ASTM F1761-00(2005)

(Test Method)Standard Test Method for Pass Through Flux of Circular Magnetic Sputtering Targets

Standard Test Method for Pass Through Flux of Circular Magnetic Sputtering Targets

SIGNIFICANCE AND USE

It is standard practice to use magnetron cathode sputter deposition sources in manufacturing thin film magnetic data storage media. But a ferromagnetic sputtering target tends to shunt a sputtering cathode’ magnetic field, thus reducing the efficiency of the sputtering process.

Makers of sputtering targets have developed various means of controlling alloy microstructure to minimize the undesirable cathode shunting effect. Because of their differing manufacturing methods, however, the targets of one supplier may have magnetic properties significantly better or worse than those of another, even when the alloy compositions are the same.

This test method permits comparing the magnetic shunting power of magnetic targets under a standard test condition. The results are useful to sputtering target suppliers and buyers in predicting target performance, in specifying target quality, and in qualifying incoming target shipments. This test may also be useful in quantifying target improvement efforts.

Manufacturing process steps that lower a target material’magnetic permeability tend to increase the PTF, and vice versa. It would in principle be possible to predict the PTF by accumulating sufficient permeability data, and knowing the target thickness and the field intensity of the magnetic assembly used for magnetron sputtering.

SCOPE

1.1 This test method covers measuring the dc magnetic field transmitted through a ferromagnetic sputtering target ("pass through flux" or "PTF"). In this test method the source magnetic field is in the test target's circumferential direction.

1.2 Planar disk-shaped targets in the diameter range 5 to 8 in. inclusive (125 to 205 mm inclusive) and of thickness 0.1 to 0.5 in. inclusive (2.5 to 13 mm) may be characterized by this procedure.

1.3 This test method is also applicable to targets having an open center, for example, to targets 5-in. outside diameter by 2.5-in. inside diameter by 0.25-in. thick (127-mm outside diameter by 63.5-mm inside diameter by 6.35-mm thick).

1.4 Targets of various diameters and thicknesses are accommodated by suitable fixturing to align the piece under test with the source magnet mounted in the test fixture. Tooling, covering several popular target designs is specified in this procedure. Additional target configurations may be tested by providing special tooling. When special fixturing is used all parties concerned with the testing must agree to the test setup.

1.5 The values stated in inch-pound units are to be regarded as the standard. The values given in parentheses are for information only.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: F1761 – 00 (Reapproved 2005)

Standard Test Method for

Pass Through Flux of Circular Magnetic Sputtering Targets

This standard is issued under the fixed designation F1761; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 2.1.2 reference field, n—For purposes of this standard the

“reference field” is the dc magnetic field measured with the

1.1 This test method covers measuring the dc magnetic field

Hall probe Gaussmeter when no sputtering target is in position

transmitted through a ferromagnetic sputtering target (“pass

on the test stand. The strength of the reference field depends

through flux” or “PTF”). In this test method the source

upon the height and position of the Hall probe relative to the

magnetic field is in the test target’s circumferential direction.

source magnet.

1.2 Planar disk-shaped targets in the diameter range 5 to 8

2.1.3 source field, n—For purposes of this standard the

in. inclusive (125 to 205 mm inclusive) and of thickness 0.1 to

“source field” is the dc magnetic field measured with the Hall

0.5 in. inclusive (2.5 to 13 mm) may be characterized by this

probe at the top surface of the target support table.

procedure.

1.3 This test method is also applicable to targets having an

3. Summary of Test Method

open center, for example, to targets 5-in. outside diameter by

3.1 The sputtering target under test is mounted on a test

2.5-in. inside diameter by 0.25-in. thick (127-mm outside

fixture in which a permanent horseshoe-shaped magnet is held

diameter by 63.5-mm inside diameter by 6.35-mm thick).

in proximity to one of the flat planar faces of the target.AHall

1.4 Targets of various diameters and thicknesses are accom-

probe Gaussmeter is used to measure the dc magnetic field

modated by suitable fixturing to align the piece under test with

penetrating the target and entering the air space from target’s

the source magnet mounted in the test fixture. Tooling, cover-

opposite face.

ingseveralpopulartargetdesignsisspecifiedinthisprocedure.

Additional target configurations may be tested by providing

4. Significance and Use

special tooling. When special fixturing is used all parties

4.1 It is standard practice to use magnetron cathode sputter

concerned with the testing must agree to the test setup.

deposition sources in manufacturing thin film magnetic data

1.5 The values stated in inch-pound units are to be regarded

storage media. But a ferromagnetic sputtering target tends to

as the standard. The values given in parentheses are for

shunt a sputtering cathode’s magnetic field, thus reducing the

information only.

efficiency of the sputtering process.

