specimen is then cured in accordance with

(1500 psi) when tested in accordance with 8.8.

instructions supplied with the adhesive. After curing, the

7.3 Packaging—Each adhesive kit shall contain the neces-

specimen is pulled apart in a universal testing machine.

sary components and instruction sheets, which shall include

8.8.2 Test Specimen—The test specimen shall be made

cure times and pot life.

using longitudinally reinforced epoxy resin laminates that are

8. Test Methods

made of the same materials as the pipe with dimensions of 5 by

1 1

13 by 75 mm ( ⁄8 by ⁄2 by 3 in.). Each specimen shall have a

8.1 Sampling—Take a sample of the pipe and fittings

bonding surface on one end made by milling off 5 mils of the

sufficient to determine conformance with this specification.

surface for a length of 2 mm ( ⁄4 in.). Test a minimum of five

About 15 m (50 ft) of pipe or tubing are required to make the

test specimens.

tests prescribed. The number of fittings required varies, de-

8.8.3 Procedure:

pending upon the size and type of fitting. It is suggested that a

8.8.3.1 Clean the milled surfaces of two 75-mm (3-in.) long

sampling plan be agreed upon by the purchaser and the

laminates using solvent supplied with adhesive.

manufacturer (see Practice D 1898).

8.8.3.2 Mix the adhesive components in accordance with

8.2 Conditioning—Unless otherwise specified, condition

instructions supplied with the adhesives.

the specimens prior to test at 23 6 2°C (73.4 6 3.6°F) and 50

8.8.3.3 Wet the cleaned surface of the laminates with the

6 5 % relative humidity for not less than 48 h, in accordance

with Procedure A of Practice D 618 for those tests where mixed adhesive.

8.8.3.4 Press the adhesive-coated areas of the laminates

conditioning is required and in all cases of disagreement.

8.3 Test Conditions—Conduct the tests in the Standard together, maintaining alignment of edges and clamp so that the

specimen is held together using uniform pressure. Pressure

Laboratory Atmosphere of 23 6 2°C (73.4 6 3.6°F), unless

otherwise specified. used shall be sufficient to yield specimens with adhesive line

thicknesses that do not exceed 0.9 mm ( ⁄32 in.

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.