ASTM A449-07be1

(Specification)Standard Specification for Hex Cap Screws, Bolts and Studs, Steel, Heat Treated, 120/105/90 ksi Minimum Tensile Strength, General Use

Standard Specification for Hex Cap Screws, Bolts and Studs, Steel, Heat Treated, 120/105/90 ksi Minimum Tensile Strength, General Use

ABSTRACT

This specification2 covers quenched and tempered steel hex cap screws, bolts, and studs having a minimum tensile strength. The fasteners are intended for general engineering use. Type 1 fasteners shall be plain carbon steel, carbon boron steel, alloy steel, or alloy boron steels conforming to the requirements. Type 3 fasteners shall be weathering steel and shall conform to one of the chemical compositions specified. Tensile strength, proof load, hardness tests, and axial tension tests shall be performed to conform with the specified requirements.

SCOPE

1.1 This specification covers quenched and tempered steel hex cap screws, bolts, and studs having a minimum tensile strength of 120 ksi for diameters 1.0 in. and smaller; 105 ksi for diameters over 1.0 in. to 1½ in.; and 90 ksi for diameters 1¾ in. to 3.0 in. inclusive. The term "fasteners" in this specification denotes hex cap screws, bolts, and studs.

1.2 The fasteners are intended for general engineering use.

1.3 The fasteners are furnished in diameters ¼ to 3.0 in. inclusive. They are designated by type denoting chemical composition as follows:

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

´1

Designation: A449 – 07b

Standard Specification for

Hex Cap Screws, Bolts and Studs, Steel, Heat Treated, 120/

1

105/90 ksi Minimum Tensile Strength, General Use

This standard is issued under the fixed designation A449; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1

