ASTM D5093-02(2008)

(Test Method)Standard Test Method for Field Measurement of Infiltration Rate Using Double-Ring Infiltrometer with Sealed-Inner Ring

Standard Test Method for Field Measurement of Infiltration Rate Using Double-Ring Infiltrometer with Sealed-Inner Ring

SIGNIFICANCE AND USE

This test method provides a means to measure low infiltration rates associated with fine-grained, clayey soils, and are in the range of 1 × 10−7 m/s to 1 × 10−9 m/s.

This test method is particularly useful for measuring liquid flow through soil moisture barriers such as compacted clay liner or covers used at waste disposal facilities, for canal and reservoir liners, for seepage blankets, and for amended soil liners such as those used for retention ponds or storage tanks.

The purpose of the sealed inner ring is to: (1) provide a means to measure the actual amount of flow rather than a drop in water elevation which is the flow measurement procedure used in Test Method D 3385 and (2) to eliminate evaporation losses.

The purpose of the outer ring is to promote one-dimensional, vertical flow beneath the inner ring. The use of large diameter rings and large depths of embedments helps to ensure that flow is essentially one-dimensional.

This test method provides a means to measure infiltration rate over a relatively large area of soil. Tests on large volumes of soil can be more representative than tests on small volumes of soil.

The data obtained from this test method are most useful when the soil layer being tested has a uniform distribution of pore space, and when the density and degree of saturation and the hydraulic conductivity of the material underlying the soil layer are known.

Changes in water temperature can introduce significant error in the volume change measurements. Temperature changes will cause water to flow in or out of the inner ring due to expansion or contraction of the inner ring and the water contained within the inner ring.

The problem of temperature changes can be minimized by insulating the rings, by allowing enough flow to occur so that the amount of flow resulting from a temperature change is not significant compared to that due to infiltration, or by connecting and disconnecting the bag from the inner ring when the water in the inner...

SCOPE

1.1 This test method describes a procedure for measuring the infiltration rate of water through in-place soils using a double-ring infiltrometer with a sealed inner ring.

1.2 This test method is useful for soils with infiltration rates in the range of 1 × 10−7 m/s to 1 × 10−10 m/s. When infiltration rates ≥1 × 10−7 m/s are to be measured Test Method D 3385 shall be used.

1.3 All observed and calculated values shall conform to the guide for significant digits and rounding established in Practice D 6026.

1.3.1 The method used to specify how data are collected, calculated, or recorded in this standard is not directly related to the accuracy to which the data can be applied in design or other uses, or both. How one applies the results obtained using this standard is beyond its scope.

1.4 This test method provides a direct measurement of infiltration rate, not hydraulic conductivity. Although the units of infiltration rate and hydraulic conductivity are similar, there is a distinct difference between these two quantities. They cannot be directly related unless the hydraulic boundary conditions, such as hydraulic gradient and the extent of lateral flow of water are known or can be reliably estimated.

1.5 This test method can be used for natural soil deposits, recompacted soil layers, and amended soils such as soil bentonite and soil lime mixtures.

1.6 The values stated in SI units are to be regarded as standard. The values in parentheses are for information only.

1.7 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D5093 −02(Reapproved 2008)

Standard Test Method for

Field Measurement of Infiltration Rate Using Double-Ring

Infiltrometer with Sealed-Inner Ring

This standard is issued under the fixed designation D5093; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 2. Referenced Documents

2.1 ASTM Standards:

1.1 This test method describes a procedure for measuring

the infiltration rate of water through in-place soils using a D653Terminology Relating to Soil, Rock, and Contained

Fluids

double-ring infiltrometer with a sealed inner ring.

D3385Test Method for Infiltration Rate of Soils in Field

1.2 Thistestmethodisusefulforsoilswithinfiltrationrates

Using Double-Ring Infiltrometer

−7 −10

intherangeof1×10 m/sto1×10 m/s.Wheninfiltration

−7 D3740Practice for Minimum Requirements for Agencies

rates ≥1×10 m/s are to be measured Test Method D3385

Engaged in Testing and/or Inspection of Soil and Rock as

shall be used.

Used in Engineering Design and Construction

1.3 All observed and calculated values shall conform to the

D6026Practice for Using Significant Digits in Geotechnical

guideforsignificantdigitsandroundingestablishedinPractice

Data

D6026.

3. Terminology

1.3.1 The method used to specify how data are collected,

calculated,orrecordedinthisstandardisnotdirectlyrelatedto

3.1 Definitions:

theaccuracytowhichthedatacanbeappliedindesignorother

3.1.1 infiltration—downward entry of liquid into a porous

uses, or both. How one applies the results obtained using this

body.

standard is beyond its scope.

3.1.2 infiltration rate, I—quantity of liquid entering a po-

3 2

1.4 This test method provides a direct measurement of

rous material (m ) per unit area (m ) per unit time (s),

infiltration rate, not hydraulic conductivity.Although the units

expressed in units of m/s.

of infiltration rate and hydraulic conductivity are similar, there

3.1.3 infiltrometer—a device used to pond liquid on a

is a distinct difference between these two quantities. They

porous body and to allow for the measurement of the rate at

cannot be directly related unless the hydraulic boundary

which liquid enters the porous body.

conditions, such as hydraulic gradient and the extent of lateral

3.1.4 Fordefinitionsofothertermsusedinthistestmethod,

flow of water are known or can be reliably estimated.

see Terminology D653.

