ASTM F682-82a(2008)

(Specification)Standard Specification for Wrought Carbon Steel Sleeve-Type Pipe Couplings

Standard Specification for Wrought Carbon Steel Sleeve-Type Pipe Couplings

ABSTRACT

This specification covers wrought carbon steel sleeve type pipe couplings suitable for joining carbon steel pipes. Couplings are furnished in two types as follows: Type I couplings are intended for use on all schedules of pipe in which the pipe wall thickness does not exceed the wall thickness of standard weight pipe. Type II couplings are intended for use on all schedules of pipe in which the pipe wall thickness does not exceed the wall thickness of extra strong pipe. The couplings shall be manufactured from material having a chemical composition conforming to the requirements specified. Couplings made from plate or tubular products need not to be heat treated. Hot-formed couplings finished at a temperature in excess of a certain value shall subsequently be annealed, normalized, or normalized and tempered. Cold-formed couplings upon which the final forming operation is completed at a temperature below a certain quantity shall be normalized or shall be stress-relieved. Carbon steel couplings made from forgings shall subsequently be annealed, normalized, or normalized and tempered. Mechanical properties of steel such as tensile strength, yield strength, yield point, and elongation shall be determined.

SCOPE

1.1 This specification covers wrought carbon steel sleeve-type pipe couplings suitable for joining carbon steel pipes.

1.2 Type I couplings are intended for use on all schedules of pipe in which the pipe wall thickness does not exceed the wall thickness of standard weight pipe. Type II couplings are intended for use on all schedules of pipe in which the pipe wall thickness does not exceed the wall thickness of extra strong pipe.

1.3 This specification does not cover cast steel couplings.

Note 1—The values stated in inch-pound units are to be regarded as the standard.

Note 2—See Appendix X1 for rationale used to develop this specification.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:F682 −82a(Reapproved 2008) An American National Standard

Standard Specification for

Wrought Carbon Steel Sleeve-Type Pipe Couplings

ThisstandardisissuedunderthefixeddesignationF682;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginal

adoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscript

epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope 2.2 Manufacturer’s Standardization Society of the Valve and

Fittings Industry Standard:

1.1 This specification covers wrought carbon steel sleeve-

MSS SP-25Standard Marking System for Valves, Fittings,

type pipe couplings suitable for joining carbon steel pipes. 4

Flanges and Unions

1.2 TypeIcouplingsareintendedforuseonallschedulesof

2.3 ASME Boiler and Pressure Vessel Code:

pipe in which the pipe wall thickness does not exceed the wall

Section VIII Unfired Pressure Vessels

thickness of standard weight pipe. Type II couplings are

Section IX Welding Qualifications

intendedforuseonallschedulesofpipeinwhichthepipewall

2.4 Federal Regulations:

thickness does not exceed the wall thickness of extra strong

Title 46,Code of Federal Regulations (CFR), Shipping,

pipe. 6

Parts 41 to 69

1.3 This specification does not cover cast steel couplings.

2.5 ANSI Standards:

B16.5Pipe Flanges and Flange Fittings

NOTE1—Thevaluesstatedininch-poundunitsaretoberegardedasthe

standard.

3. Classification

NOTE 2—See Appendix X1 for rationale used to develop this specifi-

cation.

3.1 Couplings are furnished in two types as follows:

3.1.1 Type I—Couplings (see 1.2).

2. Referenced Documents

3.1.2 Type II—Couplings (see 1.2).

2.1 ASTM Standards:

NOTE3—TypeIIcouplingsmaybeusedinplaceofTypeIcouplingsfor

A53/A53MSpecification for Pipe, Steel, Black and Hot-

all schedules of pipe in which the pipe wall thickness does not exceed the

Dipped, Zinc-Coated, Welded and Seamless wall thickness of standard weight piping through 18 in. or Schedule 40

piping through 16 in.

