ASTM D3539-87(1996)

(Test Method)Standard Test Methods for Evaporation Rates of Volatile Liquids by Shell Thin-Film Evaporometer

Standard Test Methods for Evaporation Rates of Volatile Liquids by Shell Thin-Film Evaporometer

SCOPE

1.1 These test methods cover the determination of the rate of evaporation of volatile liquids of low viscosity using the Shell Thin-Film Evaporometer. The test methods have been applied to a wide range of volatile liquids, including paint, varnish, and lacquer solvents and thinners to various hydrocarbons and to insecticide spray-base oils.

1.2 The test methods for the determination of evaporation rate using the thin-film evaporometer are: Sections Method A 2.3 ---Manual Recording 5 to 11 Method B---Automatic Recording 12 to 17

1.3 The test methods are limited only by the viscosity of the volatile liquid which must be sufficiently low to permit the dispensing of an accurately measured specimen from a syringe.

1.4 This standard does not purport to address all of the safety problems, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. Specific hazard statements are given in Notes 1 and 2.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D 3539 – 87 (Reapproved 1996)

Standard Test Methods for

Evaporation Rates of Volatile Liquids by Shell Thin-Film

Evaporometer

This standard is issued under the fixed designation D 3539; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope 3. Summary of Test Methods

1.1 These test methods cover the determination of the rate 3.1 A known volume of liquid is spread on a known area of

of evaporation of volatile liquids of low viscosity using the filter paper that is suspended from a sensitive balance in a

Shell thin-film evaporometer. These test methods have been cabinet. Dried air or nitrogen at 25°C is passed through the

applied to a wide range of volatile liquids, including paint, cabinet at a known rate. The loss of weight of the filter

varnish, and lacquer solvents and thinners to various hydrocar- paper/liquid is determined and plotted against time.

bons and to insecticide spray-base oils.

4. Significance and Use

1.2 The test methods for the determination of evaporation

4.1 The rate of evaporation of volatile liquids from a

rate using the thin-film evaporometer are:

solution or dispersion is important because it affects the rate of

Sections

2,3

Test Method A —Manual Recording 5-11

deposition of a film and flow during deposition, and thereby

Test Method B—Automatic Recording 12-17

controls the structure and appearance of the film. In the

1.3 These test methods are limited only by the viscosity of formulation of paints and related products, solvents are chosen

the volatile liquid which must be sufficiently low to permit the based on the evaporation characteristics appropriate to the

dispensing of an accurately measured specimen from a syringe. application technique and the curing temperature.