1.6 This standard does not purport to address all of the

4.2 Makers of sputtering targets have developed various

safety concerns, if any, associated with its use. It is the

means of controlling alloy microstructure to minimize the

responsibility of the user of this standard to establish appro-

undesirable cathode shunting effect. Because of their differing

priate safety and health practices and determine the applica-

manufacturing methods, however, the targets of one supplier

bility of regulatory limitations prior to use.

mayhavemagneticpropertiessignificantlybetterorworsethan

2. Terminology those of another, even when the alloy compositions are the

same.

2.1 Definitions:

4.3 This test method permits comparing the magnetic shunt-

2.1.1 pass through flux (PTF), (n)—For purposes of this

ing power of magnetic targets under a standard test condition.

standard the 88pass through flux” is the dc magnetic field

The results are useful to sputtering target suppliers and buyers

transmittedthroughaferromagneticsputteringtarget,fromone

in predicting target performance, in specifying target quality,

face to the opposite face.

andinqualifyingincomingtargetshipments.Thistestmayalso

2.1.1.1 Discussion—PTF is also frequently called 88leakage

be useful in quantifying target improvement efforts.

flux.”

4.4 Manufacturing process steps that lower a target materi-

al’s magnetic permeability tend to increase the PTF, and vice

This test method is under the jurisdiction of ASTM Committee F01 on

versa. It would in principle be possible to predict the PTF by

Electronics and is the direct responsibility of Subcommittee F01.17 on Sputtered

accumulating sufficient permeability data, and knowing the

Thin Films.

target thickness and the field intensity of the magnetic assem-

Current edition approved May 1, 2005. Published June 2005. Originally

approved in 1996. Last previous edition approved in 2000 as F1761 – 00. DOI:

bly used for magnetron sputtering.

10.1520/F1761-00R05.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

F1761 – 00 (2005)

5. Interferences 7.4 Mount the Gaussmeter probe in the fixture’s Hall probe

support tube. The bottom tip of the probe should extend 0.050

5.1 The magnetic test fixture must be located in an area free

6 0.025 in. (1.25 6 0.64 mm) beyond the support tube.

of extraneous ferromagnetic materials and strong magnetic

Mounted properly, the probe tip will be clearly visible, sticking

fields that would interfere with the source magnet—test speci-

out of its support. Gently tighten the nylon clamping screws to

men dc magnetic-field configuration.

secure and center the Hall probe blade in position in the probe

5.2 The “magnetic conditioning” effect is strong in some

support tube. Excessive tightening may result in damage to the

sputtering target alloys. It is important to verify that the target

probe that can affect test results.

under test is magnetically stabilized before finalizing a data set

7.5 By visual sighting, align the Hall probe as indicated in

(see 9.2).

Fig.1,butwiththeprobetipclosetobutnottouchingthetarget

6. Apparatus support table. The Hall probe should be roughly centered

between the magnet poles, and the flats of the probe blade

6.1 This method requires the use of a special test fixture. Its

should be parallel to the fixture’s long dimension. Note that the

construction is specified in Appendix X1.

outer vertical edge of the probe blade is aligned with the side

6.2 Gaussmeter, is required, equipped with a portable

of the magnet, illustrated in Fig. 1. Loosen the post attachment

transverse-field Hall probe blade nominally 0.040-in. thick by

screw at the baseplate and adjust the Hall probe post position,

0.170-in. wide by 2.5-in. long (1.0-mm by 4.3-mm by 64 mm).

if necessary, to achieve the correct location.

The Gaussmeter must be capable of measuring dc magnetic

7.5.1 To make the adjustments indicated in this and subse-

fields in the range 10 Gauss to 3500 Gauss, inclusive, to an

quent paragraphs, it may be necessary to loosen and retighten

accuracy of 62 %. This unit is designated the “measuring

the collars on the Hall probe support post and the appropriate

Gaussmeter,” and is used for making the magnetic field

nylon clamping screws, which secure other parts of the

measurements specified in this test method.

apparatus.

6.2.1 It is important that the semiconductor Hall probe

sensing element be mounted at the extreme tip end of the 7.6 Lower the support arm until the Hall probe blade tip is

probe. The distance from the probe tip to the center of the in bare (light) contact with the target support table. Note the

sensing element must not exceed 0.030 in. (0.75 mm). Gaussmeter reading. Swing (rotate) the cross arm to center the

6.3 It is convenient to have a second Gaussmeter available, probe blade between the magnetic poles, and slightly rotate the

alsoequippedwithaportabletransverse-fieldHallprobeblade. probe support tube, as necessary, to maximize the Gaussmeter

This unit must be capable of measuring dc magnetic fields in readings.TheproperpositionisachievedwhentheGaussmeter

reading indicates a clear maximum in the magnetic field

the range 1 Gauss to 50 Gauss, inclusive, to an accuracy of

620 %. This unit is referred to in 8.1 as the “screening strength.

