ASTM F1144-98(2012)

(Specification)Standard Specification for Manhole Cover Assembly, Bolted, Semi-Flush, Oiltight and Watertight, Hinged

Standard Specification for Manhole Cover Assembly, Bolted, Semi-Flush, Oiltight and Watertight, Hinged

ABSTRACT

This specification covers the requirements for the design and construction of a semi-flush, oiltight, and watertight bolted hinged manhole cover assembly for use in deck or bulkheads subjected to lateral pressures such as resulting from vehicle loads or hydrostatic pressure. Not covered by this specification are the design requirements for manhole cover assembly subjected to primary or cyclic loads and certain hazardous cargos. The manhole cover assembly covered by this specification are classified into various types (Types I and II based on size of access opening), grades (Grades 1-3 based on the thickness of the cover plate), and classes (Classes A and B based on surface finish). The assembly shall be comprised of covers, mounting rings, gaskets, studs, washers, hinge assemblies, and nuts. The components shall be manufactured from carbon structural steel (plate for the cover, ring, hinge pad, and hinge blade), steel (round bar for hinge pin), ordinary steel (welded studs), and yellow brass (washers, heavy hex nuts, and cotter pin). The assembly shall be free of splinters, sharp edges, burrs, projections, and weld splatters, and shall have a Class A finish. Pressure and tightness tests shall be performed and shall conform to the requirements specified.

SCOPE

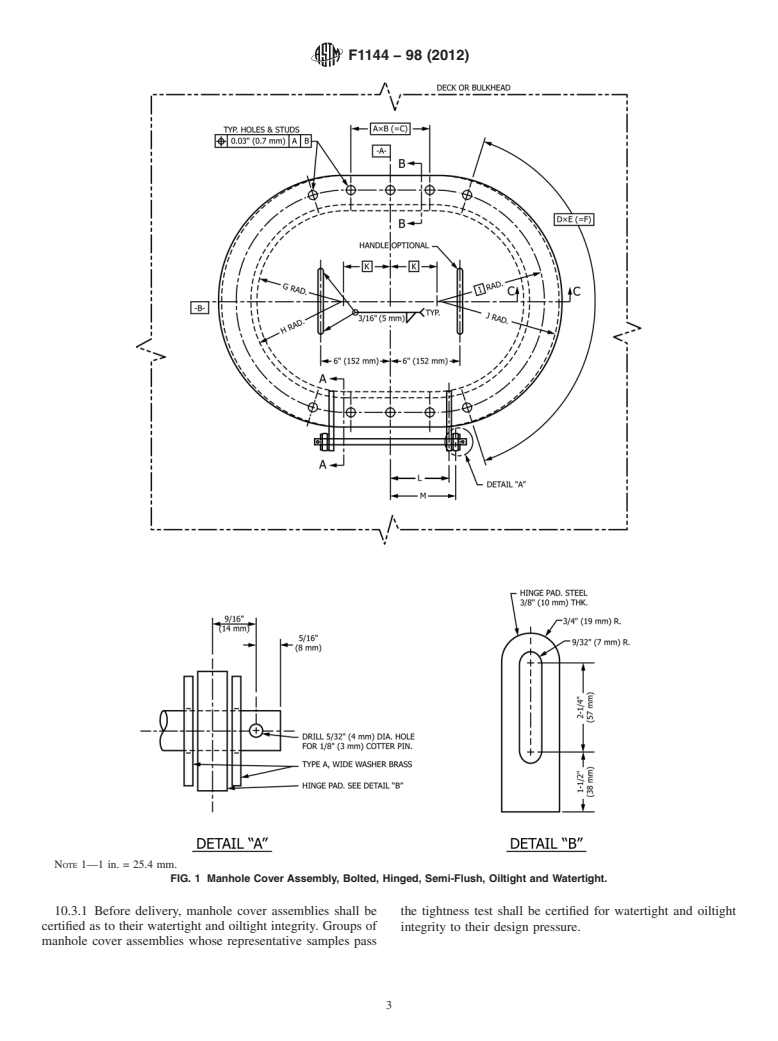

1.1 This specification provides design and construction criteria for a semi-flush, oiltight and watertight bolted hinged manhole cover assembly.

1.2 The manhole cover assemblies depicted on this specification are for use in decks or bulkheads requiring oiltight and watertight covers that are not required to be completely flush. Manhole cover assemblies shall be complete with covers, mounting rings, gaskets, studs, washers, hinge assemblies, and nuts.