1.5 This test method can be used for natural soil deposits,

recompacted soil layers, and amended soils such as soil

4. Summary of Test Method

bentonite and soil lime mixtures.

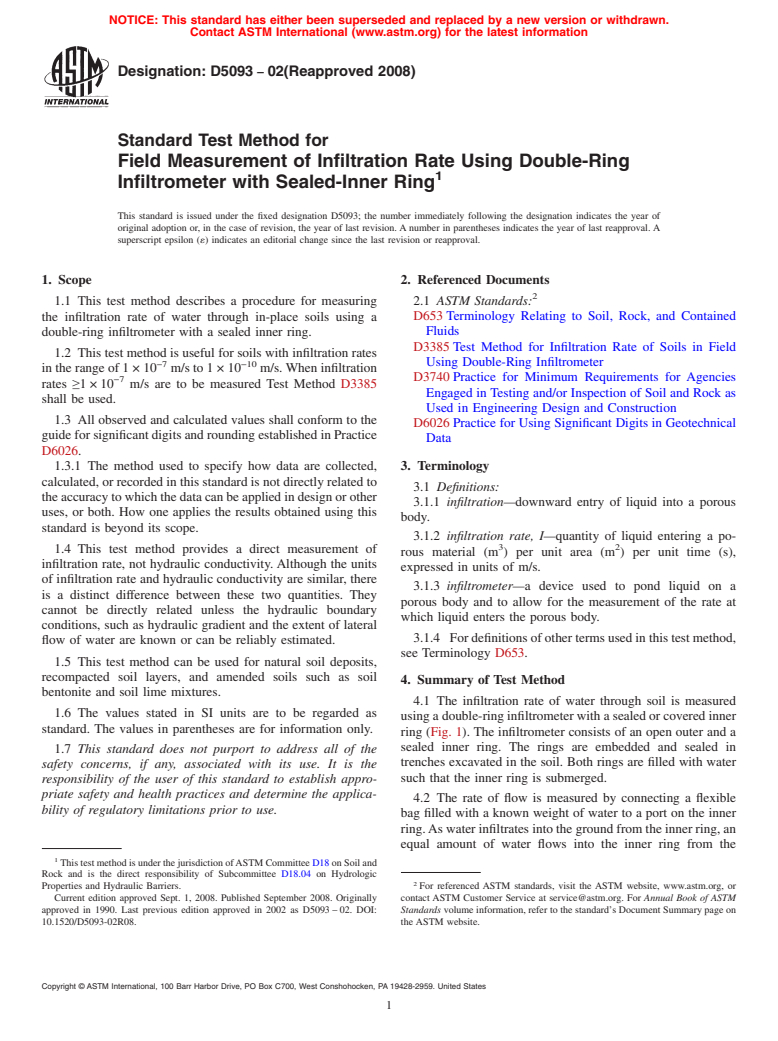

4.1 The infiltration rate of water through soil is measured

1.6 The values stated in SI units are to be regarded as

usingadouble-ringinfiltrometerwithasealedorcoveredinner

standard. The values in parentheses are for information only.

ring (Fig. 1). The infiltrometer consists of an open outer and a

sealed inner ring. The rings are embedded and sealed in

1.7 This standard does not purport to address all of the

trenches excavated in the soil. Both rings are filled with water

safety concerns, if any, associated with its use. It is the

such that the inner ring is submerged.

responsibility of the user of this standard to establish appro-

priate safety and health practices and determine the applica-

4.2 The rate of flow is measured by connecting a flexible

bility of regulatory limitations prior to use.

bag filled with a known weight of water to a port on the inner

ring.Aswaterinfiltratesintothegroundfromtheinnerring,an

equal amount of water flows into the inner ring from the

ThistestmethodisunderthejurisdictionofASTMCommitteeD18onSoiland

Rock and is the direct responsibility of Subcommittee D18.04 on Hydrologic

Properties and Hydraulic Barriers. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved Sept. 1, 2008. Published September 2008. Originally contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

approved in 1990. Last previous edition approved in 2002 as D5093–02. DOI: Standards volume information, refer to the standard’s Document Summary page on

10.1520/D5093-02R08. the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D5093−02 (2008)

5.8 The problem of temperature changes can be minimized

by insulating the rings, by allowing enough flow to occur so

that the amount of flow resulting from a temperature change is

not significant compared to that due to infiltration, or by

connectinganddisconnectingthebagfromtheinnerringwhen

the water in the inner ring is at the same temperature.

5.9 If the soil being tested will later be subjected to

increased overburden stress, then the infiltration rate can be

expected to decrease as the overburden stress increases. Labo-

ratory hydraulic conductivity tests are recommended for stud-

iesoftheinfluenceoflevelofstressonthehydraulicproperties

FIG. 1 Schematic Of A Double-Ring Infiltrometer With A Sealed

Inner Ring

of the soil.

