ASTM F1223-08(2012)

(Test Method)Standard Test Method for Determination of Total Knee Replacement Constraint

Standard Test Method for Determination of Total Knee Replacement Constraint

SIGNIFICANCE AND USE

4.1 This test method, when applied to available products and proposed prototypes, is meant to provide a database of product functionality capabilities (in light of the suggested test regimens) that is hoped will aid the physician in making a more informed total knee replacement (TKR) selection.

4.2 A proper matching of TKR functional restorative capabilities and the recipient's (patient's) needs is more likely to be provided by a rational testing protocol of the implant in an effort to reveal certain device characteristics pertinent to the selection process.

4.3 The TKR product designs are varied and offer a wide range of constraint (stability). The constraint of the TKR in the in vitro condition depends on several geometrical and kinematic interactions among the implant's components which can be identified and quantified. The degree of TKR's kinematic interactions should correspond to the recipient's needs as determined by the physician during clinical examination.

4.4 For mobile bearing knee systems, the constraint of the entire implant construct shall be characterized. Constraint of mobile bearings is dictated by design features at both the inferior and superior articulating interfaces.

4.5 The methodology, utility, and limitations of constraint/laxity testing are discussed.3, 4 The authors recognize that evaluating isolated implants (that is, without soft tissues) does not directly predict in vivo behavior, but will allow comparisons among designs. Constraint testing is also useful for characterizing implant performance at extreme ranges of motion which may be encountered in vivo at varying frequencies, depending on the patient’s anatomy, pre-operative capability, and post-operative activities and lifestyle.

SCOPE

1.1 This test method covers the establishment of a database of total knee replacement (TKR) motion characteristics with the intent of developing guidelines for the assignment of constraint criteria to TKR designs. (See the Rationale in Appendix X1.)

1.2 This test method covers the means by which a TKR constraint may be quantified according to motion delineated by the inherent articular design as determined under specific loading conditions in an in vitro environment.

1.3 Tests deemed applicable to the constraint determination are antero-posterior draw, medio-lateral shear, rotary laxity, valgus-varus rotation, and distraction, as applicable. Also covered is the identification of geometrical parameters of the contacting surfaces which would influence this motion and the means of reporting the test results. (See Practices E4.)

1.4 This test method is not a wear test.

1.5 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:F1223 −08(Reapproved 2012)

Standard Test Method for

Determination of Total Knee Replacement Constraint

This standard is issued under the fixed designation F1223; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope their human counterparts:

3.1.1 anterior curvature—a condylar design which is gen-

1.1 This test method covers the establishment of a database

erally planar except for a concave—upward region anteriorly

of total knee replacement (TKR) motion characteristics with

on the tibial component.

the intent of developing guidelines for the assignment of

constraint criteria to TKR designs. (See the Rationale in

3.1.2 anterior posterior (AP)—any geometrical length

Appendix X1.)

aligned with the AP orientation.

1.2 This test method covers the means by which a TKR

3.1.3 AP displacement—the relative linear translation be-

constraint may be quantified according to motion delineated by

tween components in the AP direction.

the inherent articular design as determined under specific

3.1.4 AP draw load—the force applied to the movable

loading conditions in an in vitro environment.

component with its vector aligned in the AP direction causing

1.3 Tests deemed applicable to the constraint determination

or intending to cause an AP displacement.

are antero-posterior draw, medio-lateral shear, rotary laxity,

3.1.5 biconcave—a condylar design with pronounced AP

valgus-varus rotation, and distraction, as applicable. Also

and MLcondylar radii seen as a “dish” in the tibial component

covered is the identification of geometrical parameters of the

or a “toroid” in the femoral component.

contacting surfaces which would influence this motion and the

3.1.6 bearing surface—those regions of the component

means of reporting the test results. (See Practices E4.)

which are intended to contact its counterpart for load transmis-

1.4 This test method is not a wear test.

sion.