1.3 Handles, if required, shall be as specified in the ordering information.

1.4 Values stated in inch-pound units are to be regarded as standard.

1.5 This standard is not applicable to certain hazardous cargos. (See 46CFR 153.254 and 46CFR 154.340.)

1.6 This specification provides design and construction for manhole cover assemblies subjected to lateral pressures such as resulting from vehicle loads or hydrostatic pressures. Where manhole cover assemblies are subjected to primary or cyclic loads, other reinforcement or construction criteria may be necessary to integrate the manhole assembly with the required structural reinforcement for openings in decks or bulkheads. Design of the manhole cover assembly for primary or cyclic loads is beyond the scope of this specification.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:F1144 −98 (Reapproved 2012) An American National Standard

Standard Specification for

Manhole Cover Assembly, Bolted, Semi-Flush, Oiltight and

Watertight, Hinged

This standard is issued under the fixed designation F1144; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 2. Referenced Documents

2.1 ASTM Standards:

1.1 This specification provides design and construction

A36/A36M Specification for Carbon Structural Steel

criteria for a semi-flush, oiltight and watertight bolted hinged

A131/A131M Specification for Structural Steel for Ships

manhole cover assembly.

A153/A153M Specification for Zinc Coating (Hot-Dip) on

1.2 The manhole cover assemblies depicted on this specifi-

Iron and Steel Hardware

cation are for use in decks or bulkheads requiring oiltight and

A575 Specification for Steel Bars, Carbon, Merchant

watertight covers that are not required to be completely flush. Quality, M-Grades

Manhole cover assemblies shall be complete with covers, B36/B36M Specification for Brass Plate, Sheet, Strip, And

Rolled Bar

mounting rings, gaskets, studs, washers, hinge assemblies, and

D2000 Classification System for Rubber Products in Auto-

nuts.

motive Applications

1.3 Handles, if required, shall be as specified in the ordering

F783 Specification for Staple, Handgrab, Handle, and Stir-

information.

rup Rung

2.2 ANSI Standards:

1.4 Values stated in inch-pound units are to be regarded as

B1.1 Unified Inch Screw Threads

standard.

Y14.5M Dimensioning and Tolerancing

1.5 This standard is not applicable to certain hazardous

B18.2.1 Square and Hex Bolts and Screws, Inch Series

cargos. (See 46CFR 153.254 and 46CFR 154.340.)

2.3 ABS Standard:

Rules for Building and Classing Steel Vessels

1.6 This specification provides design and construction for

manholecoverassembliessubjectedtolateralpressuressuchas 2.4 Steel Structures Painting Council Standard:

resulting from vehicle loads or hydrostatic pressures. Where SP-10 Surface Preparation Specification No. 10

manhole cover assemblies are subjected to primary or cyclic

2.5 Code of Federal Regulations Standard:

loads, other reinforcement or construction criteria may be

CFR 46 Code of Federal Regulations

necessary to integrate the manhole assembly with the required

3. Terminology

structural reinforcement for openings in decks or bulkheads.

Design of the manhole cover assembly for primary or cyclic

3.1 Definitions:

loads is beyond the scope of this specification.

3.1.1 manhole—accessway located in a tank structure.

1.7 This international standard was developed in accor- 3.1.2 semi-flush—refers to the placement of the hinged plate

over the ringed opening (without coaming).

dance with internationally recognized principles on standard-

ization established in the Decision on Principles for the

Development of International Standards, Guides and Recom-

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

mendations issued by the World Trade Organization Technical

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Barriers to Trade (TBT) Committee.

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website.

Available fromAmerican National Standards Institute (ANSI), 25 W. 43rd St.,

4th Floor, New York, NY 10036, http://www.ansi.org.

1 4

This specification is under the jurisdiction of ASTM Committee F25 on Ships Available from American Bureau of Shipping (ABS), ABS Plaza, 16855

and Marine Technology and is the direct responsibility of Subcommittee F25.03 on Northchase Dr., Houston, TX 77060, http://www.eagle.org.

Outfitting and Deck Machinery. Available from Society for Protective Coatings (SSPC), 40 24th St., 6th Floor,

Current edition approved June 1, 2012. Published October 2012. Originally Pittsburgh, PA 15222-4656, http://www.sspc.org.

approved in 1988. Last previous edition approved in 2007 as F1144 – 98 (2007). Available from DLA Document Services, Building 4/D, 700 Robbins Ave.,

DOI: 10.1520/F1144-98R12. Philadelphia, PA 19111-5094, http://quicksearch.dla.mil.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

F1144−98 (2012)

4. Classification 6.8 Unless otherwise specified in ordering information,

gasket to be rubber, ⁄16 in. (4.8 mm) thick, 50 6 5 durometers

4.1 Type I—15- by 23-in. (381- by 584-mm) size of access

per Classification D2000 5BC507 A14 E034. For manhole

opening

cover assemblies for government application, see Annex A2

4.2 Type II—18- by 24-in. (457- by 610-mm) size of access

for type of gasket.

