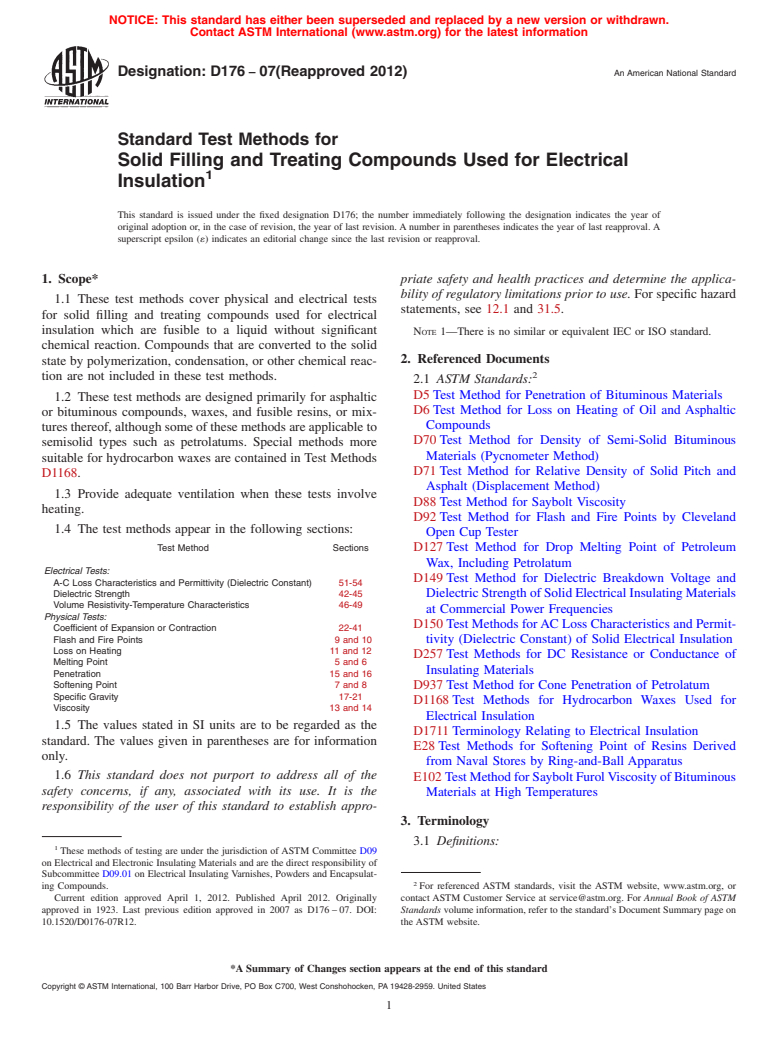

ASTM D176-07(2012)

(Test Method)Standard Test Methods for Solid Filling and Treating Compounds Used for Electrical Insulation (Withdrawn 2013)

Standard Test Methods for Solid Filling and Treating Compounds Used for Electrical Insulation (Withdrawn 2013)

SIGNIFICANCE AND USE

The melting point is useful in selecting a filling or treating compound that will not flow at the operating temperature of the device in which it will be used. It is also essential that it shall not be so high as to injure the insulation at the time of pouring. This test method is suitable for specification, classification, and for control of product uniformity.

SCOPE

1.1 These test methods cover physical and electrical tests for solid filling and treating compounds used for electrical insulation which are fusible to a liquid without significant chemical reaction. Compounds that are converted to the solid state by polymerization, condensation, or other chemical reaction are not included in these test methods.

1.2 These test methods are designed primarily for asphaltic or bituminous compounds, waxes, and fusible resins, or mixtures thereof, although some of these methods are applicable to semisolid types such as petrolatums. Special methods more suitable for hydrocarbon waxes are contained in Test Methods D1168.

1.3 Provide adequate ventilation when these tests involve heating.

1.4 The test methods appear in the following sections:

Test MethodSections Electrical Tests: A-C Loss Characteristics and Permittivity (Dielectric Constant)51-54 Dielectric Strength42-45 Volume Resistivity-Temperature Characteristics46-49 Physical Tests: Coefficient of Expansion or Contraction22-41 Flash and Fire Points 9 and 10 Loss on Heating11 and 12 Melting Point5 and 6 Penetration15 and 16 Softening Point7 and 8 Specific Gravity17-21 Viscosity13 and 14

1.5 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. For specific hazard statements, see 12.1 and 31.5.

Note 1—There is no similar or equivalent IEC or ISO standard.

