ASTM D5009-96

(Test Method)Standard Test Method for Evaluating and Comparing Transfer Efficiency of Spray Applied Coatings Under Laboratory Conditions

Standard Test Method for Evaluating and Comparing Transfer Efficiency of Spray Applied Coatings Under Laboratory Conditions

SCOPE

1.1 This test method covers the evaluation and comparison of the transfer efficiency of spray-applied coatings under controlled laboratory conditions.

1.2 This test method has been shown to yield excellent intralaboratory reproducibility. Interlaboratory precision is poorer and is highly dependent on closely controlled air flow in the spray booth, the rate at which the paint is delivered to the part, and other variables suggested in the test method.

1.3 Limitations

1.3.1 This laboratory procedure only indicates the direction of the effect of spray variables on transfer efficiency. The magnitude of the effect is determined only by specific plant experience.

Note 1—This laboratory procedure requires specific equipment and procedures. For those laboratories that do not have access to the type of equipment required a more general laboratory procedure is being prepared as Procedure B.

1.4 The values stated in inch-pound units are to be regarded as the standard. The values given in parentheses are for information only.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. For specific hazard statements, see Section 9 and Note 2 and Note 3.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: D 5009 – 96

AMERICAN SOCIETY FOR TESTING AND MATERIALS

100 Barr Harbor Dr., West Conshohocken, PA 19428

Reprinted from the Annual Book of ASTM Standards. Copyright ASTM

Standard Test Method for

Evaluating and Comparing Transfer Efficiency of Spray

Applied Coatings Under Laboratory Conditions

This standard is issued under the fixed designation D 5009; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope NFPA 33 Spray Application Using Flammable and Combus-

tible Materials

1.1 This test method covers the evaluation and comparison

NFPA 86 Standard for Ovens and Furnaces

of the transfer efficiency of spray-applied coatings under

controlled laboratory conditions.

3. Terminology

1.2 This test method has been shown to yield excellent

3.1 Definitions of Terms Specific to This Standard:

intralaboratory reproducibility. Interlaboratory precision is

3.1.1 conveyor speed—the speed of the conveyor in centi-

poorer and is highly dependent on closely controlled air flow in

meters per minute during the test.

the spray booth, the rate at which the paint is delivered to the

3.1.2 fluid mass flow rate—the mass flow rate of paint in

part, and other variables suggested in the test method.

grams per minute during the test.

1.3 Limitations:

3.1.3 mass of foil—the weight of each target foil in grams

1.3.1 This laboratory procedure only indicates the direction

before being painted.

of the effect of spray variables on transfer efficiency. The

3.1.4 mass of foil plus paint solids—the weight of each

magnitude of the effect is determined only by specific plant

target foil in grams after being painted and baked.

experience.

3.1.5 mass of paint solids—the difference in the mass of the

NOTE 1—This laboratory procedure requires specific equipment and

foils before painting and the mass of the foils after painting and

procedures. For those laboratories that do not have access to the type of

baking. This is the sum of the mass of the foil plus paint solids

equipment required a more general laboratory procedure is being prepared

less the sum of the mass of the foil.

as Procedure B.

3.1.6 transfer effıciency—the ratio of the mass of the paint

1.4 The values stated in inch-pound units are to be regarded

solids deposited on the foil to the mass of the paint solids

as the standard. The values given in parentheses are for

sprayed during the test expressed as a percent.

information only.

3.1.7 weight percent solids—the solids content in percent of

1.5 This standard does not purport to address all of the

the total weight of a sample of the paint used during the test.

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro-

4. Summary of Test Method

priate safety and health practices and determine the applica-

4.1 Metal panels covered with preweighed aluminum foil

bility of regulatory limitations prior to use. For specific hazard

are conveyed in a spraybooth past a fixed spraygun. The coated

statements, see Section 9 and Note 2 and Note 3.

foils are then baked to remove volatile matter. The transfer

efficiency is calculated on a weight basis using the solids

2. Referenced Documents

content and quantity of the paint sprayed and the amount of

2.1 ASTM Standards:

solids on the coated aluminum foil target.

D 1200 Test Method for Viscosity by Ford Viscosity Cup

D 2369 Test Method for Volatile Content of Coatings

5. Significance and Use

D 3925 Practice for Sampling Liquid Paints and Related

5.1 Subject to the limitations listed above, the procedure can

Pigmented Coatings

be used as a research tool to optimize spray equipment and

2.2 National Fire Protection Association Documents

paint formulations as well as to study the relative effect on

transfer efficiency of changing operating variables, spray

This test method is under the jurisdiction of ASTM Committee D-1 on Paint application equipment, and types of coatings.

and Related Coatings, Materials, and Applicationsand is the direct responsibility of

Subcommittee D01.55on Factory-Applied Coatings on Preformed Products.

6. Apparatus

Current edition approved Nov. 10, 1996. Published January 1997. Originally

6.1 Laboratory Scale, accurate to 60.001 g for weight

published as D 5009 – 89. Last previous edition D 5009 – 89.

Annual Book of ASTM Standards, Vol 06.01.

percent solids determination.

Available from National Fire Protection Assn., Battery March Park, Quincy,

6.2 Platform Scale, accurate, or equivalent, to 60.01 g for

MA 02269.

D 5009

mass of foil, mass of foil plus paint, and mass flow rate 8.4.1 Viscosity determined in accordance with Test Method

instrumentation calibration. D 1200.

8.4.2 Weight percent solids determined in accordance with

6.3 Mass Flow Rate Meter, or mass flow rate determination

method, accurate to 62 % of the mass flow rate to be used Test Method D 2369. If the baking temperature in Test Method

D 2369 is inadequate, use the manufacturers recommended

during the test.

