ASTM D2477-07(2020)

(Test Method)Standard Test Method for Dielectric Breakdown Voltage and Dielectric Strength of Insulating Gases at Commercial Power Frequencies

Standard Test Method for Dielectric Breakdown Voltage and Dielectric Strength of Insulating Gases at Commercial Power Frequencies

SIGNIFICANCE AND USE

4.1 The dielectric breakdown voltage and dielectric strength of an insulating gas in a uniform field depends primarily on the molecular structure of the gas. As different gases are mixed either by plan or by contamination, any change in dielectric breakdown voltage and dielectric strength will depend on both the nature and proportion of the individual gases. This test method uses plane and spherical electrodes which provide a nearly uniform field (see Appendix) in the area of electrical discharge. It is suitable for determining the dielectric breakdown voltage and dielectric strength of different gases and mixtures thereof for research and application evaluations and also as a field test. A more complete discussion of the significance of the dielectric strength test is given in the Appendix.

SCOPE

1.1 This test method covers the determination of the dielectric breakdown voltage and dielectric strength of insulating gases used in transformers, circuit breakers, cables, and similar apparatus as an insulating medium. The test method is applicable only to gases with boiling points below room temperature at atmospheric pressure.

1.2 This standard may involve hazardous materials, operations, and equipment. This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.3 Mercury has been designated by EPA and many state agencies as a hazardous material that can cause central nervous system, kidney and liver damage. Mercury, or its vapor, may be hazardous to health and corrosive to materials. Caution should be taken when handling mercury and mercury containing products. See the applicable product Material Safety Data Sheet (MSDS) for details and EPA's website — http://www.epa.gov/mercury/faq.htm for additional information. Users should be aware that selling mercury and/or mercury containing products into your state may be prohibited by state law.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: D2477 − 07 (Reapproved 2020)

Standard Test Method for

Dielectric Breakdown Voltage and Dielectric Strength of

Insulating Gases at Commercial Power Frequencies

This standard is issued under the fixed designation D2477; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 2. Referenced Documents

1.1 This test method covers the determination of the dielec- 2.1 ASTM Standards:

tric breakdown voltage and dielectric strength of insulating D2864 Terminology Relating to Electrical Insulating Liq-

gases used in transformers, circuit breakers, cables, and similar uids and Gases

apparatus as an insulating medium. The test method is appli-

2.2 IEEE Standard:

cableonlytogaseswithboilingpointsbelowroomtemperature

No. 4 Standard Techniques for High Voltage Testing

at atmospheric pressure.

2.3 ASTM Adjuncts:

Dielectric cell assembly and detail (2 drawings)

1.2 This standard may involve hazardous materials,

operations, and equipment. This standard does not purport to

3. Terminology

address all of the safety concerns, if any, associated with its

use. It is the responsibility of the user of this standard to 3.1 Definitions:

establish appropriate safety, health, and environmental prac-

3.1.1 For definitions of terms used in this test method, refer

tices and determine the applicability of regulatory limitations to Terminology D2864.

prior to use.

4. Significance and Use

1.3 Mercury has been designated by EPA and many state

agencies as a hazardous material that can cause central

4.1 The dielectric breakdown voltage and dielectric strength

nervous system, kidney and liver damage. Mercury, or its

of an insulating gas in a uniform field depends primarily on the

vapor, may be hazardous to health and corrosive to materials.

molecular structure of the gas. As different gases are mixed

Caution should be taken when handling mercury and mercury

either by plan or by contamination, any change in dielectric

containing products. See the applicable product Material

breakdown voltage and dielectric strength will depend on both

Safety Data Sheet (MSDS) for details and EPA’s website —

the nature and proportion of the individual gases. This test

http://www.epa.gov/mercury/faq.htm for additional informa-

method uses plane and spherical electrodes which provide a

tion. Users should be aware that selling mercury and/or

nearly uniform field (see Appendix) in the area of electrical

mercury containing products into your state may be prohibited

discharge. It is suitable for determining the dielectric break-

by state law.

down voltage and dielectric strength of different gases and

1.4 This international standard was developed in accor-

mixtures thereof for research and application evaluations and

dance with internationally recognized principles on standard-

also as a field test. A more complete discussion of the

ization established in the Decision on Principles for the

significance of the dielectric strength test is given in the

Development of International Standards, Guides and Recom-

Appendix.

mendations issued by the World Trade Organization Technical

Barriers to Trade (TBT) Committee.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

This test method is under the jurisdiction of ASTM Committee D27 on Standards volume information, refer to the standard’s Document Summary page on

Electrical Insulating Liquids and Gases and is the direct responsibility of Subcom- the ASTM website.

mittee D27.05 on Electrical Test. Available from The Institute of Electrical and Electronic Engineers, Inc.