NOTE1—Thequalityoftheresultproducedbythisstandarddependson

the competence of the personnel performing it and the suitability of the

equipment and facilities being used. Agencies that meet the criteria of

flexible bag.After a known interval of time, the flexible bag is

Practice D3740 are generally considered capable of competent and

removedandweighed.Theweightloss,convertedtoavolume, objective testing, sampling, inspection, etc. Users of this standard are

cautioned that compliance with Practice D3740 does not in itself ensure

is equal to the amount of water that has infiltrated into the

reliable results. Reliable results depend on many factors; Practice D3740

ground. An infiltration rate is then determined from this

provides a means of evaluating some of those factors

volume of water, the area of the inner ring, and the interval of

time. This process is repeated and a plot of infiltration rate

6. Apparatus

versus time is constructed. The test is continued until the

6.1 Infiltrometer Rings—The rings shall be constructed of a

infiltration rate becomes steady or until it becomes equal to or

stiff, corrosion-resistant material such as metal, plastic, or

less than a specified value.

fiberglass. The shape of the rings can be circular or square.

However,squareringsarerecommendedbecauseitiseasierto

5. Significance and Use

excavate straight trenches in the soil. The rings can be of any

5.1 This test method provides a means to measure low

size provided: (1) the minimum width or diameter of the inner

infiltration rates associated with fine-grained, clayey soils, and

ring is 610 mm (24 in.); and (2) a minimum distance of 610

−7 −9

are in the range of 1×10 m/s to 1×10 m/s.

mm is maintained between the inner and outer ring. The

5.2 This test method is particularly useful for measuring following is a description of a set of rings that can be

liquid flow through soil moisture barriers such as compacted constructed from commonly available materials, incorporates

clay liner or covers used at waste disposal facilities, for canal the requirements described above, and has worked well in the

andreservoirliners,forseepageblankets,andforamendedsoil field.

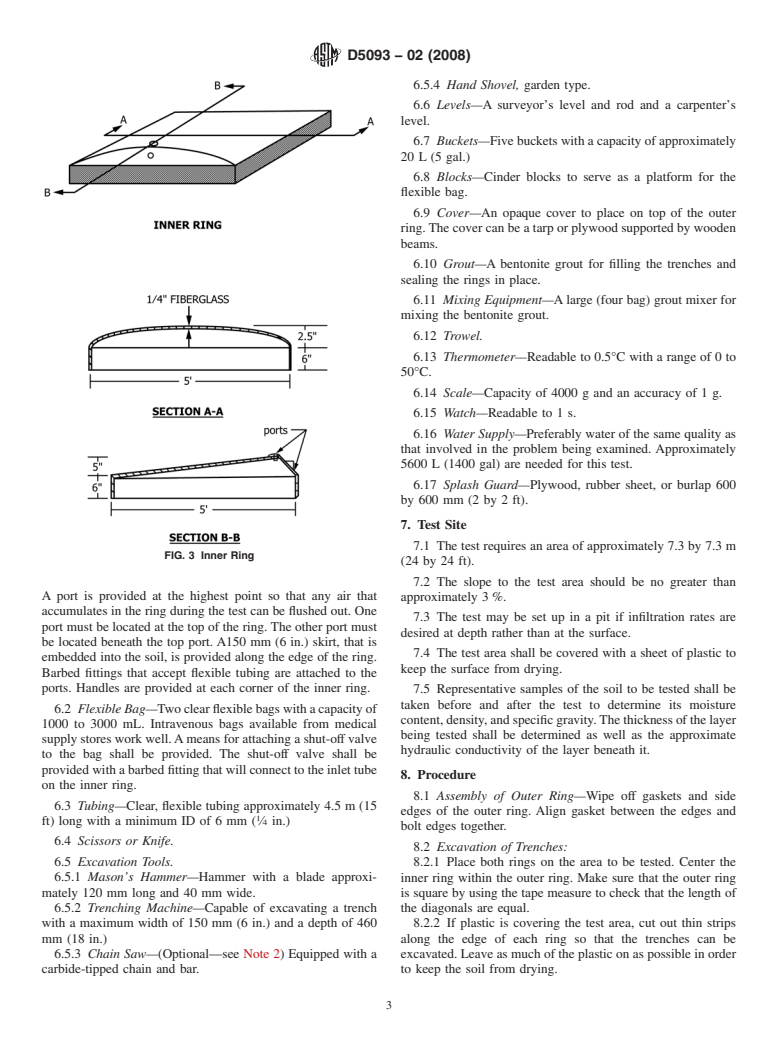

liners such as those used for retention ponds or storage tanks. 6.1.1 Outer Ring—Asquare ring (Fig. 2) comprised of four

sheets of aluminum approximately 3.6 m by 910 mm by 2 mm

5.3 The purpose of the sealed inner ring is to: (1) provide a

(12 ft by 36 in. by 0.080 in.) The top edge of the aluminum

means to measure the actual amount of flow rather than a drop

sheetisbent90°inordertoproviderigidity.Aholeisprovided

in water elevation which is the flow measurement procedure

in the center of the top edge. One edge of each sheet is bent

used in Test Method D3385 and ( 2) to eliminate evaporation

90°. Holes are drilled along each side edge so that the sheets

losses.