1.4 This standard does not purport to address all of the

TEST METHOD A—EVAPORATION RATE USING

safety concerns, if any, associated with its use. It is the

THE MANUAL THIN-FILM EVAPOROMETER

responsibility of the user of this standard to establish appro-

priate safety and health practices and determine the applica-

5. Apparatus

bility of regulatory limitations prior to use. Specific hazard

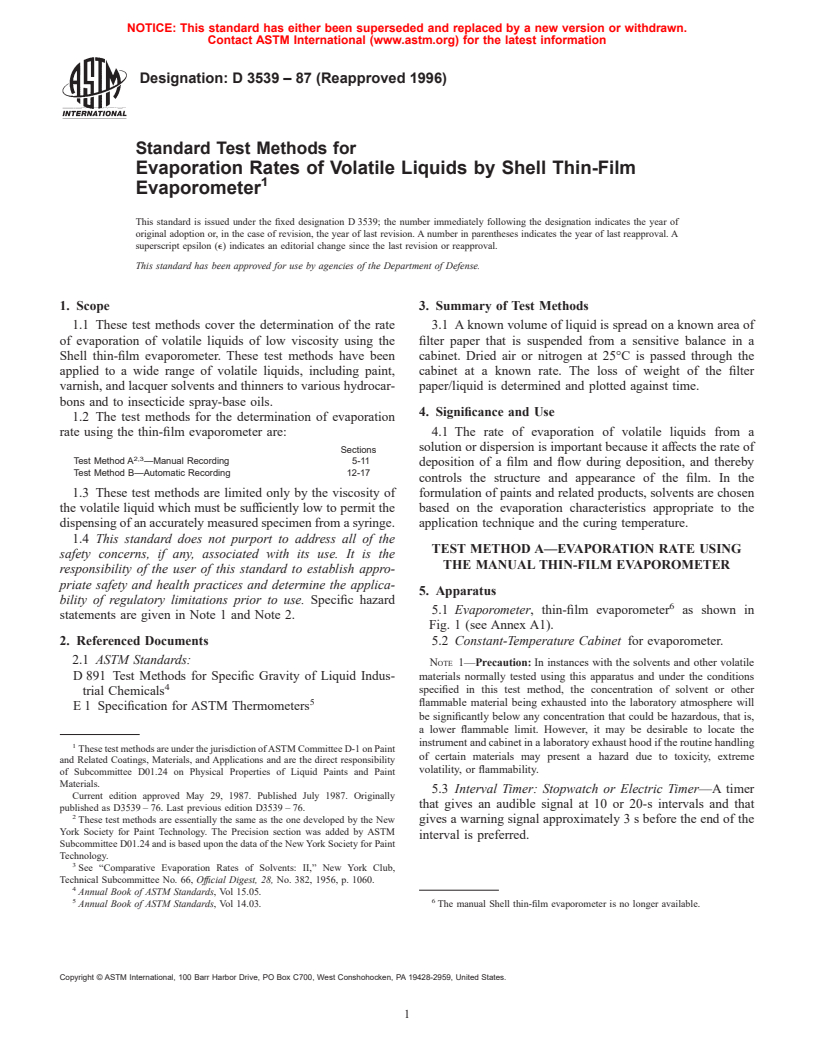

5.1 Evaporometer, thin-film evaporometer as shown in

statements are given in Note 1 and Note 2.

Fig. 1 (see Annex A1).

2. Referenced Documents 5.2 Constant-Temperature Cabinet for evaporometer.

2.1 ASTM Standards:

NOTE 1—Precaution: In instances with the solvents and other volatile

D 891 Test Methods for Specific Gravity of Liquid Indus- materials normally tested using this apparatus and under the conditions

specified in this test method, the concentration of solvent or other

trial Chemicals

flammable material being exhausted into the laboratory atmosphere will

E 1 Specification for ASTM Thermometers

be significantly below any concentration that could be hazardous, that is,

a lower flammable limit. However, it may be desirable to locate the

instrument and cabinet in a laboratory exhaust hood if the routine handling

These test methods are under the jurisdiction of ASTM Committee D-1 on Paint

of certain materials may present a hazard due to toxicity, extreme

and Related Coatings, Materials, and Applications and are the direct responsibility

volatility, or flammability.

of Subcommittee D01.24 on Physical Properties of Liquid Paints and Paint

Materials.

5.3 Interval Timer: Stopwatch or Electric Timer—A timer

Current edition approved May 29, 1987. Published July 1987. Originally

that gives an audible signal at 10 or 20-s intervals and that

published as D3539 – 76. Last previous edition D3539 – 76.

These test methods are essentially the same as the one developed by the New gives a warning signal approximately 3 s before the end of the

York Society for Paint Technology. The Precision section was added by ASTM

interval is preferred.

Subcommittee D01.24 and is based upon the data of the New York Society for Paint

Technology.

See “Comparative Evaporation Rates of Solvents: II,” New York Club,

Technical Subcommittee No. 66, Offıcial Digest, 28, No. 382, 1956, p. 1060.

Annual Book of ASTM Standards, Vol 15.05.

5 6

Annual Book of ASTM Standards, Vol 14.03. The manual Shell thin-film evaporometer is no longer available.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D 3539

5.7 Hygrometer (or other humidity-sensing device), capable

of indicating low humidities.

5.8 Thermometers, of suitable accuracy such as ASTM

Bomb Calorimeter thermometer 56C having a range from 19 to

35°C, subdivisions 0.02°C or Thermometer 56F (66 to 95°F

with 0.05°F subdivisions), and conforming to the requirements

of Specification E 1.