A106/A106MSpecification for Seamless Carbon Steel Pipe

for High-Temperature Service

4. Ordering Information

A234/A234MSpecification for Piping Fittings of Wrought

Carbon Steel and Alloy Steel for Moderate and High

4.1 Ordersformaterialunderthisspecificationshallinclude

Temperature Service

the following information:

A370Test Methods and Definitions for Mechanical Testing

4.1.1 Quantity (number of couplings of each size and type),

of Steel Products

4.1.2 Name of material (sleeve-type pipe couplings),

E59Practice for Sampling Steel and Iron for Determination

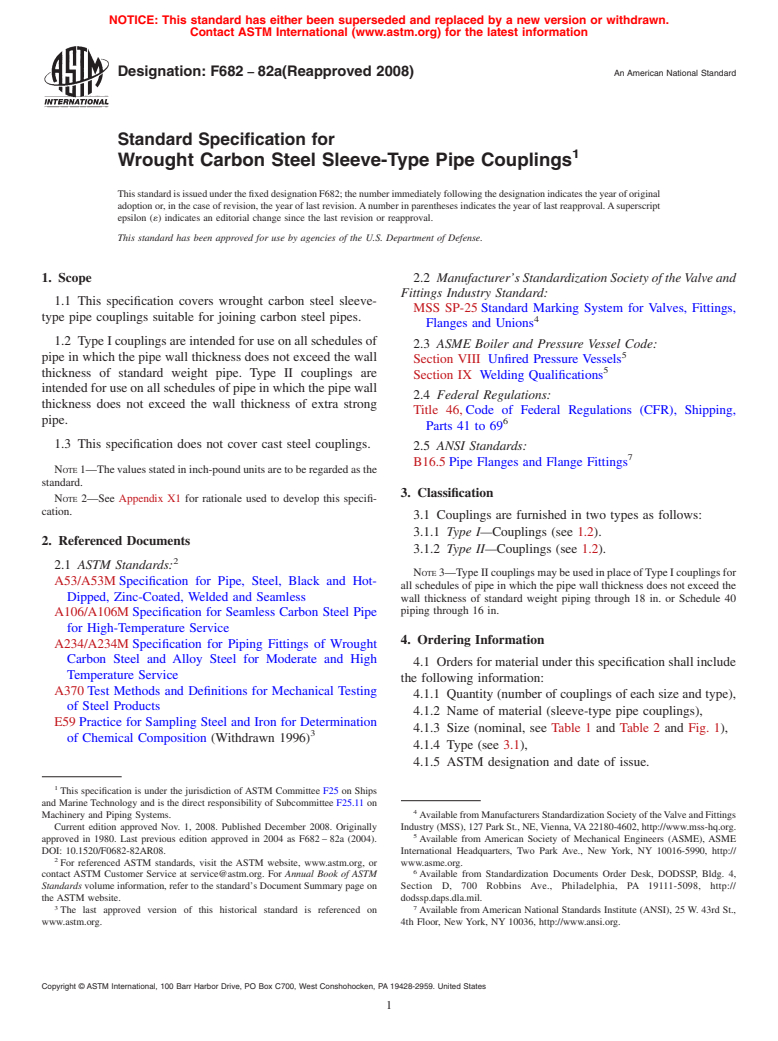

4.1.3 Size (nominal, see Table 1 and Table 2 and Fig. 1),

of Chemical Composition (Withdrawn 1996)

4.1.4 Type (see 3.1),

4.1.5 ASTM designation and date of issue.

This specification is under the jurisdiction ofASTM Committee F25 on Ships

and Marine Technology and is the direct responsibility of Subcommittee F25.11 on

Machinery and Piping Systems. AvailablefromManufacturersStandardizationSocietyoftheValveandFittings

Current edition approved Nov. 1, 2008. Published December 2008. Originally Industry(MSS),127ParkSt.,NE,Vienna,VA22180-4602,http://www.mss-hq.org.

approved in 1980. Last previous edition approved in 2004 as F682–82a (2004). Available from American Society of Mechanical Engineers (ASME), ASME

DOI: 10.1520/F0682-82AR08. International Headquarters, Two Park Ave., New York, NY 10016-5990, http://

For referenced ASTM standards, visit the ASTM website, www.astm.org, or www.asme.org.