Current edition approved Nov. 1, 2020. Published November 2020. Originally (IEEE), 445 Hoes Ln., P.O. Box 1331, Piscataway, NJ 08854-1331.

approved in 1966. Last previous edition approved in 2012 as D2477 – 07(2012). Detaileddrawingsofthisapparatusareavailableatanominalcostfrom:ASTM

DOI: 10.1520/D2477-07R20. International Headquarters. Order Adjunct No. ADJD2477-E-PDF.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D2477 − 07 (2020)

5. Apparatus 5.2.1 Vacuum Pump— The vacuum pump shall have suffi-

cient pumping capacity to be able to evacuate the test cell to a

5.1 Electrical Apparatus:

pressure below 0.133 kPa (1 torr).

5.1.1 Transformer— The desired test voltage may be most

5.2.2 Vacuum and Pressure Gage—Either a mercury

readily obtained by a step-up transformer energized from a

manometer, or one or more gages, capable of measuring

variable low-voltage commercial power frequency source. The

pressures below 0.133 kPa (1 torr) and also near atmospheric

transformer and controlling element shall be of such size and

pressure. The manometer, or vacuum and pressure gages, shall

designthat,withthetestspecimeninthecircuit,thecrestfactor

be calibrated in kPa or millimetres of mercury (torr).

(ratio of maximum to mean effective) of the 60-Hz test voltage

5.2.3 Connections— Vacuum-tight tubing and valves shall

does not differ by more than 65 % from that of a sinusoidal

be used while evacuating and purging the test cell and filling it

wave over the upper half of the range of test voltage. The crest

with the gas sample.

