ASTM D3933-98(2017)

(Guide)Standard Guide for Preparation of Aluminum Surfaces for Structural Adhesives Bonding (Phosphoric Acid Anodizing)

Standard Guide for Preparation of Aluminum Surfaces for Structural Adhesives Bonding (Phosphoric Acid Anodizing)

SIGNIFICANCE AND USE

4.1 Durable adhesive bonds between metal to metal, metal to composites can be obtained reliably only through proper selection and careful control of the materials used and the steps in the bonding process. The preparation of the metallic substrates to obtain surfaces with appropriate characteristics is a critical step. Improper surface preparation can produce seemingly acceptable bonds that can degrade rapidly with time. This guide describes one method on how to properly prepare aluminum surfaces can be obtained.

4.2 The formation of reproducible, durable, adhesive bonds in structural assemblies requires great care in the selection of materials, the preparation of the surfaces of the components to be bonded, the fit of the components, and the performance of the steps in the bonding process. Experience has shown that when adhesively bonded aluminum surfaces which have been prepared in accordance with this guide produce relatively reproducible, durable bonds.

SCOPE

1.1 This guide describes the requirements for phosphoric acid anodizing of aluminum and its alloys for structural adhesive bonding.

1.2 The procedure included herein is based on the commercial practice of numerous agencies and organizations. The method may be revised or supplemented, as necessary, to include methods based on proven performance.

1.3 The surface preparation of metal systems used for qualification and quality-control testing of the adhesive should be agreed upon between the manufacturer and the user.

1.4 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use. A specific precaution is given in 5.5.

1.6 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: D3933 − 98 (Reapproved 2017)

Standard Guide for

Preparation of Aluminum Surfaces for Structural Adhesives

Bonding (Phosphoric Acid Anodizing)

This standard is issued under the fixed designation D3933; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 2.2 Federal Specifications:

0-0-670 Orthophosphoric Acid, Technical

1.1 This guide describes the requirements for phosphoric

acid anodizing of aluminum and its alloys for structural

3. Terminology

adhesive bonding.

3.1 Definitions—Many terms in this guide are defined in

1.2 The procedure included herein is based on the commer-

Terminology D907.

cial practice of numerous agencies and organizations. The

method may be revised or supplemented, as necessary, to

4. Significance and Use

include methods based on proven performance.

4.1 Durable adhesive bonds between metal to metal, metal

1.3 The surface preparation of metal systems used for

to composites can be obtained reliably only through proper

qualification and quality-control testing of the adhesive should

selectionandcarefulcontrolofthematerialsusedandthesteps

be agreed upon between the manufacturer and the user.

in the bonding process. The preparation of the metallic

1.4 The values stated in SI units are to be regarded as the substrates to obtain surfaces with appropriate characteristics is

a critical step. Improper surface preparation can produce

standard. The values given in parentheses are for information

only. seeminglyacceptablebondsthatcandegraderapidlywithtime.

This guide describes one method on how to properly prepare

1.5 This standard does not purport to address all of the

aluminum surfaces can be obtained.

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro- 4.2 The formation of reproducible, durable, adhesive bonds

priate safety, health, and environmental practices and deter-

in structural assemblies requires great care in the selection of

mine the applicability of regulatory limitations prior to use. A materials, the preparation of the surfaces of the components to

specific precaution is given in 5.5.

be bonded, the fit of the components, and the performance of

1.6 This international standard was developed in accor-

the steps in the bonding process. Experience has shown that

dance with internationally recognized principles on standard-

when adhesively bonded aluminum surfaces which have been

ization established in the Decision on Principles for the

prepared in accordance with this guide produce relatively

Development of International Standards, Guides and Recom-

reproducible, durable bonds.

mendations issued by the World Trade Organization Technical

5. Apparatus

Barriers to Trade (TBT) Committee.

5.1 Locate surface preparation and drying facilities separate

2. Referenced Documents

from other activities or equipment, or both, to preclude

2.1 ASTM Standards: contamination by substances detrimental to adhesion.

D907 Terminology of Adhesives

5.2 Facilities should be arranged such that parts can flow

D2651 GuideforPreparationofMetalSurfacesforAdhesive

from the beginning of surface preparation to the priming

Bonding

operation without being touched.