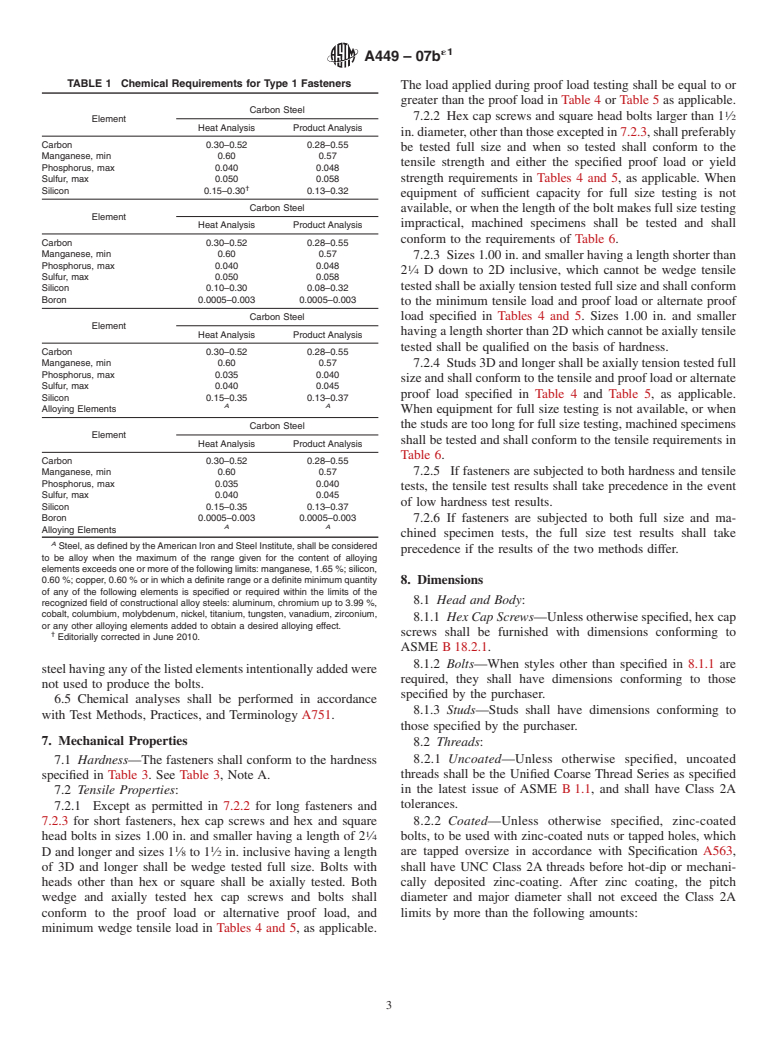

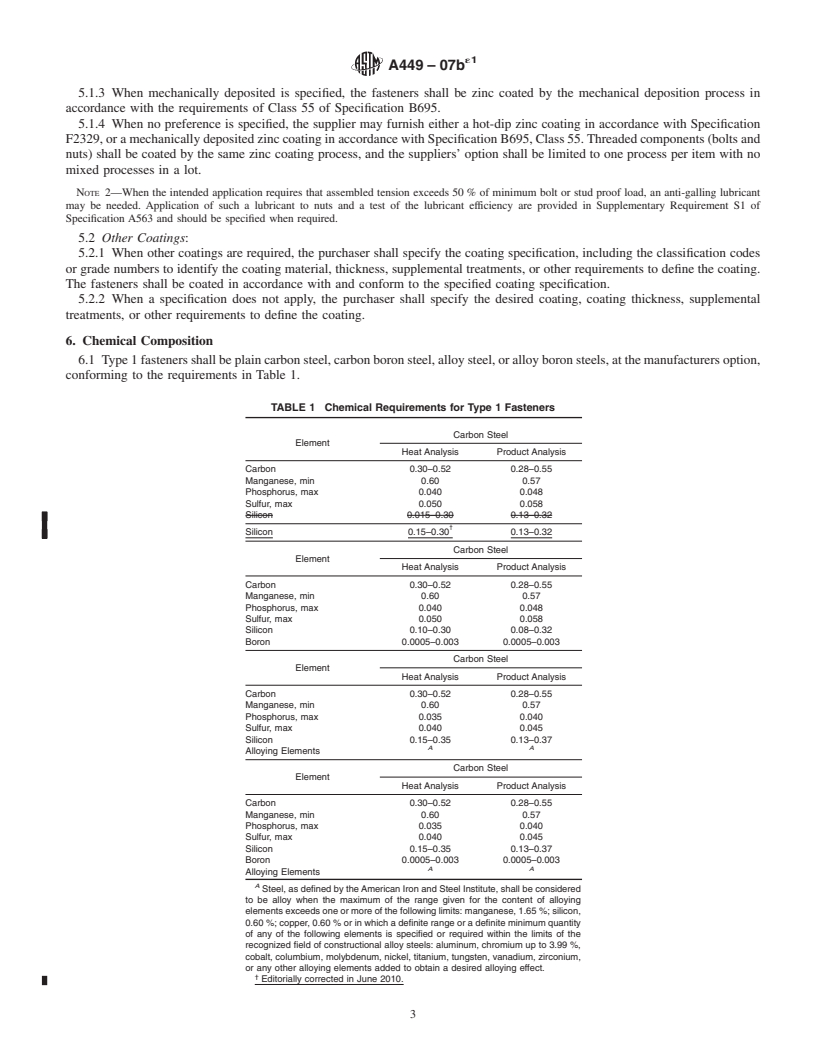

´ NOTE—Table 1 was editorially revised in June 2010.

1. Scope* 2. Referenced Documents

2 3

1.1 This specification covers quenched and tempered steel 2.1 ASTM Standards:

hex cap screws, bolts, and studs having a minimum tensile A563 Specification for Carbon and Alloy Steel Nuts

strengthof120ksifordiameters1.0in.andsmaller;105ksifor A751 Test Methods, Practices, andTerminology for Chemi-

1 3

diameters over 1.0 in. to 1 ⁄2 in.; and 90 ksi for diameters 1 ⁄4 cal Analysis of Steel Products

in. to 3.0 in. inclusive.The term 9fasteners9 in this specification B695 Specification for Coatings of Zinc Mechanically De-

denotes hex cap screws, bolts, and studs. posited on Iron and Steel

1.2 The fasteners are intended for general engineering use. D3951 Practice for Commercial Packaging

1

1.3 The fasteners are furnished in diameters ⁄4 to 3.0 in. F436 Specification for Hardened Steel Washers

inclusive. They are designated by type denoting chemical F606 Test Methods for Determining the Mechanical Prop-

composition as follows: erties of Externally and Internally Threaded Fasteners,

Washers, Direct Tension Indicators, and Rivets

Type Description

F788/F788M Specification for Surface Discontinuities of

Type I Plain carbon steel, carbon boron steel, alloy

Bolts, Screws, and Studs, Inch and Metric Series

steel, or alloy boron steel

Type 2 Withdrawn 2003 F1470 Practice for Fastener Sampling for Specified Me-

Type 3 Weathering steel

chanical Properties and Performance Inspection

F1789 Terminology for F16 Mechanical Fasteners

1.4 Terms used in this specification are defined in Termi-

F2329 Specification for Zinc Coating, Hot-Dip, Require-

nology F1789 unless otherwise defined in this specification.

ments for Application to Carbon and Alloy Steel Bolts,

1.5 The values stated in inch-pound units are to be regarded

Screws, Washers, Nuts, and Special Threaded Fasteners

as the standard. The values given in parentheses are provided

G101 Guide for Estimating the Atmospheric Corrosion

for information purposes only.

Resistance of Low-Alloy Steels

4

1.6 This standard does not purport to address all of the

2.2 ASME Standards:

safety concerns, if any, associated with its use. It is the

B 1.1 Unified Screw Threads

responsibility of the user of this standard to establish appro-

B 18.2.1 Square and Hex Bolts and Screws

priate safety and health practices and determine the applica-

B 18.24 Part Identifying Number (PIN) Code System Stan-

bility of regulatory limitations prior to use.

dard for B18 Fastener Products

1

This specification is under the jurisdiction of ASTM Committee F16 on

3

Fasteners and is the direct responsibility of Subcommittee F16.02 on Steel Bolts, For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Nuts, Rivets and Washers. contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Current edition approved Dec. 1, 2007. Published January 2008. Originally Standards volume information, refer to the standard’s Document Summary page on

approved in 1963. Last previous edition approved in 2007 as A449 – 07a. DOI: the ASTM website.

