ASTM F2195-02

(Specification)Standard Specification for Linoleum Floor Tile

Standard Specification for Linoleum Floor Tile

SCOPE

1.1 This specification covers floor tiles made of a homogeneous mixture of linoleum cement binder calendered or pressed onto a fibrous or suitable backing.

1.2 Four types of linoleum floor tile are covered. The floor covering is intended for use in commercial, light commercial, and residential buildings based on serviceability characteristics. General information and performance characteristics, which determine serviceability and recommended use, are included in this document.

1.3 The following safety hazards caveat pertains only to the test methods portion, Sections , of this specification.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory requirements prior to use.

1.5 The values stated in inch-pound units are to be regarded as the standard; the values in parentheses are provided for information only.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: F 2195 – 02

Standard Specification for

Linoleum Floor Tile

This standard is issued under the fixed designation F 2195; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope F 2055 Test Method for Size and Squareness of Resilient

Floor Tile by Dial Gage Method

1.1 This specification covers floor tiles made of a homoge-

2.2 Other Standards:

neous mixture of linoleum cement binder calendered or pressed

ANSI/ASQC Z1.4 Sampling Procedures and Tables for

onto a fibrous or suitable backing.

Inspection by Attributes

1.2 Four types of linoleum floor tile are covered. The floor

EN 433 Determination of Residual Indentation after Static

covering is intended for use in commercial, light commercial,

Loading

and residential buildings based on serviceability characteris-

EN 669 Determination of the Dimensional Changes of Tiles

tics. General information and performance characteristics,

Caused by Atmospheric Humidity Changes

which determine serviceability and recommended use, are

EN 670 Identification and Composition of Linoleum—

included in this document.

Determination of Cement and Ash Residue

1.3 The following safety hazards caveat pertains only to the

test methods portion, Sections 7 and 8, of this specification.

3. Terminology

1.4 This standard does not purport to address all of the

3.1 Definitions:

safety concerns, if any, associated with its use. It is the

3.1.1 drying room yellowing—a yellowish cast develops on

responsibility of the user of this standard to establish appro-

the surface of the linoleum during the oxidation process, which

priate safety and health practices and determine the applica-

will disappear when exposed to either natural or artificial light

bility of regulatory requirements prior to use.

to give a stable color in service; it may reappear or not

1.5 The values stated in inch-pound units are to be regarded

disappear in areas not exposed to light.

as the standard; the values in parentheses are provided for

3.1.2 linoleum—a surfacing material composed of a solidi-

information only.

fied mixture of linseed oil, pine rosin, fossil or other resins or

2. Referenced Documents rosins, or an equivalent oxidized oleoresinous binder, ground

cork and/or wood flour, mineral fillers, and pigments, bonded

2.1 ASTM Standards:

to a fibrous or other suitable backing.

F 137 Test Methods for Flexibility of Resilient Flooring

3.1.3 linoleum cement—the binder in linoleum consisting of

Materials with Cylindrical Mandrel Apparatus

a mixture of linseed oil, pine rosin, fossil or other resins or

F 141 Terminology Relating to Resilient Floor Coverings

rosins, or an equivalent oxidized oleoresinous binder.

F 150 Test Method for Electrical Resistance of Conductive

3.1.4 rosin—a translucent amber to almost black brittle,

and Static Dissipative Resilient Flooring

friable resin that is obtained by chemical means from the

F 386 Test Method for Thickness of Resilient Flooring

oleoresin dead wood of pine trees or from tall oil.

Materials Having Flat Surfaces

3.2 For additional definitions, refer to Terminology F 141.

F 410 Test Method for Wear Layer Thickness of Resilient

Floor Covering by 0ptical Measurement

4. Classification

F 925 Test Method for Resistance to Chemicals of Resilient

2 4.1 The floor coverings shall be of the following types:

Sheet Flooring

2 4.1.1 Type I—Linoleum floor tile with fibrous backing.