WITHDRAWN RATIONALE

These test methods cover physical and electrical tests for solid filling and treating compounds used for electrical insulation which are fusible to a liquid without significant chemical reaction. Compounds that are converted to the solid state by polymerization, condensation, or other chemical reaction are not included in these test methods.

Formerly under the jurisdiction of Committee D09 on Electrical and Electronic Insulating Materials, this test method was withdrawn in November 2013. This standard is being withdrawn without replacement because the products referenced in this standard are no longer used in the electrical industry.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D176 − 07(Reapproved 2012) An American National Standard

Standard Test Methods for

Solid Filling and Treating Compounds Used for Electrical

Insulation

This standard is issued under the fixed designation D176; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use. For specific hazard

1.1 These test methods cover physical and electrical tests

statements, see 12.1 and 31.5.

for solid filling and treating compounds used for electrical

insulation which are fusible to a liquid without significant

NOTE 1—There is no similar or equivalent IEC or ISO standard.

chemical reaction. Compounds that are converted to the solid

2. Referenced Documents

state by polymerization, condensation, or other chemical reac-

tion are not included in these test methods.

2.1 ASTM Standards:

D5 Test Method for Penetration of Bituminous Materials

1.2 These test methods are designed primarily for asphaltic

D6 Test Method for Loss on Heating of Oil and Asphaltic

or bituminous compounds, waxes, and fusible resins, or mix-

Compounds

tures thereof, although some of these methods are applicable to

D70 Test Method for Density of Semi-Solid Bituminous

semisolid types such as petrolatums. Special methods more

Materials (Pycnometer Method)

suitable for hydrocarbon waxes are contained in Test Methods

D71 Test Method for Relative Density of Solid Pitch and

D1168.

Asphalt (Displacement Method)

1.3 Provide adequate ventilation when these tests involve

D88 Test Method for Saybolt Viscosity

heating.

D92 Test Method for Flash and Fire Points by Cleveland

1.4 The test methods appear in the following sections:

Open Cup Tester

Test Method Sections D127 Test Method for Drop Melting Point of Petroleum

Wax, Including Petrolatum

Electrical Tests:

D149 Test Method for Dielectric Breakdown Voltage and

A-C Loss Characteristics and Permittivity (Dielectric Constant) 51-54

Dielectric Strength 42-45 DielectricStrengthofSolidElectricalInsulatingMaterials

Volume Resistivity-Temperature Characteristics 46-49

at Commercial Power Frequencies

Physical Tests:

D150 Test Methods forAC Loss Characteristics and Permit-

Coefficient of Expansion or Contraction 22-41

Flash and Fire Points 9 and 10 tivity (Dielectric Constant) of Solid Electrical Insulation

Loss on Heating 11 and 12

D257 Test Methods for DC Resistance or Conductance of

Melting Point 5 and 6

Insulating Materials

Penetration 15 and 16

Softening Point 7 and 8

D937 Test Method for Cone Penetration of Petrolatum

Specific Gravity 17-21

D1168 Test Methods for Hydrocarbon Waxes Used for

Viscosity 13 and 14

Electrical Insulation

1.5 The values stated in SI units are to be regarded as the

D1711 Terminology Relating to Electrical Insulation

standard. The values given in parentheses are for information

E28 Test Methods for Softening Point of Resins Derived

only.

from Naval Stores by Ring-and-Ball Apparatus

1.6 This standard does not purport to address all of the

E102 TestMethodforSayboltFurolViscosityofBituminous

safety concerns, if any, associated with its use. It is the

Materials at High Temperatures

responsibility of the user of this standard to establish appro-

3. Terminology

3.1 Definitions:

These methods of testing are under the jurisdiction of ASTM Committee D09

on Electrical and Electronic Insulating Materials and are the direct responsibility of

Subcommittee D09.01 on Electrical Insulating Varnishes, Powders and Encapsulat-

ing Compounds. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved April 1, 2012. Published April 2012. Originally contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

approved in 1923. Last previous edition approved in 2007 as D176 – 07. DOI: Standards volume information, refer to the standard’s Document Summary page on

10.1520/D0176-07R12. the ASTM website.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D176 − 07 (2012)

3.1.1 dielectric strength, n—the voltage gradient at which dard methods of sampling have been established. When the

dielectric failure of the insulating material occurs under spe- sample is in the form of cakes or ingots, a representative

cific conditions of test.

sample is usually secured by breaking or cutting a transverse

sectionfromthemiddleofthecakeoringot.Whenthematerial

3.1.2 For definitions of other terms relating to electrical

is shipped in pails or drums, a sample is removed with a clean

insulation see Terminology D1711.

