ASTM D7449/D7449M-08

(Test Method)Standard Test Method for Measuring Relative Complex Permittivity and Relative Magnetic Permeability of Solid Materials at Microwave Frequencies Using Coaxial Air Line

Standard Test Method for Measuring Relative Complex Permittivity and Relative Magnetic Permeability of Solid Materials at Microwave Frequencies Using Coaxial Air Line

SIGNIFICANCE AND USE

Design calculations for radio frequency (RF), microwave and millimetre-wave components require the knowledge of values of complex permittivity and permeability at operating frequencies. This test method is useful for evaluating small experimental batch or continuous production materials used in electromagnetic applications. Use this method to determine complex permittivity only (in non-magnetic materials) or both complex permittivity and permeability simultaneously.

SCOPE

1.1 This test method covers a procedure for determining relative complex permittivity (relative dielectric constant and loss) and relative magnetic permeability of isotropic, reciprocal (non-gyromagnetic) solid materials. If the material is nonmagnetic, it is acceptable to use this procedure to measure permittivity only.

1.2 This measurement method is valid over a frequency range of approximately 1 MHz to over 20 GHz. These limits are not exact and depend on the size of the specimen, the size of coaxial air line used as a specimen holder, and on the applicable frequency range of the network analyzer used to make measurements. The practical lower and upper frequencies are limited by specimen dimension requirements (large, thick specimens at low frequencies and small specimens at high frequencies). For a given air line size, the upper frequency is also limited by the onset of higher order modes that invalidate the dominant-mode transmission line model and the lower frequency is limited by the smallest measurable phase shift through a specimen. Being a non-resonant method, the selection of any number of discrete measurement frequencies in a measurement band would be suitable. The coaxial fixture is preferred over rectangular waveguide fixtures when broadband data are desired with a single sample or when only small sample volumes are available, particularly for lower frequency measurements

1.3 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems may result in non-conformance with the standard. The equations shown here assume an e+jωt harmonic time convention.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

An American National Standard

Designation:D7449/D7449M–08

Standard Test Method for

Measuring Relative Complex Permittivity and Relative

Magnetic Permeability of Solid Materials at Microwave

Frequencies Using Coaxial Air Line

This standard is issued under the fixed designation D7449/D7449M; the number immediately following the designation indicates the

year of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last

reapproval. A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use.

1.1 This test method covers a procedure for determining

relative complex permittivity (relative dielectric constant and

2. Referenced Documents

loss)andrelativemagneticpermeabilityofisotropic,reciprocal

2.1 ASTM Standards:

(non-gyromagnetic) solid materials. If the material is nonmag-

D1711 Terminology Relating to Electrical Insulation

netic, it is acceptable to use this procedure to measure

permittivity only.

3. Terminology

1.2 This measurement method is valid over a frequency

3.1 For definitions of terms used in this test method, refer to

range of approximately 1 MHz to over 20 GHz. These limits

Terminology D1711.

are not exact and depend on the size of the specimen, the size

3.2 Definitions:

of coaxial air line used as a specimen holder, and on the

3.2.1 relative complex permittivity (relative complex dielec-

applicable frequency range of the network analyzer used to

*

tric constant), ´ , n—the proportionality factor that relates the

r

make measurements. The practical lower and upper frequen-

electric field to the electric flux density, and which depends on

cies are limited by specimen dimension requirements (large,

intrinsic material properties such as molecular polarizability,

thick specimens at low frequencies and small specimens at

charge mobility, etc.:

highfrequencies).Foragivenairlinesize,theupperfrequency

→

is also limited by the onset of higher order modes that

D

invalidate the dominant-mode transmission line model and the * ’ ”

´ 5´ – j´ 5 (1)

r r r

→

lower frequency is limited by the smallest measurable phase

´ E

shift through a specimen. Being a non-resonant method, the

selection of any number of discrete measurement frequencies

where:

in a measurement band would be suitable. The coaxial fixture

´ = permittivity of free space

is preferred over rectangular waveguide fixtures when broad-

→

= electric flux density vector, and

band data are desired with a single sample or when only small

D

sample volumes are available, particularly for lower frequency

→

= electric field vector.