5.3 Filtersortraps,orboth,shouldbeinstalledforremoving

airborne dust, moisture, and oil from all air lines or ducts used

ThisguideisunderthejurisdictionofASTMCommitteeD14onAdhesivesand

is the direct responsibility of Subcommittee D14.80 on Metal Bonding Adhesives.

for solution agitation and parts drying. Periodically check,

Current edition approved Nov. 1, 2017. Published November 2017. Originally

clean, or replace filters to ensure proper operation.

approved in 1980. Last previous edition approved in 2010 as D3933 – 98 (2010).

DOI: 10.1520/D3933-98R17.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM AvailablefromU.S.GovernmentPrintingOfficeSuperintendentofDocuments,

Standards volume information, refer to the standard’s Document Summary page on 732 N. Capitol St., NW, Mail Stop: SDE, Washington, DC 20401, http://

the ASTM website. www.access.gpo.gov.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D3933 − 98 (2017)

5.4 Surface preparation facilities should not be used for surfacesandthephosphoricacidanodiccoatingaresusceptible

purposes other than the preparation of parts for adhesive to contamination or physical damage prior to the application

bonding and subsequent finishing. and cure of the primer.

5.5 Equipment requirements for this process include equip- 6.3 If it becomes necessary to handle or touch parts, clean

ment normally used in the chemical processing of aluminum

white gloves should be used and contact should be limited to

alloys, with the following special provisions: surfaces not to be adhesively bonded.

5.5.1 Racks and frames that are electrically anodic shall be

6.4 If parts become contaminated, either prior to or subse-

constructed of materials that will not cause corrosive reactions

quent to anodizing, corrective action shall be accomplished by

with the suspension wires or clips, or the parts, during the

reprocessing, beginning with alkaline cleaning.

entire process. “Picture-frame”-type racks have performed

6.5 To ensure solution homogeneity, agitate immediately

satisfactorily.

prior to process use and after every addition of water or

5.5.2 Parts shall be attached to racks or frames with con-

chemicals. (Warning—Solutions used in this process are

ductive material that anodizes, that is, aluminum or titanium in

corrosive and toxic. Avoid breathing solution mists or vapors.

the form of wire, hooks, springs, clips, etc.

Do not allow solutions to get on the eyes, on the skin, or on

5.5.3 The phosphoric acid anodizing tank lining shall be of

clothing.)

such material that interaction between the solutions, parts,

6.5.1 Consult Industrial Hygiene for safety precautions.

frames, racks, or clips and hangers does not interfere with the

anodic process and is suitable for use as a cathode. Tanks

6.6 Control the time interval between withdrawal from

should be equipped with a surface skimming device to remove

processing solutions and rinsing so that there is no drying of

surface contamination, a filtering system, and an agitation

the solution on the details.

system for mixing the tank contents.

6.7 Parts must be water-break-free following rinsing after

5.5.4 Terminals for electrical current shall be designed and

alkaline cleaning, after deoxidizing, and after anodizing.

positioned such that parts cannot be “burned.”

5.5.5 The electrical system used during a single-rack anodic

7. Procedure

process shall be adequate for producing 10-V dc and maintain-

ing any set voltage within 61-V dc. 7.1 Perform the surface preparation process in a continuous