canbeboltedatthecorners.Aflatrubbergasketprovidesaseal

5.4 The purpose of the outer ring is to promote one-

at each corner. A wire cable approximately 15 m long with a

dimensional, vertical flow beneath the inner ring. The use of

clamp may be needed to tie the top edges together.

large diameter rings and large depths of embedments helps to

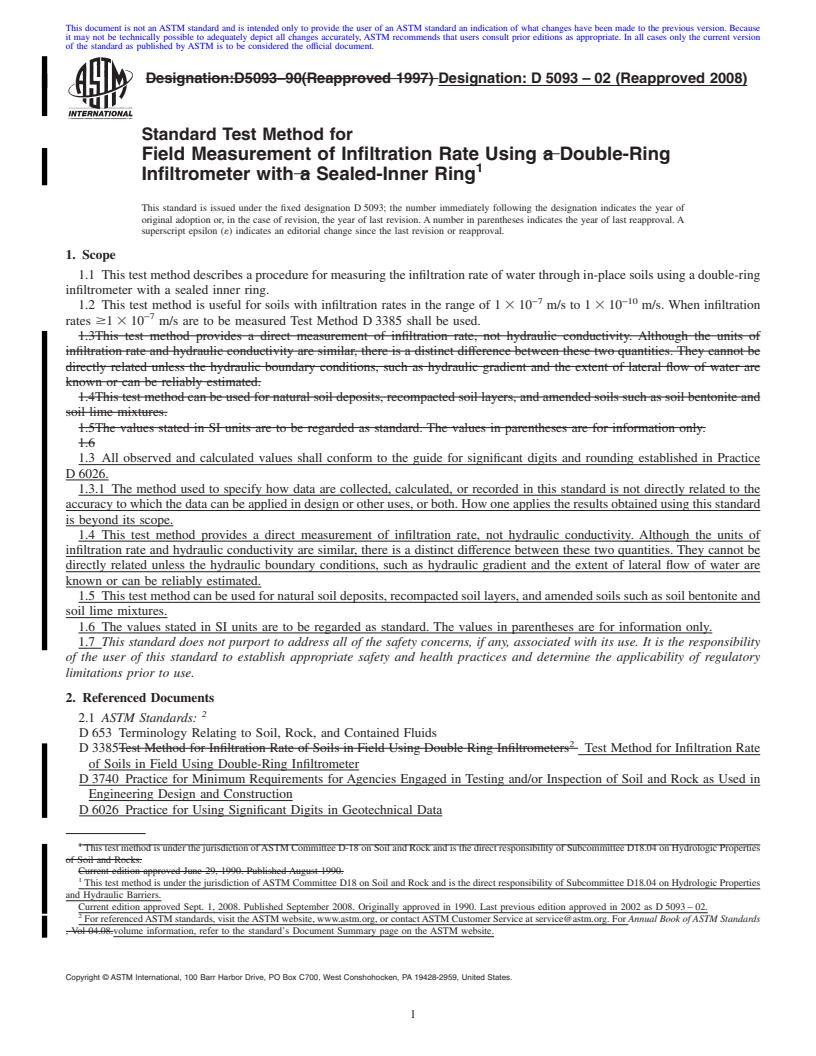

6.1.2 Inner Ring—Asquare ring (Fig. 3), 1.52 m (5 ft) on a

ensure that flow is essentially one-dimensional.

side, made of fiberglass provided with two ports. The top is

shaped in such a way as to vent air from the ring as it is filled.

5.5 This test method provides a means to measure infiltra-

tion rate over a relatively large area of soil. Tests on large

volumes of soil can be more representative than tests on small

volumes of soil.

5.6 The data obtained from this test method are most useful

when the soil layer being tested has a uniform distribution of

pore space, and when the density and degree of saturation and

the hydraulic conductivity of the material underlying the soil

layer are known.

5.7 Changes in water temperature can introduce significant

error in the volume change measurements. Temperature

changeswillcausewatertoflowinoroutoftheinnerringdue

to expansion or contraction of the inner ring and the water

contained within the inner ring. FIG. 2 Panel For Outer Ring

D5093−02 (2008)

6.5.4 Hand Shovel, garden type.

6.6 Levels—A surveyor’s level and rod and a carpenter’s

level.

6.7 Buckets—Fivebucketswithacapacityofapproximately

20 L (5 gal.)

6.8 Blocks—Cinder blocks to serve as a platform for the

flexible bag.

6.9 Cover—An opaque cover to place on top of the outer

ring.Thecovercanbeatarporplywoodsupportedbywooden

beams.

6.10 Grout—A bentonite grout for filling the trenches and

sealing the rings in place.

6.11 Mixing Equipment—Alarge (four bag) grout mixer for

mixing the bentonite grout.

6.12 Trowel.

6.13 Thermometer—Readable to 0.5°C with a range of 0 to

50°C.

6.14 Scale—Capacity of 4000 g and an accuracy of 1 g.

6.15 Watch—Readable to 1 s.

6.16 Water Supply—Preferably water of the same quality as

that involved in the problem being examined. Approximately

5600 L (1400 gal) are needed for this test.

6.17 Splash Guard—Plywood, rubber sheet, or burlap 600

by 600 mm (2 by 2 ft).