1.5 The values stated in SI units are to be regarded as

3.1.7 condyles—entity designed to emulate the joint

standard. No other units of measurement are included in this

anatomy and used as a bearing surface primarily for transmis-

standard.

sion of the joint reaction force with geometrical properties

1.6 This standard does not purport to address all of the

which tend to govern the general kinematics of the TKR.

safety concerns, if any, associated with its use. It is the

3.1.8 distraction—the separation of the femoral compo-

responsibility of the user of this standard to establish appro-

nent(s) from the tibial component(s) in the z-direction.

priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use. 3.1.9 femoral side constraint—that constraint provided by

the superior articulating interfaces, determined by fixing the

2. Referenced Documents

inferior surface of the mobile bearing component during

2.1 ASTM Standards:

testing.

E4 Practices for Force Verification of Testing Machines

3.1.10 flexion angle—the angulation of the femoral compo-

F2083 Specification for Total Knee Prosthesis

nent (about an axis parallel to the y-axis) from the fully

3. Terminology

extended knee position to a position in which a “local” vertical

axis on the component now points posteriorly.

3.1 Definitions—Items in this category refer to the geo-

3.1.10.1 Discussion—For many implants, 0° of flexion can

metricalandkinematicaspectsofTKRdesignsastheyrelateto

be defined as when the undersurface of the tibial component is

parallel to the femoral component surface that in vivo contacts

This test method is under the jurisdiction ofASTM Committee F04 on Medical

and Surgical Materials and Devices and is the direct responsibility of Subcommittee the most distal surface of the femur.This technique may not be

F04.22 on Arthroplasty.

possibleforsomeimplantsthataredesignedtohaveaposterior

Current edition approved Dec. 1, 2012. Published December 2012. Originally

tilt of the tibial component. In these cases, the user shall

approved in 1989. Last previous edition approved in 2008 as F1223 – 08. DOI:

specify how the 0° of flexion position was defined.

10.1520/F1223-08R12.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

3.1.11 hinge—a mechanical physical coupling between

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

femoral and tibial components which provides a single axis

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. about which flexion occurs.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

F1223−08 (2012)

3.1.12 hyperextension stop—a geometrical feature which component.Theactualrelativemotionvaluesshallbeprovided

arrests further progress of flexion angles of negative value. as indicators of this type of constraint.

3.1.13 inferior articulating interfaces—any interface in 3.2.2 coordinate system (see Fig. 1)—a set of arbitrary

which relative motion occurs between the underside of the cartesian coordinates affixed to the stationary component and

mobile bearing component and the tibial tray. aligned such that the origin is located at the intersection of the

y and z axes.

3.1.14 internal-external rotation—the relative angulation of

3.2.2.1 Discussion—The y-axis is parallel to the ML

the moveable component about an axis parallel to the z-axis.

direction, directed medially, and is coincident with the mated

3.1.15 joint reaction force—theappliedloadwhosevectoris

components’ contact points when the knee is in the neutral

directed parallel to the z-axis, generally considered parallel to

position (see 7.2). The z-axis is located midway between the

tibial longitudinal axis.

mated components’ contact points (or in the case of a single

3.1.16 medio-lateral (ML)—the orientation that is aligned

contact point, located at that point) and aligned in the superior-

with the y-axis in the defined coordinate system.

inferior direction of the distal component. A third axis, x,

3.1.17 ML condylar radius—the geometrical curvature of mutually orthogonal to the two previous axes is directed

the component’s condyle in the frontal plane. posteriorly. For determination of contact points, see AnnexA1

and Fig. 2. The contact point shall be located to a tolerance of

3.1.18 ML dimension—any geometrical length aligned with

61 mm. In the case of multiple contact points on a condyle, an

the ML orientation.

average location of the contact points shall be used.

