ASTM F1976-99

(Test Method)Standard Test Method for Cushioning Properties of Athletic Shoes Using an Impact Test

Standard Test Method for Cushioning Properties of Athletic Shoes Using an Impact Test

SCOPE

1.1 This test method describes procedures for the measurement of the impact response properties of athletic shoes using Procedure A of Test Method F 1614.

1.2 This test method is limited to tests using a falling weight impact machine, as defined by Procedure A of Test Method F 1614.

1.3 This test method is intended for use on the heel and or forefoot regions of whole, intact athletic shoe cushioning systems. An athletic shoe cushioning system is defined as all of the layers of material between the wearer's foot and the ground surface that are normally considered a part of the shoe. This may include any of the following components: outsole or other abrasion resistant layer, a midsole or other compliant cushioning layer, an insole, insole board, or other material layer overlying the midsole, parts of the upper and heel counter reinforcement which extend beneath the foot, and an insock or other cushioning layer inside the shoe.

1.4 This test method is not intended for use as a test of shoes classified by the manufacturer as children's shoes.

1.5 The type, size or dimensions and thickness of the specimen, and the reference maximum energy applied shall qualify test results obtained by this test method.

1.5.1 Nominal specimen thickness values for this test method are in the range from 10 to 60 mm (0.4 to 2.4 in.). The area of the shoe to be tested must present an approximately circular, flat surface of a least 65 mm (2.6 in.) in diameter for impacting.

1.5.2 The standard value for the reference maximum energy applied by this test method is d5 J(44.2 in.-lbf) for shoes which are subject to moderate impacts during normal use and 7.0 J(61.9 in.-lbf) for shoes which are subject to high impacts during normal use. Other values may be used, if they are stated in the report.

1.6 This test method is not appropriate for measuring the impact repsonse of shoes that are not subjected to moderate impact or high impact in normal use.

1.7 The values stated in SI units are to be regarded as standard.

1.8 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

An American National Standard

Designation:F1976–99

Standard Test Method for

Cushioning Properties of Athletic Shoes Using an Impact

Test

This standard is issued under the fixed designation F 1976; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope 1.7 The values stated in SI units are to be regarded as

standard.

1.1 This test method describes procedures for the measure-

1.8 This standard does not purport to address all of the

ment of the impact response properties of athletic shoes using

safety concerns, if any, associated with its use. It is the

Procedure A of Test Method F 1614.

responsibility of the user of this standard to establish appro-

1.2 This test method is limited to tests using a falling weight

priate safety and health practices and determine the applica-

impact machine, as defined by Procedure A of Test Method

bility of regulatory limitations prior to use.

F 1614.

1.3 This test method is intended for use on the heel and or

2. Referenced Documents

forefoot regions of whole, intact athletic shoe cushioning

2.1 ASTM Standards:

systems.An athletic shoe cushioning system is defined as all of

F 1614 Test Method for Shock Attenuating Properties of

the layers of material between the wearer’s foot and the ground

Materials Systems for Athletic Footwear

surface that are normally considered a part of the shoe. This

may include any of the following components: outsole or other

3. Terminology

abrasion resistant layer, a midsole or other compliant cushion-

3.1 Definitions of Terms Specific to This Standard:

ing layer, an insole, insole board, or other material layer

3.1.1 cushioning system—one or more components of the

overlying the midsole, parts of the upper and heel counter

sole of a shoe intended for the redistribution of force or shock

reinforcement which extend beneath the foot, and an insock or

attenuation, or both, including one or more of the insock,

other cushioning layer inside the shoe.

insole, midsole, and outsole.

1.4 Thistestmethodisnotintendedforuseasatestofshoes

3.1.2 drop height—theheightfromwhichthefallingmassis

classified by the manufacturer as children’s shoes.

dropped, being the distance between the top of the specimen

1.5 The type, size or dimensions and thickness of the

and the top of the tup.

specimen, and the reference maximum energy applied shall

3.1.3 impact—rapid deceleration of the lower extremity due

qualify test results obtained by this test method.

to collision between the foot and the surface.