7. Test Site

7.1 The test requires an area of approximately 7.3 by 7.3 m

FIG. 3 Inner Ring

(24 by 24 ft).

7.2 The slope to the test area should be no greater than

A port is provided at the highest point so that any air that

approximately 3%.

accumulates in the ring during the test can be flushed out. One

7.3 The test may be set up in a pit if infiltration rates are

port must be located at the top of the ring.The other port must

desired at depth rather than at the surface.

be located beneath the top port. A150 mm (6 in.) skirt, that is

7.4 The test area shall be covered with a sheet of plastic to

embedded into the soil, is provided along the edge of the ring.

keep the surface from drying.

Barbed fittings that accept flexible tubing are attached to the

ports. Handles are provided at each corner of the inner ring.

7.5 Representative samples of the soil to be tested shall be

taken before and after the test to determine its moisture

6.2 FlexibleBag—Twoclearflexiblebagswithacapacityof

content,density,andspecificgravity.Thethicknessofthelayer

1000 to 3000 mL. Intravenous bags available from medical

being tested shall be determined as well as the approximate

supplystoresworkwell.Ameansforattachingashut-offvalve

hydraulic conductivity of the layer beneath it.

to the bag shall be provided. The shut-off valve shall be

providedwithabarbedfittingthatwillconnecttotheinlettube

8. Procedure

on the inner ring.

8.1 Assembly of Outer Ring—Wipe off gaskets and side

6.3 Tubing—Clear, flexible tubing approximately 4.5 m (15

edges of the outer ring. Align gasket between the edges and

ft) long with a minimum ID of 6 mm ( ⁄4 in.)

bolt edges together.

6.4 Scissors or Knife.

8.2 Excavation of Trenches:

6.5 Excavation Tools. 8.2.1 Place both rings on the area to be tested. Center the

6.5.1 Mason’s Hammer—Hammer with a blade approxi- inner ring within the outer ring. Make sure that the outer ring

mately 120 mm long and 40 mm wide. is square by using the tape measure to check that the length of

6.5.2 Trenching Machine—Capable of excavating a trench the diagonals are equal.

with a maximum width of 150 mm (6 in.) and a depth of 460 8.2.2 If plastic is covering the test area, cut out thin strips

mm (18 in.) along the edge of each ring so that the trenches can be

6.5.3 Chain Saw—(Optional—see Note 2) Equipped with a excavated.Leaveasmuchoftheplasticonaspossibleinorder

carbide-tipped chain and bar. to keep the soil from drying.

D5093−02 (2008)

8.2.3 Usethebottomedgeofeachringtoscribealineonthe 8.3.9 Use the carpenter’s level to make sure that the ring is

ground to use as a guide for excavating the trenches. level.

8.3.10 Useatroweltopushthegroutagainstboththeinside

8.2.4 Note the orientation of the rings and set them aside.

and the outside of the ring to ensure a good seal.

8.2.5 Use the surveyor’s level and check the ground eleva-

8.3.11 Cover the grout with plastic to prevent desiccation.

tionwherethecornersofeachringwillbe.Notethehighspots

8.3.12 Place several cinder blocks between the inner and

and excavate deeper in these areas so that the rings will be

outer rings in the vicinity of the ports on the inner ring. These

level.

blocks will be used as a platform to stand on when connecting

8.2.6 Use the trenching machine and excavate a trench for

the fittings to the inner ring and also to support the flexible

the outer ring. The trench should be about 146 mm (18 in.)

bags. The blocks should be no higher than 100 mm (4 in.)

deep. Excavate deeper at high spots.

8.3.13 Pilesoilalongtheoutsideoftheouterringtoaheight

8.2.7 Use a small hand shovel to remove any loose material

of at least 30 cm (12 in.) This soil places an overburden

in the trenches.

pressureonthegroutthatwillpreventitfrombeingpushedout

8.2.8 Place the outer ring in the trench and use the carpen-

of the trench when the rings are filled with water.

ter’s level to check that the top of the ring is reasonably level

(630 mm). Also check that the outer ring is square. Remove

8.4 Filling the Rings:

the ring and excavate any areas keeping the ring from being

8.4.1 Fill two buckets with water and place one on each

level and square.

back corner of the inner ring. The buckets are placed on the

8.2.9 Set the outer ring aside and cover the trenches to inner ring to counteract the uplift force that acts on the ring as

prevent the soil from drying. it is being filled. Make sure that the buckets are placed on the

8.2.10 Usethemason’shammerandexc

...

This document is not anASTM standard and is intended only to provide the user of anASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:D5093–90(Reapproved 1997) Designation: D 5093 – 02 (Reapproved 2008)

Standard Test Method for

Field Measurement of Infiltration Rate Using a Double-Ring

Infiltrometer with a Sealed-Inner Ring

This standard is issued under the fixed designation D5093; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 Thistestmethoddescribesaprocedureformeasuringtheinfiltrationrateofwaterthroughin-placesoilsusingadouble-ring

infiltrometer with a sealed inner ring.

−7 −10

1.2 This test method is useful for soils with infiltration rates in the range of 1 310 m/s to 1 310 m/s. When infiltration

−7

rates$1 310 m/s are to be measured Test Method D3385 shall be used.