knife, hatchet, auger or other cutting tool, discarding the top 50

3.2 Definitions of Terms Specific to This Standard:

or 75 mm (2 or 3 in.) of the compound. Melting of the

3.2.1 loss on heating, n—of filling or treating compound,the

compound should be avoided unless it can be poured directly

change in weight of a compound when heated under prescribed

conditions at a standard temperature for a specified time. intothetestingcontainer.Ameltingandpouringtemperatureof

50 °C (90 °F) above the softening point is recommended for

3.2.2 melting point, n—of filling or treating compound, the

filling testing containers with asphaltic compounds. Take care

temperature at which the compound becomes sufficiently fluid

not to overheat the compound nor to entrap air.

to drop from the thermometer used in making the determina-

tion under prescribed conditions.

4.2 With certain materials that tend to entrap gasses due to

3.2.3 penetration, n— of filling or treating compound, the

high viscosity at pouring temperatures, or to froth on heating,

distance traveled by a standard needle (or cone) as it pierces a

itisnecessarytodegasthematerialpriortotestinginorderthat

specimenunderspecifiedconditionsofload,timeandtempera-

consistent results are secured (unless the particular test in-

ture.

cludes such procedure). If degassing is required, perform by

3.2.4 softening point, n—of filling or treating compound,the

heating the material in a vacuum oven. Ensure the temperature

temperature at which the central portion of a disk of the

and vacuum are high enough, and the time long enough to

compound held within a horizontal ring of specified dimen-

drive off the mechanically entrapped gasses, but not so high to

sions has sagged or flowed downward a distance of 25 mm (1

decompose the material. A temperature 50 °C (90 °F) higher

in.) under the weight of a 10-mm ( ⁄8-in.) diameter steel ball as

than the softening point of the compound, an absolute pressure

the sample is heated at a prescribed rate in a water or glycerin

of 7 to 21 kPa (1 to 3 psi), and a time of 30 to 45 min are

bath.

recommended for asphaltic compounds. Pour the sample into

the testing container.

4. Sampling and Conditioning

4.1 Due to the diverse nature of the compounds and the

various forms and packages commercially available, no stan-

PHYSICAL TESTS

MELTING POINT the compound has no definite melting point, for purposes of

specification, classification, and control of product uniformity.

5. Significance and Use

8. Procedure

5.1 The melting point is useful in selecting a filling or

8.1 Determine the softening point in accordance with Test

treating compound that will not flow at the operating tempera-

Method E28.

ture of the device in which it will be used. It is also essential

that it shall not be so high as to injure the insulation at the time

FLASH AND FIRE POINTS

of pouring. This test method is suitable for specification,

9. Significance and Use

classification, and for control of product uniformity.

9.1 Theflashandfirepointsmustbehighenoughsothatthe

6. Procedure

possibility of an explosion or fire is at a minimum when the

6.1 Determine the melting point of petrolatums, waxes, and compounds are being heated and poured. A flash point at least

similar compounds of a relatively sharp melting point by Test 35 °C (63 °F) above the pouring temperature is usually

Method D127. considered necessary for safe operations. An unusually low

flash point for a given compound indicates a mixture or

NOTE 2—This method should not be used for asphalts and other types

contamination with a volatile material. This test method is

with a prolonged melting range.

useful for purposes of specification, classification, and control

SOFTENING POINT

of product uniformity.

10. Procedure

7. Significance and Use

10.1 Determine the flash and fire points of all compounds in

7.1 The softening point is useful in selecting a filling or

accordance with Test Method D92.

treating compound that will not flow at the operating tempera-

ture of the device in which it is used. It is also an indication of 10.2 In the case of certain compounds containing chlorine,

the pouring temperature, which should not be so high as to the flash has the potential to be indefinite and no fire point

injuretheinsulationofadevice.Thistestmethodisused,when exists. Report this fact.

D176 − 07 (2012)

LOSS ON HEATING PENETRATION

15. Significance and Use

11. Significance and Use

15.1 Penetration is an indication of the softness or indent-

11.1 Loss on heating includes loss of moisture and volatile

ability of a compound. Penetration values are used as a basis

constituentslessanyweightgainduetooxidization.Itisuseful

for classification, specification, and control of product unifor-

for control of product uniformity and as an indication of pot or

mity.

tank life if the test is performed at the appropriate temperature.

This test method shall not be used to compare compounds of

16. Procedure

different basic chemical compositions.

