ASTM A830/A830M-06

(Specification)Standard Specification for Plates, Carbon Steel, Structural Quality, Furnished to Chemical Composition Requirements

Standard Specification for Plates, Carbon Steel, Structural Quality, Furnished to Chemical Composition Requirements

ABSTRACT

This specification covers structural quality carbon steel plates in standard and non-standard grades furnished to chemical composition requirements. The materials shall conform to carbon, manganese, phosphorus, sulfur, silicon, and copper contents of its specified grade. Values are also given to specify the range, limit, and maximum chemical compositions of the carbon steel.

SCOPE

1.1 This specification covers structural quality carbon steel plates furnished to chemical composition requirements.

1.2 The plates are available in several standard steel grades and non-standard grades.

1.3 The plates are usually furnished in the as-rolled (hot-rolled) condition.

1.4 Supplementary requirements are provided for additional requirements that may be specified on the order.

1.5 When the steel is to be welded, it is presupposed that a welding procedure suitable for the grade of steel and intended use or service will be utilized. See Appendix X3 of Specification A 6/A 6M for information on weldability.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: A830/A830M – 06

Standard Specification for

Plates, Carbon Steel, Structural Quality, Furnished to

1

Chemical Composition Requirements

This standard is issued under the fixed designationA830/A830M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 3.1.2 Limitation on rimmed or capped steel (see 4.3 and

Supplementary Requirement S97).

1.1 This specification covers structural quality carbon steel

plates furnished to chemical composition requirements.

4. Materials and Manufacture

1.2 The plates are available in several standard steel grades

4.1 Steel specified to a maximum carbon content of 0.39 %

and non-standard grades.

or lower on heat analysis may be made to any deoxidation

1.3 The plates are usually furnished in the as-rolled (hot-

practice unless otherwise specified on the order.

rolled) condition.

4.2 Steel specified to a maximum carbon content of 0.40 %

1.4 Supplementary requirements are provided for additional

or higher on heat analysis shall be killed unless otherwise

requirements that may be specified on the order.

specified on the order.

1.5 When the steel is to be welded, it is presupposed that a

4.3 If rimmed or capped steel is not acceptable, Supplemen-

welding procedure suitable for the grade of steel and intended

tary Requirement S97 shall be specified on the order.

use or service will be utilized. See Appendix X3 of Specifica-

tion A6/A6M for information on weldability.

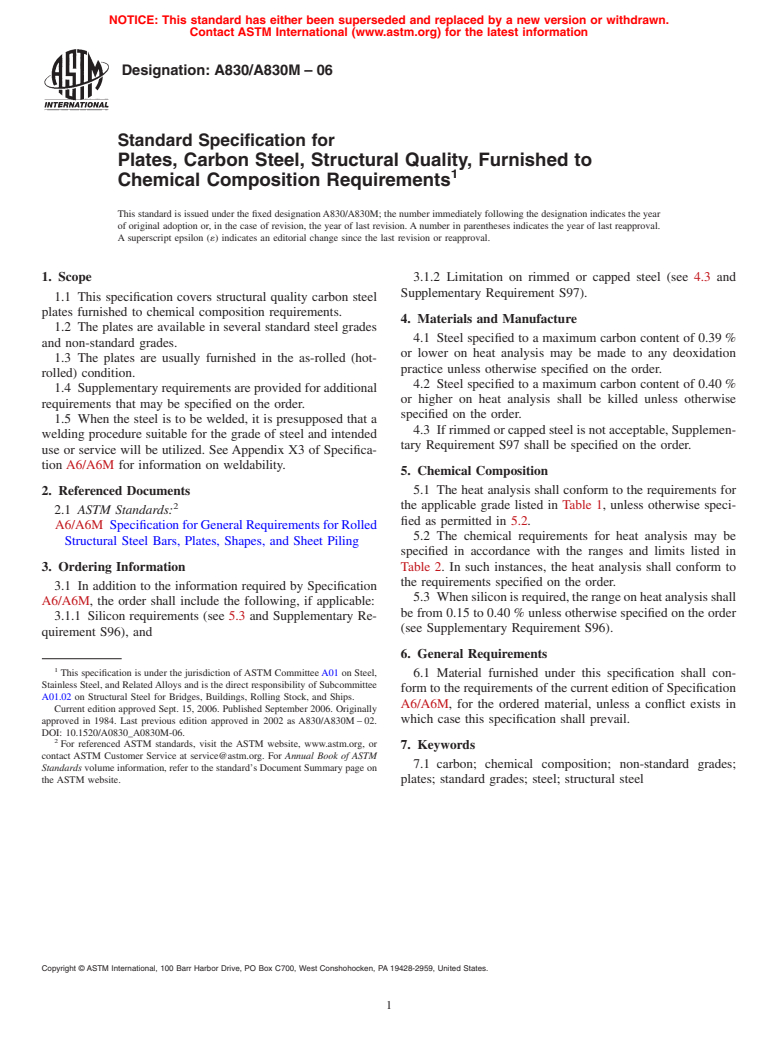

5. Chemical Composition

2. Referenced Documents 5.1 The heat analysis shall conform to the requirements for

2 the applicable grade listed in Table 1, unless otherwise speci-

2.1 ASTM Standards:

fied as permitted in 5.2.