1.3This test method provides a direct measurement of infiltration rate, not hydraulic conductivity. Although the units of

infiltration rate and hydraulic conductivity are similar, there is a distinct difference between these two quantities. They cannot be

directly related unless the hydraulic boundary conditions, such as hydraulic gradient and the extent of lateral flow of water are

known or can be reliably estimated.

1.4This test method can be used for natural soil deposits, recompacted soil layers, and amended soils such as soil bentonite and

soil lime mixtures.

1.5The values stated in SI units are to be regarded as standard. The values in parentheses are for information only.

1.6

1.3 All observed and calculated values shall conform to the guide for significant digits and rounding established in Practice

D6026.

1.3.1 The method used to specify how data are collected, calculated, or recorded in this standard is not directly related to the

accuracytowhichthedatacanbeappliedindesignorotheruses,orboth.Howoneappliestheresultsobtainedusingthisstandard

is beyond its scope.

1.4 This test method provides a direct measurement of infiltration rate, not hydraulic conductivity. Although the units of

infiltration rate and hydraulic conductivity are similar, there is a distinct difference between these two quantities. They cannot be

directly related unless the hydraulic boundary conditions, such as hydraulic gradient and the extent of lateral flow of water are

known or can be reliably estimated.

1.5 Thistestmethodcanbeusedfornaturalsoildeposits,recompactedsoillayers,andamendedsoilssuchassoilbentoniteand

soil lime mixtures.

1.6 The values stated in SI units are to be regarded as standard. The values in parentheses are for information only.

1.7 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2.1 ASTM Standards:

D653 Terminology Relating to Soil, Rock, and Contained Fluids

D3385Test Method for Infiltration Rate of Soils in Field Using Double Ring Infiltrometers Test Method for Infiltration Rate

of Soils in Field Using Double-Ring Infiltrometer

D3740 Practice for Minimum Requirements for Agencies Engaged in Testing and/or Inspection of Soil and Rock as Used in

Engineering Design and Construction

D6026 Practice for Using Significant Digits in Geotechnical Data

ThistestmethodisunderthejurisdictionofASTMCommitteeD-18onSoilandRockandisthedirectresponsibilityofSubcommitteeD18.04onHydrologicProperties

of Soil and Rocks.

Current edition approved June 29, 1990. Published August 1990.

This test method is under the jurisdiction ofASTM Committee D18 on Soil and Rock and is the direct responsibility of Subcommittee D18.04 on Hydrologic Properties

and Hydraulic Barriers.

Current edition approved Sept. 1, 2008. Published September 2008. Originally approved in 1990. Last previous edition approved in 2002 as D5093–02.

ForreferencedASTMstandards,visittheASTMwebsite,www.astm.org,orcontactASTMCustomerServiceatservice@astm.org.For Annual Book of ASTM Standards

, Vol 04.08.volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D 5093 – 02 (2008)

3. Terminology

3.1 Definitions:

3.1.1 infiltration—downward entry of liquid into a porous body.

3 2

3.1.2 infiltrationrate,I—quantityofliquidenteringaporousmaterial(m )perunitarea(m )perunittime(s),expressedinunits

of m/s.

3.1.3 infiltrometer—adeviceusedtopondliquidonaporousbodyandtoallowforthemeasurementoftherateatwhichliquid

enters the porous body.

3.1.4 For definitions of other terms used in this test method, see Terminology D653.

4. Summary of Test Method

4.1 The infiltration rate of water through soil is measured using a double-ring infiltrometer with a sealed or covered inner ring

(Fig. 1). The infiltrometer consists of an open outer and a sealed inner ring. The rings are embedded and sealed in trenches

excavated in the soil. Both rings are filled with water such that the inner ring is submerged.

4.2 The rate of flow is measured by connecting a flexible bag filled with a known weight of water to a port on the inner ring.

As water infiltrates into the ground from the inner ring, an equal amount of water flows into the inner ring from the flexible bag.

After a known interval of time, the flexible bag is removed and weighed. The weight loss, converted to a volume, is equal to the

amount of water that has infiltrated into the ground.An infiltration rate is then determined from this volume of water, the area of

the inner ring, and the interval of time. This process is repeated and a plot of infiltration rate versus time is constructed. The test

is continued until the infiltration rate becomes steady or until it becomes equal to or less than a specified value.

5. Significance and Use

5.1 Thistestmethodprovidesameanstomeasurelowinfiltrationratesassociatedwithfine-grained,clayeysoils,andareinthe

−7 −9

range of 1 310 m/s to 1 310 m/s.

5.2 Thistestmethodisparticularlyusefulformeasuringliquidflowthroughsoilmoisturebarrierssuchascompactedclayliner

or covers used at waste disposal facilities, for canal and reservoir liners, for seepage blankets, and for amended soil liners such

as those used for retention ponds or storage tanks.

5.3 The purpose of the sealed inner ring is to: (1) provide a means to measure the actual amount of flow rather than a drop in

water elevation which is the flow measurement procedure used in Test Method D3385 and ( 2) to eliminate evaporation losses.

5.4 Thepurposeoftheouterringistopromoteone-dimensional,verticalflowbeneaththeinnerring.Theuseoflargediameter

rings and large depths of embedments helps to ensure that flow is essentially one-dimensional.