opening

6.9 Welding to conform to the latest issue of American

4.3 Grade 1— ⁄4-in. (6.4-mm) thick cover plate

Bureau of Shipping Rules or other such classification society

4.4 Grade 2— ⁄8-in. (9.5-mm) thick cover plate rules as may be applicable.

6.10 Details of bolted manholes are shown in Fig. 1.

4.5 Grade 3— ⁄2-in. (12.7-mm) thick cover plate

4.6 Class A Manhole Cover Assemblies—Shall be abrasive

7. Dimensions

blasted to near white metal in accordance with SSPC SP-10

7.1 Dimensions of manhole shall be as indicated in Table 1.

and a commercial marine quality nonhazardous corrosion-

inhibiting and oil-resistant primer coating be applied for

7.2 For plating up to and including ⁄4-in. (6.4-mm)

protection for a period of one year during shipping and in 1

thickness, use cover plate of ⁄4-in. (6.4-mm) thickness. Plating

shipyard handling. 1 3

over ⁄4-in. (6.4-mm) up to and including ⁄8-in. (9.5-mm)

thickness; use cover plate of ⁄8-in. (9.5-mm) thickness. Plating

4.7 Class B Manhole Cover Assemblies—Shall be galva-

3 1

over ⁄8-in. (9.5-mm) thickness, use cover plate of ⁄2-in.

nized in accordance with Specification A153/A153M.

(12.7-mm) thickness.

5. Ordering Information

8. Finish

5.1 The purchasers ordering information shall include the

following: 8.1 Items produced under this specification shall be free of

splinters, sharp edges, burrs, projections, and weld spatters.

5.1.1 ASTM designation and date.

5.1.2 Type (see 4.1 and 4.2).

8.2 Unless otherwise specified in ordering data, items shall,

5.1.3 Grade (see 4.3, 4.4, and 4.5).

after fabrication, have a Class A finish.

5.1.4 Class see (4.6 and 4.7).

5.1.5 Quantity.

9. Sampling

5.1.6 Remarks—Handles (are/are not) required.

9.1 For orders for one or two manhole cover assemblies,

5.1.7 Approval—Classification society approval (is/is not)

each manhole assembly shall be inspected.

required.

5.1.8 Gasket, if other than specified (see 6.8). 9.2 For orders for three to ten manhole cover assemblies,

two manhole cover assemblies shall be selected at random. If

6. Materials and Manufacture

any one of them fails to meet requirements, then all manhole

cover assemblies in the order shall be inspected.

6.1 Plate for the cover, ring, hinge pad and hinge blade shall

be in accordance with Specification A36/A36M or A131/

9.3 For orders for more than ten manhole cover assemblies,

A131M steel.

they shall be separated into groups of ten (or fraction thereof)

for sampling purposes.

6.2 Round bar for the handle shall be in accordance with

Specification F783, Type A.

10. Inspection and Testing

6.3 Round bar for the hinge pin shall be of Specification

10.1 Responsibility—Unless otherwise specified in the

A575 steel.

order, the manufacturer is responsible for the performance of

6.4 Weldedstudsshallbe ⁄4 in.(19.1mm)—10UNC-2Aby

all inspection and testing specified herein. The manufacturer

1 ⁄4 in. (44.5 mm) long and manufactured of ordinary steel to

may use his own facilities or any commercial facility accept-

commercialstandards.Threadsshallbethecoarsethreadseries

able to the purchaser. The purchaser reserves the right to

in accordance with the latest issue of ANSI B1.1.

perform any of the inspections and tests set forth where such

6.5 Washers shall be ANSI B18.2.1 Type A, ⁄4-in. (19.1- are deemed necessary to assure that supplies conform to

mm) washer, 2-in. (50.8-mm) by 0.148-in. (3.8-mm) thick prescribed requirements. Nonconforming manhole cover as-

standard flat manufactured of yellow brass, in accordance with semblies shall not be offered for delivery.

Specification B36/B36M.

10.2 Inspection—The dimensions of the manhole cover

6.6 Heavy hex nuts shall be ⁄4 in. (19.1 mm)—10 UNC-2B assembly and its components shall be checked to ensure that

and manufactured of yellow brass, in accordance with Speci- they are within specified tolerances.

fication B36/B36M. Threads in nuts shall conform to the

10.3 Test Methods—Each manhole cover assembly shall be

dimensions for coarse threads with tolerances prescribed in

designed to the pressure listed in Table 1 and tested to a

accordance with ANSI B1.1. The nuts shall conform to

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.