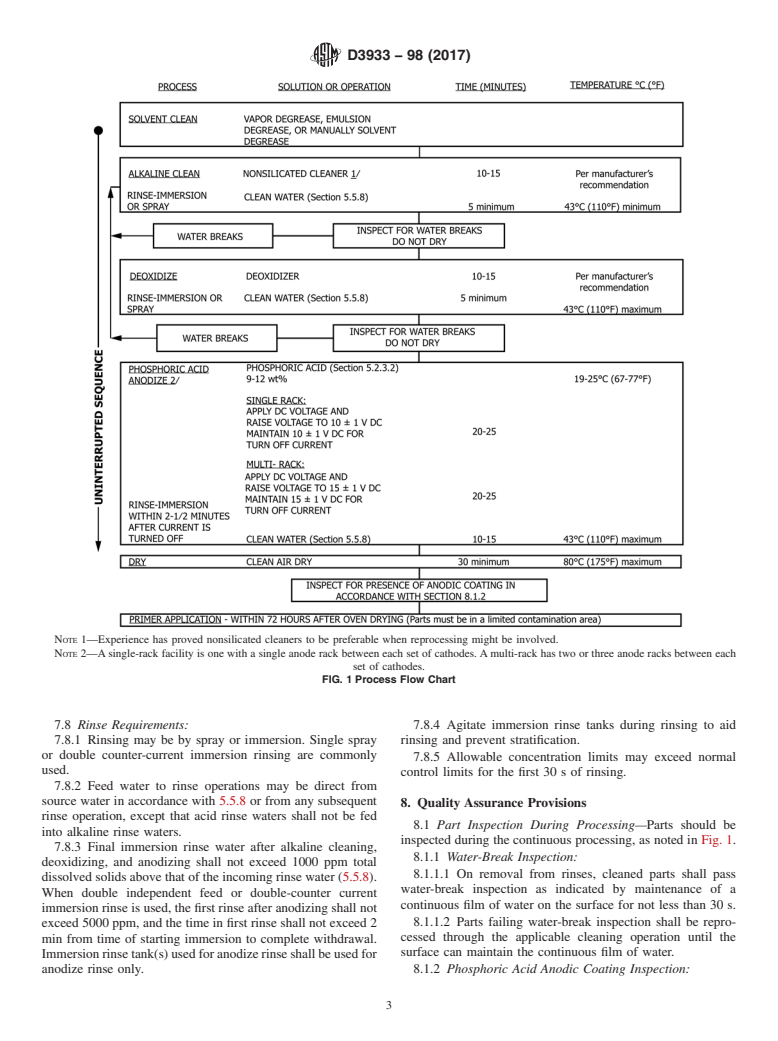

operation as detailed in the flow chart, Fig. 1.

5.5.6 The electrical system used during a multiple-rack

process shall be adequate for producing 15-V dc and maintain-

7.2 Complete all fabrication processes, inspections, prefit,

ing any set voltage within 61-V dc.

etc. before the start of the preparation cycle.

5.5.7 Rinse tanks should be placed adjacent to processing

7.3 Complete all “hand work” before solvent cleaning.

tanks in such a manner that parts can be easily and quickly

moved from one solution to another so that the parts will not

7.4 Once racked for alkaline cleaning, parts shall not be

become dry during successive steps of the process.

touched by anything except the applicable processing solution

5.5.8 Incoming solution makeup water and rinse water shall

and rinse waters, until the parts are dried after primer applica-

contain not more than the “recommended upper limit” for

tion (5.2).

fluoride and not more than the “highest desirable level” of

7.5 The “wet” processing steps, from alkaline cleaning

dissolved chemicals based on American Chemical Society

through drying after phosphoric acid anodizing, should be

standards for deionized or distilled water, or both (1.7 ppm

performed in one continuous uninterrupted sequence of

fluoride, 500 ppm total dissolved solids, etc.) except that:

processes, with the parts not drying at any time until the oven

5.5.8.1 Chloride shall not exceed 25 ppm.

drying after the rinse following phosphoric acid anodizing.

5.5.8.2 pH shall be between 5.5 and 8.0.

7.5.1 Should the parts become delayed prior to anodizing

NOTE 1—Most regionally distributed potable water will meet these

during this wet processing, hold the parts in the applicable

requirements.

rinse tank.

5.5.8.3 If the above requirements cannot be met, the incom- 7.5.2 There shall be no holding of parts in the processing

ing water shall be deionized and maintained within the sequencing after anodizing.

following limits:

7.6 Should the electric current fail or otherwise be inter-

(a) Total dissolved solids shall not exceed 150 ppm.

ruptedduringthephosphoricacidanodizing,anodizingmaybe

(b) pH shall be between 5.5 and 8.0.

continued for an additional 20 to 25 min, if the potential can be

reestablished within 2 min. If the potential cannot be reestab-

6. Manufacturing

lished within 2 min, then rinse and reprocess starting with the

6.1 Partsshallberackedorsuspendedfromframessuchthat deoxidizer.

they all have firm, reliable electrical contact with t

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.