A6/A6M SpecificationforGeneralRequirementsforRolled

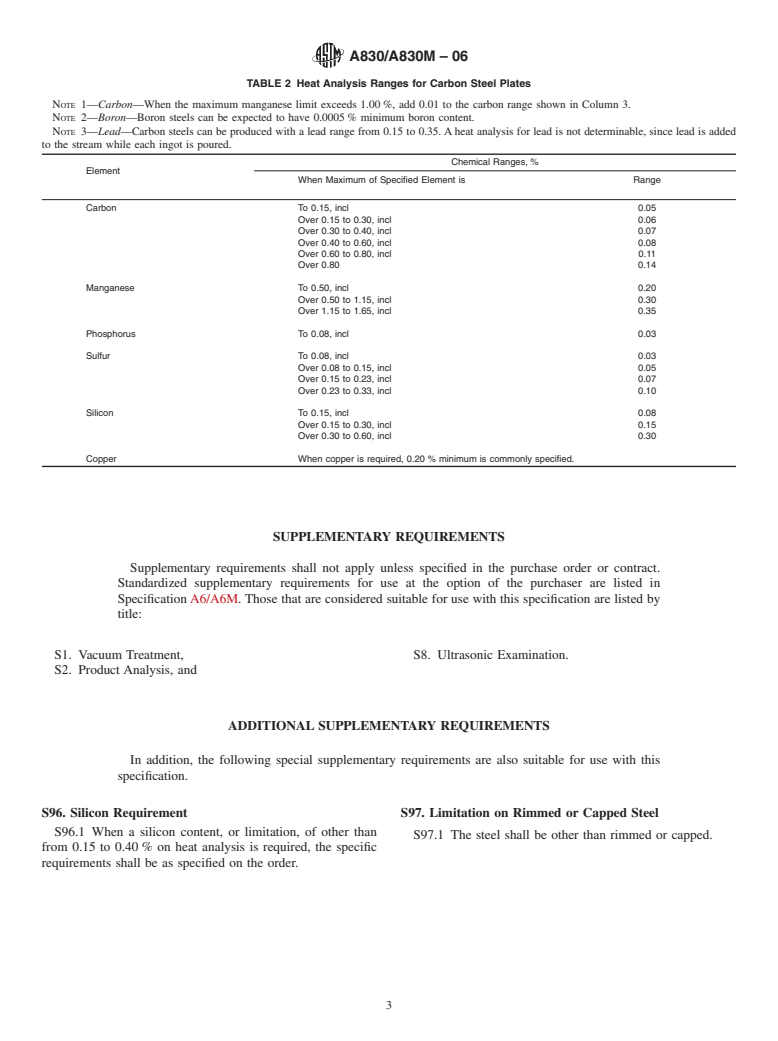

5.2 The chemical requirements for heat analysis may be

Structural Steel Bars, Plates, Shapes, and Sheet Piling

specified in accordance with the ranges and limits listed in

3. Ordering Information Table 2. In such instances, the heat analysis shall conform to

the requirements specified on the order.

3.1 In addition to the information required by Specification

5.3 Whensiliconisrequired,therangeonheatanalysisshall

A6/A6M, the order shall include the following, if applicable:

be from 0.15 to 0.40 % unless otherwise specified on the order

3.1.1 Silicon requirements (see 5.3 and Supplementary Re-

(see Supplementary Requirement S96).

quirement S96), and

6. General Requirements

1

This specification is under the jurisdiction of ASTM Committee A01 on Steel,

6.1 Material furnished under this specification shall con-

Stainless Steel, and RelatedAlloys and is the direct responsibility of Subcommittee

form to the requirements of the current edition of Specification

A01.02 on Structural Steel for Bridges, Buildings, Rolling Stock, and Ships.

A6/A6M, for the ordered material, unless a conflict exists in

Current edition approved Sept. 15, 2006. Published September 2006. Originally

which case this specification shall prevail.

approved in 1984. Last previous edition approved in 2002 as A830/A830M – 02.

DOI: 10.1520/A0830_A0830M-06.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

7. Keywords

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

7.1 carbon; chemical composition; non-standard grades;

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. plates; standard grades; steel; structural steel

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

A830/A830M – 06

A

TABLE 1 Carbon Plate Compositions, Standard Steels

Grade Chemical Composition Limits, %

UNS Number Carbon Manganese Phosphorous, max Sulfur, max

G10060 1006 0.08 max 0.45 max 0.035 0.04

G10080 1008 0.10 max 0.50 max 0.035 0.04

G10090 1009 0.15 max 0.60 max 0.035 0.04

G10100 1010 0.08 to 0.13 0.30 to 0.60 0.035 0.04

G10120 1012 0.10 to 0.15 0.30 to 0.60 0.035 0.04

G10150 1015 0.13 to 0.18 0.30 to 0.60 0.035 0.04

G10160 1016 0.13 to 0.18 0.60 to 0.90 0.035 0.04

G10170 1017 0.15 to 0.20 0.30 to 0.60 0.035 0.04

G10180 1018 0.15 to 0.20 0.60 to 0.90 0.035 0.04

G10190 1019 0.15 to 0.20 0.70 to 1.00 0.035 0.04

G10200 1020 0.18 to 0.23 0.30 to 0.60 0.035 0.04

G10210 1021 0.18 to 0.23 0.60 to 0.90 0.035 0.04

G10220 1022 0.18 to 0.23 0.70 to 1.00 0.035 0.04

G10230 1023 0.20 to 0.25 0.30 to 0.60 0.035 0.04

G10250 1025 0.22 to 0.28 0.30 to 0.60 0.035 0.04

G10260 1026 0.22 to 0.28 0.60 to 0.90 0.035 0.04

G10300 1030 0.28 to 0.34 0.60 to 0.90 0.035 0.04

G10330 1033 0.30 to 0.36 0.70 to 1.00 0.035 0.04

G10350 10

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.