6.4 Conveyor Timer or conveyor timing method, accurate cure schedule.

8.4.3 Resistivity for the samples being applied electrostati-

to6 1 % of the conveyor speed to be used during the test. The

equipment may consist of photoelectric cells or limit switches cally (An ASTM method is under development).

8.5 Set up the conveyor speed measuring equipment.

used in conjunction with a digital timer or timing marks on the

conveyor used in conjunction with a stopwatch. Take at least 8.6 Cut the aluminum foil to dimensions of 15 in. (38 cm)

by approximately 50 in. (127 cm) or 2 in. (5 cm) longer than

two readings with a stopwatch and average the readings.

6.5 Targets, consisting of a set of ten steel panels 6 in. (15.2 the length of the target panel.

8.7 Consecutively number each precut foil strip before

cm) wide by 0.0625 in. (0.15875 cm) with 0.25-in. (0.635-cm)

radius corners. A minimum panel length of 48 in. (121.9 cm) weighing using a permanent marking pen.

8.8 Weigh each test foil strip and record the uncoated

should be used. The length of the panel should be set so that a

minimum of 12 in. (30.4 cm) above and below the spray weight and the foil number.

8.9 Attach the preweighed, labeled test foil to six targets

pattern is achieved.

6.5.1 It is essential to do this so that the entire height of the using the technique shown in Fig. 1. Attach the unlabeled foil

on four scavenger targets as shown in Fig. 1.

spray pattern is effectively captured.

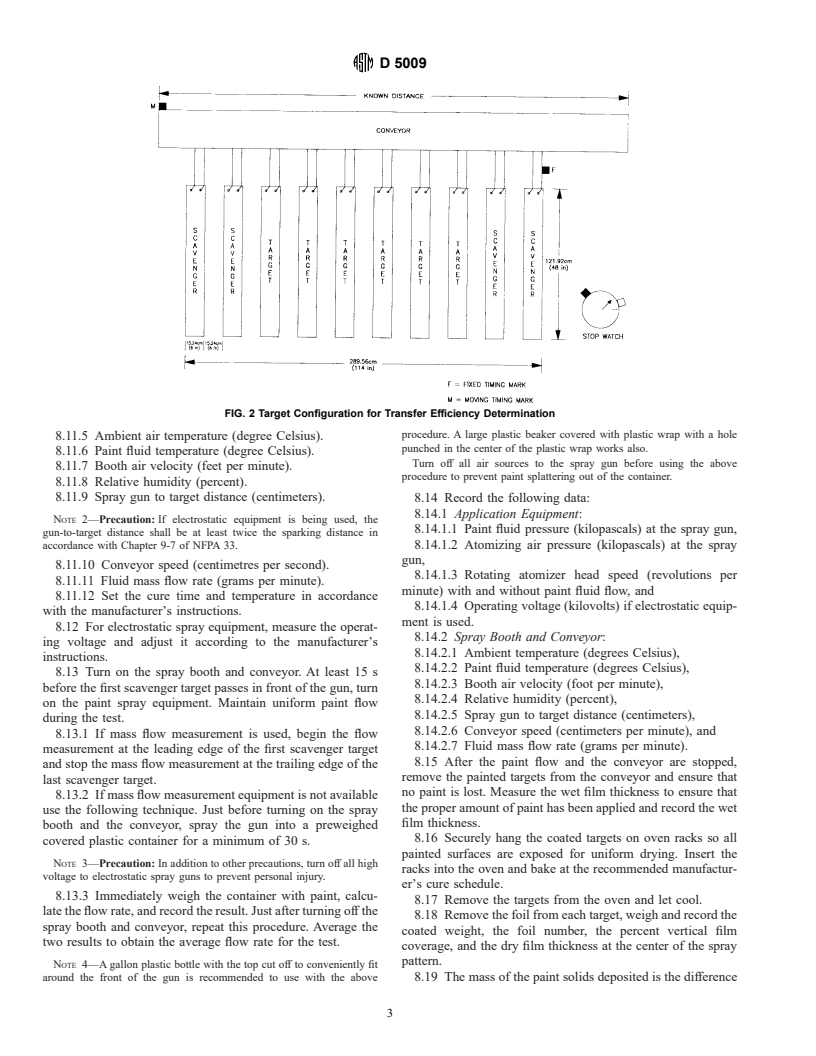

8.10 Mount the foil covered targets in consecutive order as

6.6 Aluminum Foil, medium temper or equivalent, 1.5 mil

shown in Fig. 2, with the foil seam on each target facing away

(0.0037 cm) thick.

from the spray gun.

6.7 Back-Draw Water Wash Spray Booth, or equivalent. The

8.10.1 If electrostatic equipment is being used the resistance

booth should be a minimum of 6 ft (1.8 m) wide and capable

shall be less than 1 by 10 V between the target and the earth

of up to 120 ft/min (0.61 m/s) air velocity in the middle at the

ground in accordance with Chapter 9-8 of NFPA 33.

plane of the target. If a dry filter booth is used, filters should be

8.11 Adjust the following equipment operating parameters

changed as necessary to maintain uniform air velocity.

to the values desired for testing:

6.8 Adjustable Rate Overhead Conveyor System, capable of

8.11.1 Paint fluid pressure (kilopascals) at spray gun.

hanging targets as specified, and capable of up to 40 ft/min

8.11.2 Atomizing air pressure (kilopascals) at spray gun.

(0.20 m/s) or the maximum speed desired by the user.

8.11.3 Rotating atomizer head speed (revolutions per

6.9 Forced Draft Curing

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.