3.1.19 ML displacement—the relative linear translation be-

3.2.3 degrees of freedom—although the knee joint is noted

tween components in the ML direction.

to have 6 df, or directions in which relative motion is guided

3.1.20 ML shear load—the force applied to the moveable

(three translations:AP, ML, vertical; three angulations: flexion,

component with its vector aligned in the ML direction and

internal-external rotation, valgus-varus), the coupling effects

causing or intending to cause an ML displacement.

due to geometrical features reduce this number to five which

3.1.21 mobile bearing component—the ultra-high molecular

are the bases of this test method: AP draw, ML shear,

weight polyethylene (UHMWPE) component that, by design,

internal-external rotation, valgus-varus rotation, and distrac-

articulates against both the femoral bearing and the tibial tray.

tion.

3.1.22 mobile bearing knee system—a knee prosthesis

3.2.4 neutral position (see 7.2)—that position in which the

system, comprised of a tibial component, a mobile bearing

TKR is at rest with no relative linear or angular displacements

component that can rotate or rotate and translate relative to the

between components.

tibial component, and a femoral component.

3.2.4.1 Discussion—This is design-dependent and there

may be a unique neutral position at each flexion angle. It may

3.1.23 post-in-well feature—a TKR design which tends to

be indicated that the femoral component, when implanted, be

influence kinematics through the coupling of a prominent

positioned at some angle of hyperextension as seen when the

eminence with a recess or housing in a mating component.

patient’s knee is fully extended; this, then becomes the neutral

3.1.24 rotary laxity(RL)—degreeofrelativeangularmotion

position for negative flexion angle tests. The neutral position

permitted for a moveable component about the z-axis as

governed by inherent geometry and load conditions.

3.1.25 rotary torque—the moment applied to the moveable

component with its vector aligned to an axis parallel to the

z-axis and causing or intending to cause an internal or external

rotation.

3.1.26 superior articulating interfaces—any interface in

whichrelativemotionoccursbetweenthetopsideofthemobile

bearing component and the femoral bearing component.

3.1.27 tibial eminence—a raised geometrical feature sepa-

rating the tibial condyles.

3.1.28 tibial side constraint—thatconstraintprovidedbythe

inferior articulating interface.

3.1.29 valgus-varus constraint—degree of relative angular

motion allowed between the femoral and tibial components of

post-in-well designs (or similar designs) in the coronal plane.

