ASTM C860-15(2019)

(Test Method)Standard Test Method for Determining the Consistency of Refractory Castable Using the Ball-In-Hand Test

Standard Test Method for Determining the Consistency of Refractory Castable Using the Ball-In-Hand Test

SIGNIFICANCE AND USE

3.1 This test method is used to determine if a freshly mixed refractory castable is of the proper consistency to provide optimum performance. There are times when the manufacturer’s specified water content and consistency will purposely not lead to the correct ball in hand but should be used to provide optimum performance. Contact the manufacturer when in doubt. This test method can also be used to estimate the correct water addition rate of a castable when either the manufacturer's specified water content is not available or when unique circumstances have rendered that recommendation unusable.

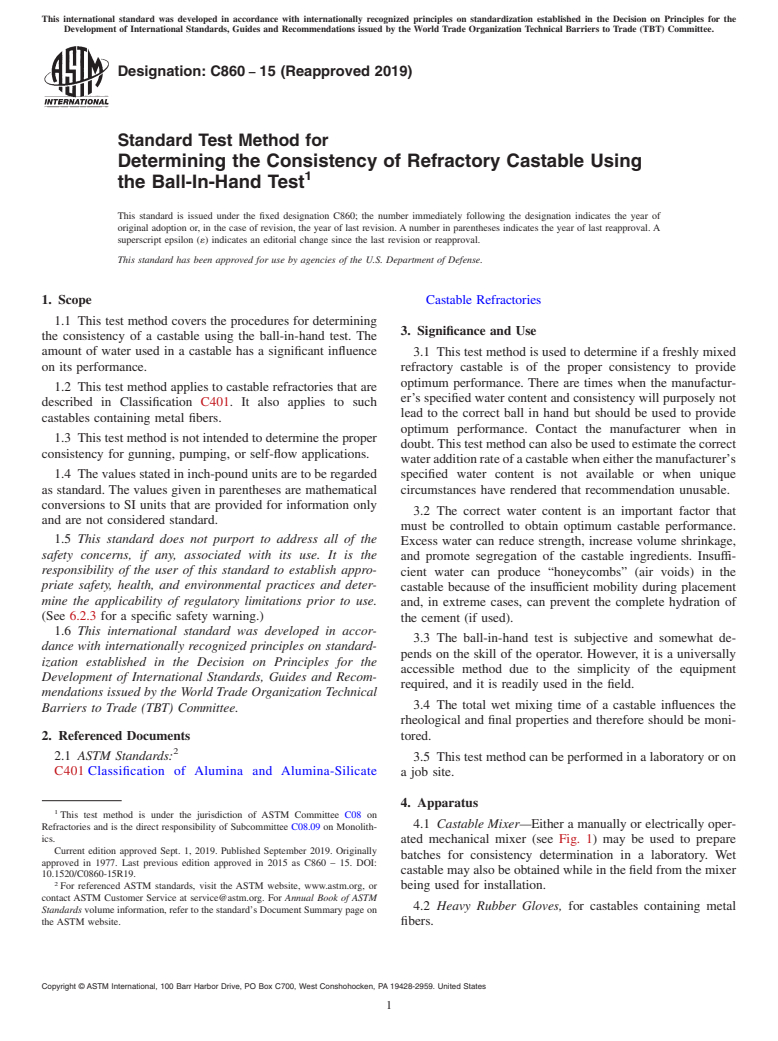

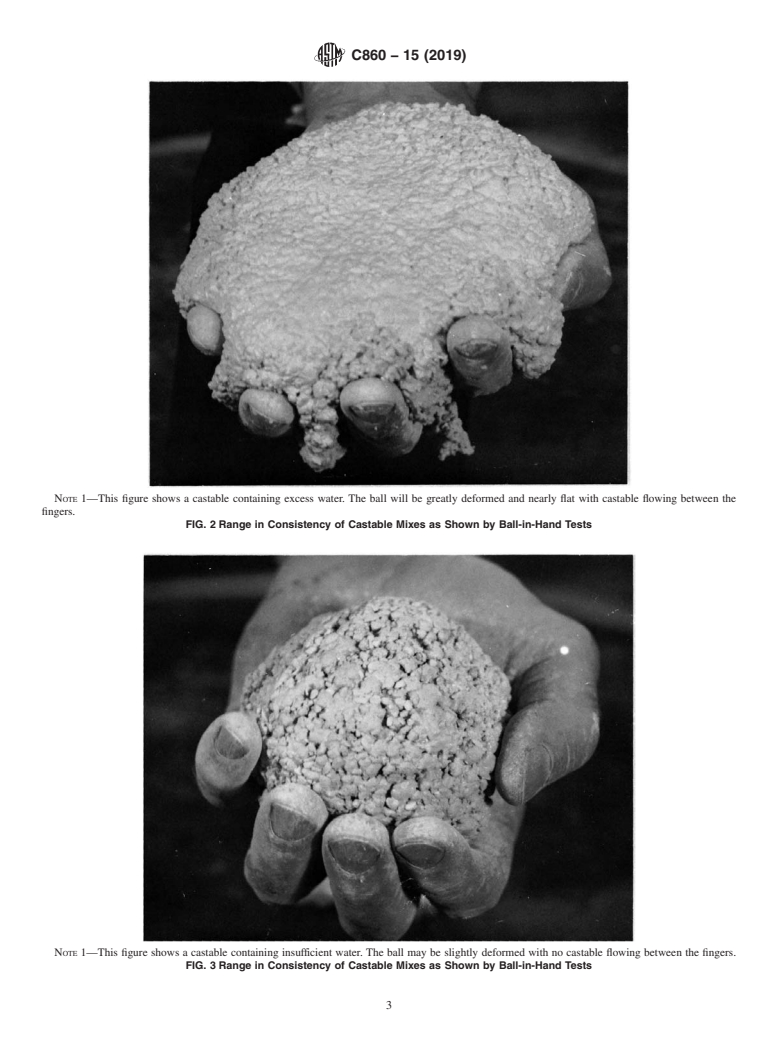

3.2 The correct water content is an important factor that must be controlled to obtain optimum castable performance. Excess water can reduce strength, increase volume shrinkage, and promote segregation of the castable ingredients. Insufficient water can produce “honeycombs” (air voids) in the castable because of the insufficient mobility during placement and, in extreme cases, can prevent the complete hydration of the cement (if used).

3.3 The ball-in-hand test is subjective and somewhat depends on the skill of the operator. However, it is a universally accessible method due to the simplicity of the equipment required, and it is readily used in the field.

3.4 The total wet mixing time of a castable influences the rheological and final properties and therefore should be monitored.

3.5 This test method can be performed in a laboratory or on a job site.

SCOPE

1.1 This test method covers the procedures for determining the consistency of a castable using the ball-in-hand test. The amount of water used in a castable has a significant influence on its performance.

1.2 This test method applies to castable refractories that are described in Classification C401. It also applies to such castables containing metal fibers.

1.3 This test method is not intended to determine the proper consistency for gunning, pumping, or self-flow applications.

1.4 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use. (See 6.2.3 for a specific safety warning.)

1.6 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: C860 − 15 (Reapproved 2019)

Standard Test Method for

Determining the Consistency of Refractory Castable Using

the Ball-In-Hand Test

This standard is issued under the fixed designation C860; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope Castable Refractories

1.1 This test method covers the procedures for determining

3. Significance and Use

the consistency of a castable using the ball-in-hand test. The

amount of water used in a castable has a significant influence

3.1 This test method is used to determine if a freshly mixed

on its performance. refractory castable is of the proper consistency to provide

optimum performance. There are times when the manufactur-

1.2 This test method applies to castable refractories that are

er’s specified water content and consistency will purposely not

described in Classification C401. It also applies to such

lead to the correct ball in hand but should be used to provide

castables containing metal fibers.

optimum performance. Contact the manufacturer when in

1.3 This test method is not intended to determine the proper