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Available from Standardization Documents Order Desk, DODSSP, Bldg. 4,

Standards volume information, refer to the standard’s Document Summary page on Section D, 700 Robbins Ave., Philadelphia, PA 19111-5098, http://

the ASTM website. dodssp.daps.dla.mil.

3 7

The last approved version of this historical standard is referenced on Available fromAmerican National Standards Institute (ANSI), 25 W. 43rd St.,

www.astm.org. 4th Floor, New York, NY 10036, http://www.ansi.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

F682−82a (2008)

TABLE 1 Dimensions for Type I Couplings (See Fig. 1)

Dimension A, Inside Dimension B, Outside Dimension C, Thick- Dimension D,

Nominal Size, in.

A B C

Diameter, in. (mm) Diameter, in. (mm) ness, min, in. (mm) Length, in. (mm)

⁄4 0.589 (15.0) 0.875 (22.2) 0.143 (3.6) 1 (25)

3 1

⁄8 0.724 (18.4) 0.992 (25.2) 0.134 (3.4) 1 ⁄4 (32)

1 1

⁄2 0.889 (22.6) 1.201 (30.5) 0.156 (4.0) 1 ⁄4 (32)

3 1

⁄4 1.099 (27.9) 1.401 (35.6) 0.151 (3.8) 1 ⁄2 (38)

1 1.364 (34.6) 1.710 (43.4) 0.173 (4.4) 1 ⁄2 (38)

1 1

1 ⁄4 1.709 (43.4) 2.057 (52.2) 0.174 (4.4) 1 ⁄2 (38)

1 1

1 ⁄2 1.949 (49.5) 2.306 (58.6) 0.179 (4.5) 1 ⁄2 (38)

2 2.424 (61.6) 2.807 (71.3) 0.192 (4.9) 1 ⁄2 (38)

1 1

2 ⁄2 2.924 (74.3) 3.444 (87.5) 0.260 (6.6) 1 ⁄2 (38)

3 3.545 (90.0) 4.105 (104.3) 0.280 (7.1) 1 ⁄2 (38)

3 ⁄2 4.070 (103.4) 4.633 (117.7) 0.282 (7.2) 2 (51)

4 4.570 (116.1) 5.164 (131.2) 0.297 (7.5) 2 (51)

5 5.660 (143.8) 6.286 (159.7) 0.313 (8.0) 2 (51)

6 6.720 (170.7) 7.409 (188.2) 0.345 (8.8) 2 (51)

8 8.720 (221.5) 9.527 (242.0) 0.404 (10.3) 2 ⁄2 (64)

10 10.880 (276.4) 11.875 (301.6) 0.498 (12.6) 2 ⁄2 (64)

12 12.880 (327.2) 13.800 (350.5) 0.460 (11.7) 2 ⁄2 (64)

14 14.140 (359.2) 15.050 (382.3) 0.455 (11.6) 2 ⁄2 (64)

16 16.160 (410.5) 17.050 (433.1) 0.445 (11.3) 2 ⁄2 (64)

18 18.180 (461.8) 19.050 (483.9) 0.435 (11.0) 2 ⁄2 (64)

A

Tolerances shall be (1) Sizes through 3 in. incl: +0.000, −0.010 in. (+0.000, −0.254 mm); (2) Sizes 3 ⁄2 through 10 in. incl: +0.030, −0.000 in. (+0.762, −0.000 mm); and

(3) Sizes above 10 in.: +0.060, −0.000 in. (+1.524, −0.000 mm).

B

Tolerances shall be (1) Sizes through 10 in. incl: +0.125, −0.000 in. (+3.175, −0.000 mm) and (2) Sizes above 10 in.: +1.000, −0.000 in. (+25.4, −0.000 mm).

C

Tolerances for all sizes shall be +0.250, −0.000 in. (+6.4, −0.000 mm).

TABLE 2 Dimensions for Type II Couplings (See Fig. 1)

Dimension A, Inside Dimension B, Outside Dimension C, Thick- Dimension D,

Nominal Size, in.