Gaussmeter.” It is used to monitor residual magnetic fields in

NOTE 2—If a clear maximum cannot be identified, the Hall probe blade

test specimen sputtering targets.

is not adequately centered in the probe support tube (see 7.4), or the blade

is not in correct transverse alignment (7.6), Repeat 7.4 or 7.6 as required,

NOTE 1—If a “screening Gaussmeter” is not available, the targets under

to provide a discernible maximum point in 7.6.

testmustbedegaussedandverified(8.3)usingthemeasuringGaussmeter,

before starting Section 7.

7.6.1 The maximum Gaussmeter reading at the target sup-

6.4 Demagnetizer , is needed that is capable of removing

port table (7.6) is the “source field” (2.1.3).

the remnant magnetization in sputtering targets to be tested.

NOTE 3—Measuring and recording (preferably using an SPC control

chart) the source field provides important information about the stability

7. Preparation of Apparatus

of the measuring system. A significant deviation in source field strength

7.1 Verify that the source magnet is securely clamped with

may indicate a problem with the Hall probe, or a change in the operating

its vertical center plane located 5.750 6 0.015 in. (146.1 6 0.4

environment that may influence the test results.

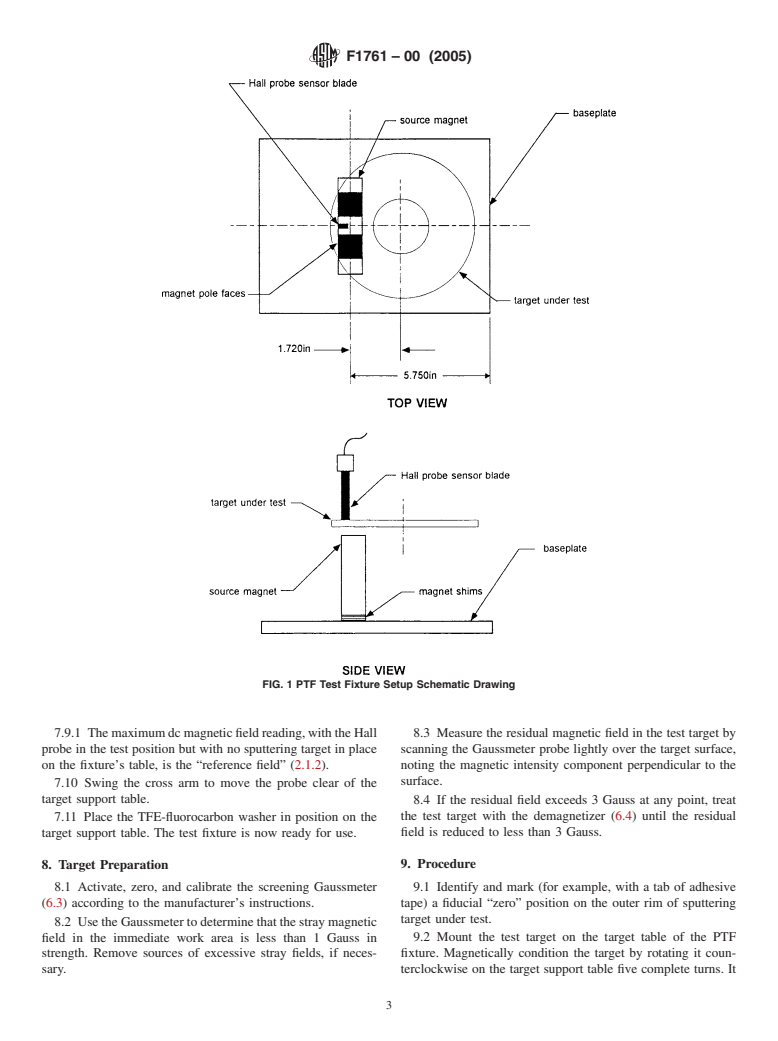

mm) from the end of the baseplate. This is illustrated in Fig. 1.

7.7 The source field (7.6.1) must be in the range 825 6 50

7.2 Verify that the pole faces of the source magnet are in

Gauss.

light contact with the bottom of the target support table.

7.7.1 If the dc magnetic field is not in the required range

Adjustment of the magnet’s vertical position can be made by

(7.7) the Hall probe should be inspected and replaced if any

loosening the magnet clamp screws, inserting nonmagnetic

evidence of damage is observed. If there are no indications of

shims under the magnet, and retightening the clamp screws.

probe damage the measurement of the source field (7.2-7.6)

Recheck magnet location, in accordance with 7.1, if shims are

should be repeated, as needed, until the requirement of 7.7 is

adjusted.

satisfied.

7.3 Activate, zero, and calibrate the measuring Gaussmeter

7.8 Lift the probe support cross arm to a position in which

(6.2) using the manufacturer’s instructions.

the clearance between Hall probe tip and the top surface of the

targettobetested(withtheTFE-fluorocarbonwasherinplace),

will be 0.075 6 0.025 in. (2.0 6 0.6 mm). Adjust and tighten

The sole source of supply of the

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.