3.2 Definitions of Terms Specific to This Standard:

3.2.1 constraint—the relative inability of a TKR to be

further displaced in a specific direction under a given set of

loading conditions as dictated by the TKR’s geometrical

design. This motion is limited, as defined in this test, to the

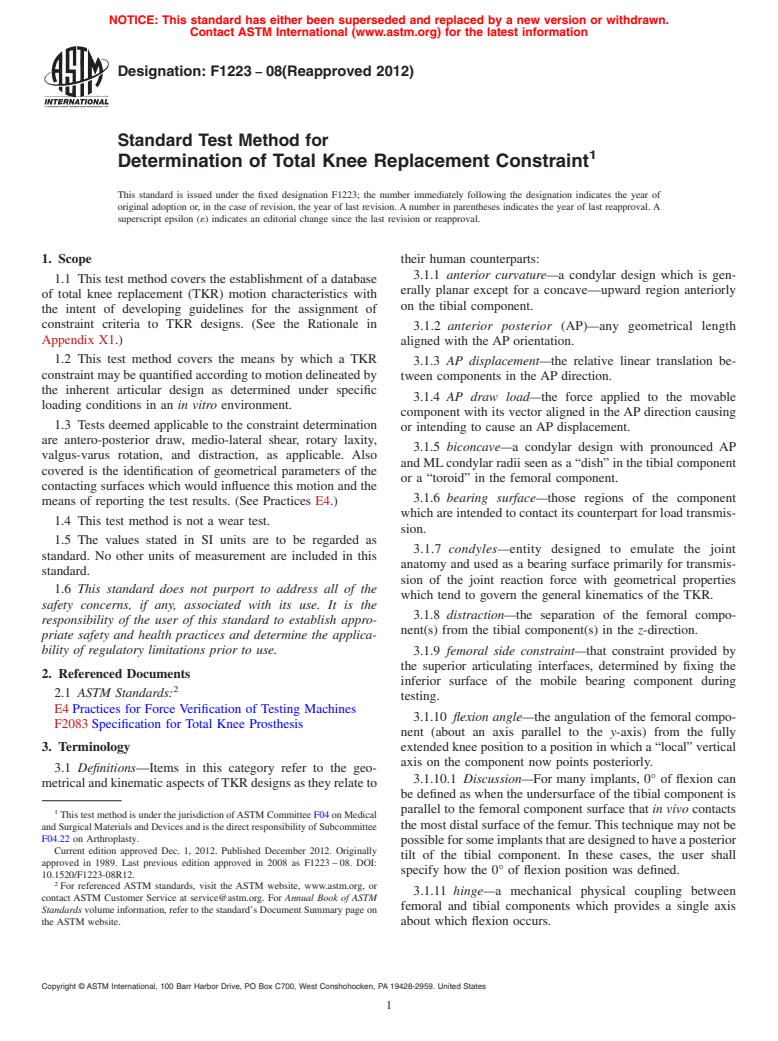

available articular or bearing surfaces found on the tibial FIG. 1 Defined Coordinate System Examples

F1223−08 (2012)

3.3.4 DIST—a “yes/no” response to distraction test at the

reported angle at which distraction is most likely to occur.

4. Significance and Use

4.1 This test method, when applied to available products

and proposed prototypes, is meant to provide a database of

product functionality capabilities (in light of the suggested test

regimens)thatishopedwillaidthephysicianinmakingamore

informed total knee replacement (TKR) selection.

4.2 A proper matching of TKR functional restorative capa-

bilities and the recipient’s (patient’s) needs is more likely to be

provided by a rational testing protocol of the implant in an

effort to reveal certain device characteristics pertinent to the

selection process.

4.3 The TKR product designs are varied and offer a wide

range of constraint (stability).The constraint of theTKR in the

in vitro condition depends on several geometrical and kine-

matic interactions among the implant’s components which can

be identified and quantified. The degree of TKR’s kinematic

interactions should correspond to the recipient’s needs as

determined by the physician during clinical examination.

4.4 For mobile bearing knee systems, the constraint of the

entire implant construct shall be characterized. Constraint of

mobile bearings is dictated by design features at both the

inferior and superior articulating interfaces.

