ASTM F1675-13(2017)

(Practice)Standard Practice for Life-Cycle Cost Analysis of Plastic Pipe Used for Culverts, Storm Sewers, and Other Buried Conduits

Standard Practice for Life-Cycle Cost Analysis of Plastic Pipe Used for Culverts, Storm Sewers, and Other Buried Conduits

SIGNIFICANCE AND USE

5.1 LCC analysis is an economic method to evaluate alternatives that are characterized by differing cash flows over the designated project design life. The method entails calculating the LCC of each alternative capable of satisfying the functional requirements of the project and comparing them to determine which have the lowest estimated LCC over the project design life.

5.2 The LCC method is particularly suitable for determining whether the higher initial cost of an alternative is economically justified by reductions in future costs (for example, operating maintenance, rehabilitation, or replacement) when compared to an alternative with lower initial costs but higher future costs. If a design alternative has both a lower initial cost and lower future costs than other alternatives, an LCC analysis is not necessary to show the former is the economically preferable choice.

SCOPE

1.1 This practice establishes a procedure for using life cycle cost (LCC) analysis techniques to evaluate alternative drainage system designs, using plastic pipe that satisfy the same functional requirements.

1.2 The LCC technique measures the present value of all relevant costs to install, operate, and maintain alternative drainage systems such as engineering, construction, maintenance, rehabilitation, or replacement over a specified period of time. The practice also accommodates any remaining residual or salvage value.

1.3 The decision maker, using the results of the LCC analysis, can then identify the alternative(s) with the lowest estimated total cost based on the present value of all costs.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: F1675 − 13 (Reapproved 2017)

Standard Practice for

Life-Cycle Cost Analysis of Plastic Pipe Used for Culverts,

1

Storm Sewers, and Other Buried Conduits

This standard is issued under the fixed designation F1675; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* 2.2 ASTM Adjuncts:

4

Discount Factor Tables

1.1 This practice establishes a procedure for using life cycle

cost (LCC) analysis techniques to evaluate alternative drainage

3. Terminology

system designs, using plastic pipe that satisfy the same

3.1 Definitions:

functional requirements.

3.1.1 common costs, n—costs that are common to all alter-

1.2 The LCC technique measures the present value of all

natives in nature and amount, such as initial planning fees or

relevant costs to install, operate, and maintain alternative

future annual inspection costs.

drainage systems such as engineering, construction,

3.1.2 discount rate, n—the investor’s time value of money,

maintenance, rehabilitation, or replacement over a specified

expressed as a percent, used to convert costs occurring at

period of time. The practice also accommodates any remaining

different times, to equivalent costs at a common point in time.

residual or salvage value.

3.1.3 drainage project, n—a project having a definable,

1.3 The decision maker, using the results of the LCC

functional drainage requirement that can be satisfied by two or

analysis, can then identify the alternative(s) with the lowest

more design or construction alternatives, or both.

estimated total cost based on the present value of all costs.

3.1.4 future costs, n—costs required to keep the system

1.4 This standard does not purport to address all of the

operating that are incurred after the project is placed in service,

safety concerns, if any, associated with its use. It is the

such as operation, maintenance, rehabilitation, or replacement

responsibility of the user of this standard to establish appro-

costs.

priate safety and health practices and determine the applica-

3.1.5 inflation, n—the general trend or rising prices that,

bility of regulatory limitations prior to use.

over time, result in the reduction of the purchasing power of

1.5 This international standard was developed in accor-

the dollar from year to year.

dance with internationally recognized principles on standard-

ization established in the Decision on Principles for the

3.1.6 initial cost, n—the total of all costs; such as design

Development of International Standards, Guides and Recom-

costs, material purchase costs, and construction/installation

mendations issued by the World Trade Organization Technical

costs, that are specific to each alternative and are incurred to

Barriers to Trade (TBT) Committee.

bring each alternative to a point of functional readiness.

3.1.7 maintenance cost, n—the annual or periodic costs,

2. Referenced Documents

such as inspection and cleaning to keep a drainage structure

2.1 Other Standards:

functioning for the project design life, but do not extend the

TM-5-802-1 Economic Studies for Military Construction

material service life.

2

Design Applications (12/86)

3.1.8 material service life, n—the number of years of

Federal Office of Management and Budget Guidelines and

service a particular material, system, or structure will provide

Discount Rates for Benefit-Cost Analysis of Federal

before rehabilitation or replacement is necessary.

Programs and state documents for guidelines or require-

3

3.1.9 project design life, n—the planning horizon for the

ments

project,expressedasthenumberofyearsofusefulliferequired

of the drainage structure.

1

This practice is under the jurisdiction of ASTM Committee F17 on Plastic

3.1.10 rehabilitation cost, n—the total of all costs incurred

Piping Systems and is the direct responsibility of Subcommittee F17.62 on Sewer.

to extend the material service life of a specific alternative.

Current edition approved Aug. 1, 2017. Published August 2017. Originally

approved in 1996. Last previous edition approved in 2013 as F1675–13. DOI:

10.1520/F1675-13R17.

2 4

Available from Headquarters, Department of the Army, Washington, DC. Available from ASTM International Headquarters. Order Adjunct No.