4

10.1520/A0449-07B. Available from American Society of Mechanical Engineers (ASME), ASME

2

For ASME Boiler and Pressure Vessel Code applications see related Specifi- International Headquarters, Three Park Ave., New York, NY 10016-5990, http://

cations SA-449 in Section II of that Code. www.asme.org.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

´1

A449 – 07b

3. Ordering Information 4.2 Threading—Threads shall be rolled, cut, or ground.

4.3 Secondary Processing—If any processing which can

3.1 Orders for fasteners under this specification shall in-

affect the mechanical properties of the fasteners is performed

clude the following:

after the initial testing, the fasteners shall be retested for all

3.1.1 Quantity (number of pieces),

specified mechanical properties affected by the reprocessing.

3.1.2 Size, including nominal diameter and length,

3.1.3 Name of product,

5. Protective Coatings

3.1.4 Type, that is, Type 1, or Type 3 as required,

3.1.

...

This document is not anASTM standard and is intended only to provide the user of anASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

´1

Designation:A449–07b Designation: A449 – 07b

Standard Specification for

Hex Cap Screws, Bolts and Studs, Steel, Heat Treated, 120/

1

105/90 ksi Minimum Tensile Strength, General Use

This standard is issued under the fixed designation A449; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (ϵ) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1

ϵ NOTE—Table 1 was editorially revised in June 2010.

1. Scope*

2

1.1 This specification covers quenched and tempered steel hex cap screws, bolts, and studs having a minimum tensile strength

1 3

of 120 ksi for diameters 1.0 in. and smaller; 105 ksi for diameters over 1.0 in. to 1 ⁄2 in.; and 90 ksi for diameters 1 ⁄4 in. to 3.0

in. inclusive. The term "fasteners" in this specification denotes hex cap screws, bolts, and studs.

1.2 The fasteners are intended for general engineering use.

1

1.3 The fasteners are furnished in diameters ⁄4 to 3.0 in. inclusive. They are designated by type denoting chemical composition

as follows:

Type Description

Type I Plain carbon steel, carbon boron steel, alloy

steel, or alloy boron steel

Type 2 Withdrawn 2003

Type 3 Weathering steel

1.4 Terms used in this specification are defined in Terminology F1789 unless otherwise defined in this specification.

1.5 The values stated in inch-pound units are to be regarded as the standard. The values given in parentheses are provided for

information purposes only.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

3

2.1 ASTM Standards:

A563 Specification for Carbon and Alloy Steel Nuts

A751 Test Methods, Practices, and Terminology for Chemical Analysis of Steel Products

B695 Specification for Coatings of Zinc Mechanically Deposited on Iron and Steel

D3951 Practice for Commercial Packaging

F436 Specification for Hardened Steel Washers

F606 TestMethodsforDeterminingtheMechanicalPropertiesofExternallyandInternallyThreadedFasteners,Washers,Direct

Tension Indicators, and Rivets

F788/F788M Specification for Surface Discontinuities of Bolts, Screws, and Studs, Inch and Metric Series

F1470 Practice for Fastener Sampling for Specified Mechanical Properties and Performance Inspection

F1789 Terminology for F16 Mechanical Fasteners

F2329 Specification for Zinc Coating, Hot-Dip, Requirements for Application to Carbon and Alloy Steel Bolts, Screws,

Washers, Nuts, and Special Threaded Fasteners

G101 Guide for Estimating the Atmospheric Corrosion Resistance of Low-Alloy Steels

1

This specification is under the jurisdiction of ASTM Committee F16 on Fasteners and is the direct responsibility of Subcommittee F16.02 on Steel Bolts, Nuts, Rivets

and Washers.

Current edition approved Dec. 1, 2007. Published January 2008. Originally approved in 1963. Last previous edition approved in 2007 as A449 – 07a. DOI:

10.1520/A0449-07B.

2

For ASME Boiler and Pressure Vessel Code applications see related Specifications SA-449 in Section II of that Code.

3

For referencedASTM standards, visit theASTM website, www.astm.org, or contactASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

´1

A449 – 07b

4

2.2 ASME Standards:

B 1.1 Unified Screw Threads

B 18.2.1 Square and Hex Bolts and Screws

B 18.24 Part Identifying Number (PIN) Code System Standard for B18 Fastener Products

3. Ordering Information

3.1 Orders for fasteners under this specification shall include the following:

3.1.1 Quantity (number of pieces),

3.1.2 Size, including nominal diameter and length,

3.1.3 Name of product,

3.1.4 Type, that is, Type 1, or Type 3 as required,

3.1.5 ASTM designation and year of issue, and

3.1.6 Other components such as nuts and washers if required.

3.1.7 Hot-Dip or Mechanically Deposited Zinc Coatings—For hot-dip or mechanically deposited zinc coatings cov

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.