16.1 Determine penetration in accordance withTest Method

12. Procedure

D5. This test method is applicable to all compounds except

very soft materials and petrolatums. Unless specified other-

12.1 Determine the loss on heating of asphaltic and certain

wise, the standard conditions of test are:

other types of compounds by Test Method D6.

Weight, g Time, s

NOTE 3—The reproducibility of this test method has the potential to be

poor due to insufficient control of the air circulation over the specimens

At 25 °C (77 °F) 100 5

and to weight gain from oxidation of some compounds. With certain

Other standard conditions are:

compounds it is desirable to conduct the test at a lower temperature than

the specified temperature of 163 °C (325 °F). Weight, g Time, s

Warning—When compounds of low flash point and high

At0°C(32°F) 200 60

At 46 °C (115 °F) 50 5

volatility are tested, the oven shall have low-temperature

heating elements and a safety door latch to relieve pressure in

16.2 For very soft materials, such as petrolatums, use Test

case of an explosion.

Method D937.

VISCOSITY

SPECIFIC GRAVITY

13. Significance and Use

17. Significance and Use

13.1 The Saybolt viscosity is nearly proportional to the

17.1 Specific gravity is useful for indicating product unifor-

kinematic viscosity of filling and treating compounds and

mity and for calculating the weight of a given volume of

hence, it is an indication of whether or not the material will

material.Insomeinstancesitisusefulinestimatingtheamount

flow readily under its own weight at a prescribed temperature.

of mineral fillers in a compound. If specific gravity is known at

It is also satisfactory for control of product uniformity and for

several temperatures, the coefficient of expansion is calculated.

specification purposes. If the specific gravity of a compound is determined before and

after degassing, it is possible to calculate the volume of

14. Procedure entrapped gasses.

14.1 For waxes, petrolatums, and other low-viscosity-type 17.2 Displacement tests are used to determine the specific

gravity of both untreated and degassed compounds. Conven-

compounds determine the viscosity as Saybolt Universal vis-

cosity by Test Method D88. The standard temperatures for tional methods are used for the solid state, and plummet

displacement for the liquid state. The values obtained have the

testing are: 21, 38, 54, or 99 °C (70, 100, 130, or 210 °F).

potential to be used to compute the approximate coefficient of

14.2 For asphaltic and other high-viscosity compounds,

cubical expansion by Test Method C (see Sections 34-36).

determine the Saybolt Furol viscosity. The standard tempera-

tures for testing Furol viscosity are: 25, 38, 50, 60, 82, and 99

WATER DISPLACEMENT METHODS

°C (77, 100, 122, 140, 180, 210 °F).

18. Procedure

14.3 For higher temperatures, special techniques and ther-

mometers are required. The standard temperatures are 121,

18.1 Determine the specific gravity by Test Method D70 or

149, 177, 204, and 232 °C (250, 300, 350, 400, 450 °F). In

Test Method D71.

these cases determine the viscosity by Test Method E102.

PLUMMET DISPLACEMENT METHOD

NOTE 4—For testing waxes and petrolatums, the standard temperature

for comparison purposes is 99 °C (210 °F), and Saybolt Universal

19. Scope

viscosity is used. For estimation of the properties of asphaltic and other

compounds of high viscosity, it is desirable to measure the viscosity at a

19.1 The specific gravity of the material at the desired

number of standard temperatures above the softening point. A curve is

temperature is calculated from the weight of the compound

plotted on log-log paper and the temperature at which the Saybolt Furol

displaced by a calibrated aluminum plummet.

viscosity is 470 s is determined.This viscosity corresponds approximately

toakinematicviscosityof1000centistokes,andisaviscosityatwhichthe

compound is conveniently poured from the container. With potting

20. Apparatus

compounds, it is also desirable to know the temperature at which the

20.1 Balance—An analytical balance equipped with pan

Saybolt Furol viscosity is 100 s, since this viscosity is low enough for

production potting operations. straddle.

D176 − 07 (2012)

20.2 Plummet—An aluminum plummet of suitable shape These test methods are used for determining either true or

weighing 5 to 10 g. effective coefficient of expansion but are not used as referee

test methods.

20.3 Beaker—A 400-mL heat-resistant glass beaker

wrapped with a suitable thermal insulation.

23. Significance and Use

23.1 Coefficient of expansion is useful in computing the

20.4 Thermometer—A thermometer of suitable range.

amount of void space that will remain in a device filled with

20.5 Wire—Two pieces of fine copper wire.

compound after the compound has cooled to the ambient

temperature. It also is one indic

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.