F 970 Test Method for Static Load Limit

4.1.2 Type II—Linoleum floor tile with special backing.

F 1514 Test Method for Measuring Heat Stability of Resil-

2 4.1.3 Type III—Linoleum floor tile without backing.

ient Floor Covering by Color Change

4.1.4 Type IV—Static dissipative linoleum floor tile with or

F 1515 Test Method for Measuring Light Stability of Resil-

2 without backing.

ient Floor Covering by Color Change

NOTE 1—If any of the above structures incorporate a stabilizing

This specification is under the jurisdiction of ASTM Committee F06 on

Resilient Floor Coverings and is the direct responsibility of Subcommittee F06.80 Available from American National Standards Institute (ANSI), 25 W. 43rd St.,

on Specifications. 4th Floor, New York, NY 10036.

Current edition approved July 10, 2002. Published September 2002. Available from CEN European Committee for Standardization—Central Sec-

Annual Book of ASTM Standards, Vol 15.04. retariat: rue de Stassart, 36 B-1050 Brussels.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

F2195–02

inner-layer mat or fabric between the top wear-layer and the back of the

added such as cork, foam, or other suitable backing.

structure, the flooring type will include the hyphenated suffix of “-IL.” (for

6.3 Composition:

example, Type II-IL, a linoleum floor tile with a special backing including

6.3.1 Linoleum Cement Content—The minimum amount of

an inner-layer mat or fabric).

linoleum cement shall be 30 % when tested in accordance with

European Norm 670.

5. Ordering Information

5.1 Linoleum floor tile shall be ordered by type, thickness, 7. Physical Properties

and other characteristics important to the purchaser for the

7.1 Wear Surface—The thickness of the wear surface shall

intended use.

be determined in accordance with Test Method F 410. The

5.1.1 Title, number, and date of this specification,

minimum thickness of the wear surface/topcoat, shall be 0.040

5.1.2 Type and pattern number,

in. (1.0 mm).

5.1.3 Quantity in square feet, square meters, pieces or

7.2 Size—Unless otherwise specified (see 5.1.4), the tile

cartons,

size shall be nominal 13 by 13 in. (333 by 333 mm), 20 by 20

5.1.4 Size required (Section 7),

in. (500 by 500 mm), 24 by 24 in. (610 by 610 mm). A

5.1.5 Thickness required (Section 7),

tolerance of 60.016 in. (0.4 mm) per linear ft (305 mm) shall

5.1.6 Sampling if other than as specified in ANSI/ASQC

be permitted when measured in accordance with Test Method

Z1.4, level 5-1 as noted in Table 1,

F 2055. Other sizes may be available.