5.5 This test method provides a means to measure infiltration rate over a relatively large area of soil. Tests on large volumes

of soil can be more representative than tests on small volumes of soil.

5.6 The data obtained from this test method are most useful when the soil layer being tested has a uniform distribution of pore

space, and when the density and degree of saturation and the hydraulic conductivity of the material underlying the soil layer are

known.

5.7 Changesinwatertemperaturecanintroducesignificanterrorinthevolumechangemeasurements.Temperaturechangeswill

cause water to flow in or out of the inner ring due to expansion or contraction of the inner ring and the water contained within

the inner ring.

5.8 The problem of temperature changes can be minimized by insulating the rings, by allowing enough flow to occur so that

the amount of flow resulting from a temperature change is not significant compared to that due to infiltration, or by connecting

and disconnecting the bag from the inner ring when the water in the inner ring is at the same temperature.

5.9 If the soil being tested will later be subjected to increased overburden stress, then the infiltration rate can be expected to

decrease as the overburden stress increases. Laboratory hydraulic conductivity tests are recommended for studies of the influence

of level of stress on the hydraulic properties of the soil.

NOTE 1—The quality of the result produced by this standard depends on the competence of the personnel performing it and the suitability of the

equipment and facilities being used. Agencies that meet the criteria of Practice D3740 are generally considered capable of competent and objective

FIG. 1 Schematic Of A Double-Ring Infiltrometer With A Sealed

Inner Ring

D 5093 – 02 (2008)

testing, sampling, inspection, etc. Users of this standard are cautioned that compliance with Practice D3740 does not in itself ensure reliable results.

Reliable results depend on many factors; Practice D3740 provides a means of evaluating some of those factors

6. Apparatus

6.1 InfiltrometerRings—Theringsshallbeconstructedofastiff,corrosion-resistantmaterialsuchasmetal,plastic,orfiberglass.

The shape of the rings can be circular or square. However, square rings are recommended because it is easier to excavate straight

trenches in the soil. The rings can be of any size provided: (1) the minimum width or diameter of the inner ring is 610 mm (24

in.); and (2) a minimum distance of 610 mm is maintained between the inner and outer ring. The following is a description of a

set of rings that can be constructed from commonly available materials, incorporates the requirements described above, and has

worked well in the field.

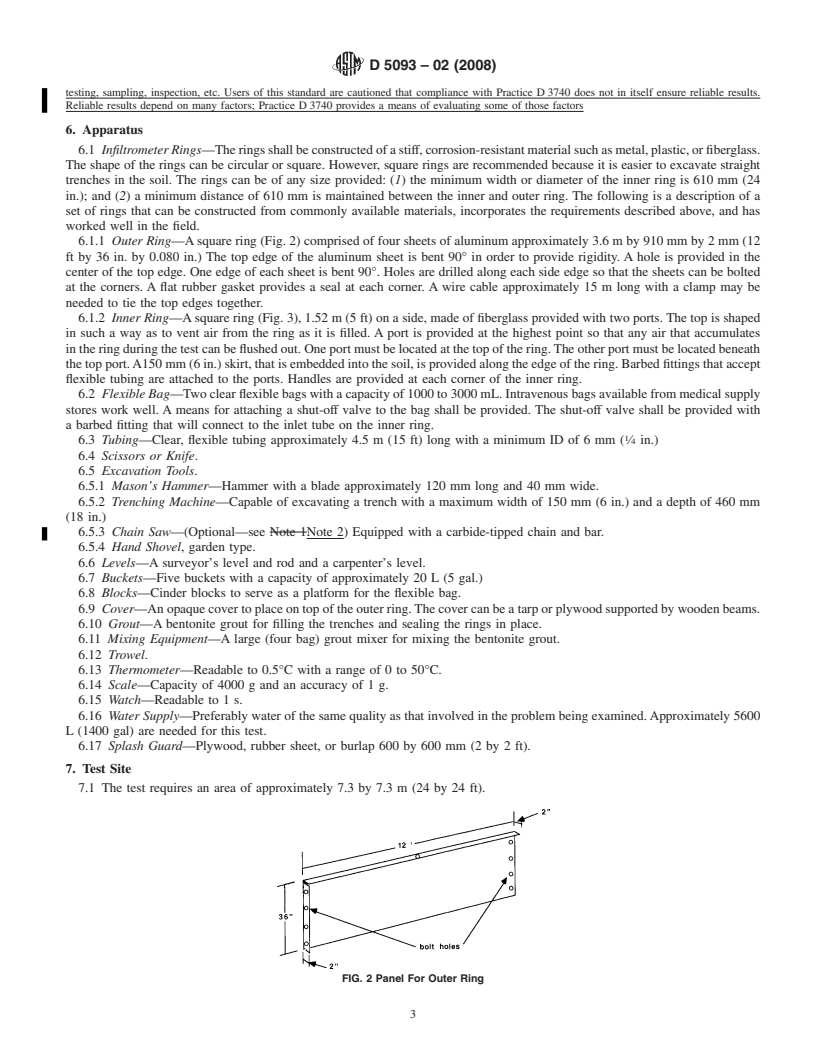

6.1.1 Outer Ring—Asquare ring (Fig. 2) comprised of four sheets of aluminum approximately 3.6 m by 910 mm by 2 mm (12

ft by 36 in. by 0.080 in.) The top edge of the aluminum sheet is bent 90° in order to provide rigidity. A hole is provided in the

center of the top edge. One edge of each sheet is bent 90°. Holes are drilled along each side edge so that the sheets can be bolted

at the corners. A flat rubber gasket provides a seal at each corner. A wire cable approximately 15 m long with a clamp may be

needed to tie the top edges together.