6. Preparation of Evaporometer

6.1 Place the filter paper disk on the wire support, threading

the hook through a small hole in the center of the paper. Attach

the hook to the steel spring below the sighting disk and allow

the paper and the paper support to hang therefrom.

6.2 Close the evaporometer and cabinet doors and allow the

temperature in both chambers and the humidity to equilibrate at

the following test conditions:

FIG. 1 Details of the Thin-Film Evaporometer

Cabinet and evaporation temperature: 77 6 0.5°F (25 6 0.25°C)

Evaporometer humidity: 0 to 5 % relative humidity

5.4 Filter Paper Disk—Fast, open-textured filter paper, 90 Approximately 2 h are required for the humidity to drop to

mm in diameter, with a circle approximately 60 mm in less than 5 %.

diameter (and concentric with the edge) lightly drawn on the

6.3 Adjust the air flow to 21 L/min (center of ball float

paper with a pencil.

opposite correct mark on the rotometer scale).

5.5 Syringe—A 1.00-mL hypodermic syringe equipped with

a 225-mm needle of 1.3-mm outside diameter stainless steel

7. Conditioning

tubing. Due to manufacturing variations, the syringe should be

7.1 Bring the sample or a portion of it to an equilibrium

calibrated before use.

temperature of 77 6 1.0°F (25 6 0.5°C) in a constant-

5.6 Dehumidification Equipment—A suggested setup is

temperature bath. Determine the specific gravity of the sample

given in a schematic diagram, Fig. 2.

at this temperature in accordance with Test Methods D 891.

NOTE 2—Precaution: Use of this dehumidification apparatus requires

the safety practices relative to the handling, use, and disposal of hazardous

8. Procedure

acids and caustics be observed. When handling these materials, protective

8.1 Record the position of the filter paper as indicated by

eye or face shields, or both, and protective clothing are recommended.

NOTE 3—In those instances where dry nitrogen is available it may be alignment of the sighting disk with its mirror image. This is the

used directly instead of air and thus eliminate the dehumidification

no-load position.

equipment. The use of nitrogen does not alter the evaporation rate.

8.2 Raise the wire mesh bracket until the bottom of the disk

support rests lightly on it.

8.3 Withdraw into the syringe 0.70 mL of the solvent which

is at 77 6 1.0°F (25 6 0.5°C). Make certain that all air bubbles

Syringe: Becton, Dickinson and Co., No. 1YT available from Fisher Scientific

Co. Needle: Special Syringe Needle Type LNR, 18-gage, 9-in. long blunt round end, are expelled from the syringe and the needle before application

no bevel available on special order from Becton, Dickinson and Co. through Fisher

of the specimen to the filter paper.

Scientific Co., 711 Forbes Ave., Pittsburgh, PA 15239.

NOTE 1—One-litre flasks should be used throughout.

FIG. 2 Diagram of Dehumidification Apparatus

D 3539

8.4 Insert the hypodermic needle into the small opening on 10. Report

the right-hand side of the instrument and position the needle tip

10.1 Report the elapsed time in seconds at 10 weight %

so that it almost touches the disk and is just over the line that

intervals through 90 % and for 95 and 100 % evaporation, and

was drawn.

the relative evaporation rate (n-butyl acetate 5 1.0). Relative

8.5 Start applying the solvent to the disk. As the first drop

evaporation rate is calculated from the 90 weight % evaporated

hits the disk, start the timer. The solvent should be applied at a

times for the test solvent and for n-butyl acetate (99 % ester).

uniform rate in 62 s and as evenly as possible along the drawn

line. To ensure consistent specimen size, touch the tip of the

11. Precision

hypodermic needle to the filter paper to dispense the last drop

11.1 On the basis of an interlaboratory study of the test

of solvent.

method in which operators in six laboratories determined the

8.6 Immediately lower the wire mesh bracket away from the

90 % evaporation point of six solvents covering a broad range

disk support. Obtain the first reading of the position of the

in evaporation rate, the between-laboratories coeffi-cient of

sighting disk at 40 s and then every 20 s. Record the time and

variation was found to be 6.3 %relative at 24 df after discard-

the scale reading on the report form. A sample report form is

ing two divergent values. On the basis of the results obtained

shown in Annex A2.

by three laboratories on three of the solvents having 90 %

NOTE 4—With very slow evaporating solvents, it is not necessary to evaporated times of 200 to 600 s, the within-laboratory

take readings as often as every 20 s. The operator can determine a suitable

coefficient of variation was found to be 0.83 % relative at 18 df.

time interval after the first 200 s.