5.1.7 Packing requirement if other than as specified (Section

7.3 Thickness—Unless otherwise specified (see 5.1.5), the

14),

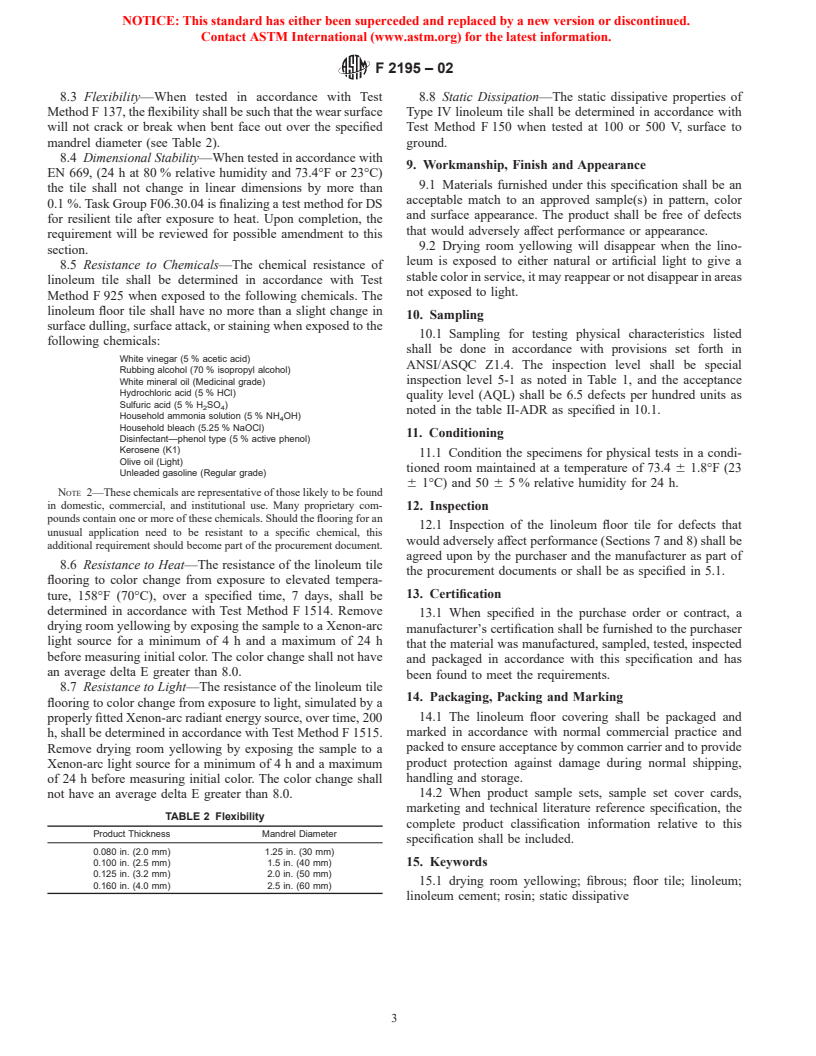

tile shall be furnished in 0.080 in. (2.0 mm), 0.100 in.(2.5 mm),

5.1.8 Marking required if other than specified (Section 14),

0.125 in. (3.2 mm), 0.160 in. (4.0 mm). The overall thickness

and

when measured shall be determined in accordance with Test

5.1.9 Specific Chemical Resistance (Section 8).

Method F 386.

7.4 Squareness—When tested in accordance with Test

6. Materials and Manufacture

Method F 2055, the out-of-squareness of the tile shall not

6.1 Wear Surface—The wear surface is the portion above

exceed 0.010 in. (0.25 mm) for tiles #16 in. (400 mm) or 0.014

the fibrous or suitable backing/bedding layer or base coat. The

in. (0.35 mm) for tiles >16 in. (400 mm).

wear surface should have a minimum thickness of 0.04 in. (1

8. Performance Requirements

mm).

6.1.1 TypeI/Type II/Type III/Type IV—For all types, the 8.1 Residual Indentation—When tested in accordance with

wear surface of the linoleum shall consist of a homogeneous Test Method EN 433 under 112 lb (50.8 kg) load, 0.445 in.

mixture as described in 3.1.2. For Type IV, the linoleum shall (11.30 mm) diameter flat foot and 150 min indentation, the

have incorporated into the wearing surface additives, which average residual indentation at the end of 150 min recovery

will give the linoleum electrostatic discharge controlling prop- shall not exceed 0.006 in. (0.15 mm) for tiles #0.100 in. (2.5

erties. mm) thick or 0.008 in. (0.20 mm) for tiles >0.100 in. (2.5 mm)

6.2 Backings: thick.

6.2.1 Fibrous—The fibrous backing shall be firmly bonded 8.2 Static Load Resistance—When tested in accordance

and keyed to the linoleum mix so as to be partially imbedded

with Test Method F 970, the residual indentation shall not

in the mix. exceed 0.005 in. (0.12 mm) tested with a load of 150 lb (67.5

6.2.2 Special Backing—In some cases a special backing is kg).

TABLE 1 Characteristics and Tests

Property Requirement Test Method Reference

Wear Surface Wear surface shall be a minimum thickness of 0.040 in. (1.0 mm). ASTM F 410 7.1

Size, tolerance 60.016 in. (0.4 mm) per linear

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.