doubt.This test method can also be used to estimate the correct

consistency for gunning, pumping, or self-flow applications.

wateradditionrateofacastablewheneitherthemanufacturer’s

1.4 The values stated in inch-pound units are to be regarded specified water content is not available or when unique

as standard. The values given in parentheses are mathematical circumstances have rendered that recommendation unusable.

conversions to SI units that are provided for information only

3.2 The correct water content is an important factor that

and are not considered standard.

must be controlled to obtain optimum castable performance.

1.5 This standard does not purport to address all of the

Excess water can reduce strength, increase volume shrinkage,

safety concerns, if any, associated with its use. It is the

and promote segregation of the castable ingredients. Insuffi-

responsibility of the user of this standard to establish appro-

cient water can produce “honeycombs” (air voids) in the

priate safety, health, and environmental practices and deter-

castable because of the insufficient mobility during placement

mine the applicability of regulatory limitations prior to use.

and, in extreme cases, can prevent the complete hydration of

(See 6.2.3 for a specific safety warning.)

the cement (if used).

1.6 This international standard was developed in accor-

3.3 The ball-in-hand test is subjective and somewhat de-

dance with internationally recognized principles on standard-

pends on the skill of the operator. However, it is a universally

ization established in the Decision on Principles for the

accessible method due to the simplicity of the equipment

Development of International Standards, Guides and Recom-

required, and it is readily used in the field.

mendations issued by the World Trade Organization Technical

3.4 The total wet mixing time of a castable influences the

Barriers to Trade (TBT) Committee.

rheological and final properties and therefore should be moni-

2. Referenced Documents tored.

2.1 ASTM Standards:

3.5 This test method can be performed in a laboratory or on

C401 Classification of Alumina and Alumina-Silicate a job site.

4. Apparatus

This test method is under the jurisdiction of ASTM Committee C08 on

4.1 Castable Mixer—Either a manually or electrically oper-

Refractories and is the direct responsibility of Subcommittee C08.09 on Monolith-

ics.

ated mechanical mixer (see Fig. 1) may be used to prepare

Current edition approved Sept. 1, 2019. Published September 2019. Originally

batches for consistency determination in a laboratory. Wet

approved in 1977. Last previous edition approved in 2015 as C860 – 15. DOI:

castable may also be obtained while in the field from the mixer

10.1520/C0860-15R19.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or being used for installation.

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

4.2 Heavy Rubber Gloves, for castables containing metal

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. fibers.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

C860 − 15 (2019)

wet-out has occurred. Follow the manufacturer’s recommen-

dations for minimum mixing time.

6.1.3.1 The moisture content of lightweight, porous aggre-

gates can affect the water demand of a castable. Dry aggregates

can change the consistency of a castable after mixing is

completed by absorbing the mixing water into its pores. This

can cause premature stiffening and poor consolidation of the

castable.

6.1.4 The total mixing time, including

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.