1.5.1 Nominal specimen thickness values for this test

3.1.3.1 low impact—an impact during which the peak

method are in the range from 10 to 60 mm (0.4 to 2.4 in.). The

ground reaction force is less than 1.5 body weights and the

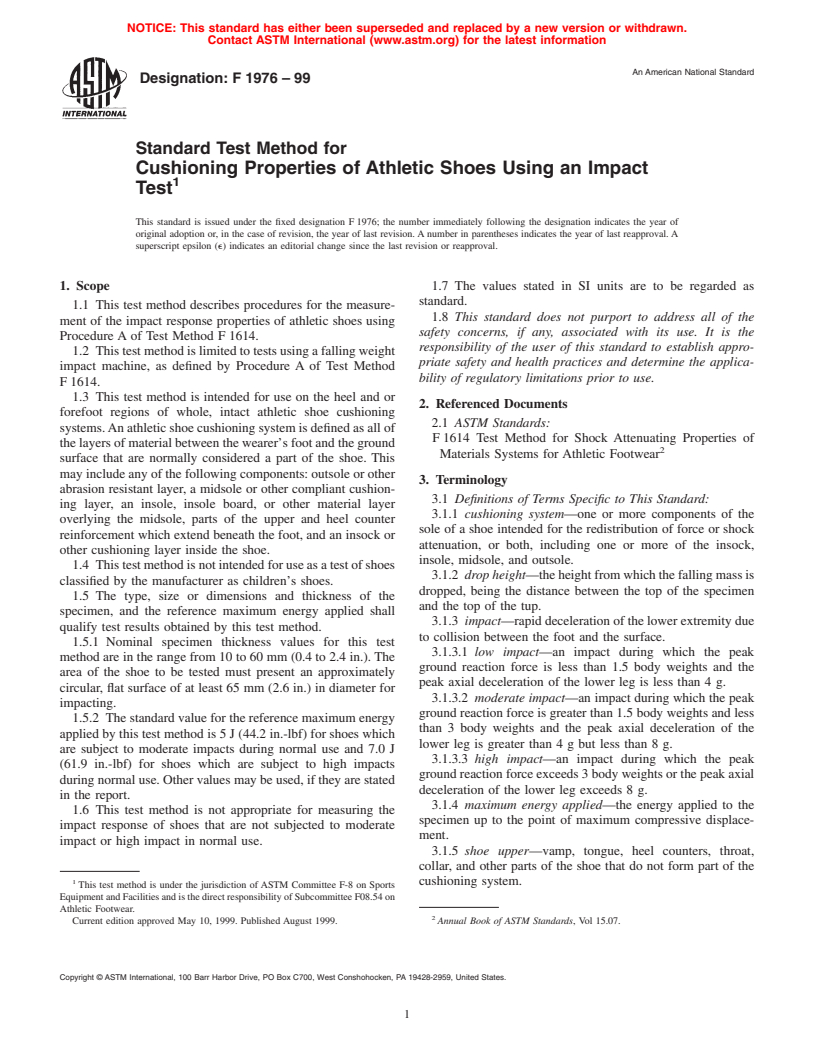

area of the shoe to be tested must present an approximately

peak axial deceleration of the lower leg is less than 4 g.

circular, flat surface of at least 65 mm (2.6 in.) in diameter for

3.1.3.2 moderate impact—an impact during which the peak

impacting.

ground reaction force is greater than 1.5 body weights and less

1.5.2 The standard value for the reference maximum energy

than 3 body weights and the peak axial deceleration of the

applied by this test method is 5 J (44.2 in.-lbf) for shoes which

lower leg is greater than 4 g but less than 8 g.

are subject to moderate impacts during normal use and 7.0 J

3.1.3.3 high impact—an impact during which the peak

(61.9 in.-lbf) for shoes which are subject to high impacts

ground reaction force exceeds 3 body weights or the peak axial

during normal use. Other values may be used, if they are stated

deceleration of the lower leg exceeds 8 g.

in the report.

3.1.4 maximum energy applied—the energy applied to the

1.6 This test method is not appropriate for measuring the

specimen up to the point of maximum compressive displace-

impact response of shoes that are not subjected to moderate

ment.

impact or high impact in normal use.

3.1.5 shoe upper—vamp, tongue, heel counters, throat,

collar, and other parts of the shoe that do not form part of the

cushioning system.

This test method is under the jurisdiction of ASTM Committee F-8 on Sports

Equipment and Facilities and is the direct responsibility of Subcommittee F08.54 on

Athletic Footwear.

Current edition approved May 10, 1999. Published August 1999. Annual Book of ASTM Standards, Vol 15.07.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

F1976

3.1.6 tup—leading surface of moving portion of test ma- 6. Test Apparatus

chine in contact with specimen during the impact cycle.

6.1 Test apparatus shall conform to Test Method F 1614,

Procedure A.

4. Summary of Test Method

7. Test Specimen

4.1 A test specimen is supported on a rigid foundation and

7.1 Preparation of Test Specimens—The cushioning test

rapidly loaded in compression by a falling mass. The compres-

specimen shall be isolated from the shoe by cutting away the

sive force is applied through the circular flat face of 45-mm

upper.Thelowerportionoftheupper(thatwhichextends10 6

(1.8-in.) diameter tup. Force and displacement transducers are

5 mm (0.4 6 0.2 in.) above the top surface of the cushioning

employed for continuous measurement of the complete loading

system) shall not be removed, providing it does not interfere

and unloading compression cycle. Alternatively, specimen

with the falling mass.

displacement history may be calculated from the force history.

4.2 The maximum energy applied to the test specimen must

NOTE 3—The retention of a rim of upper materials around the edge of

be within 610 % of a standard reference value. The reference the test specimen prevents disturbance of the cushioning materials during

removal of the upper, preserves the attachments between the sole and the

value is typically 5 J (44.2 in.-lbf) or 7 J (61.9 in.-lbf) but may

upper (which can influence shock attenuation), and serves as a retainer for

be varied depending of the type of shoe and whether the heel

any loosely attached components of the cushioning system that normally

or forefoot is being tested. Other reference energy values may

reside inside the shoe (an insock for example).

be used, if they are stated in the report.

7.2 Geometry—In order for this test method to be appli-

4.3 This test method uses the gravity-driven impact of a

cable, the region of the cushioning system to be tested shall

defined mass as the method for force application. The impact

have an approximately flat surface, approximately circular in

velocity is determined by the drop height. The maximum force

shape, with a minimum diameter of 65 6 2 mm (2.6 6 0.1 in.).

and maximum displacement are determined by the cushioning

The center of this presenting surface shall coincide with the

characteristics of the shoe. The maximum energy applied is

center of the tup of the test apparatus, such that on initial

determined by both the drop height and the cushioning

contact between the tup and the test specimen there is a

characteristics of the shoe.

minimum of 10 6 1-mm (0.4 6 0.05-in.) clearance between

the edge of the tup and the edge of the test specimen, in all

5. Significance and Use

directions.

5.1 This test method is used by athletic footwear manufac-

NOTE 4—The geometry of the test specimen will vary with the design

turers and others, both as a tool for development of athletic

of the shoe under test. Since the geometry of the shoe is a factor which

shoecushioningsystemsandasatestofthegeneralcus

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.