Based on these coefficients, the following criteria should be

used for judging the acceptability of results at the 95 %

8.7 Stop the timer when the sighting disk has returned to the

confidence level:

original unloaded position.

11.1.1 Repeatability—For solvents with 90 % evaporation

NOTE 5—The filter paper may be reused provided the solvent leaves no

times of 200 to 600 s, two results, each the mean of two

appreciable residue in evaporating.

determinations, obtained by the same operator on different

days should be considered suspect if they differ by more than

9. Calculation

2.5 %.

9.1 Calculate the evaporation rate as follows:

11.1.2 Reproducibility—Two results, each the mean of two

C

determinations, obtained by operators in different laboratories

ER 5 3 100~B 2 Z! (1)

S

should be considered suspect if they differ by more than

18.2 %.

where:

S 5 V 3 D and Z 5 N −(S/C)

TEST METHOD B—EVAPORATION RATE USING

ER 5 evaporation rate, wt %,

THIN-FILM EVAPOROMETER, AUTOMATIC

C 5 spring constant, g/cm elongation,

RECORDING

S 5 specimen weight,

V 5 0.70-mL aliquot volatile liquid at 77 6 1.0°F (25 6

12. Apparatus

0.5°C),

D 5 density of volatile liquid at 77 6 1.0°F (25 6 0.5°C)

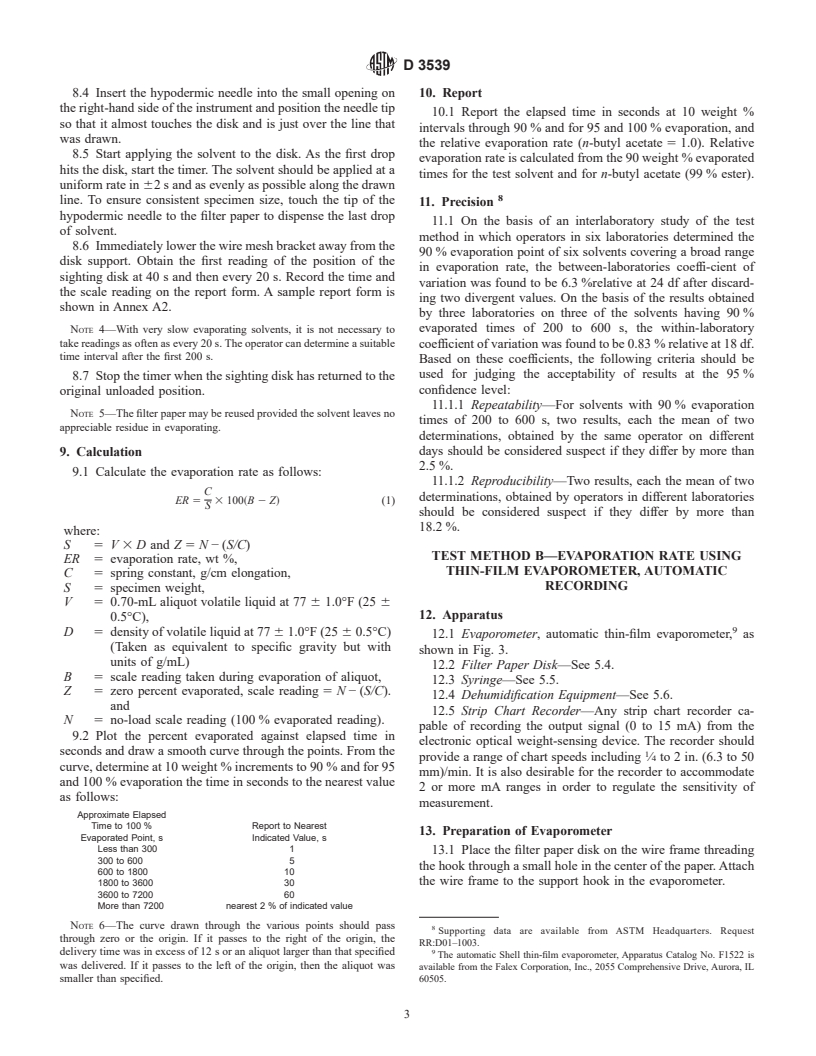

12.1 Evaporometer, automatic thin-film evaporometer, as

(Taken as equivalent to specific gravity but with

shown in Fig. 3.