6.1.2 Inner Ring—Asquare ring (Fig. 3), 1.52 m (5 ft) on a side, made of fiberglass provided with two ports.The top is shaped

in such a way as to vent air from the ring as it is filled. A port is provided at the highest point so that any air that accumulates

intheringduringthetestcanbeflushedout.Oneportmustbelocatedatthetopofthering.Theotherportmustbelocatedbeneath

thetopport.A150mm(6in.)skirt,thatisembeddedintothesoil,isprovidedalongtheedgeofthering.Barbedfittingsthataccept

flexible tubing are attached to the ports. Handles are provided at each corner of the inner ring.

6.2 Flexible Bag—Twoclearflexiblebagswithacapacityof1000to3000mL.Intravenousbagsavailablefrommedicalsupply

stores work well. A means for attaching a shut-off valve to the bag shall be provided. The shut-off valve shall be provided with

a barbed fitting that will connect to the inlet tube on the inner ring.

6.3 Tubing—Clear, flexible tubing approximately 4.5 m (15 ft) long with a minimum ID of 6 mm ( ⁄4 in.)

6.4 Scissors or Knife.

6.5 Excavation Tools.

6.5.1 Mason’s Hammer—Hammer with a blade approximately 120 mm long and 40 mm wide.

6.5.2 Trenching Machine—Capable of excavating a trench with a maximum width of 150 mm (6 in.) and a depth of 460 mm

(18 in.)

6.5.3 Chain Saw—(Optional—see Note 1Note 2) Equipped with a carbide-tipped chain and bar.

6.5.4 Hand Shovel, garden type.

6.6 Levels—A surveyor’s level and rod and a carpenter’s level.

6.7 Buckets—Five buckets with a capacity of approximately 20 L (5 gal.)

6.8 Blocks—Cinder blocks to serve as a platform for the flexible bag.

6.9 Cover—Anopaquecovertoplaceontopoftheouterring.Thecovercanbeatarporplywoodsupportedbywoodenbeams.

6.10 Grout—A bentonite grout for filling the trenches and sealing the rings in place.

6.11 Mixing Equipment—A large (four bag) grout mixer for mixing the bentonite grout.

6.12 Trowel.

6.13 Thermometer—Readable to 0.5°C with a range of 0 to 50°C.

6.14 Scale—Capacity of 4000 g and an accuracy of 1 g.

6.15 Watch—Readable to 1 s.

6.16 Water Supply—Preferablywaterofthesamequalityasthatinvolvedintheproblembeingexamined.Approximately5600

L (1400 gal) are needed for this test.

6.17 Splash Guard—Plywood, rubber sheet, or burlap 600 by 600 mm (2 by 2 ft).

7. Test Site

7.1 The test requires an area of approximately 7.3 by 7.3 m (24 by 24 ft).

FIG. 2 Panel For Outer Ring

D 5093 – 02 (2008)

FIG. 3 Inner Ring

7.2 The slope to the test area should be no greater than approximately 3%.

7.3 The test may be set up in a pit if infiltration rates are desired at depth rather than at the surface.

7.4 The test area shall be covered with a sheet of plastic to keep the surface from drying.

7.5 Representative samples of the soil to be tested shall be taken before and after the test to determine its moisture content,

density, and specific gravity. The thickness of the layer being tested shall be determined as well as the approximate hydraulic

conductivity of the layer beneath it.

8. Procedure

8.1 Assembly of Outer Ring—Wipe off gaskets and side edges of the outer ring.Align gasket between the edges and bolt edges

together.

8.2 Excavation of Trenches:

8.2.1 Placebothringsontheareatobetested.Centertheinnerringwithintheouterring.Makesurethattheouterringissquare

by using the tape measure to check that the length of the diagonals are equal.

8.2.2 If plastic is covering the test area, cut out thin strips along the edge of each ring so that the trenches can be excavated.

Leave as much of the plastic on as possible in order to keep the soil from drying.

8.2.3 Use the bottom edge of each ring to scribe a line on the ground to use as a guide for excavating the trenches.

8.2.4 Note the orientation of the rings and set them aside.

8.2.5 Use the surveyor’s level and check the ground elevation where the corners of each ring will be. Note the high spots and

excavate deeper in these areas so that the rings will be level.

8.2.6 Use the trenching machine and excavate a trench for the outer ring. The trench should be about 146 mm (18 in.) deep.

Excavate deeper at high spots.

8.2.7 Use a small hand shovel to remove any loose material in the trenches.

8.2.8 Place the outer ring in the trench and use the carpenter’s level to check that the top of the ring is reasonably level (630

mm). Also check that the ou

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.