A B C

Diameter, in. (mm) Diameter, in. (mm) ness, min, in. (mm) Length, in. (mm)

⁄4 0.589 (15.0) 1.055 (26.8) 0.233 (5.9) 1 (25)

3 1

⁄8 0.724 (18.4) 1.156 (29.4) 0.216 (5.5) 1 ⁄4 (32)

1 1

⁄2 0.889 (22.6) 1.369 (34.8) 0.240 (6.1) 1 ⁄4 (32)

3 1

⁄4 1.099 (27.9) 1.557 (39.5) 0.229 (5.8) 1 ⁄2 (38)

1 1.364 (34.6) 1.876 (47.7)† 0.256 (6.5)† 1 ⁄2 (38)

1 1

1 ⁄4 1.709 (43.4) 2.221 (56.4)† 0.256 (6.5)† 1 ⁄2 (38)

1 1

1 ⁄2 1.949 (49.5) 2.469 (62.7)† 0.260 (6.6)† 1 ⁄2 (38)

2 2.424 61.6) 2.986 (75.8)† 0.281 (7.1)† 1 ⁄2 (38)

1 1

2 ⁄2 2.924 (74.3) 3.648 (92.7)† 0.362 (9.2)† 1 ⁄2 (38)

3 3.545 (90.0) 4.340 (110.2)† 0.398 (10.1)† 1 ⁄2 (38)

3 ⁄2 4.070 (103.4) 4.891 (124.2)† 0.411 (10.4)† 2 (51)

4 4.570 (116.1) 5.444 (138.3) 0.437 (11.1) 2 (51)

5 5.660 (143.8) 6.613 (168.0) 0.477 (12.1) 2 (51)

6 6.720 (170.7) 7.875 (200.0) 0.578 (14.7) 2 (51)

8 8.720 (221.5) 10.125 (257.2) 0.703 (17.8) 2 ⁄2 (64)

10 10.880 (276.4) 12.150 (308.6) 0.635 (16.1) 2 ⁄2 (64)

12 12.880 (327.2) 14.150 (359.4) 0.635 (16.1) 2 ⁄2 (64)

14 14.140 (359.2) 15.400 (391.2) 0.630 (16.0) 2 ⁄2 (64)

16 16.160 (410.5) 17.400 (442.0) 0.620 (15.7) 2 ⁄2 (64)

18 18.180 (461.8) 19.400 (492.8) 0.610 (15.5) 2 ⁄2 (64)

A

Tolerances shall be (1) Sizes through 3 in. incl: +0.000, −0.010 in. (+0.000, −0.254 mm); (2) Sizes 3 ⁄2 through 10 in. incl: +0.030, −0.000 in. (+0.762, −0.000 mm); and

(3) Sizes above 10 in.: +0.060, −0.000 in. (+1.524, −0.000 mm).

B

Tolerances shall be (1) Sizes through 10 in. incl: +0.125, −0.000 in. (+3.175, −0.000 mm) and (2) Sizes above 10 in.: +1.000, −0.000 in. (+25.4, −0.000 mm).

C

Tolerances for all sizes shall be +0.250, −0.000 in. (+6.4, −0.000 mm).

† Editorially corrected.

5. Materials and Manufacture such that the finished couplings conform to all of the specified

requirements (see Appendix X2).

5.1 Materials—The couplings shall be manufactured from

material having a chemical composition conforming to the

5.3 Couplings fabricated by welding shall be (a) made by

requirements of 7.1 and with the mechanical properties of

welders, welding operators, and welding procedures qualified

Section 9.

under the provisions of ASME Boiler and Pressure Vessel

5.2 Manufacture—The initial form of the raw material shall Code, Section IX; (b) heat treated in accordance with Section

6 of this specification; and (c) nondestructively tested as

be at the discretion of the manufacturer except couplings shall

not be machined from unformed plate. The material shall be follows:

F682−82a (2008)

6.1.4 Cold-formed couplings upon which the final forming

operationiscompletedatatemperaturebelow1150°F(621°C)

shall be normalized or shall be stress-relieved at 1100 to

1250°F (593 to 677°C) for 1 h/in. of thickness.