units of g/mL)

12.2 Filter Paper Disk—See 5.4.

B 5 scale reading taken during evaporation of aliquot,

12.3 Syringe—See 5.5.

Z 5 zero percent evaporated, scale reading 5 N−(S/C).

12.4 Dehumidification Equipment—See 5.6.

and

12.5 Strip Chart Recorder—Any strip chart recorder ca-

N 5 no-load scale reading (100 % evaporated reading).

pable of recording the output signal (0 to 15 mA) from the

9.2 Plot the percent evaporated against elapsed time in

electronic optical weight-sensing device. The recorder should

seconds and draw a smooth curve through the points. From the

provide a range of chart speeds including ⁄4 to 2 in. (6.3 to 50

curve, determine at 10 weight % increments to 90 % and for 95

mm)/min. It is also desirable for the recorder to accommodate

and 100 % evaporation the time in seconds to the nearest value

2 or more mA ranges in order to regulate the sensitivity of

as follows:

measurement.

Approximate Elapsed

Time to 100 % Report to Nearest

13. Preparation of Evaporometer

Evaporated Point, s Indicated Value, s

Less than 300 1

13.1 Place the filter paper disk on the wire frame threading

300 to 600 5

the hook through a small hole in the center of the paper. Attach

600 to 1800 10

the wire frame to the support hook in the evaporometer.

1800 to 3600 30

3600 to 7200 60

More than 7200 nearest 2 % of indicated value

NOTE 6—The curve drawn through the various points should pass

Supporting data are available from ASTM Headquarters. Request

through zero or the origin. If it passes to the right of the origin, the

RR:D01–1003.

delivery time was in excess of 12 s or an aliquot larger than that specified

The automatic Shell thin-film evaporometer, Apparatus Catalog No. F1522 is

was delivered. If it passes to the left of the origin, then the aliquot was

available from the Falex Corporation, Inc., 2055 Comprehensive Drive, Aurora, IL

smaller than specified. 60505.

D 3539

FIG. 3 Automatic Thin-Film Evaporometer

13.2 Close the evaporometer and cabinet doors and equili- specimen onto the filter paper. The complete specimen should

brate both chambers as in 6.2. be dispensed uniformly in 106 2 s along the line. The recorder

13.3 Adjust the air flow to 21 L/min.

pen will “advance” immediately to an “apex” position equiva-

lent to the total weight of the specimen, less that portion that

14. Conditioning of Sample

evaporated during the application period. The pen will gradu-

14.1 See 7.1.

ally return to its original position as the solvent evaporates and

the chart advances. The evaporation is complete when the

15. Procedure

recording pen has returned to its original “no-load” position.

15.1 When all components (including the filter paper in

NOTE 9—It is common for the final portion of the curve to exhibit a

place) are at equilibrium, adjust the recording pen to a

“tailing-off.” This is due to artifacts of the method such as (1) hydrogen

prominent “zero” position near the edge of the chart on the

bonding of the last traces of solvent with the cellulose fibers of the filter

recorder; then turn the switch for the chart motor to the OFF

paper and (2) a gradual diminution of the area of the filter paper wet by

position. This constitutes the “zero” load and time position for

solvent (that is, in the final stage of evaporation, drying of the paper

the test.

progresses from the outer edge toward the center of the disk). Thus, it is

common practice for the evaporation cycle to be considered “complete”

NOTE 7—The milliampere range and chart speed should be selected, if

when the recording pen returns to 99.5 % of the original displacement.

possible, so that the dimensions of the weight and time axes of the plotted

curve are approximately t

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.