measurements

E

1.3 The values stated in either SI units or inch-pound units

are to be regarded separately as standard. The values stated in

3.2.1.1 Discussion—In common usage the word “relative”

each system may not be exact equivalents; therefore, each

is frequently dropped. The real part of complex relative

’

system shall be used independently of the other. Combining

permittivity ~´ ! is often referred to as simply relative permit-

r

values from the two systems may result in non-conformance

tivity, permittivity or dielectric constant. The imaginary part of

+jvt

”

with the standard. The equations shown here assume an e

complexrelativepermittivity ~´ !isoftenreferredtoastheloss

r

harmonic time convention.

factor.Inanisotropicmedia,permittivityisdescribedbyathree

1.4 This standard does not purport to address all of the

dimensional tensor. For the purposes of this test method, the

safety concerns, if any, associated with its use. It is the

media is considered to be isotropic, and therefore permittivity

responsibility of the user of this standard to establish appro-

is a single complex number at each frequency.

This test method is under the jurisdiction of ASTM Committee D09 on

Electrical and Electronic Insulating Materials and is the direct responsibility of For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Subcommittee D09.12 on Electrical Tests. contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Current edition approved Nov. 15, 2008. Published December 2008. DOI: Standards volume information, refer to the standard’s Document Summary page on

10.1520/D7449_D7449M-08. the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D7449/D7449M–08

*

coefficientofacomponentataspecifiedsetofinputandoutput

3.2.2 relative complex permeability, µ , n—the proportion-

r

reference planes with an incident signal on only a single port.

ality factor that relates the magnetic flux density to the

3.3.5.1 Discussion—As most commonly used, these coeffi-

magnetic field, and which depends on intrinsic material prop-

cients represent the quotient of the complex electric field

erties such as magnetic moment, domain magnetization, etc.:

strength (or voltage) of a reflected or transmitted wave divided

→

B by that of an incident wave. The subscripts i and j of a typical

* ’ ”

µ 5 µ – jµ 5 (2)

r r r

→ coefficient S refer to the output and input ports, respectively.

ij

µ H

For example, the forward transmission coefficient S is the

ratioofthetransmittedwavevoltageatReferencePlane2(Port

2) divided by the incident wave voltage measured at Reference

where:

Plane 1 (Port 1). Similarly, the Port 1 reflection coefficient S

µ = permeability of free space 11

→ is the ratio of the Port 1 reflected wave voltage divided by the

= magnetic flux density vector, and

B

Port 1 incident wave voltage at reference plane 1 (Port 1).

→

= magnetic field vector.

3.3.6 transverse electromagneticc (TEM) wave, n—an elec-

H

tromagnetic wave in which both the electric and magnetic

3.2.2.1 Discussion—In common usage the word “relative”

fields are everywhere perpendicular to the direction of propa-

is frequently dropped. The real part of complex relative

gation.

’

permeability ~µ ! is often referred to as relative permeability or

r

3.3.6.1 Discussion—In coaxial transmission lines the domi-

simply permeability. The imaginary part of complex relative

nant wave is TEM.

”

permeability ~µ !isoftenreferredtoasthemagneticlossfactor.

r

In anisotropic media, permeability is described by a three

4. Summary of Test Method

dimensional tensor. For the purposes of this test method, the

4.1 A carefully machined test specimen is placed in a

media is considered to be isotropic, and therefore permeability

coaxial air line and connected to a calibrated network analyzer

is a single complex number at each frequency.

that is used to measure the S-parameters of the transmission

3.3 Definitions of Terms Specific to This Standard:

line-with-specimen. A specified data-reduction algorithm is

3.3.1 A list of symbols specific to this test method is given

then used to calculate permittivity and permeability. If the

in Annex A1.

material is nonmagnetic, a different algorithm is used to

3.3.2 calibration, n—a procedure for connecting character-

calculate permittivity only. Error corrections are then applied

ized standard devices to the test ports of a network analyzer to

to compensate for air gaps between the specimen and the

characterize the measurement system’s systematic errors. The

transmission line conductor surfaces.

effects of the systematic errors are then mathematically re-

moved from the indicated measurements. The calibration also

5. Significance and Use

establishes the mathematical reference plane for the measure-

5.1 Design calculations for radio frequency (RF), micro-

ment test ports.