6.1.5 Couplings produced by fusion welding shall be

postweld heat treated at 1100 to 1250°F (593 to 677°C), when

the nominal wall thickness at the welded joint is ⁄4 in. or

greater.

6.2 Carbon Steel Couplings Made from Forgings—

Couplingsmadefromforgingsshallsubsequentlybeannealed,

normalized, or normalized and tempered.

6.3 Heat Treatment Procedures—Couplingsafterformingat

anelevatedtemperatureshallbecooledtoatemperaturebelow

the critical range under suitable conditions to prevent injuries

by too rapid cooling, but in no case more rapidly than the

cooling rate in still air. Couplings that are to be heat treated

shall be treated as follows:

6.3.1 Full Annealing—Couplings shall be uniformly re-

FIG. 1 Sleeve-Type Pipe Coupling

heated to a temperature above the transformation range and,

afterbeingheldforasufficienttimeatthistemperature,cooled

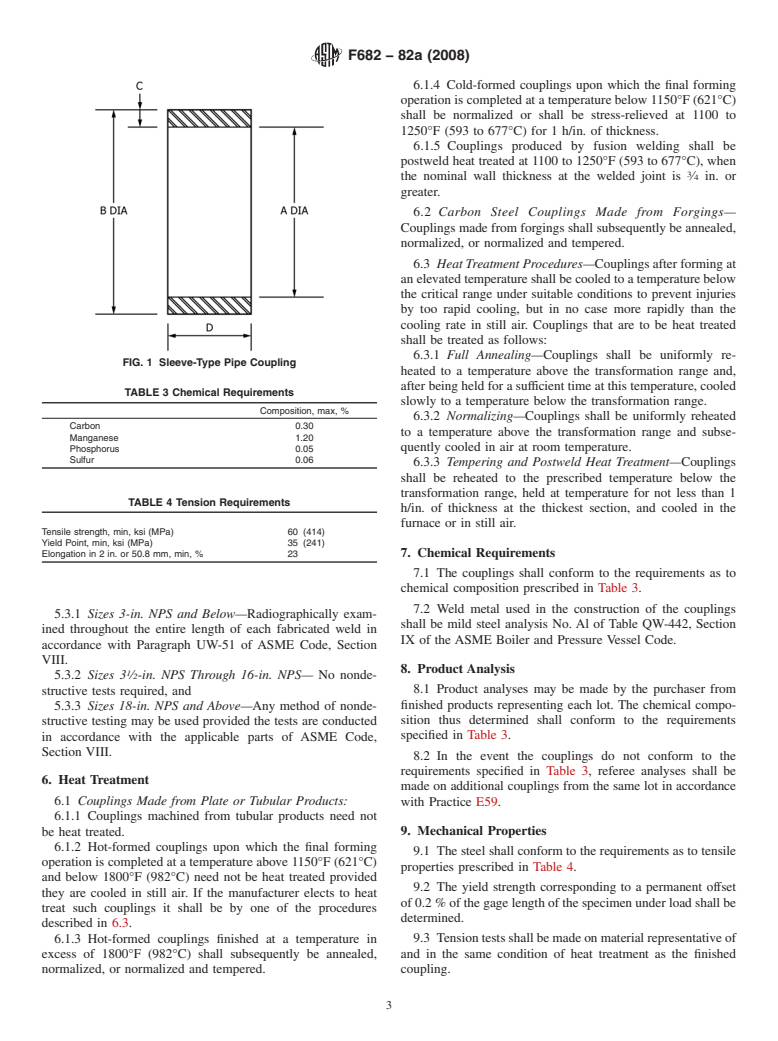

TABLE 3 Chemical Requirements

slowly to a temperature below the transformation range.

Composition, max, %

6.3.2 Normalizing—Couplings shall be uniformly reheated

Carbon 0.30

to a temperature above the transformation range and subse-

Manganese 1.20

quently cooled in air at room temperature.

P

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.