factor may be checked by means of an oscilloscope, a sphere

5.3 Electrodes and Test Cell:

gap, or a peak-reading voltmeter in conjunction with an rms

5.3.1 The sphere and plane electrodes shall be mounted

voltmeter. Where the waveform cannot be determined

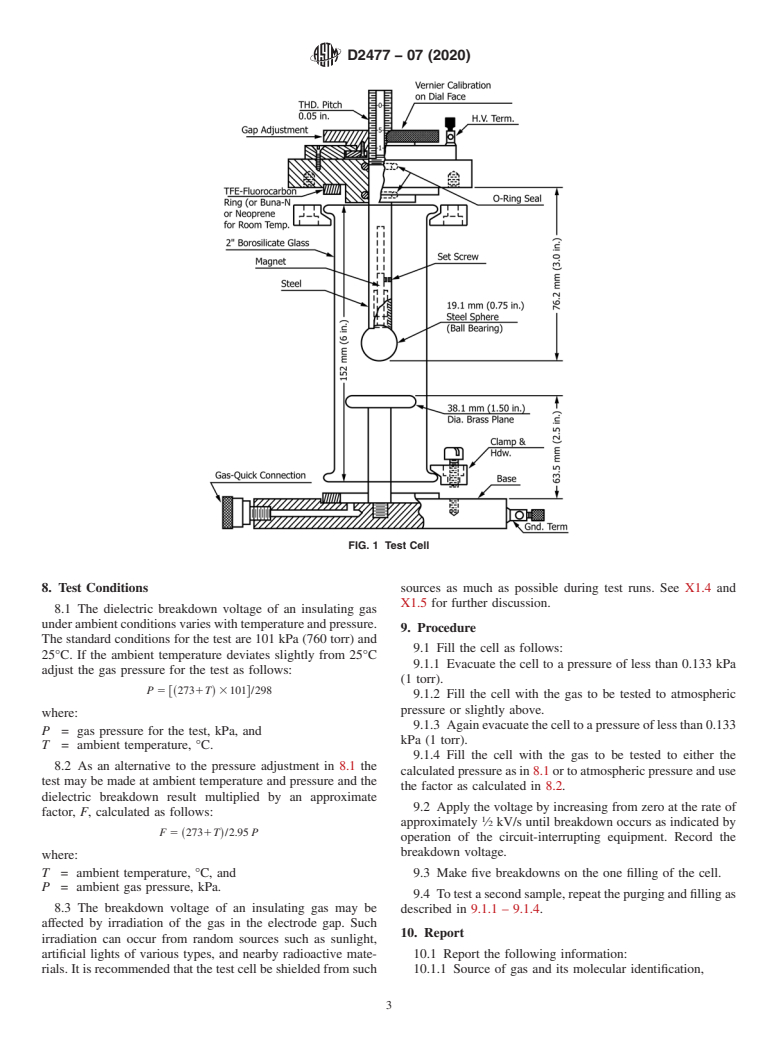

vertically as shown in Fig. 1. The sphere shall be a precision

conveniently, a transformer having a rating of not less than ⁄2

steel bearing ball 19.1 mm (0.75 in.) in diameter. The plane

kVAat the usual breakdown voltage shall be used. Transform-

electrode shall be of brass 38.1 mm (1.50 in.) in diameter. The

ers of larger kVA capacity may be used, but in no case should

gap setting shall be 2.54 6 0.025 mm (0.100 6 0.001 in.). The

the power frequency short circuit current in the specimen

tolerance of all dimensions is 62 %, unless otherwise stated.

circuit be outside the range of 1 to 10 mA/kV of applied

5.3.2 The cell shall consist of a borosilicate glass cylinder

voltage. This limitation of current may be accomplished by

clamped by flanges to end plates which seal the cell and

using a suitable external series resistor or by employing a

support the electrodes. The lower plane electrode shall be

transformer with sufficient inherent reactance.

fixed. The sphere electrode, held in place by a magnet, shall be

5.1.2 Circuit-Interrupting Equipment —Thetesttransformer

adjustable by means of a micrometer screw suitably mounted

primary circuit shall be protected by an automatic circuit-

through the top plate. The micrometer screw must be suitable

breaking device capable of opening (as nearly instantaneously

for setting the electrodes to within the specified tolerance. The

as possible) on the current produced by the breakdown of the

bottom plate shall have a valved port for evacuation and

test specimen; a circuit breaker that opens within 5 cycles may

admission of the sample. If considered more convenient, two

be used if the short-circuit current as described in 5.1.1 does

ports, one in the top for evacuation and one in the bottom for

not exceed 200 mA.Aprolonged flow of current at the time of

admission of the sample may be used. The dimensions are

breakdown causes contamination of the gases and damage of

shown in Fig. 1.

theelectrodes,therebyaffectingthesubsequenttestresults,and

increasing the electrode and test cell maintenance and time of

6. Sampling

testing.

6.1 Obtainthegassamplefromthegascylinderorgas-filled

5.1.3 Voltage-Control Equipment—The rate of voltage rise

1 equipment through a pressure-reducing regulator valve so that

shall be ⁄2 kV/s 6 20 %. Voltage control may be secured by a

the flow into the cell may be controlled. The sample and cell

motor-driven variable-ratio-autotransformer. Preference is

must be at room temperature before the gas is admitted to the

given to equipment having an approximately straight-line

cell.

voltage-time curve over the desired operating range. Motor

drive is preferred to manual drive because of the ease of

7. Preparation of Cell

maintaining a reasonably uniform rate-of-voltage rise with this

7.1 Clean the cell except for the electrodes by washing with

test method. The rate-of-voltage rise may be calculated from

soap or detergent, then rinse with distilled or demineralized

measurements of the time required to raise the voltage between

water and oven-dry. Clean the cell whenever necessary to

two prescribed values. When motor-driven equipment is used,

remove detectable decomposition products formed by the

calibrate the speed control rheostat in terms of rate-of-voltage

breakdown arc, or when testing different gases.

rise for the test transformer used.

5.1.4 Voltmeter—Measure the voltage by a method that

7.2 Clean the electrodes with crocus cloth and naphtha.

fulfills the requirements of IEEE Standard No. 4, giving crest

When the sphere electrode becomes pitted, it may be turned to

and a

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.