wave and millimetre-wave components require the knowledge

3.3.2.1 Discussion—Modern network analyzers have this

ofvaluesofcomplexpermittivityandpermeabilityatoperating

capability built in. There are a variety of calibration kits that

frequencies. This test method is useful for evaluating small

can be used depending on the type of test port. The models

experimental batch or continuous production materials used in

used to predict the measurement response of the calibration

electromagnetic applications. Use this method to determine

devices depends on the type of calibration kit. Most calibration

complex permittivity only (in non-magnetic materials) or both

kits come with media that can be used to load the definitions of

complex permittivity and permeability simultaneously.

the calibration devices into the network analyzer. Calibration

kit definitions loaded into the network analyzer must match the

6. Interferences

devices used to calibrate. Since both transmission and reflec-

tion measurements are used in this standard, a two-port

6.1 The upper limits of permittivity and permeability that

calibration is required. can be measured using this test method are restricted by the

3.3.3 cutoff frequency, n—the lowest frequency at which

transmission line and specimen geometries, which can lead to

non-evanescent, higher-order mode propagation can occur unwanted higher order waveguide modes. In addition, exces-

within a coaxial transmission line

sive electromagnetic attenuation due to a high loss factor

3.3.4 network analyzer, n—a system that measures the within the test specimen can prevent determination of permit-

two-port transmission and one-port reflection characteristics of

tivity and permeability. No specific limits are given in this

a multiport system in its linear range and at a common input standard, but this test method is practically limited to low-to-

and output frequency.

medium values of permittivity and permeability.

3.3.4.1 Discussion—For the purposes of this standard, this 6.2 The existence of air gaps between the test specimen and

descriptionincludesonlythosesystemsthathaveasynthesized the transmission line introduces a negative bias into measure-

signal generator, and that measure the complex scattering ments of permittivity and permeability. In this test method,

parameters (both magnitude and phase) in the forward and

compensation for this bias is required, and to do so requires

reverse directions of a two-port network (S , S , S , S ). knowledge of the air gap sizes. Air gap sizes are estimated

11 21 12 22

3.3.5 scatteringparameter(S-parameter),S ,n—acomplex from dimensional measurements of the specimen and the

ij

number consisting of either the reflection or transmission specimen holder. Several different error correction models

D7449/D7449M–08

have been developed, and a frequency independent series 7.4.4 Be sure that the specimen holder dimensions are

capacitor model is described inAnnexA2.Air gap corrections within proper tolerances for the transmission line size in use.

are only approximate and therefore this test method is practi-

For a rectangular coaxial transmission line, the diameter of the

cally limited to low-to-medium values of permittivity and

center conductor, D , and the inside diameter of the outer

permeability.

conductor, D , are the critical dimensions. Proper tolerances

for a “7-mm” coax are then:

7. Apparatus

7-mm coax center conductor diameter:

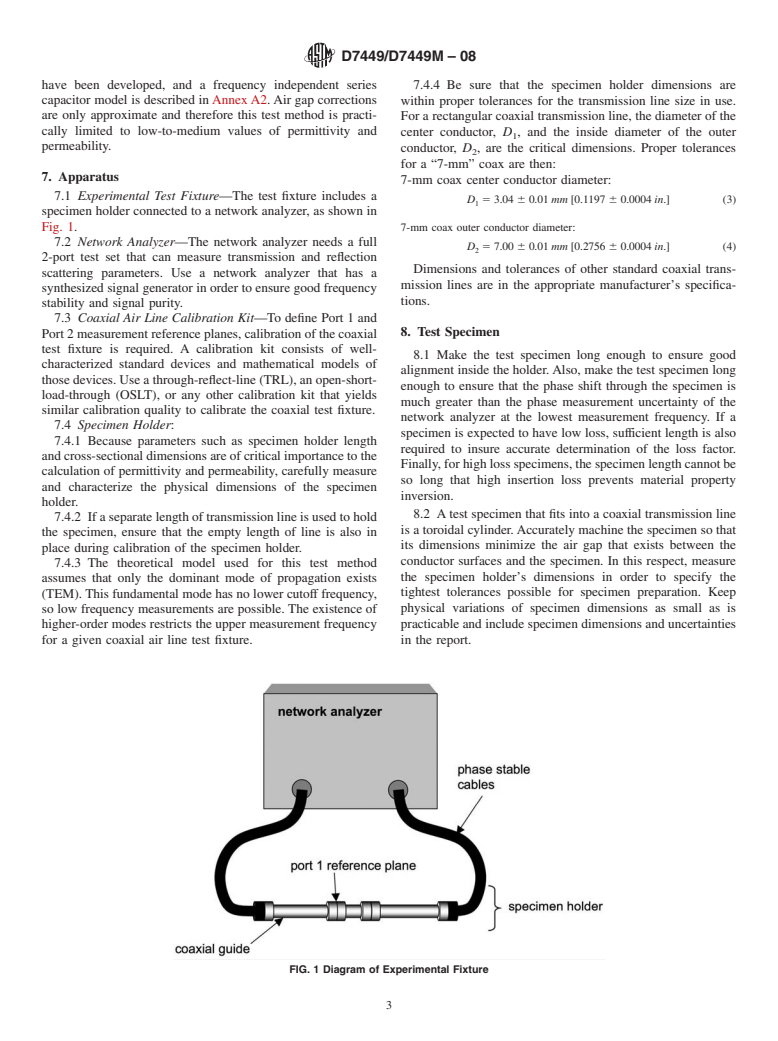

7.1 Experimental Test Fixture—The test fixture includes a

D 5 3.04 6 0.01 mm [0.1197 6 0.0004 in.] (3)

specimen holder connected to a network analyzer, as shown in

Fig. 1. 7-mm coax outer conductor diameter:

7.2 Network Analyzer—The network analyzer needs a full

D 5 7.00 6 0.01 mm [0.2756 6 0.0004 in.] (4)

2-port test set that can measure transmission and reflection

Dimensions and tolerances of other standard coaxial trans-

scattering parameters. Use a network analyzer that has a

mission lines are in the appropriate manufacturer’s specifica-

synthesized signal generator in order to ensure good frequency

tions.

stability and signal purity.

7.3 Coaxial Air Line Calibration Kit—To define Port 1 and

8. Test Specimen

Port 2 measurement reference planes, calibration of the coaxial

test fixture is required. A calibration kit consists of well-

8.1 Make the test specimen long enough to ensure good

characterized standard devices and mathematical models of

alignment inside the holder.Also, make the test specimen long

those devices. Use a through-reflect-line (TRL), an open-short-

enough to ensure that the phase shift through the specimen is

load-through (OSLT), or any other calibration kit that yields

much greater than the phase measurement uncertainty of the

similar calibration quality to calibrate the coaxial test fixture.

network analyzer at the lowest measurement frequency. If a

7.4 Specimen Holder:

specimen is expected to have low loss, sufficient length is also

7.4.1 Because parameters such as specimen holder length

required to insure accurate determination of the loss factor.

and cross-sectional dimensions are of critical importance to the

Finally, for high loss specimens, the specimen length cannot be

calculation of permittivity and permeability, carefully measure

so long that high insertion loss prevents material property

and characterize the physical dimensions of the specimen

inversion.

holder.

8.2 Atest specimen that fits into a coaxial transmission line

7.4.2 If a separate length of transmission line is used to hold

is a toroidal cylinder.Accurately machine the specimen so that

the specimen, ensure that the empty length of line is also in

its dimensions minimize the air gap that exists between the

place during calibration of the specimen holder.

conductor surfaces and the specimen. In this respect, measure

7.4.3 The theoretical model used for this test method

the specimen holder’s dimensions in order to specify the

assumes that only the dominant mode of propagation exists

tightest tolerances possible for specimen preparation. Keep

(TEM). This fundamental mode has no lower cutoff frequency,

physical variations of specimen dimensions as small as is

so low frequency measurements are possible. The existence of

higher-order modes restricts the upper measurement frequency practicable and include specimen dimensions and uncertainties

for a given coaxial air line test fixture. in the report.

FIG. 1 Diagram of Experimental Fixture

D7449/D7449M–08

9. Preparation of Apparatus parameters depend on the calculation procedure used to deter-

mine intrinsic properties (refer to Section 11).

9.1 Inspect Network Analyzer Test Ports—Insure that the

recession of both test ports’ center conductor shoulder behind 10.2.5 Calculate the intrinsic properties of the verification

the outer conductor mating plane meets the minimum specifi- specimen from the measured scattering parameters, as de-

cations. Refer to network analyzer manufacturer’s documenta- scribed in the section on calculation. If the calculated intrinsic

tion to provide connector

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.