4.5 The methodology, utility, and limitations of constraint/

3,4

laxity testing are discussed. The authors recognize that

evaluating isolated implants (that is, without soft tissues) does

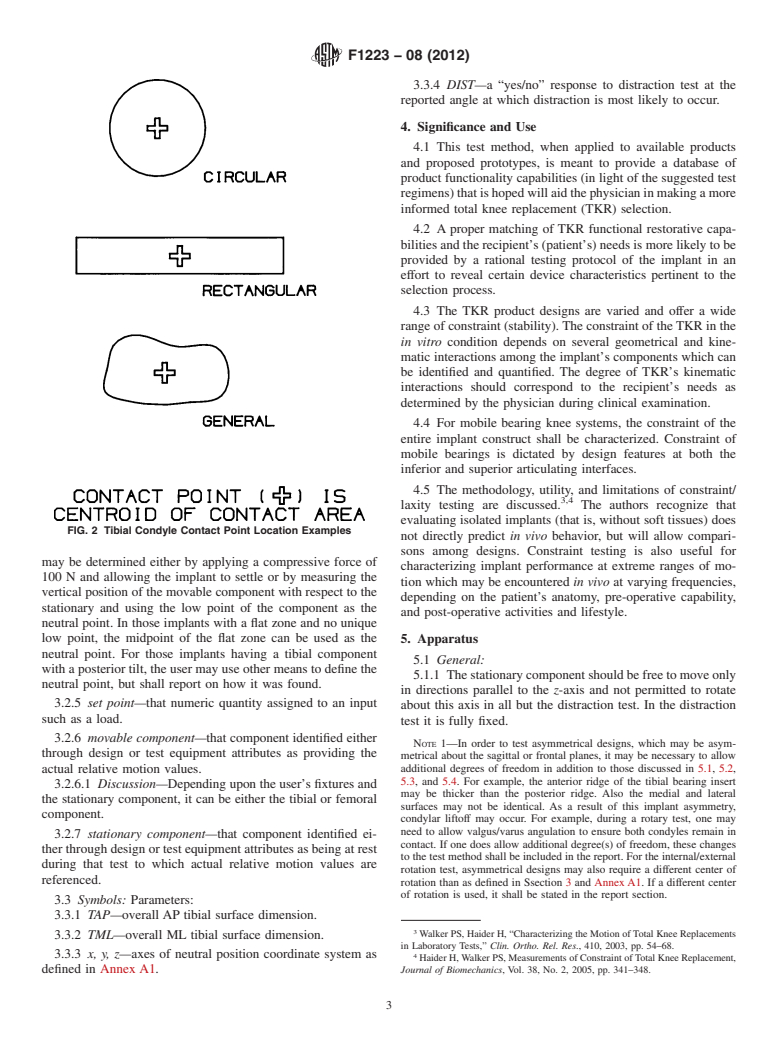

FIG. 2 Tibial Condyle Contact Point Location Examples

not directly predict in vivo behavior, but will allow compari-

sons among designs. Constraint testing is also useful for

may be determined either by applying a compressive force of

characterizing implant performance at extreme ranges of mo-

100 N and allowing the implant to settle or by measuring the

tion which may be encountered in vivo at varying frequencies,

vertical position of the movable component with respect to the

depending on the patient’s anatomy, pre-operative capability,

stationary and using the low point of the component as the

and post-operative activities and lifestyle.

neutral point. In those implants with a flat zone and no unique

low point, the midpoint of the flat zone can be used as the 5. Apparatus

neutral point. For those implants having a tibial component

5.1 General:

with a posterior tilt, the user may use other means to define the

5.1.1 Thestationarycomponentshouldbefreetomoveonly

neutral point, but shall report on how it was found.

in directions parallel to the z-axis and not permitted to rotate

3.2.5 set point—that numeric quantity assigned to an input

about this axis in all but the distraction test. In the distraction

such as a load.

test it is fully fixed.

3.2.6 movable component—that component identified either

NOTE 1—In order to test asymmetrical designs, which may be asym-

through design or test equipment attributes as providing the

metrical about the sagittal or frontal planes, it may be necessary to allow

additional degrees of freedom in addition to those discussed in 5.1, 5.2,

actual relative motion values.

5.3, and 5.4. For example, the anterior ridge of the tibial bearing insert

3.2.6.1 Discussion—Depending upon the user’s fixtures and

may be thicker than the posterior ridge. Also the medial and lateral

the stationary component, it can be either the tibial or femoral

surfaces may not be identical. As a result of this implant asymmetry,

component.

condylar liftoff may occur. For example, during a rotary test, one may

need to allow valgus/varus angulation to ensure both condyles remain in

3.2.7 stationary component—that component identified ei-

contact. If one does allow additional degree(s) of freedom, these changes

ther through design or test equipment attributes as being at rest

to the test method shall be included in the report. For the internal/external

during that test to which actual relative motion values are

rotation test, asymmetrical designs may also require a different center of

referenced.

rotation than as defined in Ssection 3 and Annex A1. If a different center

of rotation is used, it shall be stated in the report section.

3.3 Symbols: Parameters:

3.3.1 TAP—overall AP tibial surface dimension.

Walker PS, Haider H, “Characterizing the Motion of Total Knee Replacements

3.3.2 TML—overall ML tibial surface dimension.

in Laboratory Tests,” Clin. Ortho. Rel. Res., 410, 2003, pp. 54–68.

3.3.3 x, y, z—axes of neutral position coordinate system as

Haider H,Walker PS, Measurements of Constraint ofTotal Knee Replacement,

defined in Annex A1. Journal of Biomechanics, Vol. 38, No. 2, 2005, pp. 341–348.

F1223−08 (2012)

5.1.2 The movable component shall be the displaced mem- 5.5.1 The movable component shall be rigidly set in a

ber when under loads specific to that test and shall be fixture free to move in only t

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.