3

Available from Office of Management and Budget, Washington, DC. ADJE091703.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

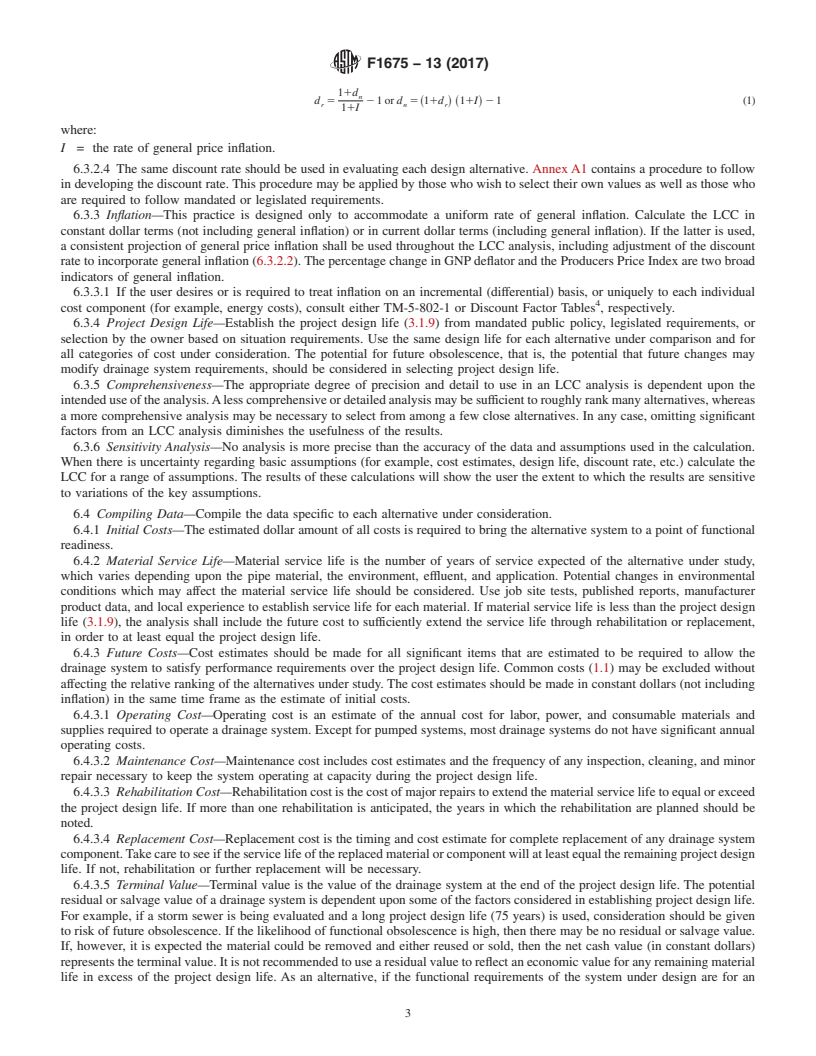

F1675 − 13 (2017)

3.1.11 replacement cost, n—the total of all costs incurred to 6.3.1

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: F1675 − 13 F1675 − 13 (Reapproved 2017)

Standard Practice for

Life-Cycle Cost Analysis of Plastic Pipe Used for Culverts,

1

Storm Sewers, and Other Buried Conduits

This standard is issued under the fixed designation F1675; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope*

1.1 This practice establishes a procedure for using life cycle cost (LCC) analysis techniques to evaluate alternative drainage

system designs, using plastic pipe that satisfy the same functional requirements.

1.2 The LCC technique measures the present value of all relevant costs to install, operate, and maintain alternative drainage

systems such as engineering, construction, maintenance, rehabilitation, or replacement over a specified period of time. The practice

also accommodates any remaining residual or salvage value.

1.3 The decision maker, using the results of the LCC analysis, can then identify the alternative(s) with the lowest estimated total

cost based on the present value of all costs.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2.1 Other Standards:

2

TM-5-802-1 Economic Studies for Military Construction Design Applications (12/86)

Federal Office of Management and Budget Guidelines and Discount Rates for Benefit-Cost Analysis of Federal Programs and

3

state documents for guidelines or requirements

2.2 ASTM Adjuncts:

4

Discount Factor Tables

3. Terminology

3.1 Definitions:

3.1.1 common costs, n—costs that are common to all alternatives in nature and amount, such as initial planning fees or future

annual inspection costs.

3.1.2 discount rate, n—the investor’s time value of money, expressed as a percent, used to convert costs occurring at different

times, to equivalent costs at a common point in time.

3.1.3 drainage project, n—a project having a definable, functional drainage requirement that can be satisfied by two or more

design or construction alternatives, or both.

3.1.4 future costs, n—costs required to keep the system operating that are incurred after the project is placed in service, such

as operation, maintenance, rehabilitation, or replacement costs.

3.1.5 inflation, n—the general trend or rising prices that, over time, result in the reduction of the purchasing power of the dollar

from year to year.

1

This practice is under the jurisdiction of ASTM Committee F17 on Plastic Piping Systems and is the direct responsibility of Subcommittee F17.62 on Sewer.

Current edition approved Aug. 1, 2013Aug. 1, 2017. Published August 2013August 2017. Originally approved in 1996. Last previous edition approved in 20092013 as

F1675–09.F1675–13. DOI: 10.1520/F1675-13.10.1520/F1675-13R17.

2

Available from Headquarters, Department of the Army, Washington, DC.

3

Available from Office of Management and Budget, Washington, DC.

4

Available from ASTM International Headquarters. Order Adjunct No. ADJE091703.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

F1675 − 13 (2017)

3.1.6 initial cost, n—the total of all costs; such as design costs, material purchase costs, and construction/installation costs, that

are specific to each alternative and are incurred to bring each alternative to a point of functional readiness.

3.1.7 maintenance cost, n—the annual or periodic costs, such as inspection and cleaning to keep a drainage structure functioning

for the project design life, but do not extend the material service life.

3.1.8 material service life, n—the number of years of service a particular material, system, or structure will provide before

rehabilitation or replacement is necessary.

3.1.

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.